Reinforcing steel bar cutting machine

A cutting machine and steel bar technology, applied in the field of steel bar cutting equipment, can solve the problems of rough cutting edge of metal circular saw cutting knife, fast loss of grinding wheel cutting blade, high production cost, etc., achieve good self-sharpening, convenient transportation and movement, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

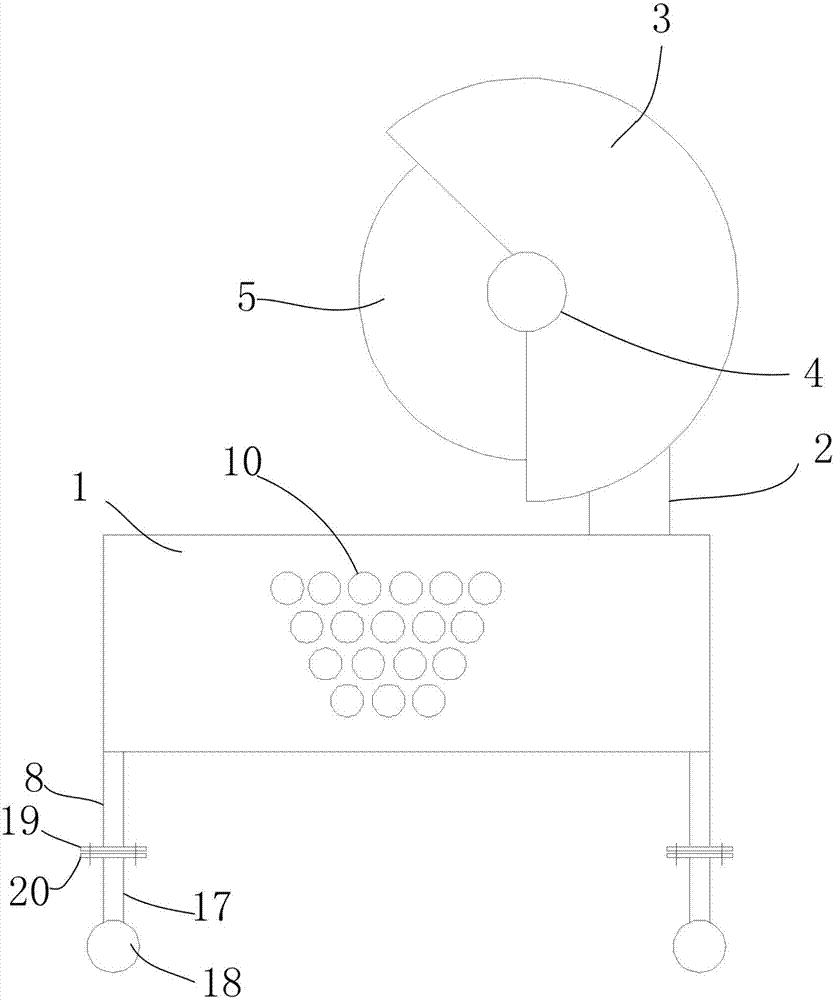

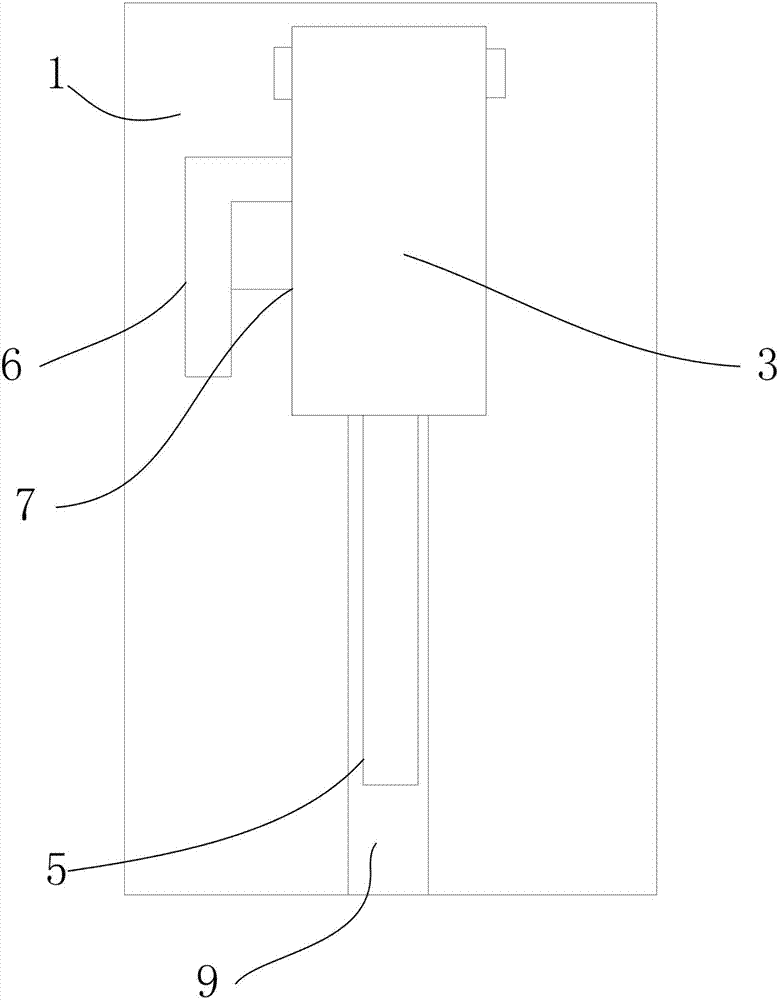

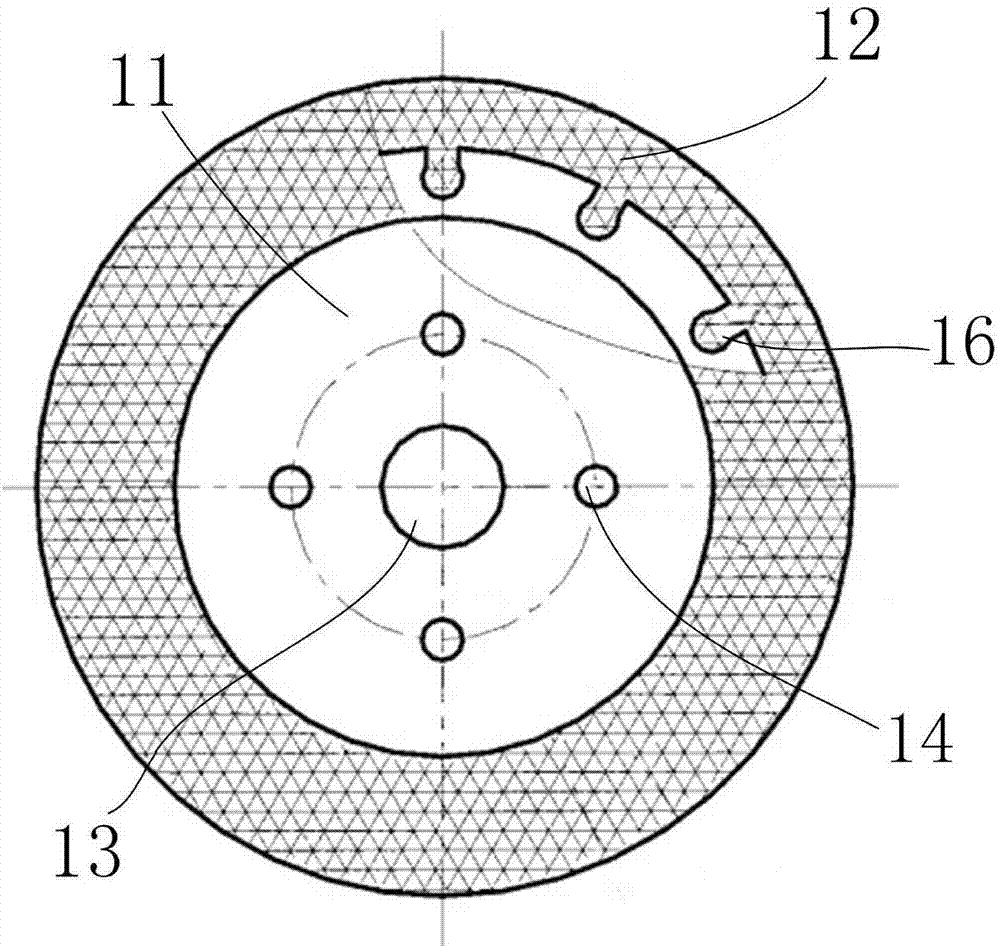

[0023] Such as Figure 1~4 As shown, a steel bar cutting machine includes a base 1, a support 2, a detachable cover 3, a central shaft 4, a cutting knife 5, a handle 6, a driving motor 7, a supporting leg 8, and a moving mechanism; wherein, the supporting There are four legs 8, the machine base 1 is longitudinally provided with a cutting groove 9, the machine base 1 is provided with a circular through hole 10 penetrating transversely, the circular through holes 10 are multiple and arranged in an inverted trapezoidal shape, and the cutting knife 5 consists of alloy steel The disc-shaped cutter body 11 made of high-quality material and the grinding wheel 12 arranged on the outer edge of the cutter body 11 and sintered and connected with the cutter body 11 as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com