Hydraulic gravity ram pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

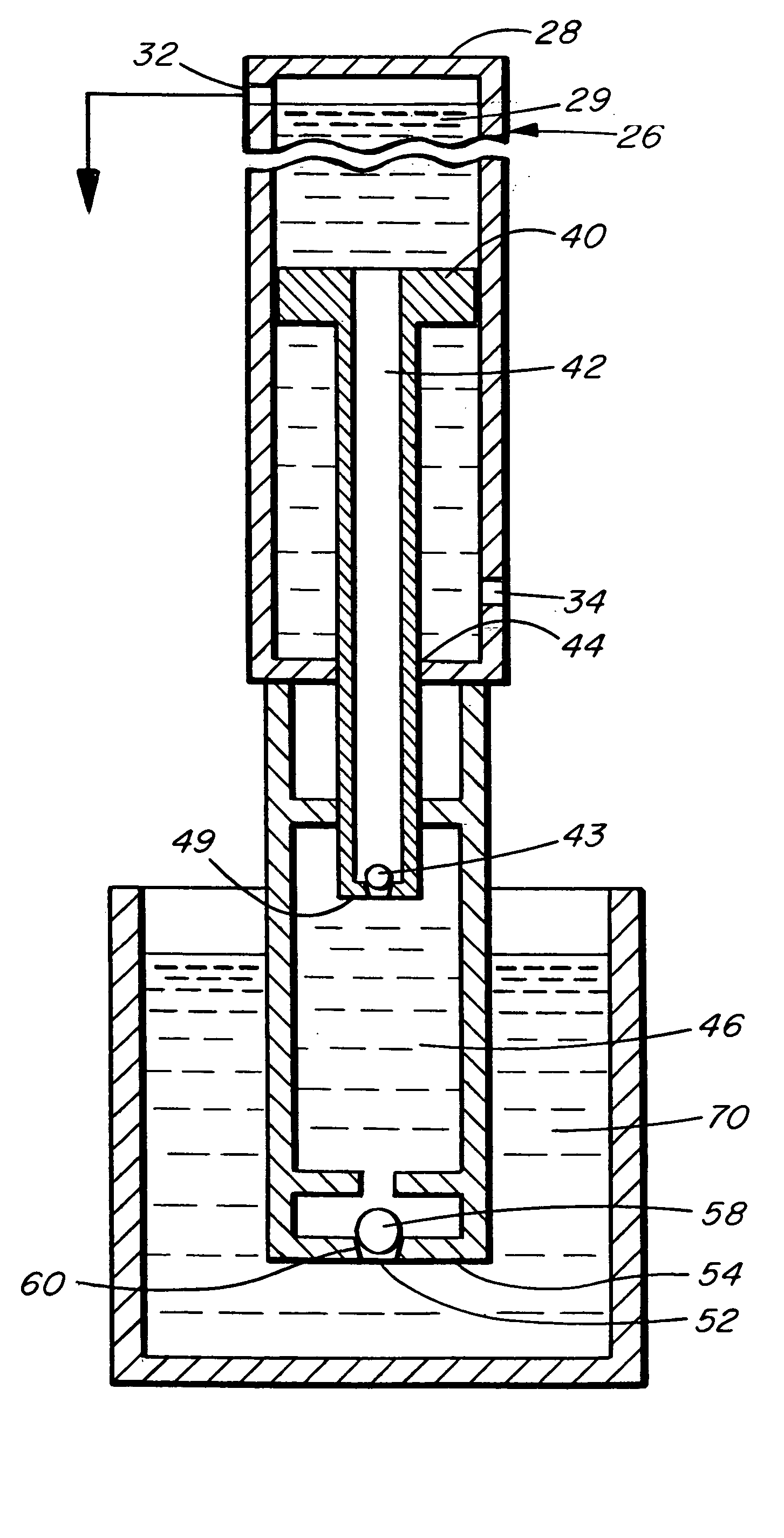

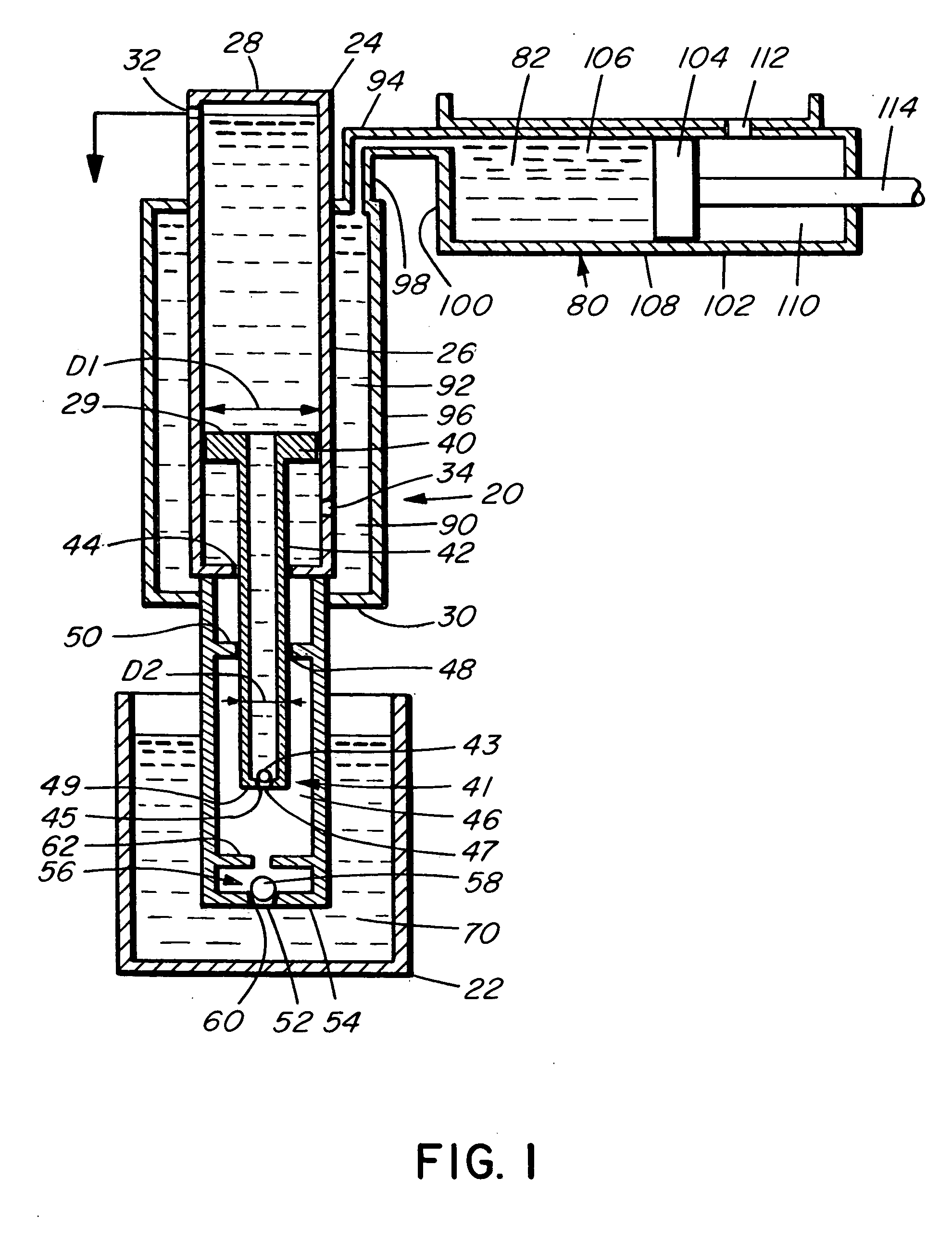

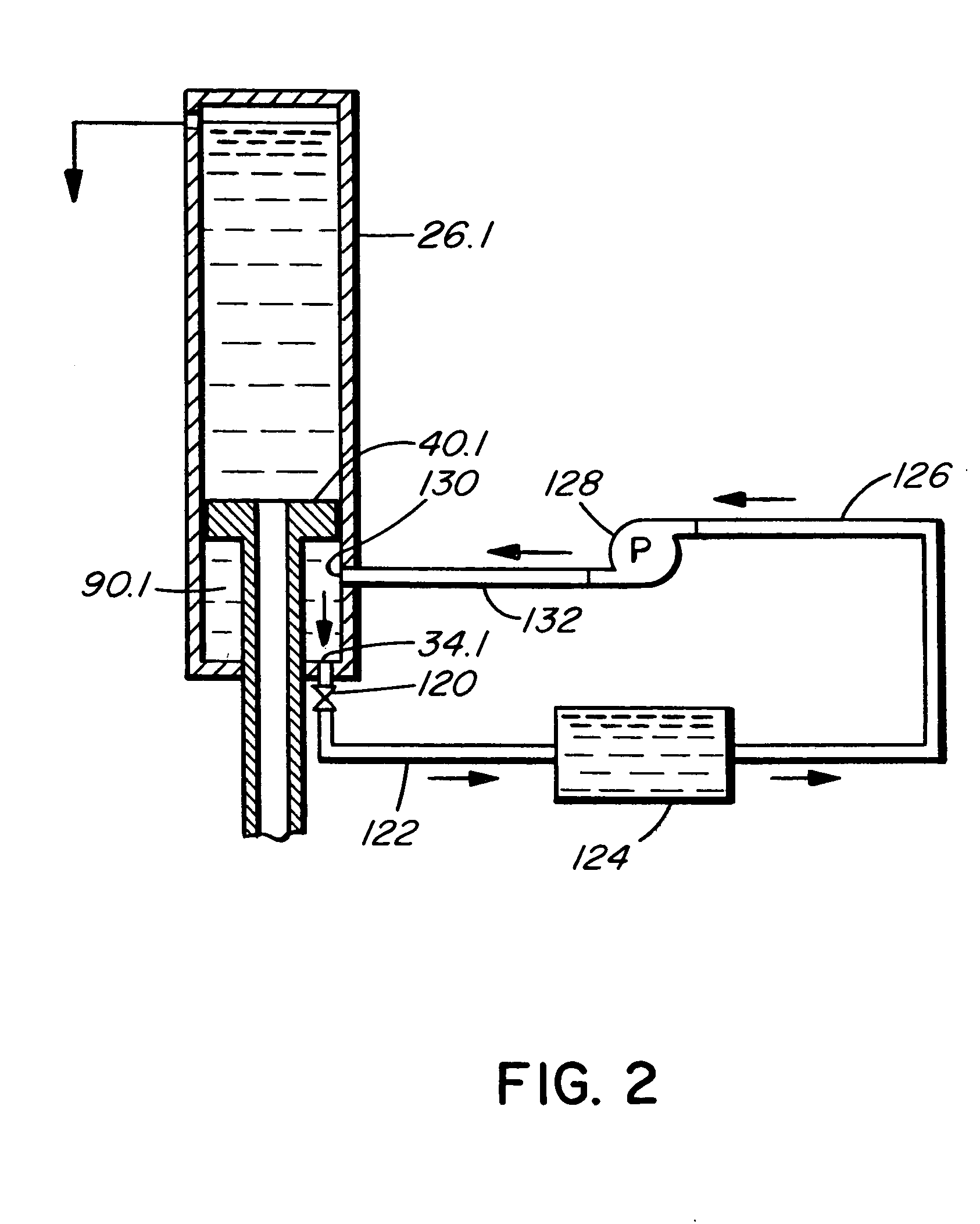

[0019] Referring to the drawings, and first to FIG. 1, this shows a piston type pumping apparatus 20 according to an embodiment of the invention. The apparatus is intended to pump liquids, typically water, up relatively great vertical distances, such as from the bottom of a mine to the surface as exemplified by the distance between points 22 and 24. The system includes a vertically oriented first transfer cylinder 26 having a top 28, adjacent point 24, and a bottom 30. There is a first passageway 32 for liquid adjacent the top where liquid is discharged from the cylinder. There is a second passageway 34 near the bottom of the cylinder which allows liquid to enter or exit the cylinder.

[0020] A transfer piston 40 is reciprocatingly mounted within the cylinder and is connected to a vertically oriented, hollow piston rod 42 which extends slidably and sealingly through aperture 44 in the bottom of the cylinder. The piston 40 has an area 29 at the top thereof against which pressurized fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com