Method for obtaining fibers from at least one plant stem

a technology of plant stems and fibers, applied in the field of obtaining fibers from at least one plant stem or plant bast, can solve the problems of increasing solubility products, low power consumption, and negative effects of wood component stripping, and achieve the effect of less energy input and lower processing was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

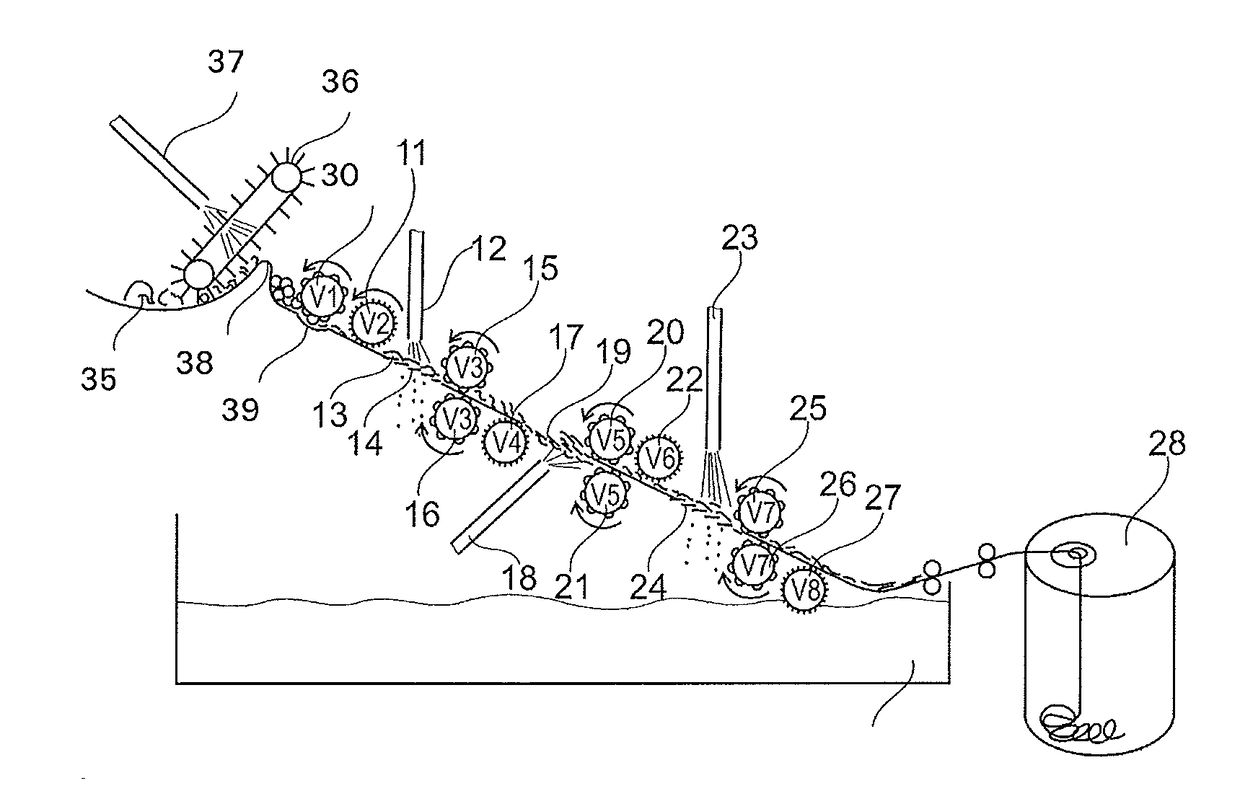

[0080]A U-profile 1 can be seen in FIG. 1, having a slot-shaped opening in the lower region. A flat-jet nozzle 4 is disposed in this opening, disposed such that its high-speed water jet is disposed with its width parallel to the base of the U-profile, and with its jet direction forming an angle of 10° to the longitudinal direction of a straight plant stem 2 placed in the U-profile 1 in the longitudinal direction.

[0081]Another nozzle 5 can also be seen therein, which generates a rotating high-speed water jet, which covers an angular range of 30° to 95° to the longitudinal extension of the inserted plant stem 2 with its jet direction.

[0082]Moreover, a third nozzle 6 can also be seen therein, which generates a flat-jet high-speed water jet, which forms an angle of 75° to the longitudinal extension of the inserted plant stem 2 with its jet direction, and is disposed with its width parallel to the first flat jet.

[0083]The plant stem 2 can be placed in the U-profile 1 by a user, and pulle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com