A rolling device for ensuring the straightness of flange edges of cold-formed products

A cold-formed, straightness technology, applied in the field of rolling devices, can solve the problems of increasing production costs, not taking into account, affecting production efficiency, etc., and achieving the effects of low transformation cost, easy adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

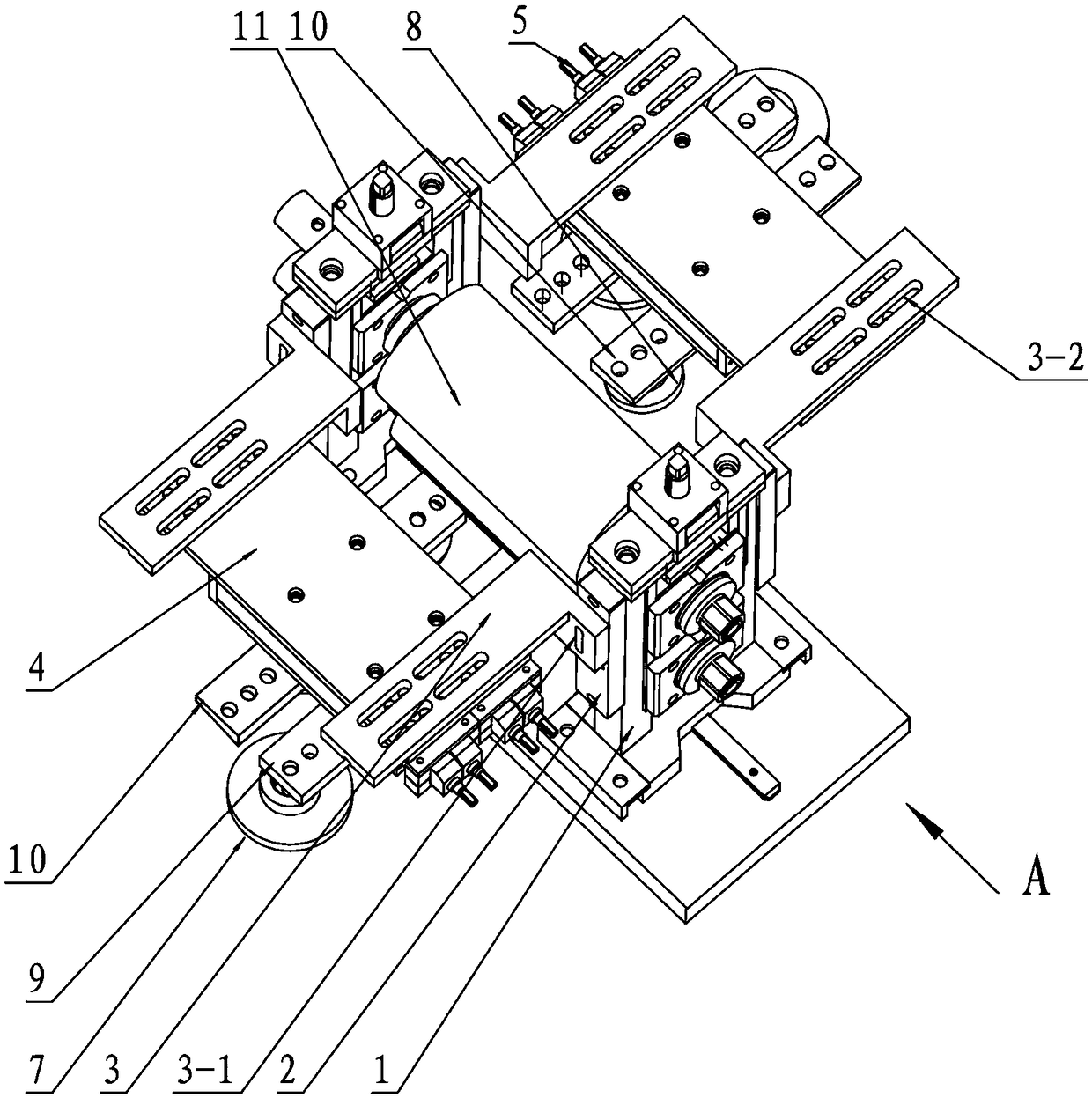

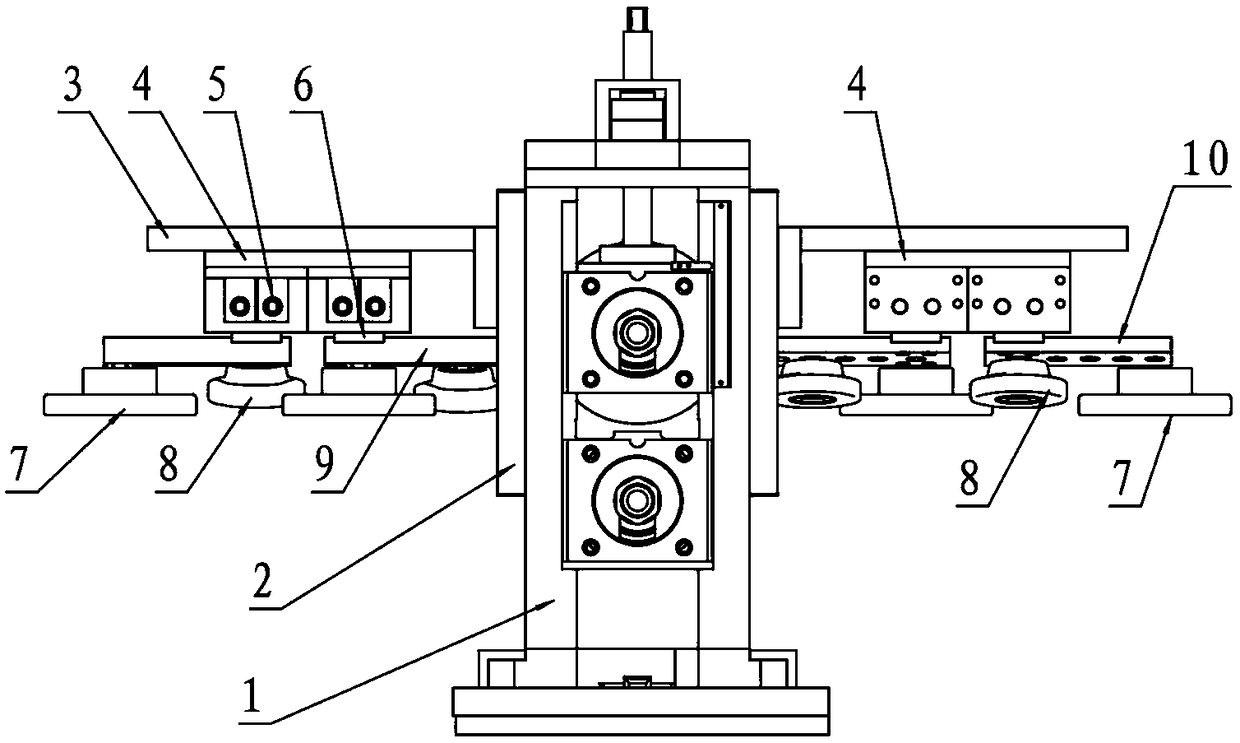

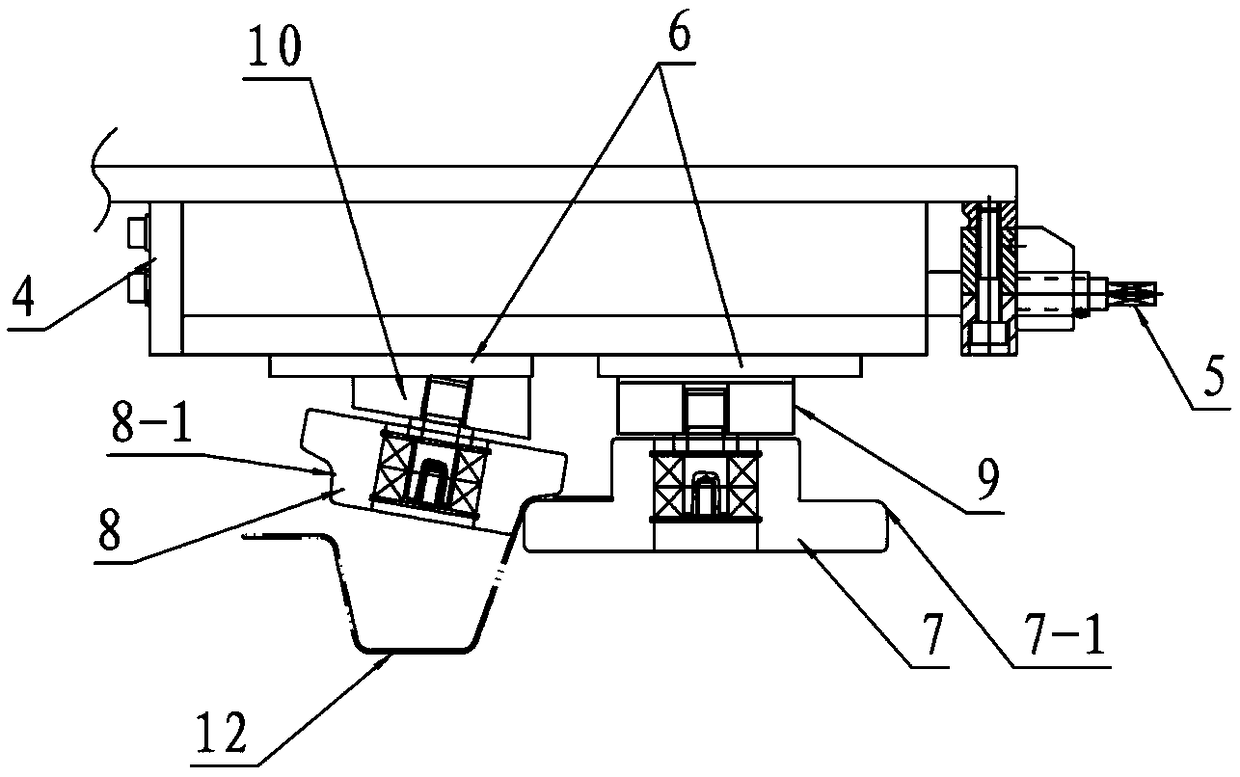

[0017] see figure 1 , the device of the present invention is located at the last pass of the rolling line of the product piece. While the rollers are rolling the product piece for the last time, the flange edge straightness adjustment mechanism provided will adjust the flange edges on both sides of the product piece. Carry out shaping. The device includes rollers 11 and two roller brackets 1 supporting the rollers, and also includes two sets of flanges that are respectively installed on the front and rear sides of the roller bracket 1 (the feed side and the discharge side of the product) through the mounting plate 3 Edge straightness adjustment mechanism. Two sets of flange straightness adjustment mechanisms respectively trim and shape the flanges on both sides of the product to ensure that the flanges on both sides of the roll-formed product meet the straightness requirements.

[0018] see figure 1 , figure 2 and image 3 , each set of flange straightness adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com