Novel crucible and manufacturing method thereof

A crucible, a new type of technology, applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth and other directions, can solve the problems of high material cost, silicon vapor erosion, erosion strength loss, etc., to overcome thermal stress and resist erosion. , The effect of less material processing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Please refer to Figure 6 , this embodiment is a flow chart for manufacturing a crucible using a sheet-like carbon-carbon composite material as a raw material. The thickness range of the sheet-like carbon-carbon composite material is 5-50mm, and the density is: 1.3-1.85g / cm3. It can be seen that it mainly includes The following steps include:

[0054] S201: Perform structural design on the structure of the crucible;

[0055] According to the actual thermal design requirements, the crucible structure can be flexibly designed without the need to make an embryo body, which can effectively save costs and shorten the delivery time, and can be mass-produced at the same time.

[0056] S202: Decompose the drawing into several parts according to the structural design;

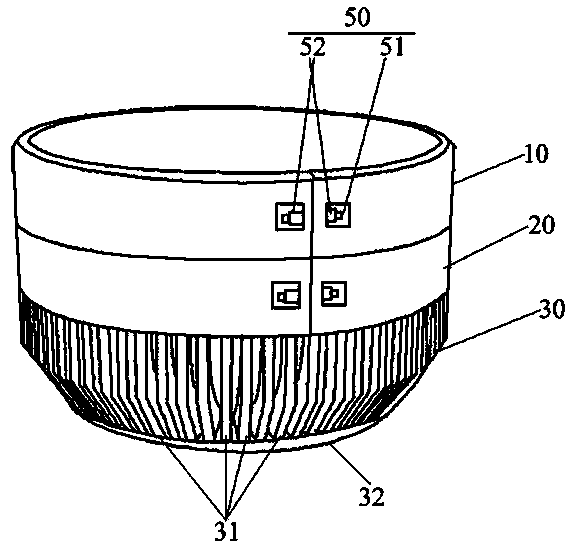

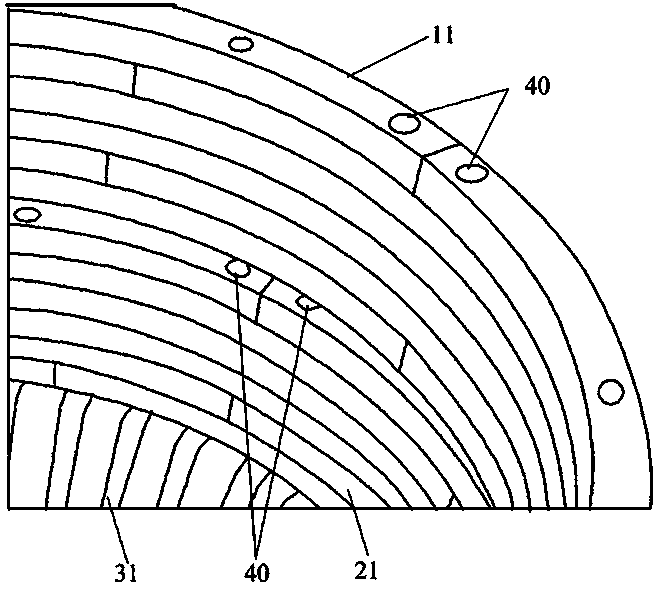

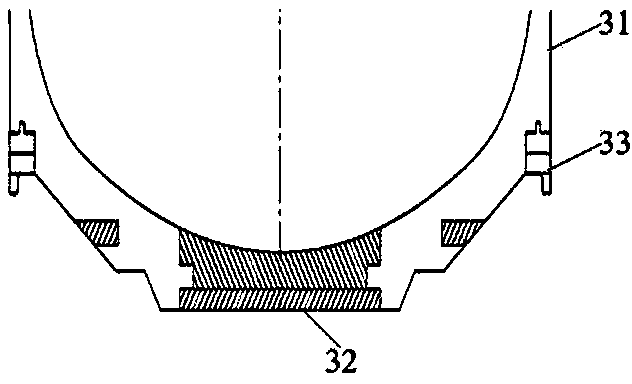

[0057] The structure of the crucible is decomposed into an upper ring part 10 , a middle ring part 20 and a lower bowl part 30 .

[0058] S203: Design each component;

[0059] Design the combined piece of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com