Backlash compensation method for laser welding and device implementing same

A technology of gap compensation and laser tailor welding, applied in the direction of planer, metal processing equipment, manufacturing tools, etc., to achieve the effect of small vibration, less processing waste and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

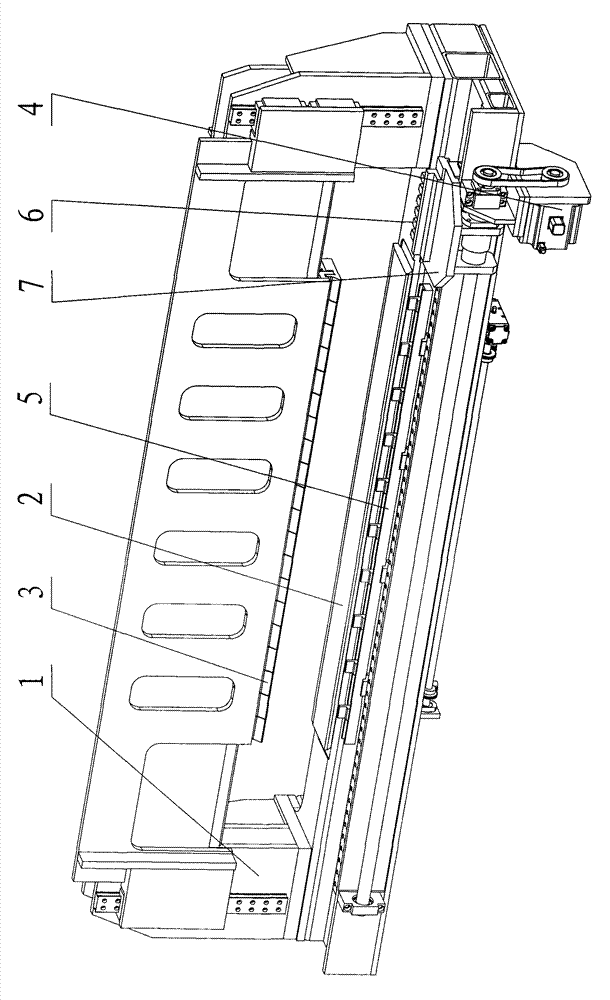

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] The gap compensation method for laser tailor welding of the present invention: planing the edge to be welded of the base metal to be welded, planing a butt end face with high straightness and high flatness, reducing the gap between the plates when the base metal is butted, and improving Seam tracking accuracy. Include the following steps:

[0054] A. Position and fix the welding base metal to prevent disturbances such as jumping and vibration during the planing process of the welding base metal, so as to ensure the processing quality;

[0055] B. Determine the amount of planing by adjusting the positioning reference of the welding base metal or the position of the tool;

[0056] C. Determine the planing angle by adjusting the attitude of the tool relative to the edge to be welded of the welding base metal;

[0057] D. Use a cutter to plan the edge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com