Apparatus and method for controlling workpiece temperature

a technology for workpieces and thermostats, applied in lighting and heating apparatus, machine operation modes, final product manufacture, etc., can solve the problems of small cooling/heating rate on workpieces, difficult if not impossible design of appropriate seals and mechanisms, and reduced material quality, so as to reduce heating and cooling times, precise final workpiece temperature, and greater workpiece temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

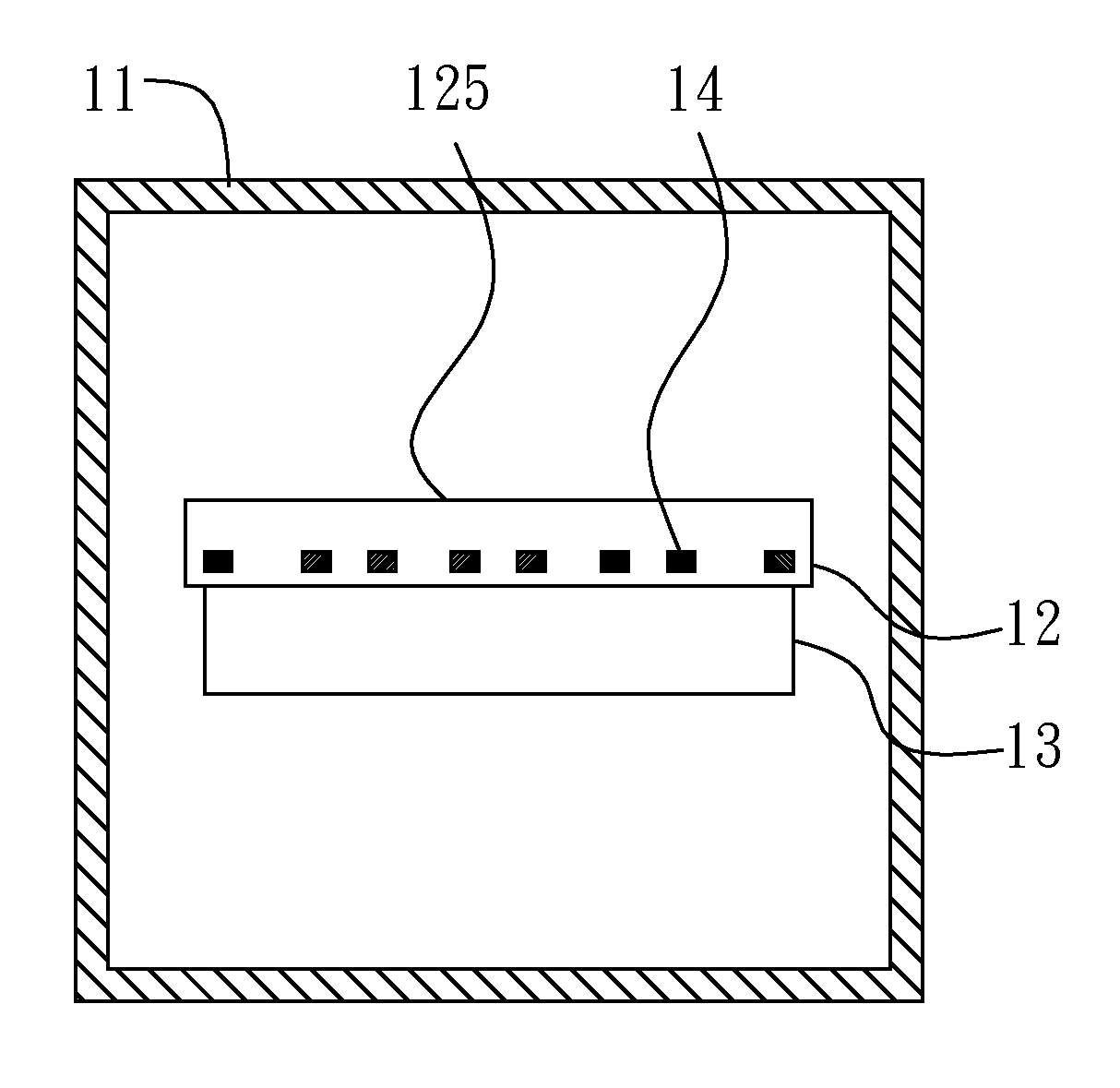

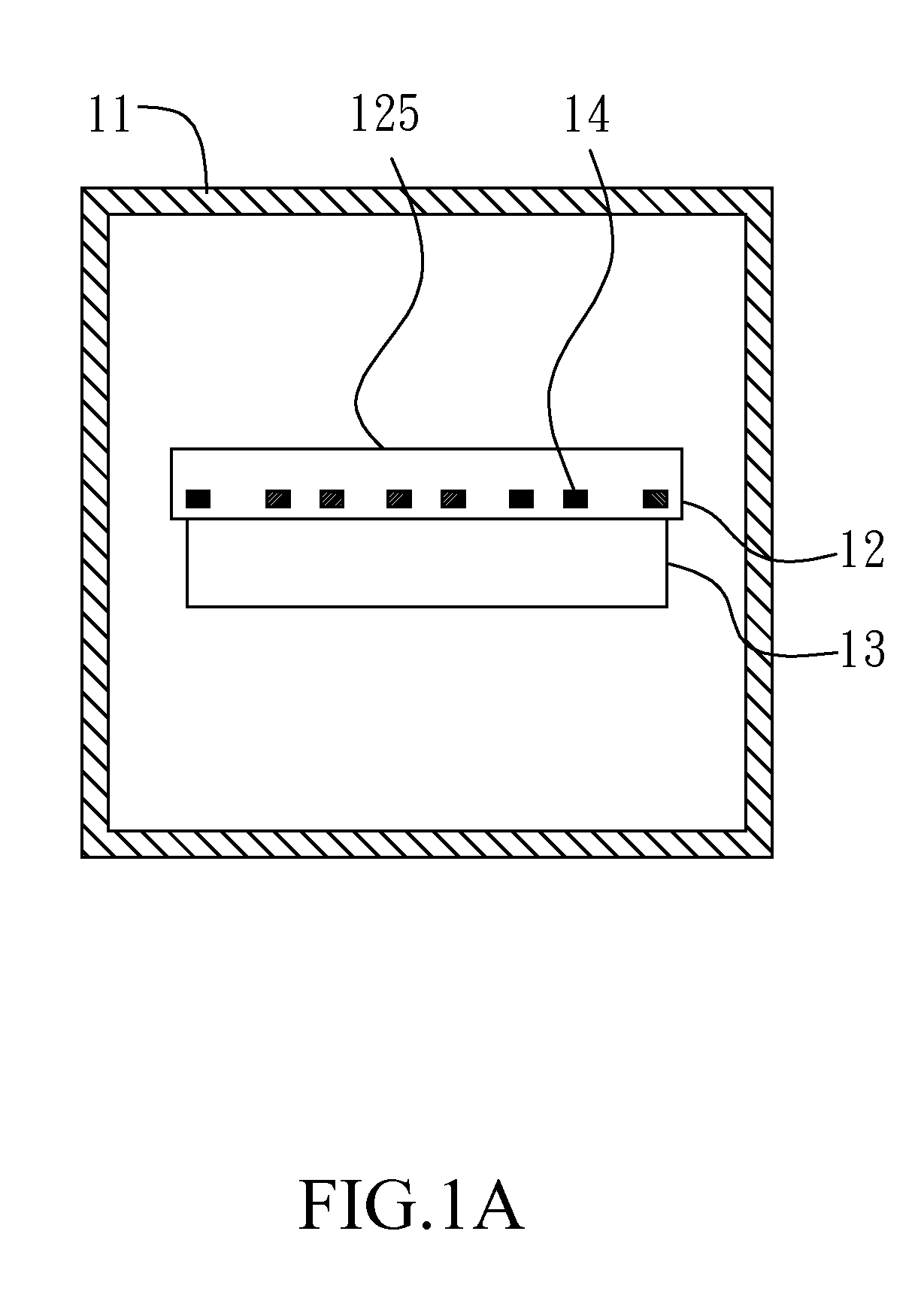

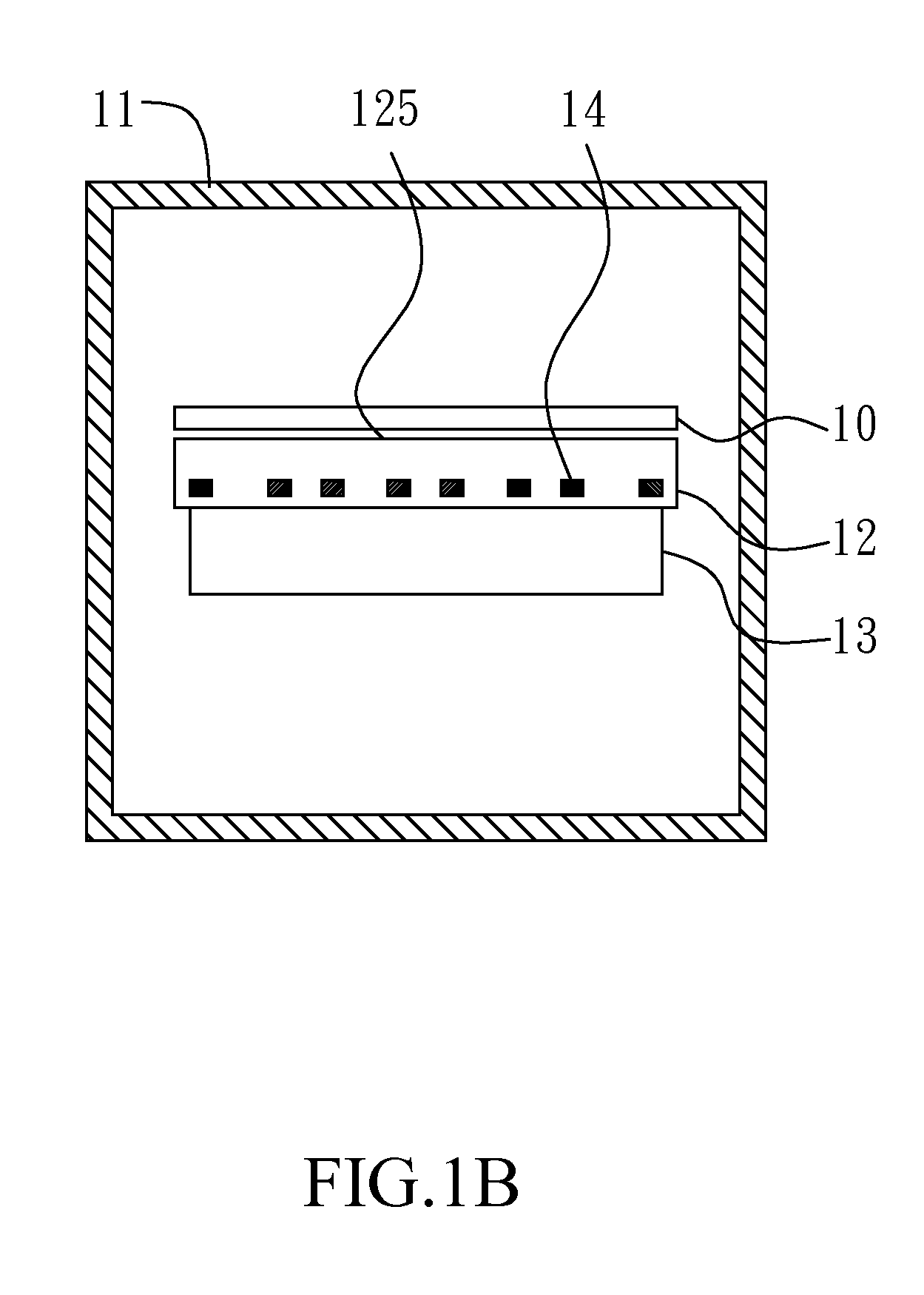

[0026]FIG. 1A shows a cross-sectional sketch of an atmospheric controlled chamber capable of controlling workpiece temperature according to one embodiment of the present invention. The experimental atmospheric controlled chamber includes a chamber wall 11, a support assembly 12, a heat-transfer assembly 13, and at least one thermopile device 14. FIG. 1B shows the condition that a workpiece 10 is held inside the atmospheric controlled chamber present on FIG. 1A.

[0027]The chamber wait 11 surrounds a space, and has one or more openings (not shown in the figure for brevity) disposed on different portions of the chamber wall 11, so that the workpiece 10 may be transferred into the space and / or transferred away from the space. The support assembly 12 is located in the space and is capable of holding the workpiece 10 over a specific (e.g., special, or predetermined) surface 125 of the support assembly 12. The workpiece 10 to be processed in, stored in and / or transferred through the atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com