Method and equipment for producing tire

A technology for raw tires and tires, applied in tires, other household appliances, household appliances, etc., can solve the problems of large investment, high manufacturing complexity, and complicated manufacturing of reinforcing bags, and achieve the effect of simplifying the production process and reducing processing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

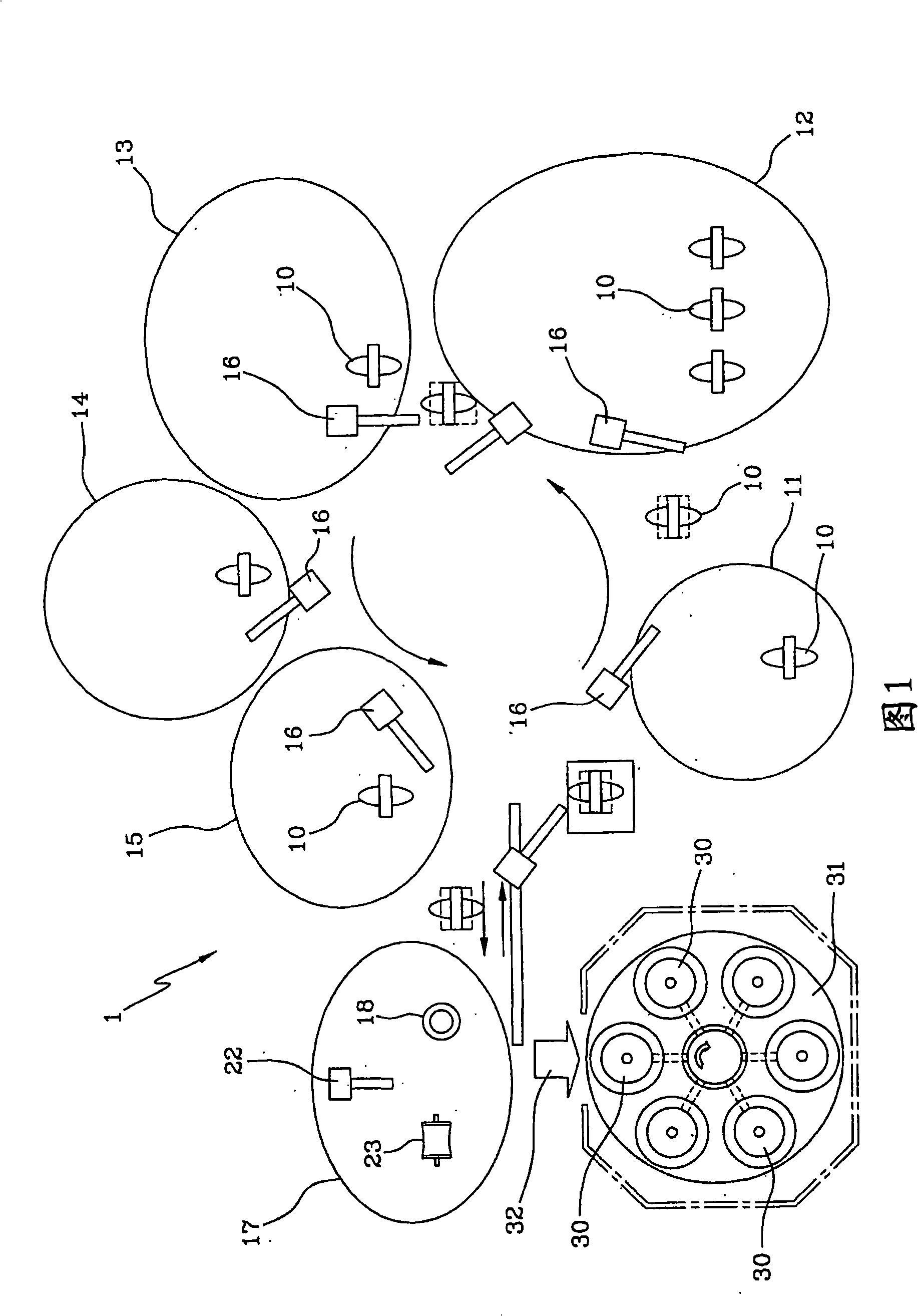

[0037] Referring to the drawings, reference numeral 1 generally designates an apparatus for the production of tires according to the invention.

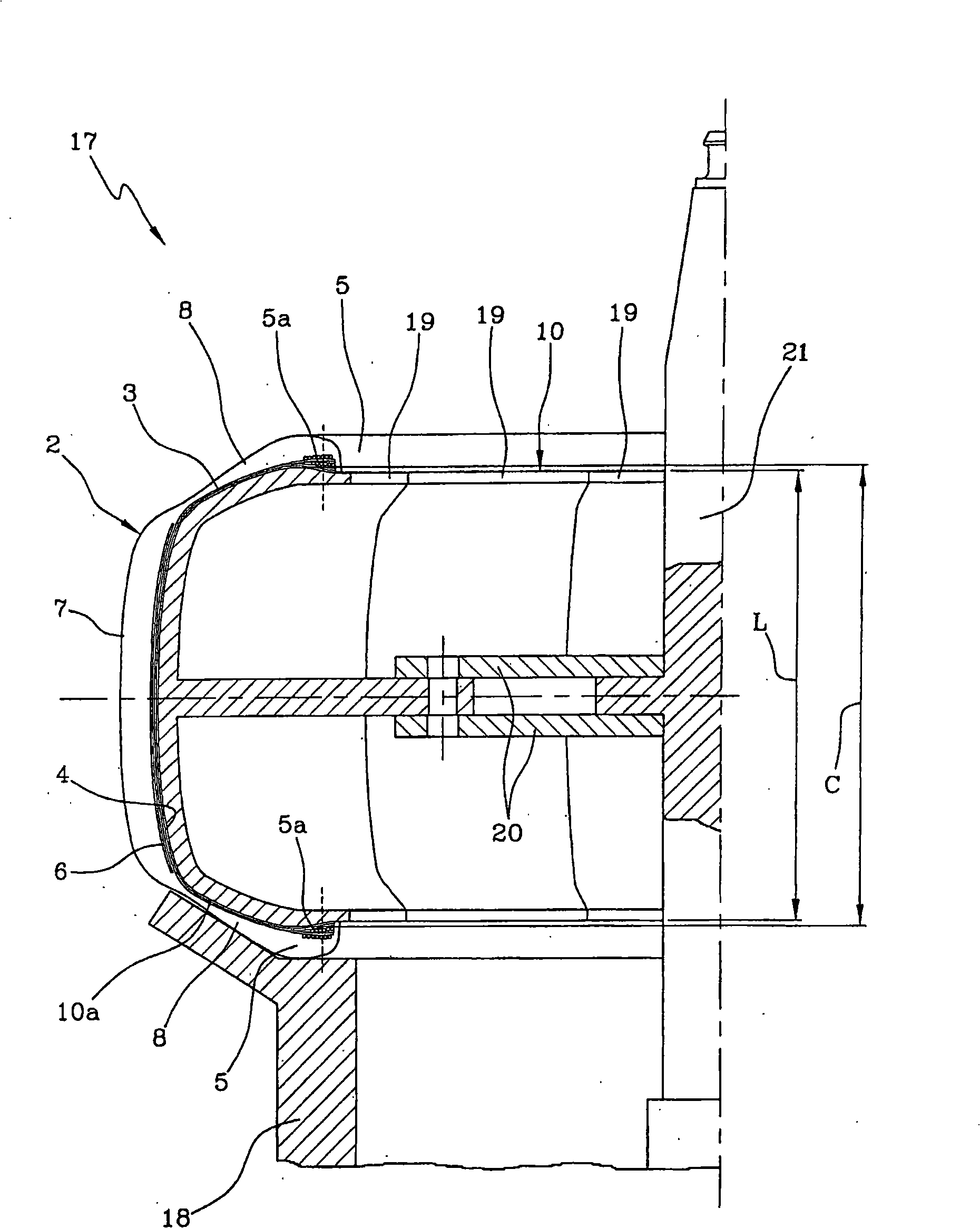

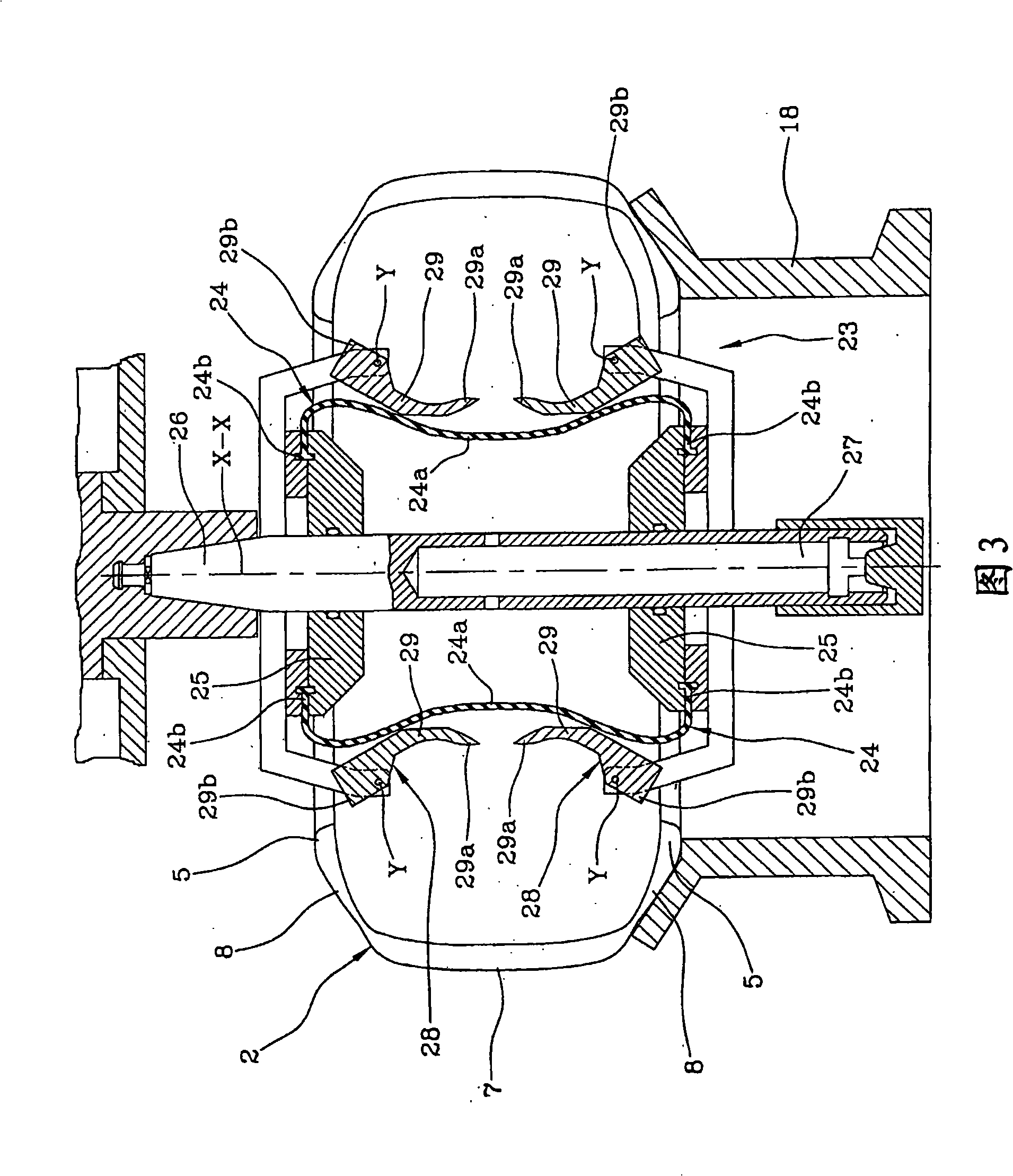

[0038] Equipment 1 is designed to produce tires 2 ( figure 2 ), the tire essentially comprising at least one carcass ply 3, two annular anchoring structures 5a engaged with the circumferential edges of the carcass ply near the area commonly referred to as the "bead" 5, circumferentially applied to the carcass The belt structure 6 of the ply 3 , the tread band 7 superimposed on the belt structure 6 and the two sidewalls 8 circumferentially, wherein the carcass ply 3 is internally coated with a layer of airtight elastic Body material (so-called liner 4 ), sidewalls 8 are applied to the carcass ply 3 in laterally opposite positions and each extend from a respective bead 5 to a respective side edge of the tread band 7 .

[0039] Plant 1 mainly comprises means for building tires 2 running along a building line generally indicated at 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com