Novel outer row compressed type multi-row axial plunger pump/motor

A technology of axial piston pump and external discharge, applied in multi-cylinder pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem of increasing the radial size of axial piston pumps/motors, compacting The force distribution is not uniform enough, which is not conducive to the compactness of the structure, so as to avoid stress concentration and overturning, the structure is compact, and the structure has good symmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

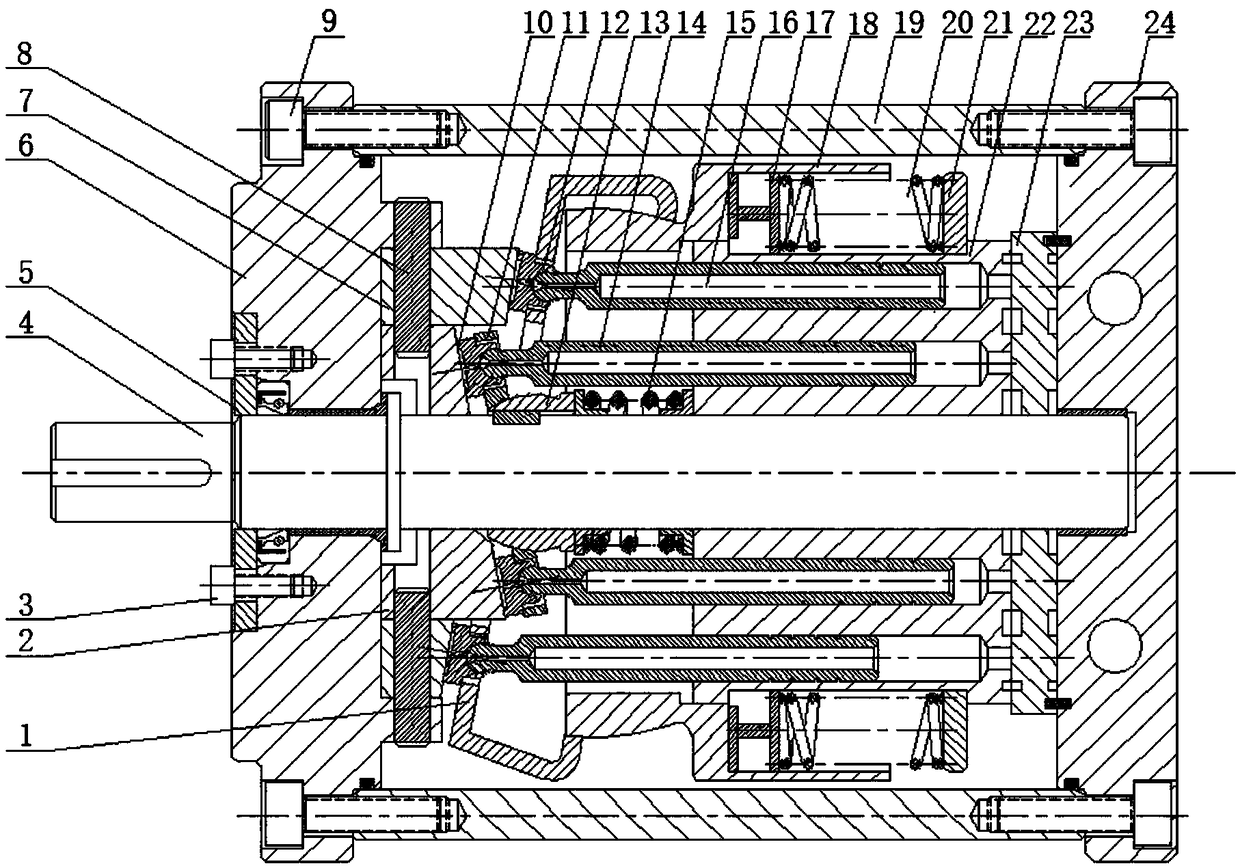

[0039] see Figure 1 to Figure 7As shown, the present invention provides a novel multi-row axial piston pump / motor that is compacted by the outer row, including a housing 19, a cylinder body 22, a transmission shaft 4, a distribution plate 23, an inner swash plate 2 and an outer swash plate 7 , the front gland 5 is connected to the front end cover 6 through the hexagonal screw 3, the front end cover 6 is connected to the housing 19 through the hexagonal screw 9, and the housing 19 is connected to the rear pump cover 24 through the hexagonal screw 9, the Transmission shaft 4 drives cylinder body 22 to rotate through spline, and baffle plate 21 is installed in the baffle plate groove of described cylinder body 22, and outer compression ball sleeve 18 is sleeved on the outside of described cylinder body 22, and described outer compression ball The outer spherical surface of the sleeve 18 is hinged with the inner spherical surface of the outer pressure plate 1 so as to press the o...

Embodiment 2

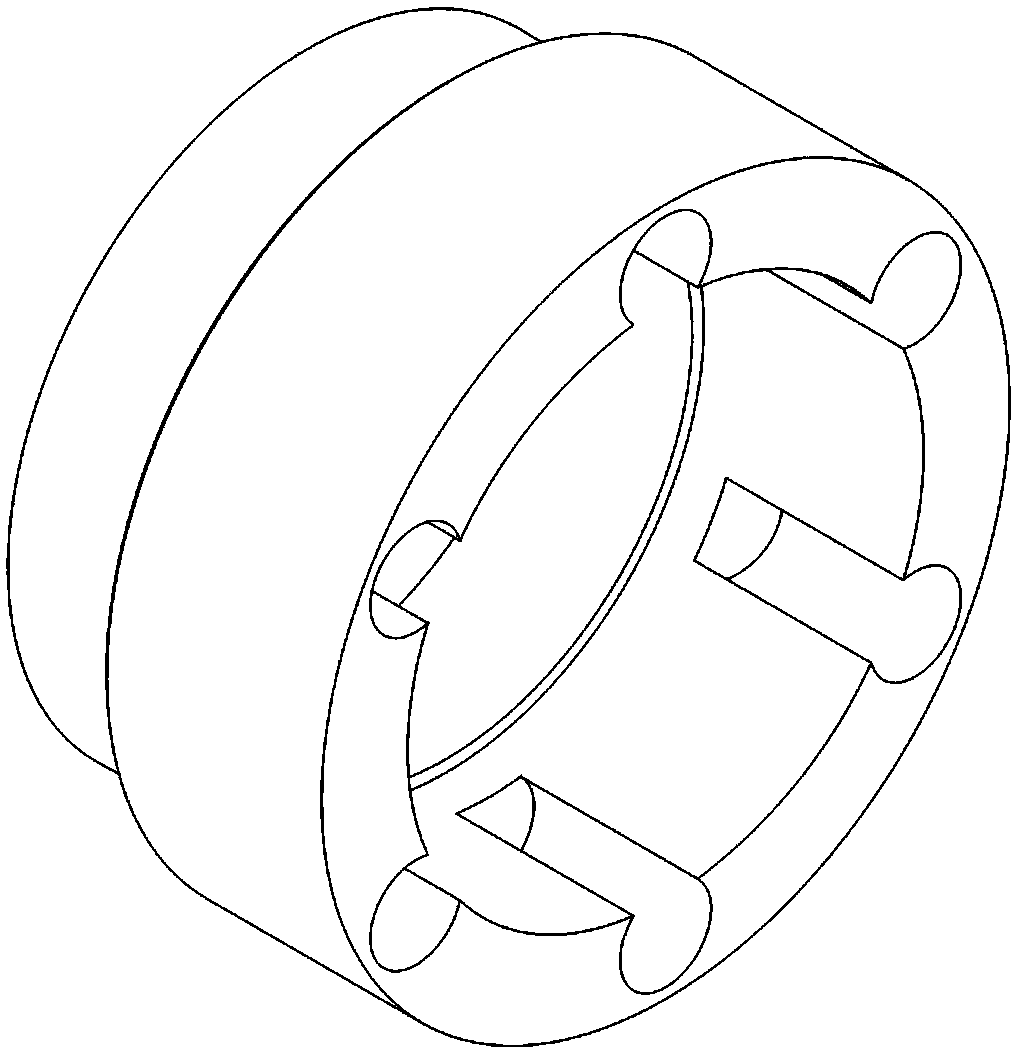

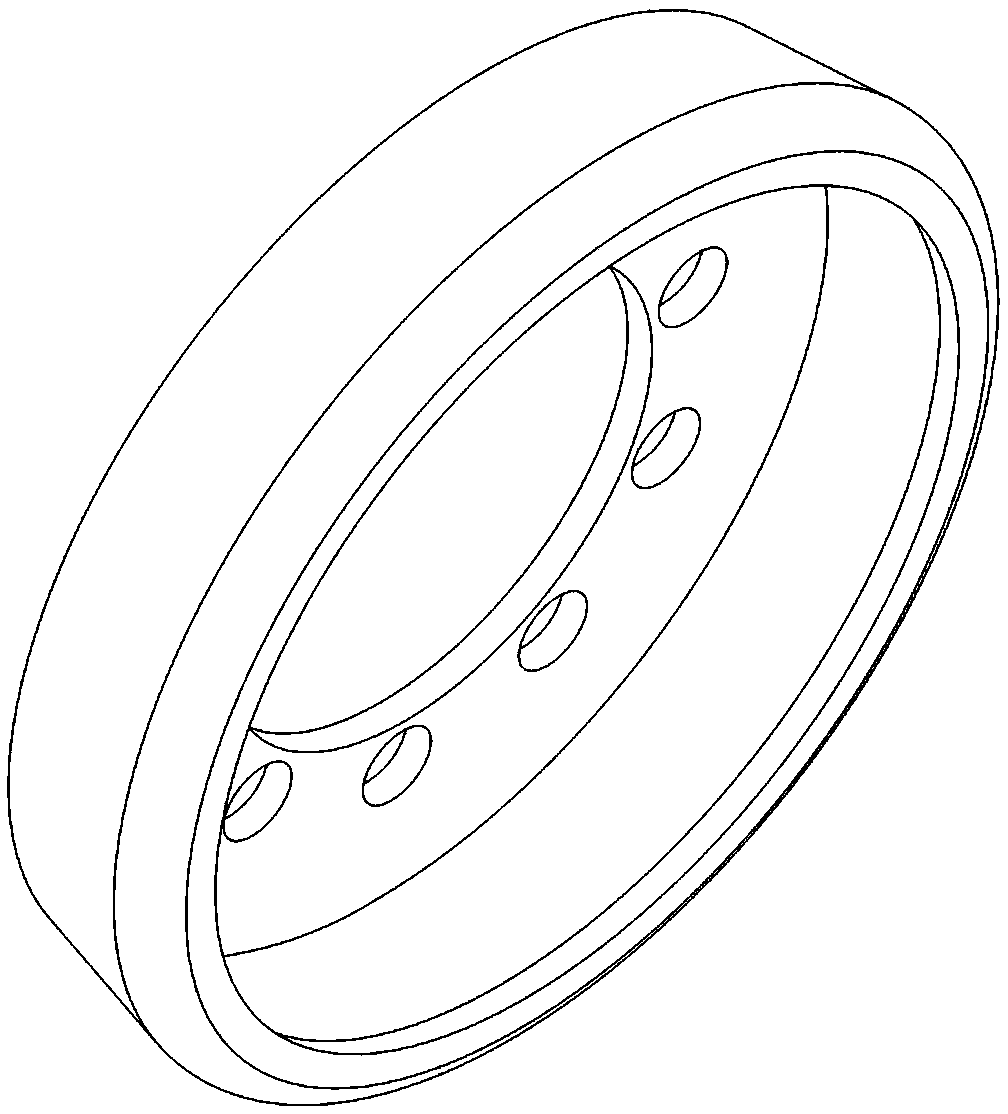

[0046] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, and the differences are as follows: Figure 8 to Figure 11 As shown, the structure of the outer pressure plate 1 and the outer compression ball sleeve 18 is different, that is, the outer pressure plate 1 is disc-shaped, and the surface is provided with evenly distributed fan-shaped holes. The inner surface of the hole is a spherical surface, and the outer compression ball sleeve 18 The front end is provided with a corresponding protruding claw. The outer surface of the protruding claw is a spherical surface. The outer pressure plate 1 and the outer pressing ball sleeve 18 are still in a completely symmetrical structure. The extending claw of the outer pressing ball sleeve 18 passes through the outer pressing The fan-shaped hole on the surface of the disc 1 is hinged with its spherical surface, and there is a part of the gap between the inner surface of the outer pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com