Wood working lathe for wooden vase machining

A technology for woodworking lathes and vases, which is applied in the field of woodworking lathes for processing wooden vases, can solve the problems of cumbersome process steps, inability to ream holes, reduce the efficiency of wooden vases, etc., and achieve the effect of reducing processing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

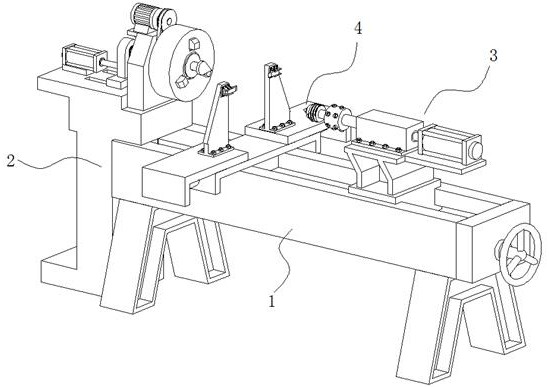

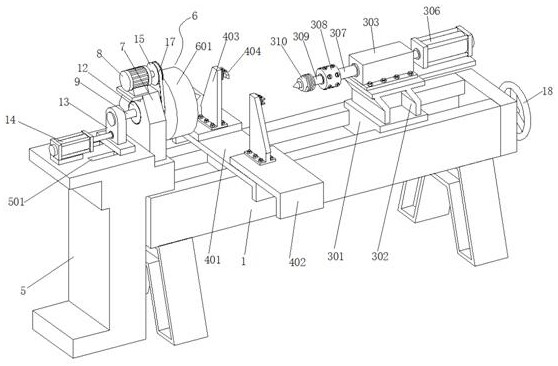

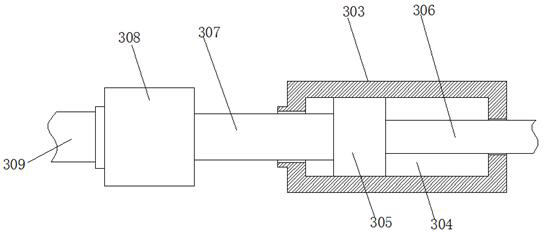

[0043] Embodiment 1 has introduced a kind of woodworking lathe for wooden vase processing, with reference to attached figure 1 And attached figure 2 , its main structure includes a bed 1, a headstock 2, a tailstock 3 and a turning tool mechanism 4. Wherein, the headstock 2 is fixedly arranged on the left end of the bed 1, the tailstock 3 is movably arranged on the upper surface of the right end of the bed 1, and its turning tool mechanism 4 is arranged on the bed 1 between the headstock 2 and the tailstock 3 . Wherein, the tailstock 3 includes a moving block 301 that moves along the bed 1, the upper surface of the moving block 301 is fixed with a mount 302, and a long block 303 is fixed on the mount 302, refer to the attached image 3 A square sliding chamber 304 along the direction of the bed 1 is opened inside the long block 303, and through holes are opened at both ends of the direction sliding chamber 304, and a square sliding block 305 is slidably arranged in the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com