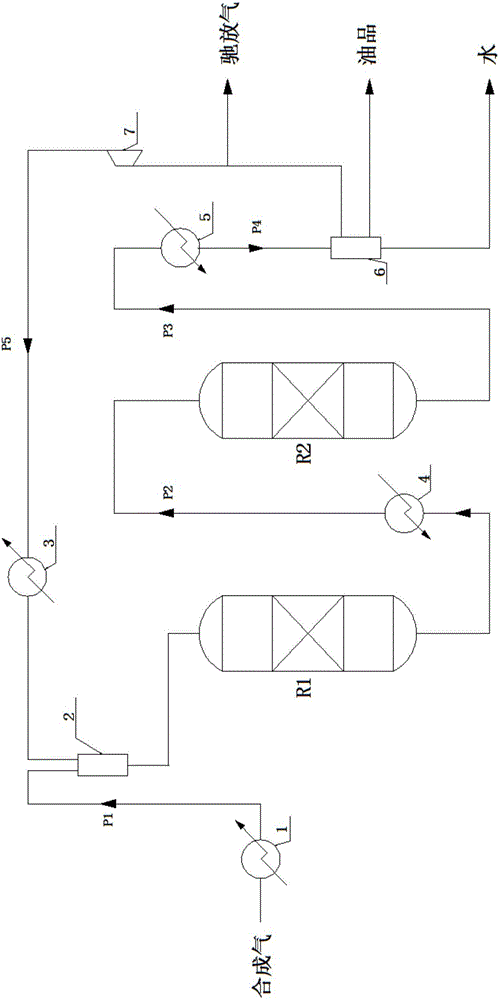

Combination process for producing aromatic hydrocarbon from synthetic gas

A combined process and synthesis gas technology, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, the preparation of hydroxyl compounds, and the preparation of organic compounds, etc., can solve the problems of declining product market competitiveness, increasing process complexity, and increasing product costs. , to achieve the effect of reducing cooling separation and reheating process, reducing energy consumption and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

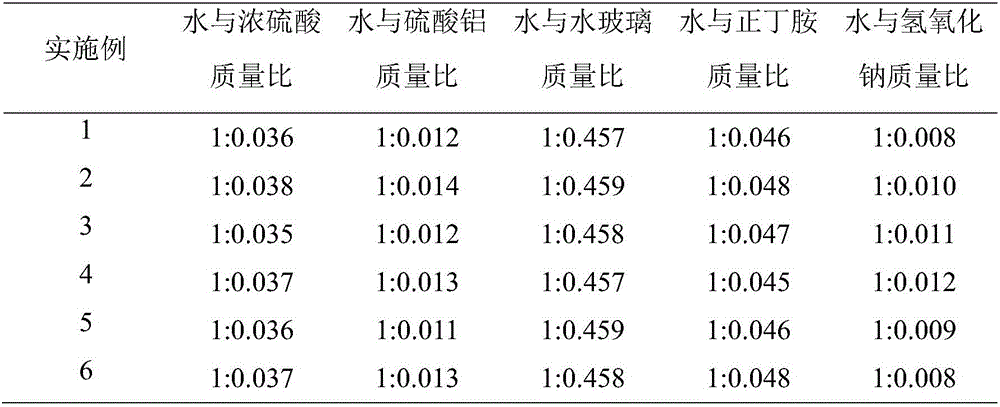

[0023] The preparation of the aromatization catalyst in the fixed bed reactor R2 is performed first. Concentrated sulfuric acid and aluminum sulfate are used to prepare aqueous solution A, wherein the mass ratio of water to concentrated sulfuric acid and aluminum sulfate is 1:0.036:0.012. Water glass, n-butylamine, and sodium hydroxide are used to prepare aqueous solution B, wherein the mass ratio of water to water glass, n-butylamine, and sodium hydroxide is 1:0.457:0.046:0.008. Under stirring conditions, an equal volume of solution A was added dropwise to solution B, and stirring was continued at room temperature for 24 h. Under airtight conditions, the temperature was raised to 110°C, and stirring was continued for 3 hours, then the temperature was raised to 180°C, and stirring was continued for 46 hours. The reaction kettle was taken out, and the product was filtered, washed until neutral, and dried to obtain ZSM-5 sodium molecular sieve. Subsequently, the molecular siev...

Embodiment 2-6

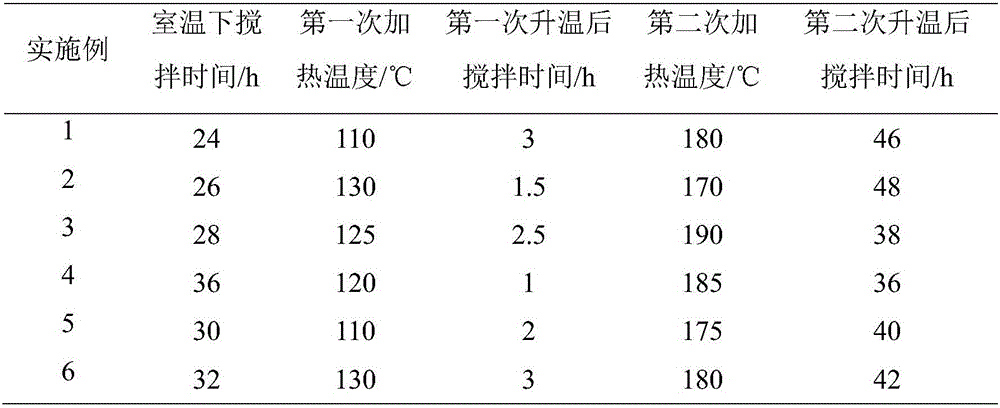

[0026] The catalyst preparation method used in reactor R2 is the same as that in Example 1, and the specific preparation conditions are shown in Attached Table 1. Technological process is identical with embodiment 1 in the reaction process, and concrete technological condition sees attached table 2. The mass content of each component of the reaction product is shown in Attached Table 3.

[0027] Schedule 1

[0028]

[0029] Continued Table 1

[0030]

[0031] Continued Table 1

[0032]

[0033] Continued Table 1

[0034]

[0035] Schedule 2

[0036]

[0037] Continued Table 2

[0038]

[0039] Schedule 3

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com