Reducing rotary forging method for internal thread copper pipe

A processing method and internal thread technology, which are used in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of large workshop area, high mold operation cost, high equipment maintenance cost, and achieve processing waste. Less, high production efficiency, easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

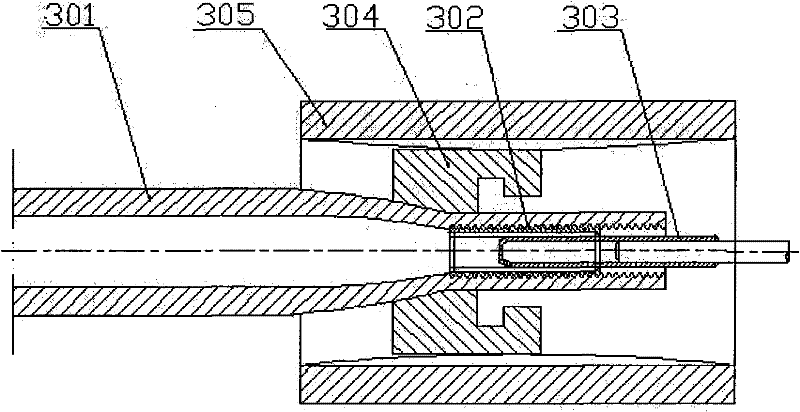

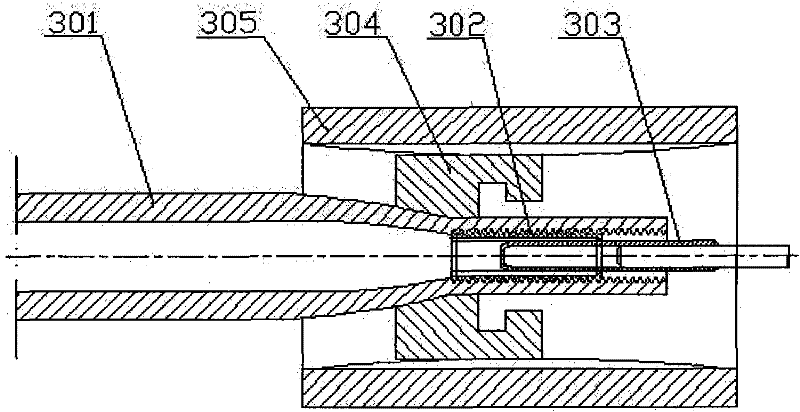

[0018] figure 1 A method for processing an internally threaded copper pipe with variable diameter and swaging is shown, comprising the following steps:

[0019] 1) Using the hollow copper tube 301 as the processing object saves raw materials compared with the prior art that takes the solid copper rod as the processing object, and the pipe wall of the processed internally threaded copper pipe is also relatively thin.

[0020] 2) By adjusting the proportioning voltage and input current value in the power mechanism, when the variable-diameter shrink cavity mold is driven to reduce the diameter, the hollow copper tube 301 is frictionally heated to make the temperature of the friction area reach 990°C ~1030°C, so that the rotating thread processing area of the hollow copper tube 301 reaches a semi-solid state, and at the same time, the contact surface and contact angle between the hollow copper tube 301 and the rotating thread core 302 reach the best matching point. During this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com