Split crank shaft structure of reciprocating compressor

A compressor and reciprocating technology, applied in the direction of the crankshaft, etc., can solve the problems of increasing parts inventory, increasing piston wear and power consumption, and difficult to guarantee precision precision, so as to improve productivity, save processing costs, and maintain structural integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

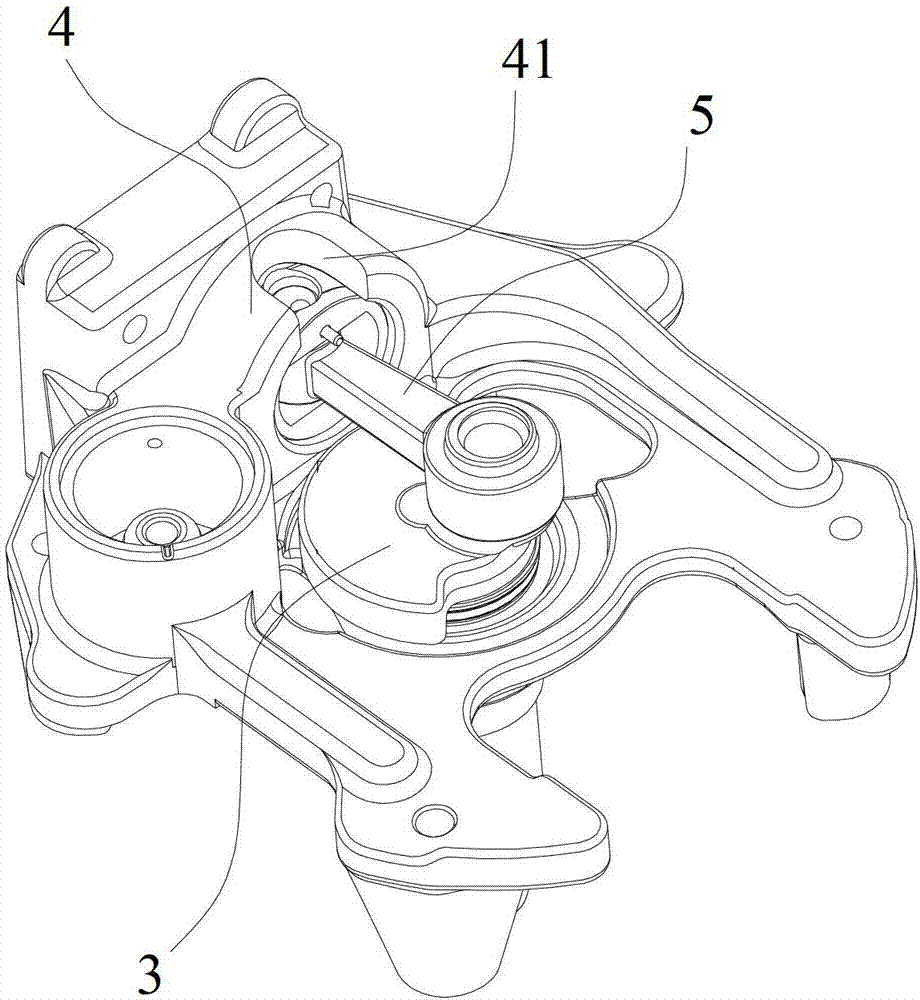

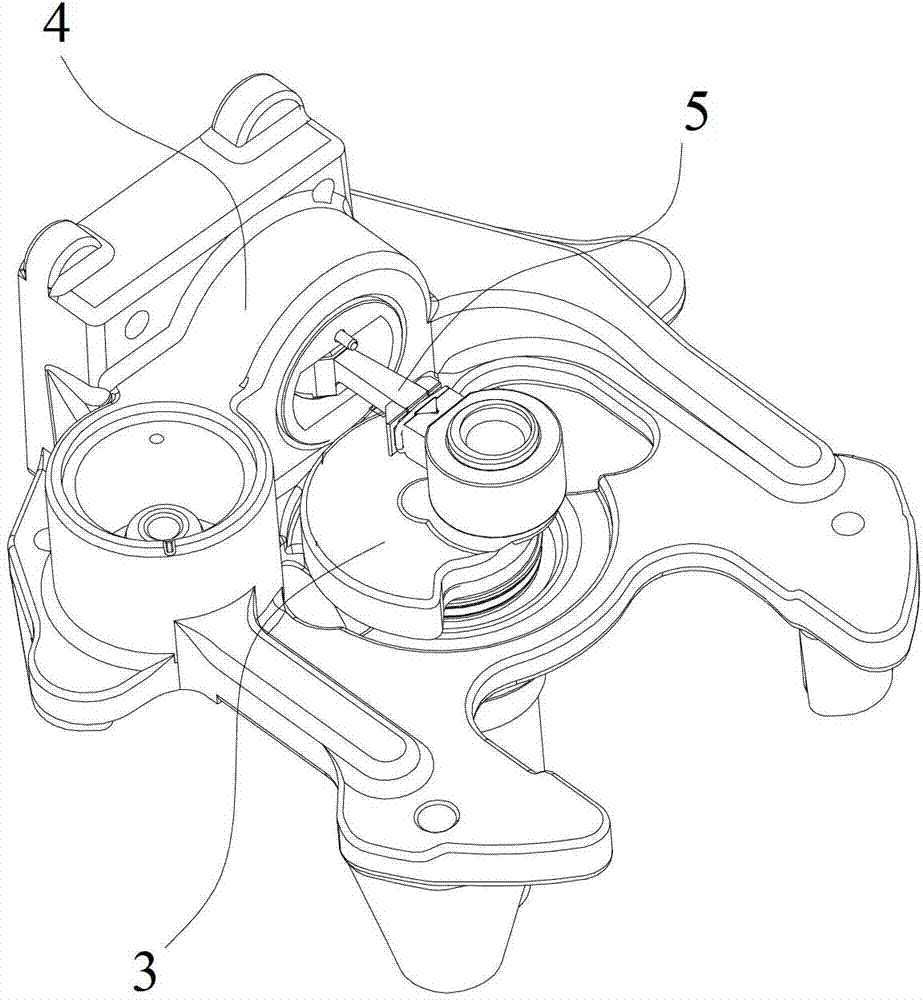

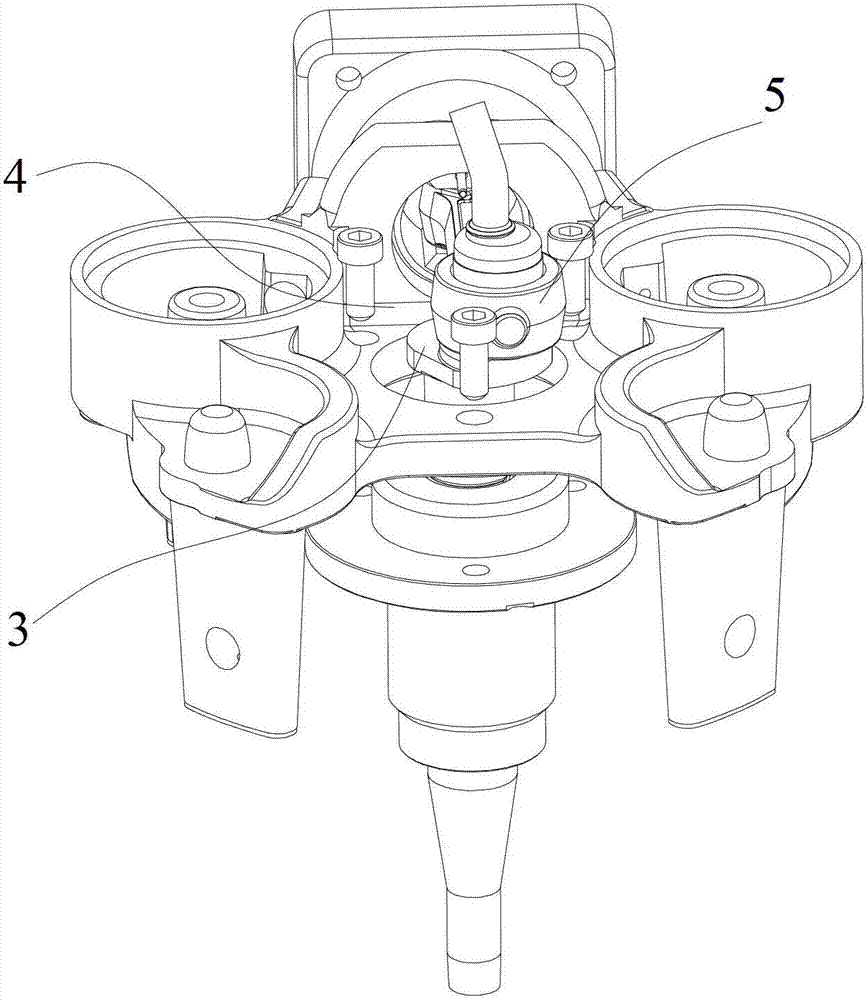

[0016] refer to Figure 4 , Figure 5 , the present invention provides a split crankshaft structure of a reciprocating compressor, including a split main shaft part 1 and a crank pin 2, one end of the main shaft part 1 is eccentrically docked with the crank pin 2 and a balance is provided on the opposite side of the crank pin 2 Block 11.

[0017] In the present invention, the crankshaft 3 adopts a split structure. When in use, the two ends of the connecting rod 5 are respectively connected with the piston in the cylinder block 4 and the crank pin 2 of the crankshaft 3, and then the crank pin 2 is fixedly connected with the main shaft part 1. , the structure maintains the structural integrity of the cylinder block 4 and the connecting rod 5, reduces the processing waste of the cylinder block 4, the connecting rod 5 and the crankshaft 3, saves the processing cost, and improves the productivity.

[0018] With the split crankshaft 3, there is no need to process the avoidance gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com