A high-throughput external light Fe-Al intermetallic compound filter element and preparation method thereof

An intermetallic compound, high-flux technology, applied in the field of powder metallurgy, can solve the problems of low flux and resistance drop, and achieve the effect of improving filter flux, good air permeability and thin wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

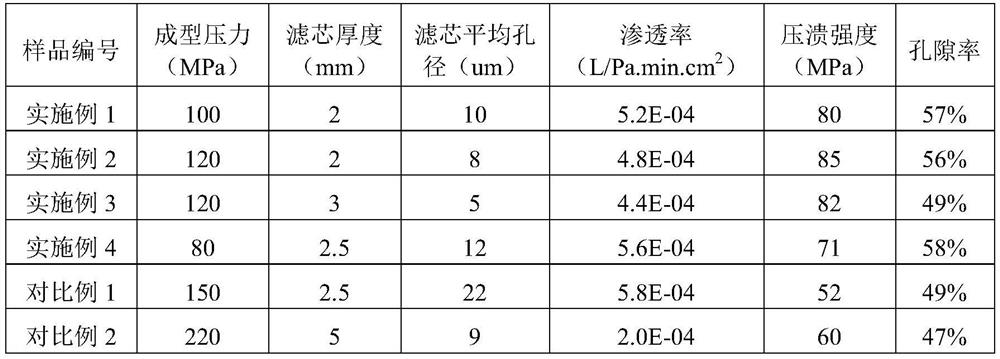

Examples

Embodiment 1

[0031] This embodiment is used for pressing the high-throughput external light Fe-Al intermetallic compound filter element, and its filter element size To obtain a Fe-Al intermetallic compound filter element with small pore size, high air permeability and certain strength, the specific preparation method includes:

[0032] Preparation of powder raw materials: sieve and grade the iron and aluminum powder, and select the powder particle size as -150+500 mesh Fe 3 Al powder is the raw material, polyethylene glycol 4000 and polyvinyl alcohol are selected as the binder; powder raw material ratio: 88% -150+500 mesh Fe 3 Al powder+10% polyethylene glycol+2% polyvinyl alcohol;

[0033] Fully dissolve the selected amount of binder in absolute ethanol, and fully mix the iron-aluminum powder with the binder dissolved in absolute ethanol and keep stirring. The mixing temperature is controlled at 80°C and mixed for about 1 hour until Dry with absolute ethanol and mix evenly to obtain mi...

Embodiment 2

[0038] This embodiment is used to press the high-throughput external light Fe-Al intermetallic compound filter element, the filter element size To obtain a Fe-Al intermetallic compound filter element with small pore size, high air permeability and certain strength, the specific preparation method includes:

[0039] The powder is screened and graded, and the particle size of the powder is selected to be -150+500 mesh Fe 3 Al powder is the raw material, polyethylene glycol 4000 and polyvinyl alcohol are selected as the binder, and the ratio of powder raw materials: 88% -150+500 mesh Fe 3 Al powder+10% polyethylene glycol+2% polyvinyl alcohol;

[0040] Fully dissolve the selected amount of binder in absolute ethanol, and fully mix the iron-aluminum powder with the binder dissolved in absolute ethanol and keep stirring. The mixing temperature is controlled at 80°C and mixed for about 1 hour until Dry with absolute ethanol and mix evenly to obtain mixed powder;

[0041] Sieve t...

Embodiment 3

[0045] This embodiment is used to press the high-throughput external light Fe-Al intermetallic compound filter element, the filter element size To obtain a Fe-Al intermetallic compound filter element with small pore size, high air permeability and certain strength, the specific preparation method includes:

[0046] The powder is screened and graded, and the particle size of the powder is selected to be -150+300 mesh Fe 3 Al powder is the raw material, polyethylene glycol is selected as the binder, and the powder raw material ratio: 95% -150+300 mesh Fe 3 Al powder+5% polyethylene glycol;

[0047] Fully dissolve the selected amount of binder in water, and fully mix the iron-aluminum powder with the binder dissolved in absolute ethanol and keep stirring. The mixing temperature is controlled at 100°C, mixed for about 2 hours, and dried until moisture and mix evenly to obtain mixed powder;

[0048] Sieve the uniformly mixed powder with 40 mesh twice, put the uniformly mixed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com