A kind of preparation method of polyvinyl chloride decorative sheet

A technology of polyvinyl chloride and decorative sheets, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., and can solve the problem of unreasonable design of coating devices, molecular chain entanglement, coating thickness and uniformity Differences and other problems, to overcome the high requirements of coating softness and fluidity, good coating flatness, and accurate accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The features and advantages of the present invention will be further described in detail below with reference to the accompanying drawings and preferred embodiments. The following embodiments are only exemplary, and those skilled in the art can make obvious modifications on this basis, and these modifications are also included in the scope of the present invention.

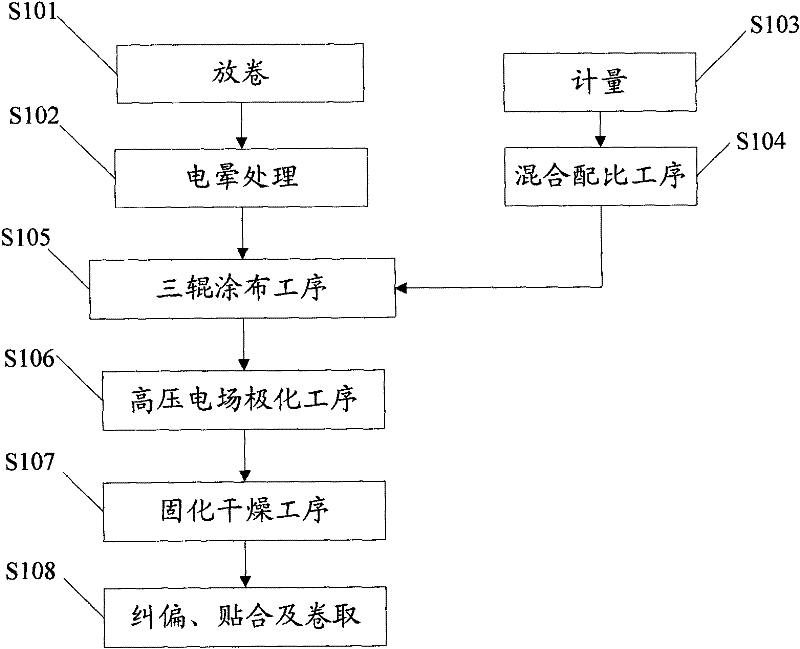

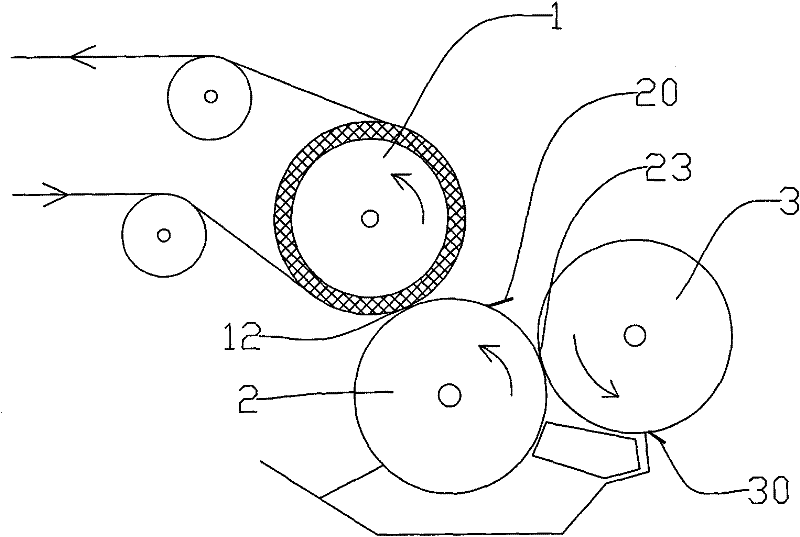

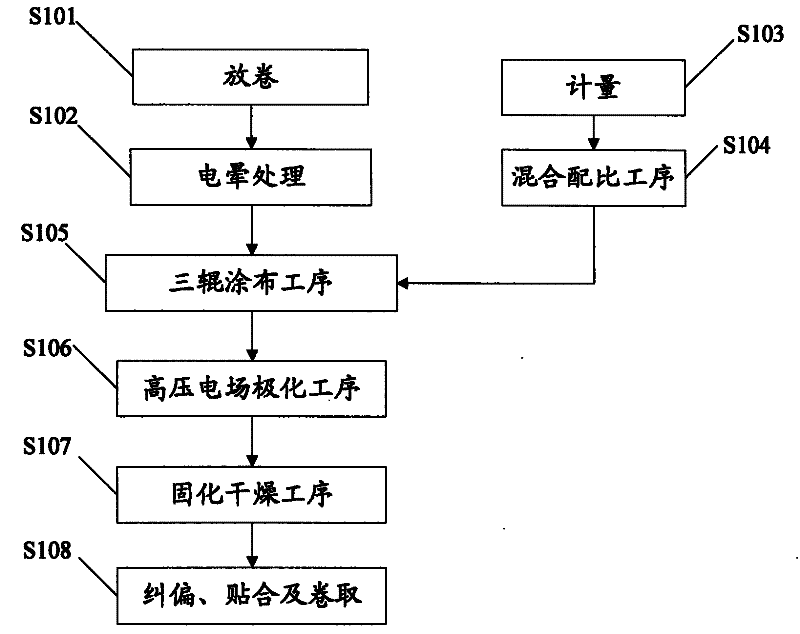

[0026] Such as figure 1 As shown, the present invention provides a preparation method of a polyvinyl chloride decorative sheet provided in an embodiment, which includes in turn: a mixing and proportioning process, a three-roll coating process, a DC high voltage electric field polarization process, a curing and drying process, a deviation correction process, Laminating process and coiling process, in addition, the amount of each component in the formula needs to be weighed before the mixing and proportioning process, and the base material of the PVC decorative sheet needs to be corona treated before coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com