Silicon steel sheet press fitting tooling

A technology for press-fitting tooling and silicon steel sheets, applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of limited size of silicon steel sheets, high production costs, cumbersome operations, etc., to reduce processing costs and adjust operations Convenience and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

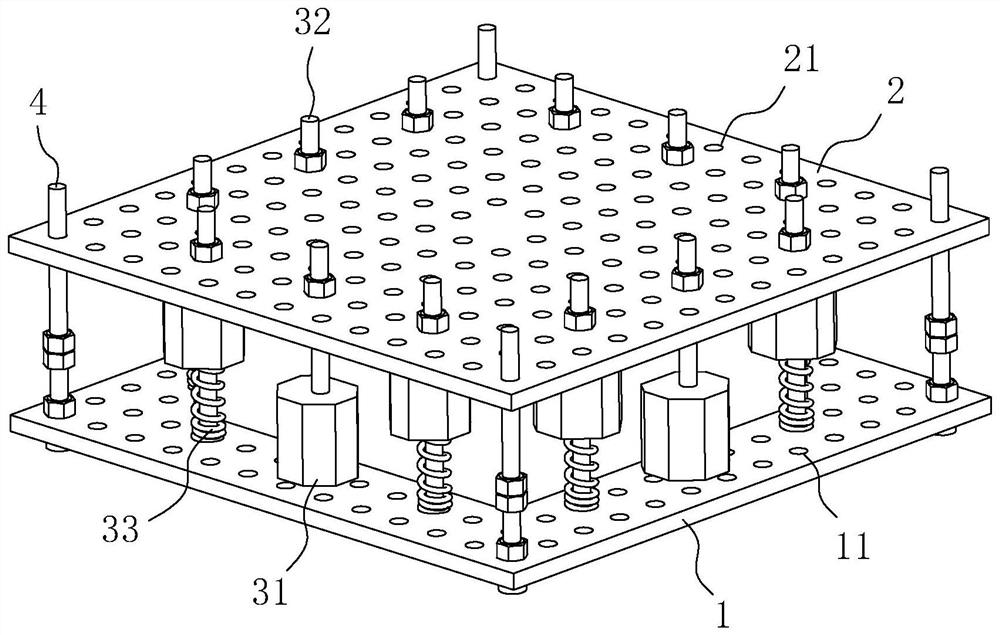

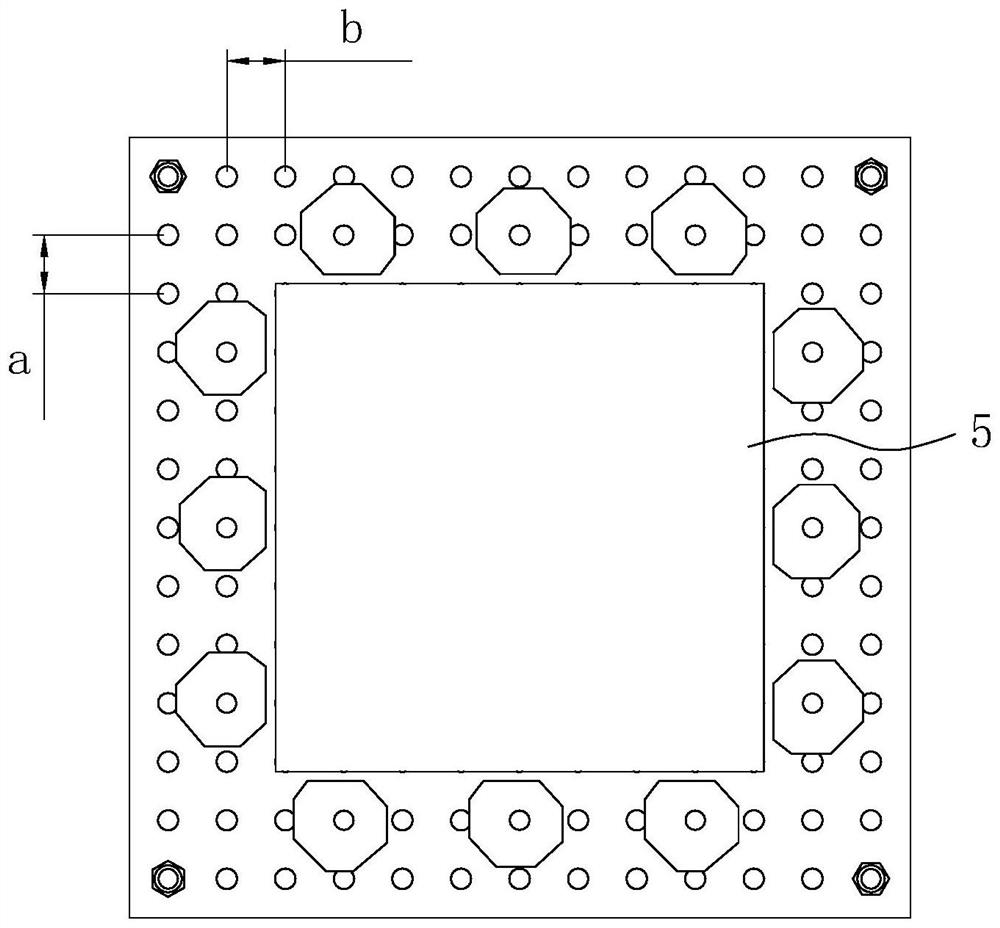

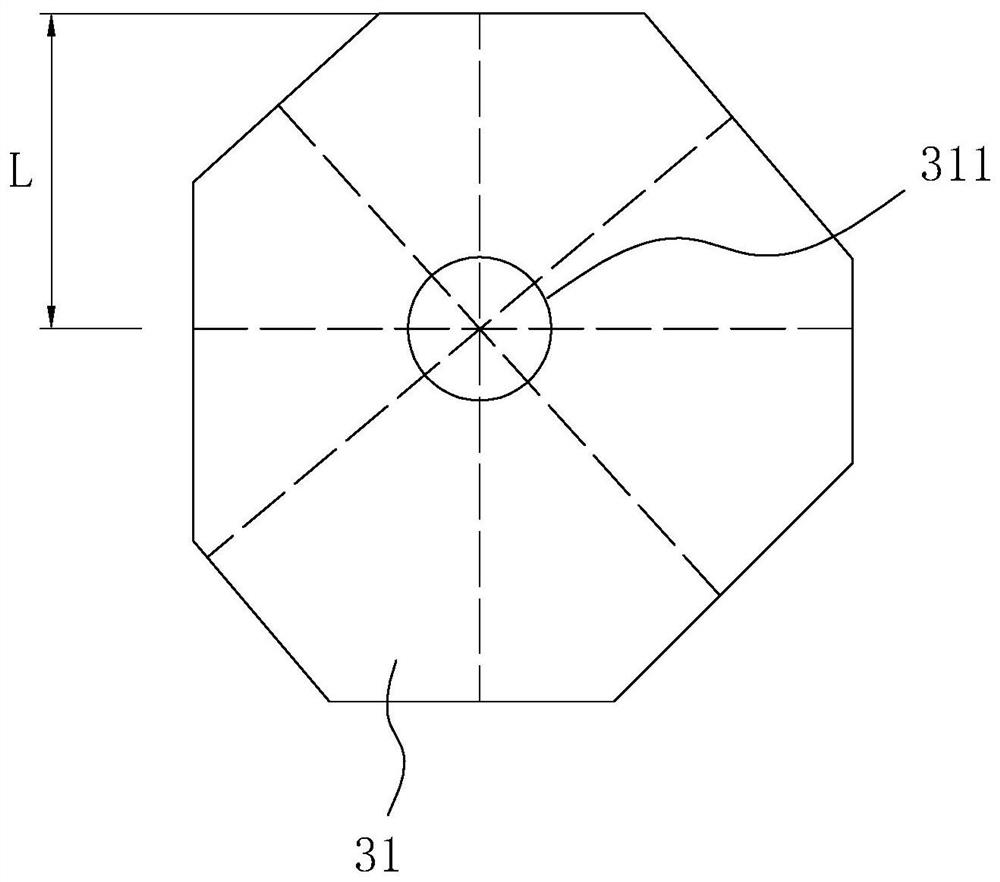

[0034] One kind of steel sheet press-fit tooling, with reference to figure 1 with figure 2 Which includes a lower platen 1 is provided on a lower platen of a finite bit structure, limiting structure for limiting of the silicon steel sheet 5 5 press-fit process; limiting structure comprises a rotatably adjustable limit stop 31 , 31 comprises a plurality of limit stops, respectively, for different sizes of silicon steel for limiting stopper surface, and the surface of the plurality of limit stop limiting the minimum distance between the rotation axis 31 are not same; embodiment not the same minimum distance between the respective stop surfaces on the axis of rotation limit stop 31 of the present embodiment, can be applied to different sizes of silicon, if necessary adjusting the rotation limit stop block 31 can, easy operation, and thus the production efficiency can be improved.

[0035] Refer Figure 1 to 3 Specifically, the present embodiment further comprises a limiting structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com