Prefabricated box girder flange template

A formwork and flange technology, applied in the field of prefabricated box girder flange formwork, can solve the problems of poor sealing, troublesome installation, non-reusable use, etc., and achieve the effect of good sealing, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

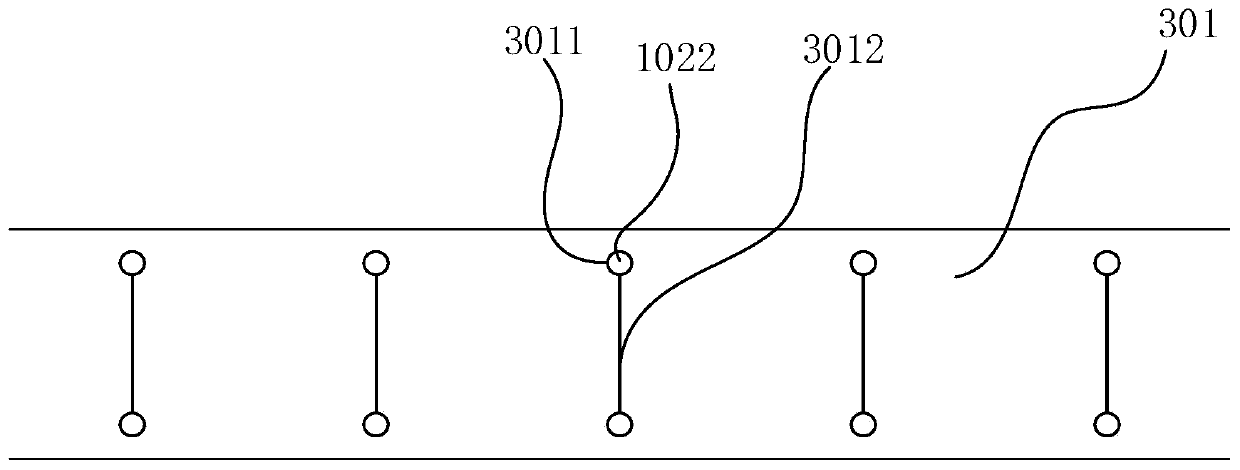

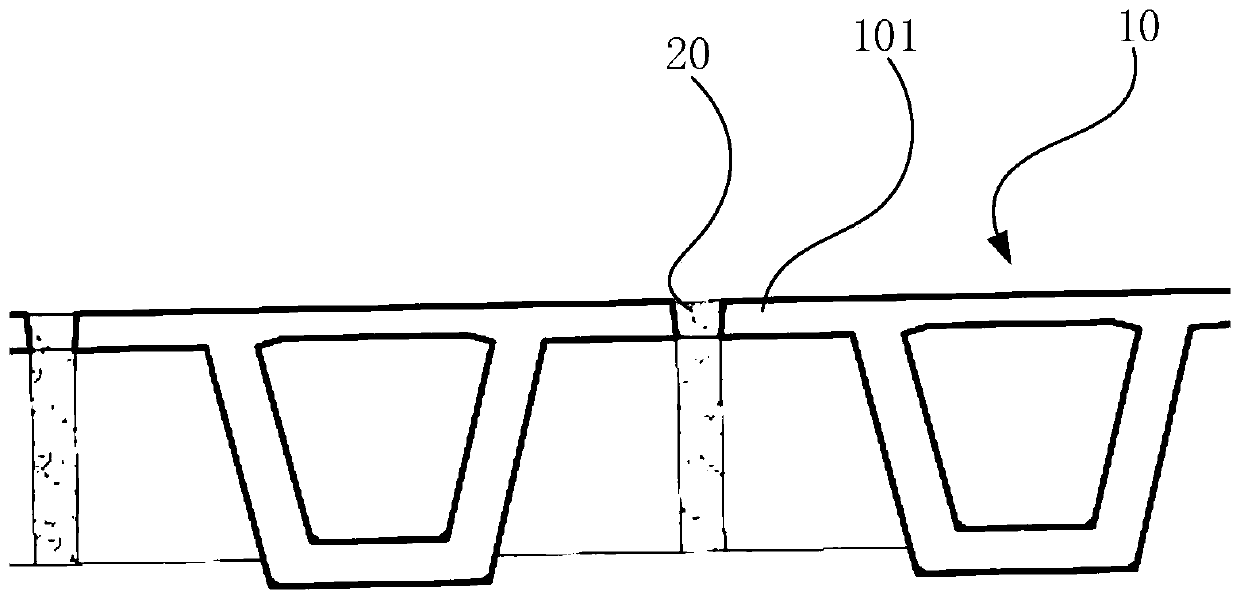

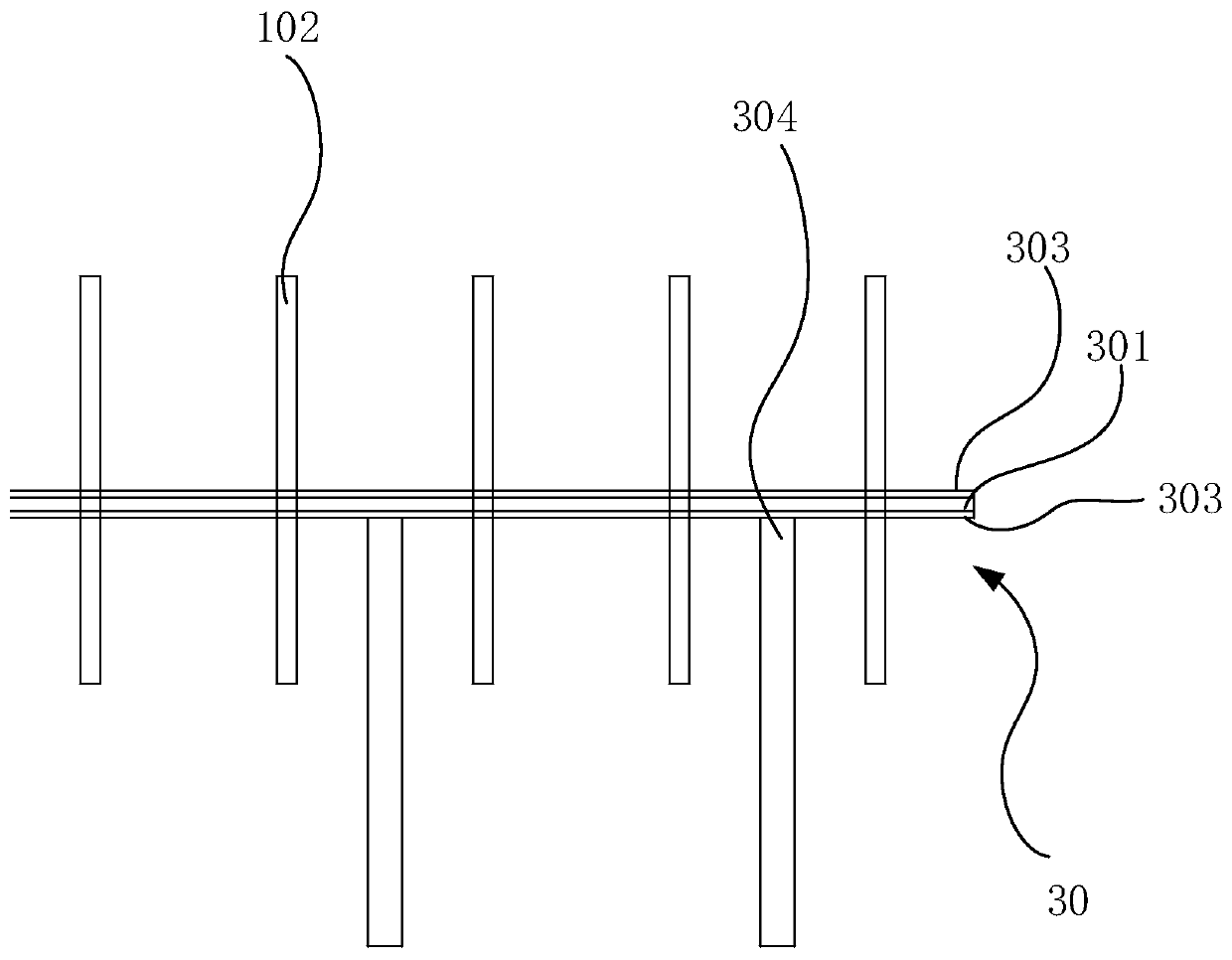

[0048] Such as Figure 1 to Figure 4 As shown, this embodiment provides a prefabricated box girder flange formwork, which is used to install on both sides of the roof reinforcement framework to prevent concrete from flowing out when pouring the reinforcement framework of the box girder 10 . This prefabricated box girder flange formwork 30 includes a formwork body 301 , and a plurality of escape grooves for passing the flange steel bars 102 are arranged at intervals along the length direction of the formwork body 301 . Wherein, the flange reinforcement is a necessary component for strengthening the strength of the wet joint 20 when adjacent box girders are spliced together. The flange reinforcement 102 includes an arc-shaped end 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com