Automatic film coating device

一种镀膜装置、驱动装置的技术,应用在喷射装置、溅射镀覆、真空蒸发镀覆等方向,能够解决增加镀膜周期、双面镀膜层膜特征不一致、无法保持真空室参数一致性等问题,达到减少镀膜的时间、减少加热和抽真空次数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

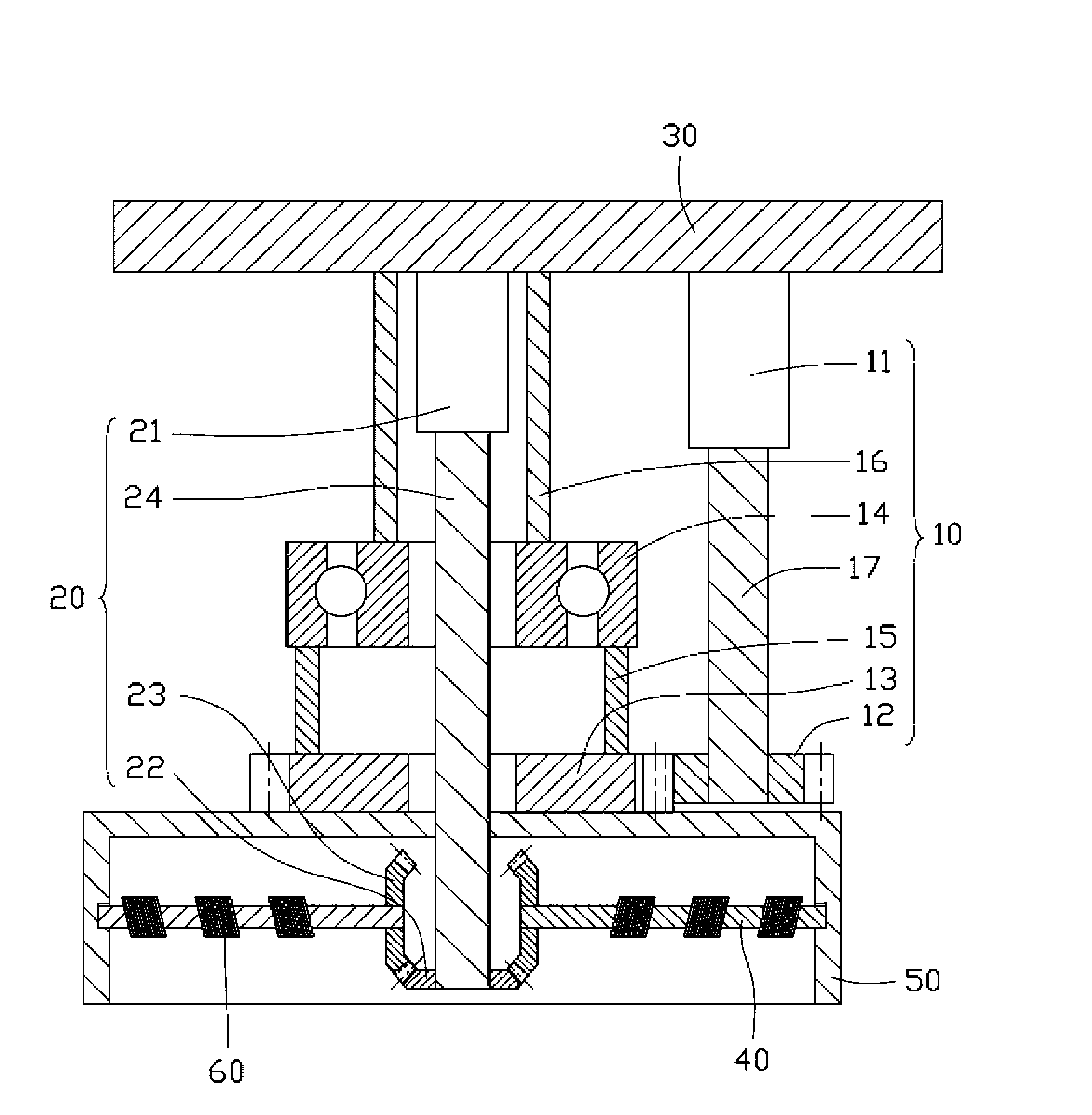

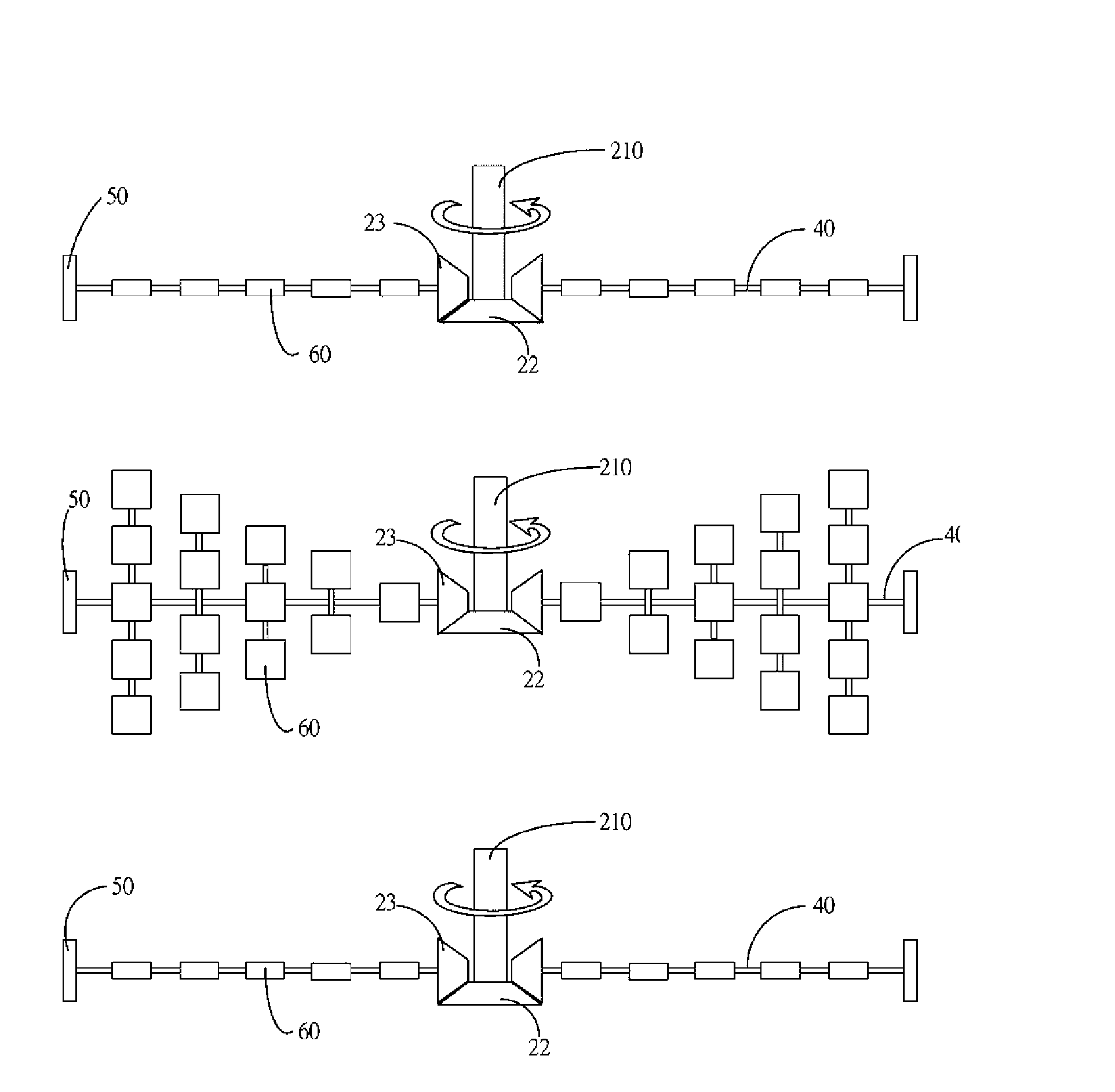

[0010] see figure 1 and figure 2 , the automatic coating device 100 provided by the embodiment of the present invention includes a rotating device 10 , a turning device 20 , a machine body 30 , a substrate 40 and a supporting frame 50 .

[0011] The rotating device 10 includes: a first driving device 11 , a rotating driving gear 12 , a rotating driven gear 13 , a bearing 14 , a connecting rod 15 , a fixed rod 16 and a first transmission shaft 17 . The first driving device 11 is fixed on the top of the body 30; the rotating drive gear 12 is connected to the other end of the first transmission shaft 17 fixed on the first driving device 11, and the first transmission shaft 17 drives the rotating driving gear 12 rotates; the rotating driven gear 13 meshes with the rotating driving gear 12, and the rotating driving gear 12 drives the rotating driven gear 13 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com