Textile coating with radiation refrigeration function and preparation method thereof

A technology of textile coating and radiation refrigeration, applied in textiles and papermaking, etc., can solve the problems of increasing the cost of preparation and application, which is not conducive to the efficient application of passive radiation refrigeration materials, etc. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

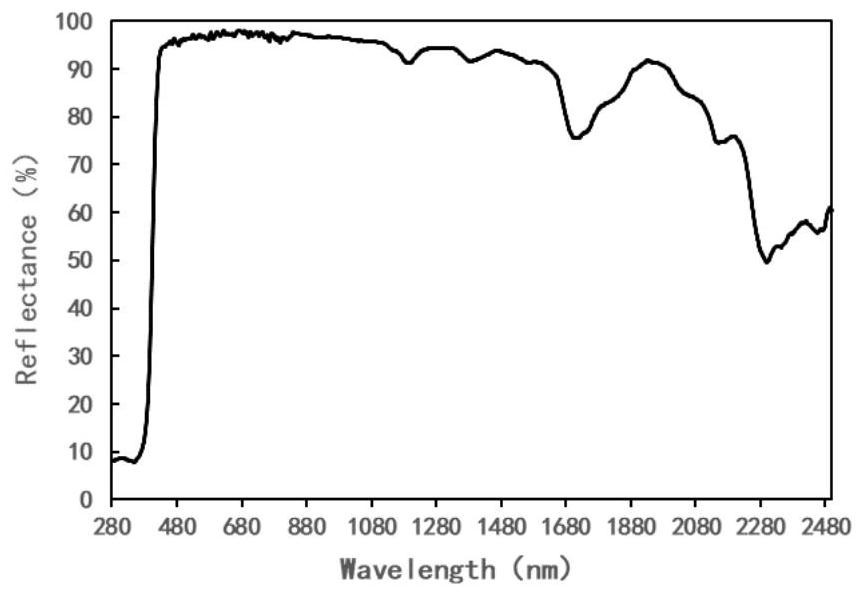

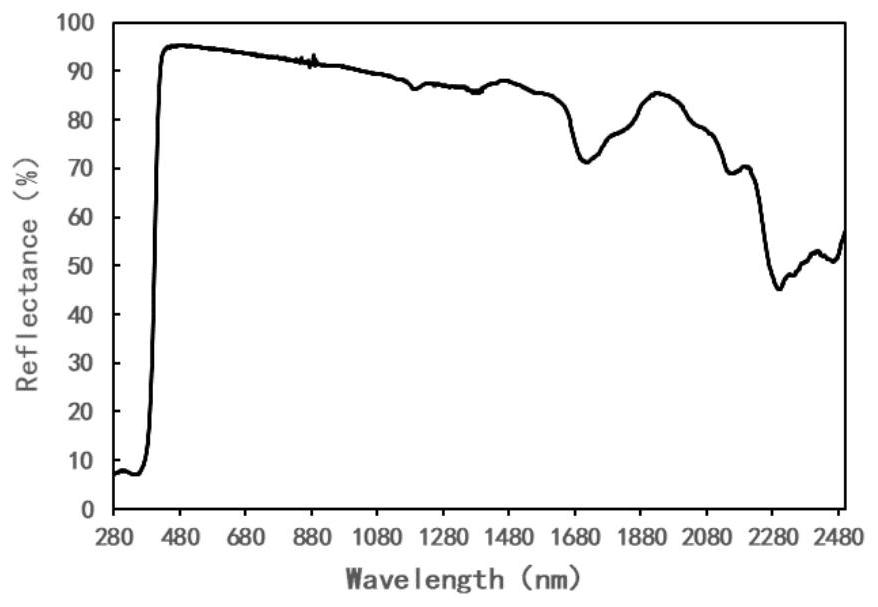

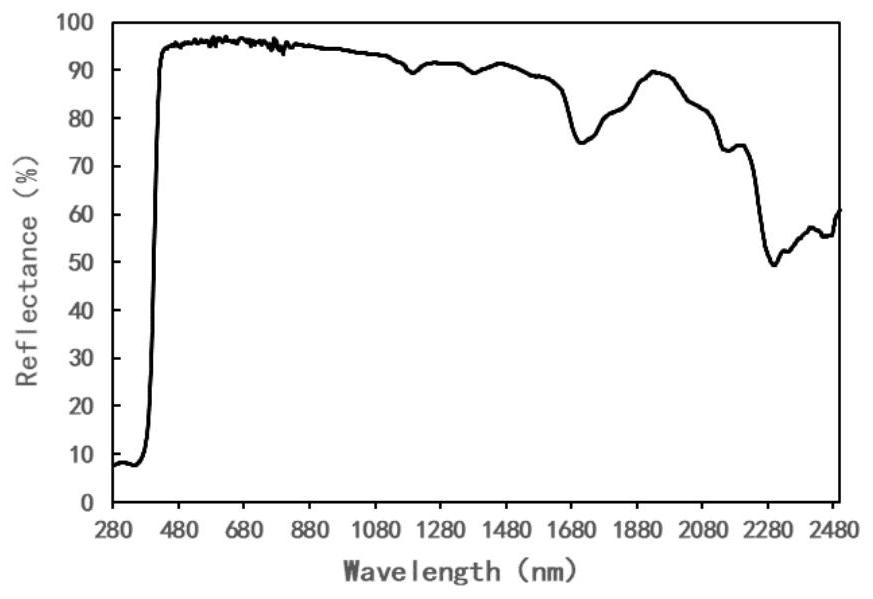

Image

Examples

Embodiment 1

[0027] Embodiment 1: The textile coating with radiant refrigeration function according to the present invention, the raw materials are calculated by mass percentage, including the following components: 28.57% of polyurethane modified acrylic resin, 42.86% of reflective pigment and filler, 0.35% of dispersant, wetting agent 0.15%, defoamer 0.30%, thickener 0.27%, film-forming aid 0.51% and water 26.99%, among them, the elongation at break of polyurethane modified acrylic resin is 780%, the first filler type in reflective pigments and fillers It is titanium dioxide with a particle size of 0.01-0.26 μm, the second filler is ceramic powder with a particle size of 1.8-3.5 μm, the mass ratio of the first filler to the second filler is 6.5:1, the reflective pigment filler and polyurethane modified acrylic acid The resin mass ratio is 1.5:1.

[0028] After mixing the raw materials of the above-mentioned textile coating evenly, a functional layer is formed on the flexible substrate by ...

Embodiment 2

[0029] Embodiment 2: The textile coating with radiant refrigeration function according to the present invention, the raw materials are calculated by mass percentage, including the following components: 30.04% of polyurethane modified acrylic resin, 30.04% of reflective pigment and filler, 0.23% of dispersant, wetting agent 0.09%, defoamer 0.45%, thickener 0.62%, film-forming aid 0.54% and water 37.99%, wherein, the elongation at break of polyurethane modified acrylic resin is 630%, the first filler in reflective pigment filler includes Titanium dioxide, zinc oxide, and aluminum oxide, the particle size is 0.10-0.43μm, the second filler includes hollow glass beads, the particle size is 11.3-18.6μm, the mass ratio of the first filler to the second filler is 4.8:1, the reflective color The mass ratio of filler to polyurethane modified acrylic resin is 1:1.

[0030] After mixing the raw materials of the above-mentioned textile coating evenly, a functional layer is formed on the fl...

Embodiment 3

[0031] Embodiment 3: The textile coating with radiant refrigeration function according to the present invention, the raw materials include the following components in terms of mass percentage: 20.5% of silicone modified acrylic resin, 47.15% of reflective pigment and filler, 0.43% of dispersant, wetting 0.12% antifoaming agent, 0.25% defoaming agent, 0.42% thickening agent, 0.37% film-forming aid and 30.76% water. Among them, the elongation at break of silicone-modified acrylic resin is 850%, ranking first among reflective pigments and fillers. The filler includes titanium dioxide and ceramic powder with a particle size of 0.30-1.2 μm. The second filler includes alumina, kaolin and talc powder with a particle size of 0.5-6 μm. The mass ratio of the first filler to the second filler is 2:1. The mass ratio of pigment and filler to polyurethane modified acrylic resin is 2.3:1.

[0032] After mixing the raw materials of the above-mentioned textile coating evenly, a functional laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com