Intermittent-annealing isothermal-growth multi-quantum well LED extension structure and manufacturing method thereof

A multi-quantum well and epitaxial structure technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of ineffective formation of electron holes, high quantum barrier dislocation density, affecting luminous efficiency, etc., to save heating and cooling time. , the crystal plane orientation is unified, and the production capacity is obviously improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

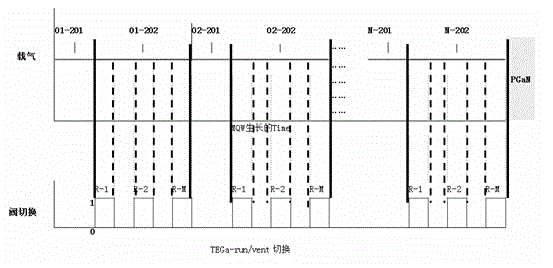

[0038] The invention provides a discontinuous annealing and same-temperature growth multi-quantum well LED epitaxial structure and a manufacturing method. The method adopts MOCVD equipment of Aixtron Company for epitaxial growth, and uses NH 3 , TMGa / TEGa, and TMIn are respectively used as N, Ga, and In sources.

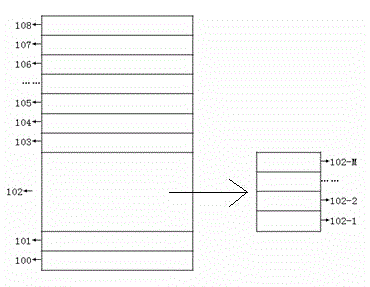

[0039] A multi-quantum well LED epitaxial structure grown at the same temperature by intermittent annealing, including a substrate on which a buffer layer, an n-GaN layer, an MQW active layer, p-GaN and a p-type contact layer are sequentially grown , the MQW active layer includes at least two multi-quantum well layers, generally 5-20, and 15 are grown in this embodiment. The multi-quantum well layer includes an InGaN quantum well layer, a GaN protection layer and a GaN quantum barrier layer from bottom to top, and the GaN quantum barrier layer consists of at least one GaN quantum barrier thin layer and a quantum barrier annealed layer grown at intervals. Generally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com