Silk linen fiber multi-component stretch fabric and production method thereof

A production method and multi-component technology, applied in textiles, yarns, fabrics, etc., can solve the problems of chlorine bleaching resistance, high temperature resistance, etc., and achieve the effect of comfortable elasticity and good elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

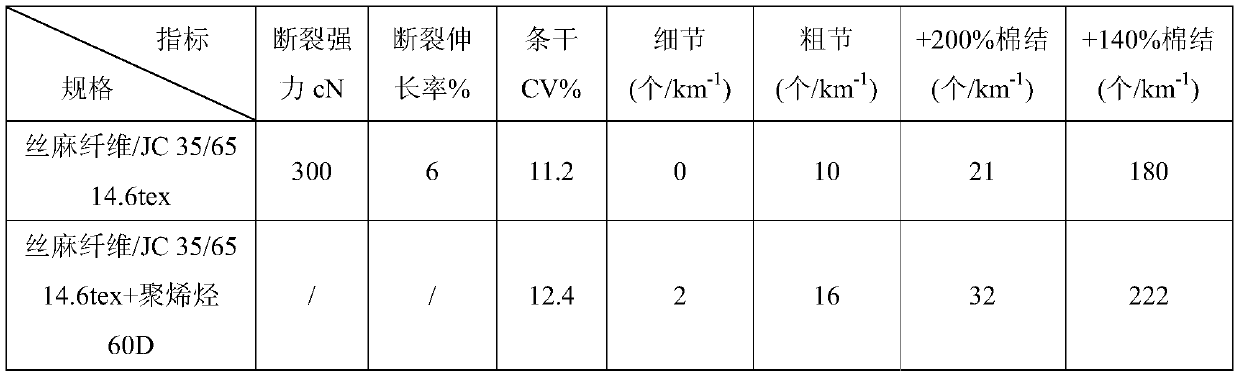

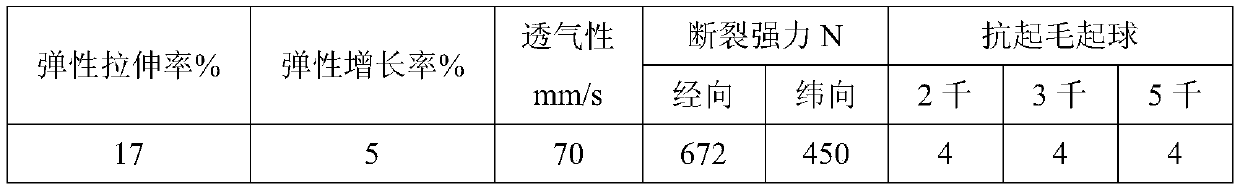

[0047] A silk and linen fiber multi-component elastic fabric, the fabric specification is silk and linen fiber / JC 35 / 65 14.6tex*silk and linen fiber / JC 35 / 6514.6tex+polyolefin 60D 128*80 2 / 2↖, and the warp is silk and linen fiber / Combed cotton 35 / 65 14.6tex, the weft is silk and hemp fiber / Combed cotton 35 / 65 14.6tex + polyolefin 60D, the warp density is 128 threads / inch, the weft density is 80 threads / inch, the weaves are two upper and two lower Left twill.

Embodiment 2

[0049] A production method of silk and hemp fiber multi-component elastic fabric, comprising a spinning process and a weaving process,

[0050] (1) The spinning process comprises the blowing and carding of cotton fibers, drawing, combing, the blowing and drawing of silk and linen fibers, drawing, and the steps of drawing, roving and spun yarn of cotton fibers and silk and linen fibers, wherein,

[0051] The process parameters of the carding part in the cotton fiber blowing and carding step and the silk and linen fiber blowing and carding step are:

[0052] The licker-in speed is 830r / min, the cylinder speed is 330r / min, the doffer speed is 18r / min, the distance between the feeding plate and the licker-in roller is 0.22mm, the distance between the cylinder and the licker-in roller is 0.20mm, and the distance between the cover plate is 0.18 / 0.13 / 0.13 / 0.13 / 0.14mm, cylinder and doffer gauge 0.16mm, raw sliver weight 19.2g / 5m;

[0053] The process parameter of the drawing frame ste...

Embodiment 3

[0068] On the basis of embodiment 2, the production method of silk hemp fiber multi-component elastic fabric also includes the dyeing and finishing process, and the dyeing and finishing process includes enzyme desizing, oxygen bleaching, setting, dyeing and finishing steps, wherein,

[0069] The process parameters for the enzymatic desizing step are:

[0070] The desizing enzyme 2000L is 3g / L, and the penetrant HF-JL7 is 2g / L;

[0071] The technological parameter of oxygen bleaching step is:

[0072] The hydrogen peroxide is 6g / L, the hydrogen peroxide stabilizer is 3g / L, the refining agent HF-JL10 is 5g / L, and the pH value is 10;

[0073] The processing parameters of the shaping step are:

[0074] The setting temperature is 170°C, and the setting time is 30s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com