Method and device for installing typical underwater manifold in swing mode

An installation method and manifold technology, which can be used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as large tension loss, overcome axial resonance and large tension loss, and optimize the operation process. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

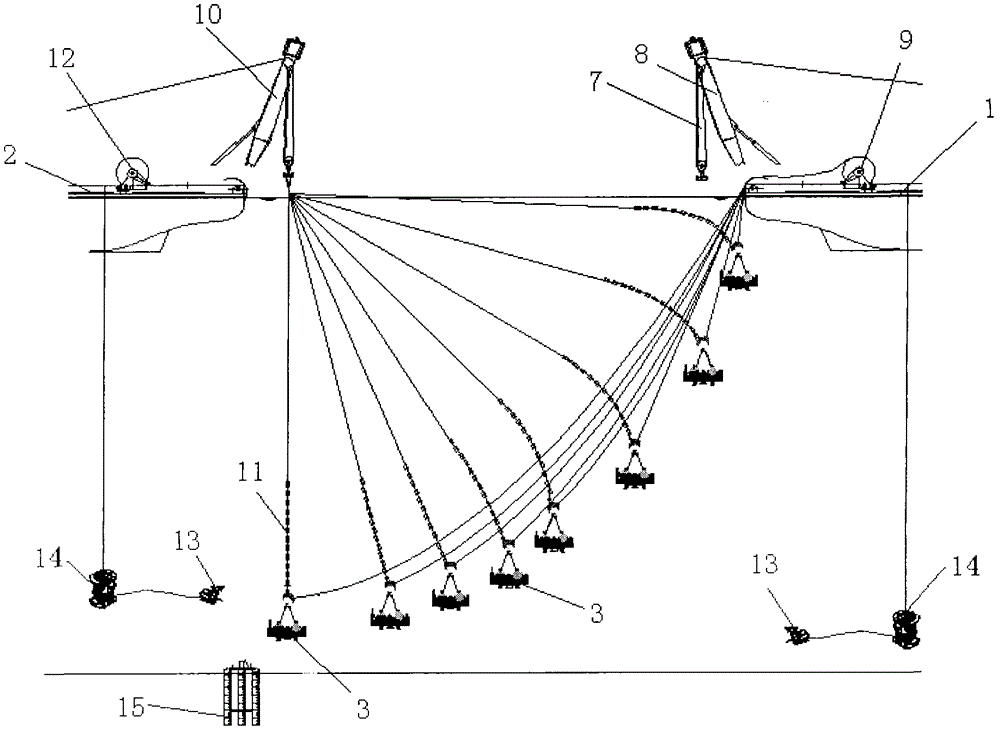

[0016] like figure 1 As shown, the manifold installation device of the present invention includes No. 1 installation ship 1 and No. 2 installation ship 2, and No. 1 installation ship 1 and No. 2 installation ship 2 are equipped with A-shaped cranes and hydraulic winches.

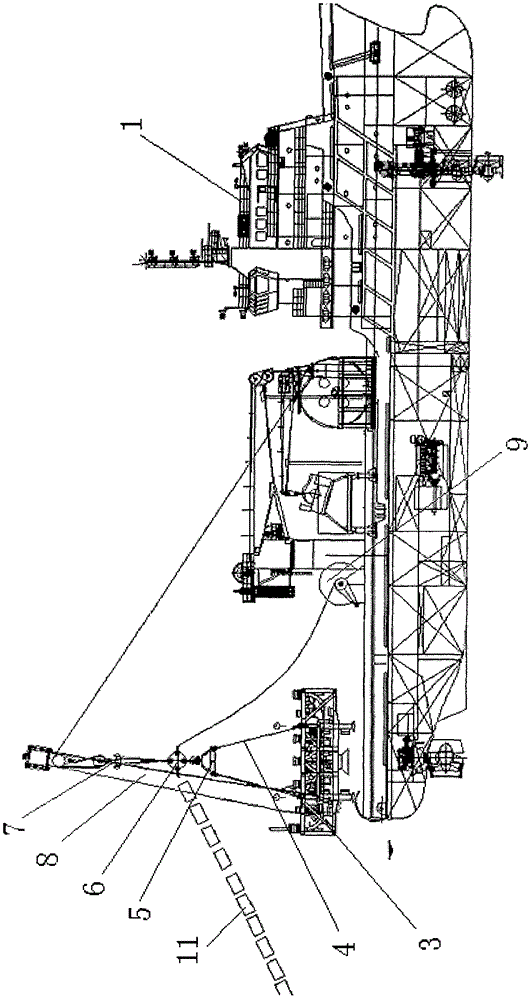

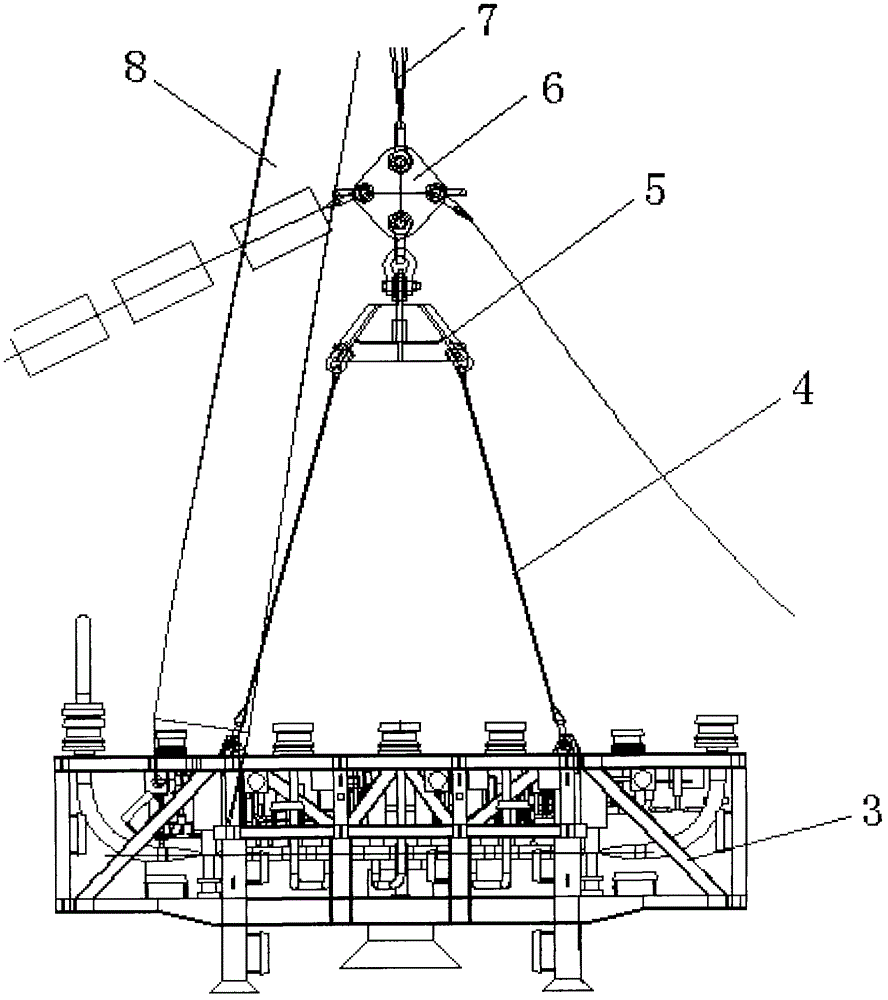

[0017] like figure 2 , image 3 As shown, the manifold 3 is placed on the deck of No. 1 installation ship 1; four hydraulic release snap rings are arranged on the upper part of the manifold 3, and each of the four hydraulic release snap rings is connected to a steel wire rope 4, and the other ends of the four steel wire ropes 4 pass through the The hydraulic release snap ring is connected to the bottom four-corner end of a triangular plate body 5 whose vertical section is an isosceles triangle. The corner end, the other corner end opposite to the corner end is connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com