Isopressing forming method and die for powder forming tube blank

A technology of isostatic pressing and powder, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of difficult size control and rough outer surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

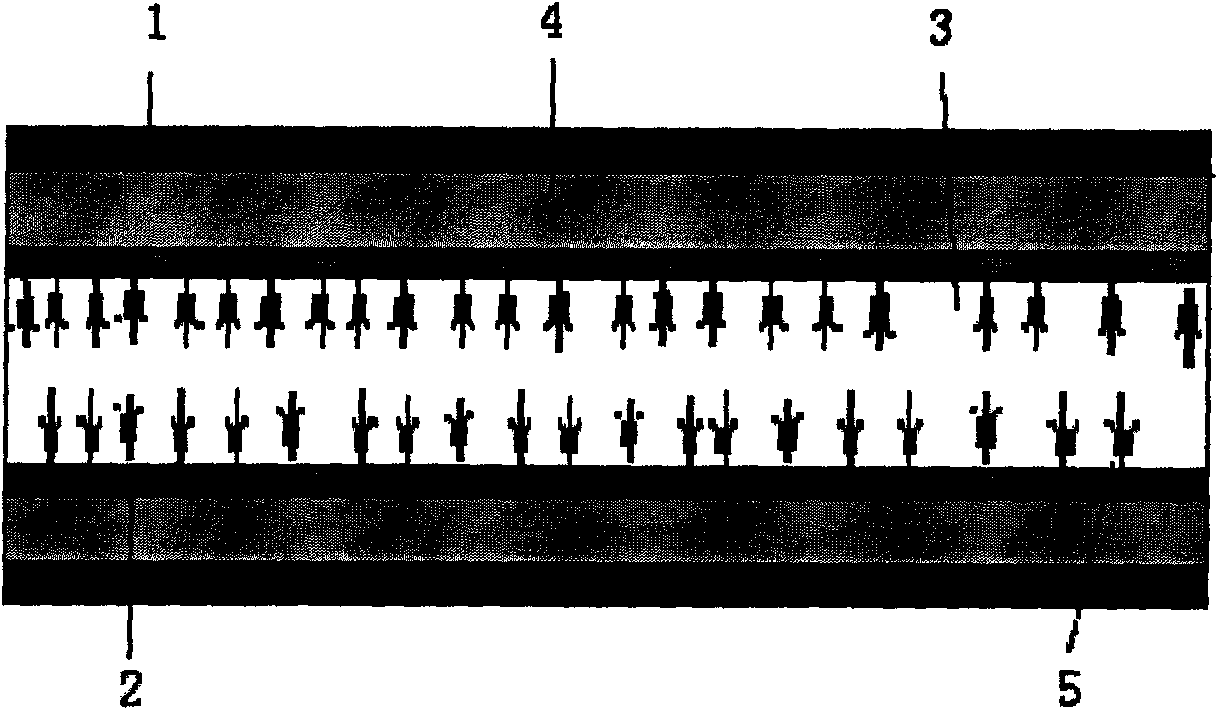

[0020] Example 1 A mullite tubular parison with an inner diameter of 35 mm, an outer diameter of 50 mm and a length of 1500 mm was prepared.

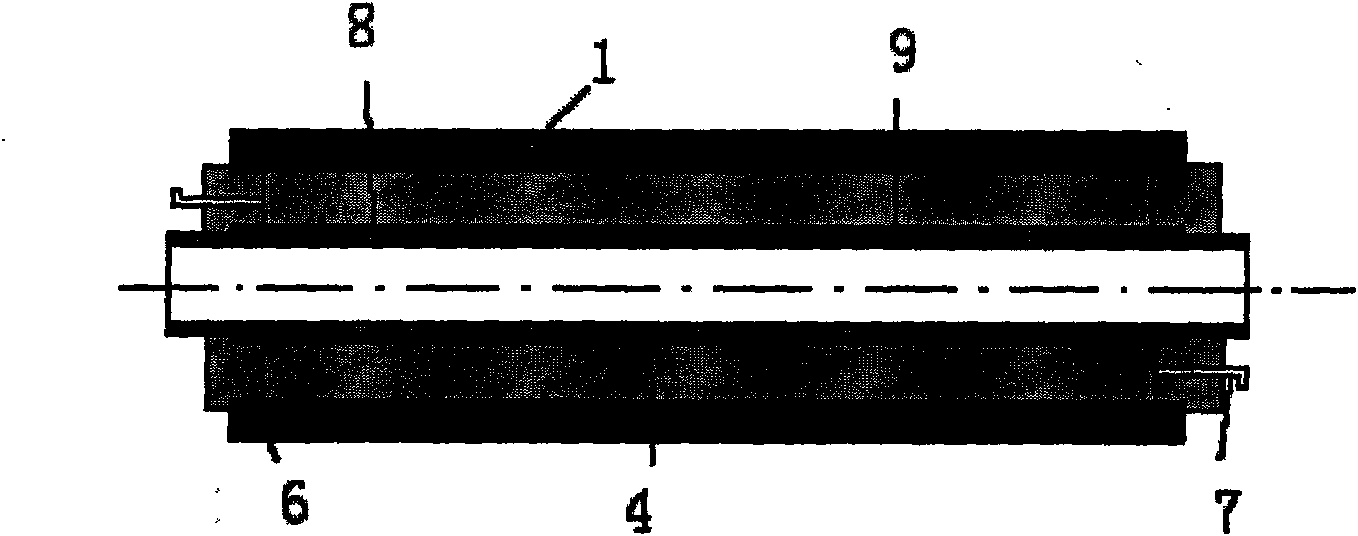

[0021] Use 5-mesh stainless steel mesh to make a round tube with an outer diameter of 29mm and a length of 1700mm as the rigid inner tube, and use a rubber sleeve with an inner diameter of 29mm, a length of 1700mm, and a thickness of 1mm, and the rubber sleeve will form an inner mold tube on the rigid inner tube; The outer mold tube is made of stainless steel pipe with an inner diameter of 50mm, a length of 1500mm, and a thickness of 50mm. The inner surface of the outer mold tube is carefully machined to obtain a proper finish; the end plugs are made of stainless steel. Combine the inner mold tube and the outer mold tube to form a cavity, fill the above cavity with properly granulated mullite powder, and mechanically vibrate the powder in the cavity during the filling process; when the cavity is filled with powder After solidification, ...

example 2

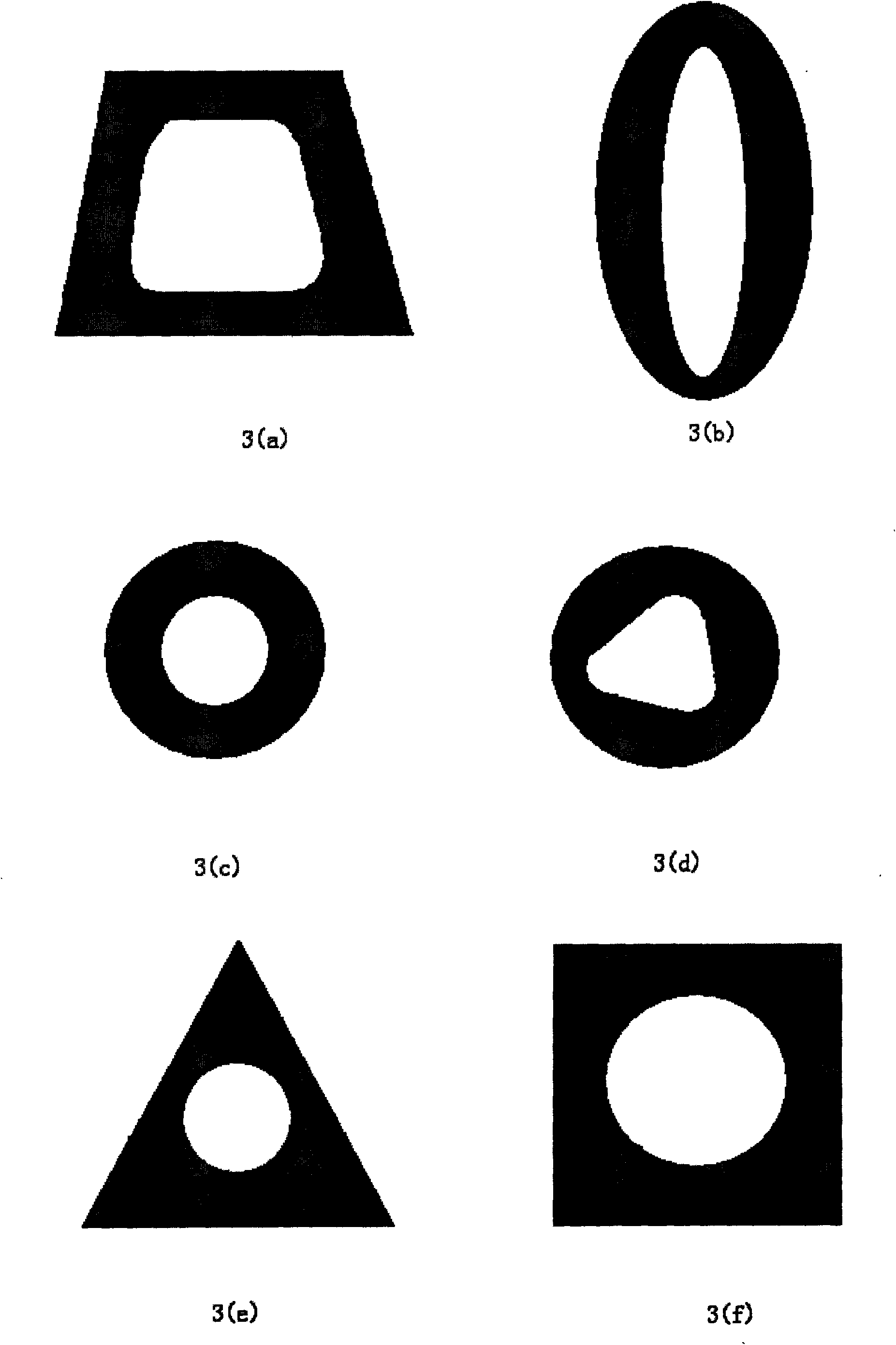

[0022] Example 2 prepares an internal diameter of 10mm circular shape, a square shape with a side length of 30mm, and a copper tubular parison with a length of 200mm

[0023] Use 5-mesh stainless steel mesh to make a round tube with an outer diameter of 6mm and a length of 250mm as the rigid inner tube, select a rubber tube with an inner diameter of 6mm, a length of 250mm, and a thickness of 1mm, and cover the rubber tube on the rigid inner tube to form an inner mold tube ; Make the outer mold tube with a square inner cavity with a side length of 30mm and a length of 250mm. The inner surface of the outer mold tube is carefully machined to obtain an appropriate finish; combine them into the cavity. Fill the above-mentioned cavity with properly granulated copper powder, and perform mechanical vibration during the filling process; after the cavity is filled with powder, seal the two ends of the cavity with two end plugs; use the pump on the end plug to The air pipe vacuumizes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com