Flame retardant dilphosphonic heterocyclic polysilicate compound and preparation method thereof

A technology of bisphosphonyl and flame retardant, which is applied in the field of flame retardant bisphosphonyl heterocyclic polysilicate compound and its preparation, can solve problems such as threats to life and property safety, fire, etc., and achieves improved flame retardant carbonization Efficacy, improved compatibility, novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

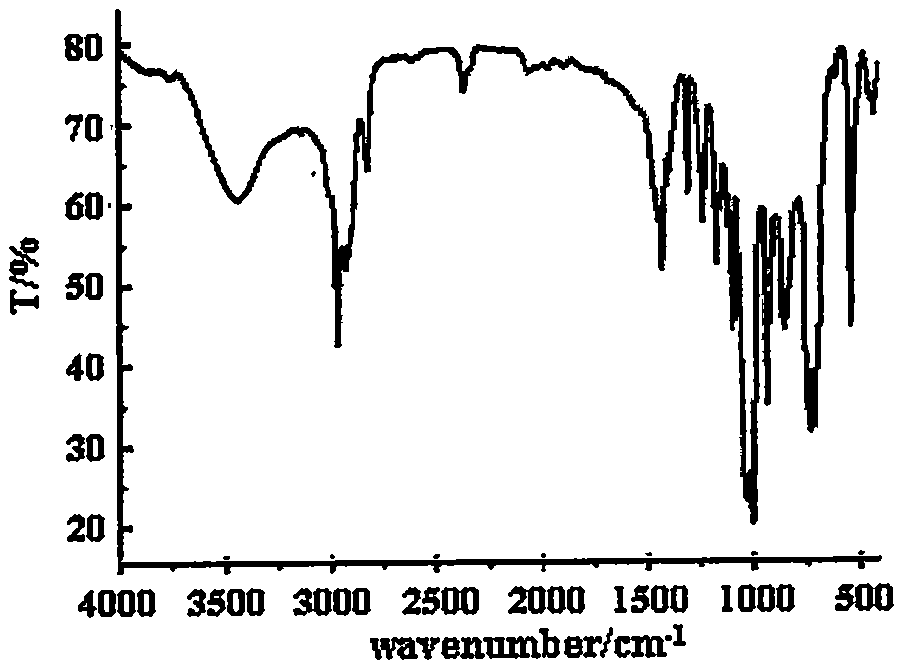

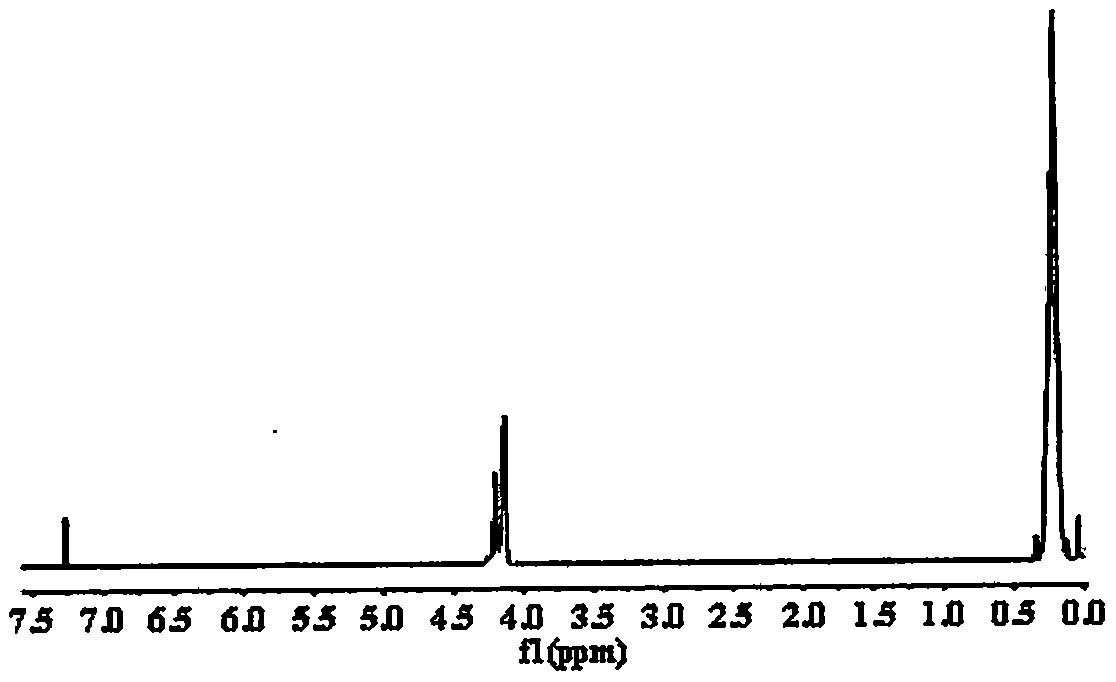

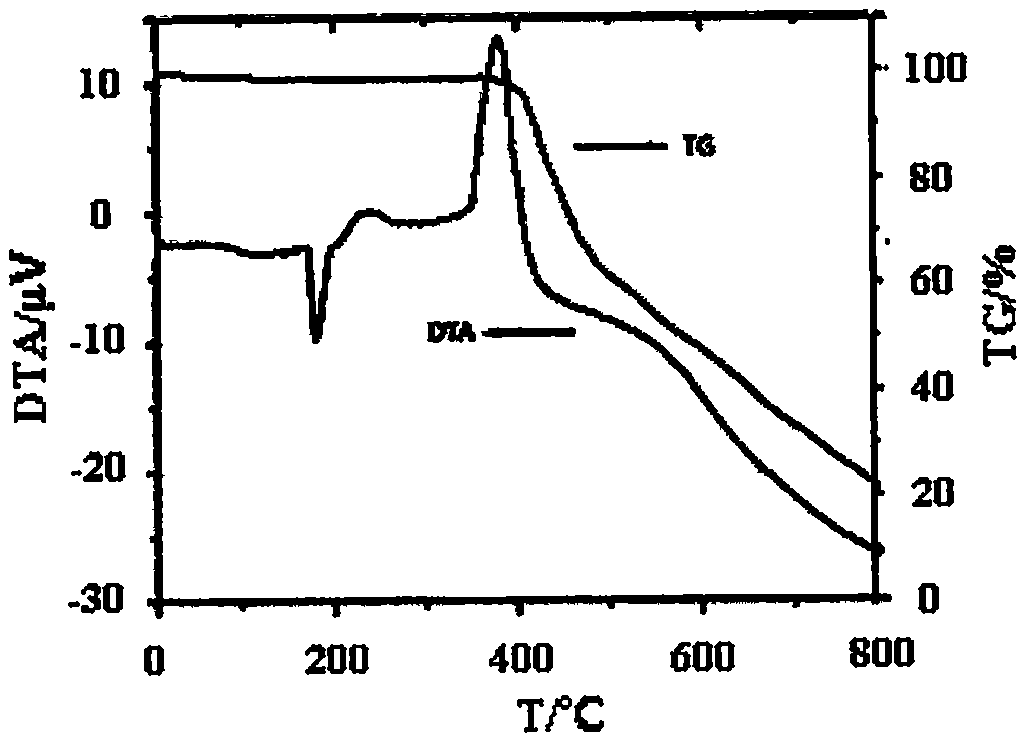

Embodiment 1

[0025] Example 1 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a drying tube on the upper mouth of the condenser, replace the air in the bottle with nitrogen, and add 19.6g (0.10mol) di Trihydroxymethylphosphine oxide cyclic ester of methyl silicate and 90ml of ethylene glycol diethyl ether, then add 6.45g (0.05mol) of dimethyldichlorosilane dropwise, and control the temperature of the dropping process not to be higher than 50°C. Afterwards, the temperature was raised to 70°C, and the temperature was kept for 3 hours, and then the temperature was raised to 120°C under reflux, and the temperature was kept for 9 hours. into 60ml of ice water, stirred rapidly for 30min, filtered with suction, and the filter cake was vacuum-dried to obtain the flame retardant bisphosphonoheterocyclic polysilicate product. The yield is 92.2%, the melting point is 190±2°C, and the decomposition temperature is 376±5°C.

Embodiment 2

[0026] Example 2 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a drying tube on the upper mouth of the condenser, replace the air in the bottle with nitrogen, and add 20.58g (0.105mol) di Trihydroxymethylphosphine oxide cyclic ester of methyl silicate and 100ml of diethylene glycol dimethyl ether, then add 6.45g (0.05mol) of dimethyldichlorosilane dropwise, and control the temperature of the dropping process to not be higher than 50°C. After dripping, raise the temperature to 70°C, keep the temperature for 3 hours, then reflux and raise the temperature to 140°C, keep the temperature for 7 hours, let the hydrogen chloride be released, stop the reaction, cool to room temperature, and distill the solvent under reduced pressure to obtain a turbid viscous liquid; The product was poured into 60ml of ice water, stirred rapidly for 30 minutes, filtered with suction, and the filter cake was vacuum-dried to obtain the produc...

Embodiment 3

[0027] Example 3 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a drying tube on the upper mouth of the condenser, replace the air in the bottle with nitrogen, and add 21.56g (0.11mol) of di Trihydroxymethylphosphine oxide cyclic ester of methyl silicate and 110ml of tetrachloroethane, then add 6.45g (0.05mol) of dimethyldichlorosilane dropwise, and control the temperature of the dropping process not to be higher than 50°C. Raise the temperature to 70°C, keep the temperature for 3 hours, then reflux and raise the temperature to 130°C, keep the temperature for 7 hours, let the hydrogen chloride be released, stop the reaction, cool to room temperature, and distill the solvent under reduced pressure to obtain a cloudy viscous liquid; then pour the crude product into 60ml of ice water, stirred rapidly for 30 minutes, suction filtered, and the filter cake was vacuum-dried to obtain the product flame retardant bisphosphon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com