Post-extraction process for producing antibacterial peptide through bacillus subtilis

A technology of Bacillus subtilis and extraction process, which is applied to the preparation method of peptides, peptides, desipeptides, etc., can solve the problems of affecting the reputation of animal products, loss of product potency, narrow antibacterial spectrum, etc. The effect of low loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

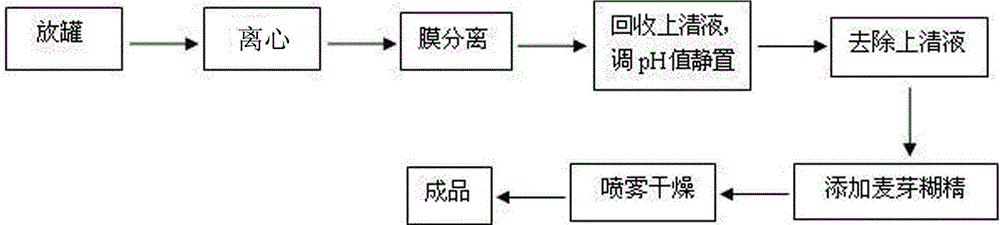

[0032] Embodiment 1, a kind of Bacillus subtilis produces the post-extraction process of antimicrobial peptide, such as figure 1 shown, including the following steps:

[0033] 1) put the tank

[0034] Use compressed air to adjust the pressure of the fermentation tank to about 0.05MPa, and the pressure of the storage tank is zero. Use the pressure difference between the fermentation tank and the storage tank to transfer the fermentation pressure of Bacillus subtilis to the storage tank through the stainless steel material pipeline. , stored for 2 hours for centrifugation.

[0035] It has been verified by experiments that when the storage time is too long, the antimicrobial peptide will be lost to a certain extent, and the antibacterial potency will drop sharply, and if the storage time is too short, it will not be conducive to the further metabolic release of the antimicrobial peptide in the bacteria, thereby affecting the product potency . The storage time of the fermentati...

Embodiment 2

[0058] Embodiment 2, a kind of post-extraction process of Bacillus subtilis fermented liquid, such as figure 1 shown, including the following steps:

[0059] 1) put the tank

[0060] Use compressed air to adjust the pressure of the fermentation tank at about 0.07MPa, and the pressure of the storage tank is zero. Use the pressure difference between the fermentation tank and the storage tank to transfer the fermentation pressure of Bacillus subtilis to the storage tank through the stainless steel material pipeline. , stored for no more than 2 hours for centrifugation.

[0061] It has been verified by experiments that when the storage time is too long, the antimicrobial peptide will be lost to a certain extent, and the antibacterial potency will drop sharply, and if the storage time is too short, it will not be conducive to the further metabolic release of the antimicrobial peptide in the bacteria, thereby affecting the product potency . The storage time of the fermentation li...

Embodiment 3

[0080] Embodiment 3, a kind of post-extraction process of Bacillus subtilis fermented liquid, such as figure 1 shown, including the following steps:

[0081] 1) put the tank

[0082] Use compressed air to adjust the pressure of the fermentation tank at about 0.1MPa, and the pressure of the storage tank is zero. Using the pressure difference between the fermentation tank and the storage tank, the fermentation pressure of Bacillus subtilis to produce antimicrobial peptides is transferred to the storage tank through stainless steel material pipelines. , stored for no more than 2 hours for centrifugation.

[0083] It has been verified by experiments that when the storage time is too long, the antimicrobial peptide will be lost to a certain extent, and the antibacterial potency will drop sharply, and if the storage time is too short, it will not be conducive to the further metabolic release of the antimicrobial peptide in the bacteria, thereby affecting the product potency . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com