A rapid compression molding process of carbon fiber prepreg

A carbon fiber prepreg, molding technology, applied in the field of polymer material preparation, can solve the problems of long molding process cycle and low molding efficiency, and achieve the effects of good quality of molded products, improved production efficiency, and reduced molding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A rapid compression molding process for carbon fiber prepreg, wherein the prepreg is unidirectional carbon fiber epoxy resin prepreg, the curing temperature is 150°C, and it can be maintained at 150°C for 20s without gelling or curing, and the curing time is 1min. The glass transition temperature is 140-150°C, and a flat self-cleaning non-stick mold is used. The self-cleaning non-stick mold substrate is prepared from metal materials, and its cavity is coated with a layer of non-stick coating; no mold release agent is required, and there is no residue when the product is demoulded, and no additional mold cleaning process is required. The non-stick coating is polytetrafluoroethylene; in the curing temperature range from room temperature to 200°C, under the curing pressure of 3-20MPa, within 100,000 mold times, no foaming, cracking, falling off, discoloration, etc. question.

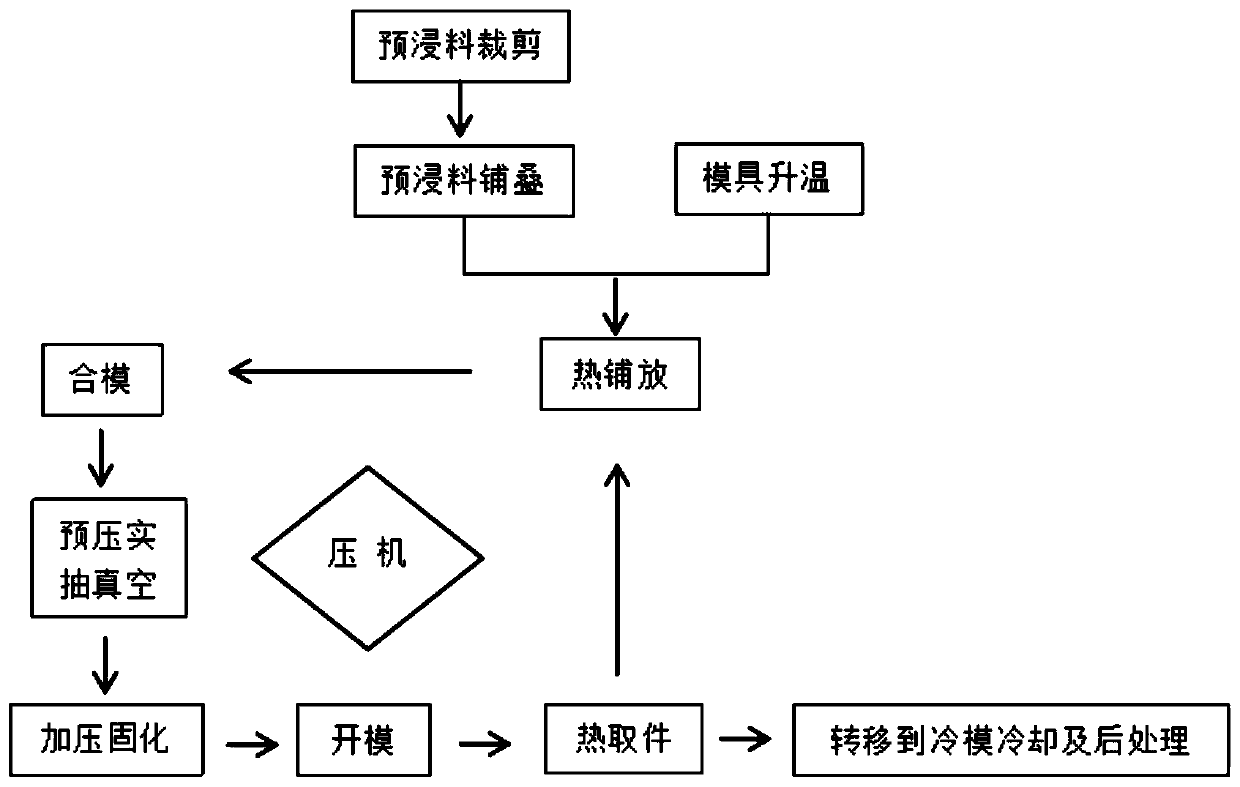

[0025] Please refer to figure 1 , the specific process steps are as follows: open the equipment...

Embodiment 2

[0032] A carbon fiber prepreg rapid molding process, wherein the prepreg is a unidirectional carbon fiber epoxy resin prepreg, the curing temperature is 90°C, and it can be kept at 90°C for 30s without gelling or curing, and the curing time is 1min. The glass transition temperature is 80-90°C, and a flat self-cleaning non-stick mold is used. The self-cleaning non-stick mold substrate is prepared from metal materials, and its cavity is coated with a layer of non-stick coating; no mold release agent is required, and there is no residue when the product is demoulded, and no additional mold cleaning process is required. The non-stick coating is made of silica gel; within a curing temperature range of room temperature to 200°C, under a curing pressure of 3-20 MPa, within 100,000 mold times, problems such as foaming, cracking, falling off, and discoloration do not occur.

[0033] Please refer to figure 1 , the specific process steps are as follows: open the equipment and quickly he...

Embodiment 3

[0036] A carbon fiber prepreg rapid molding process, wherein the prepreg is a plain carbon fiber epoxy resin prepreg, the curing temperature is 120°C, it can be kept at 120°C for 30s without gelling and curing, and the curing time is 1min. After curing, the glass The melting temperature is 110-120°C, and a flat self-cleaning non-stick mold is used. The self-cleaning non-stick mold substrate is prepared from metal materials, and its cavity is coated with a layer of non-stick coating; no mold release agent is required, and there is no residue when the product is demoulded, and no additional mold cleaning process is required. The non-stick coating is a mixture of polytetrafluoroethylene and silica gel materials; within the curing temperature range of room temperature to 200 ° C, under the curing pressure of 3-20 MPa, within 100,000 mold times, no foaming, Cracking, peeling, discoloration and other problems.

[0037] Please refer to figure 1, the specific process steps are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com