Novel pneumatic hydraulic synchronous clamp device

A pneumatic hydraulic and fixture device technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of inability to automatically locate the center positioning accuracy of the workpiece, reduce the qualified rate of workpiece processing, waste manpower and material resources, etc., so as to improve the processing qualification. High efficiency, high repeat positioning accuracy, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

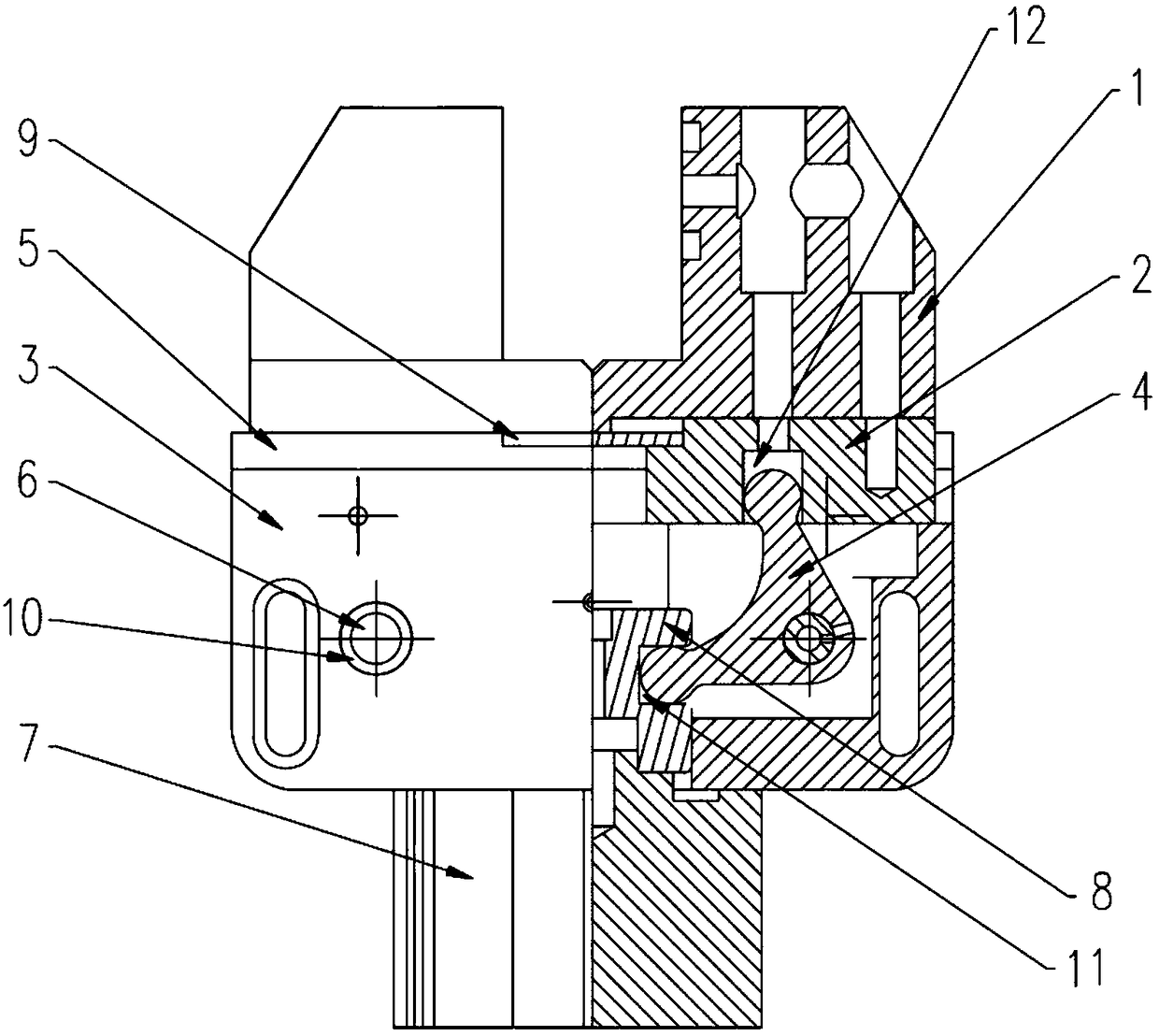

[0016] refer to figure 1 , the embodiment of the present invention discloses a new type of pneumatic-hydraulic synchronous clamping device, including a clamping block 1, a slider 2, a clamping base 3, a triangular lever 4, a horizontal pressing plate 5, a pin 6, a pressure cylinder 7, a piston 8, a horizontal anti- The dust plate 9 and the fixed shaft sleeve 10, a cavity is provided in the clamp base 3, and a piston 8 that can reciprocate up and down along the shaft is installed coaxially in the cavity of the clamp base 3, and the piston 8 The lower part of the lower part is connected with the pressure cylinder 7 installed under the fixture base 3. The pressure cylinder 7 provides power for the reciprocating movement of the piston 8. In this embodiment, the transmission connection between the pressure cylinder 7 and the piston 8 is known and commonly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com