Heat exchange structure of power battery box

A technology of power battery and heat exchange structure, applied in the direction of secondary battery, battery temperature control, circuit, etc., can solve the problems of increasing the load of the air conditioning system, not considering the requirements of heating, and being unable to achieve, reducing flow resistance and heating Good effect, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

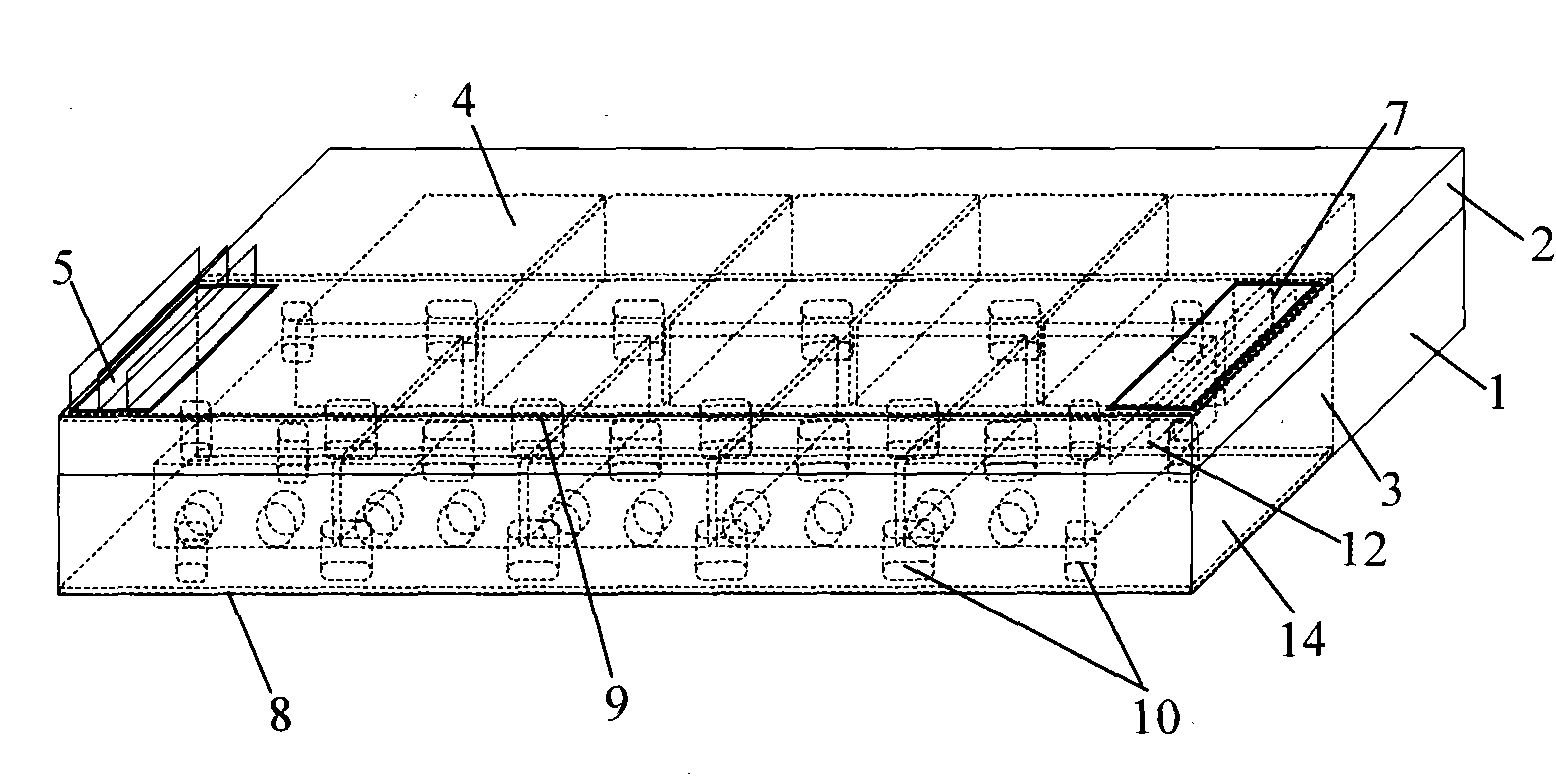

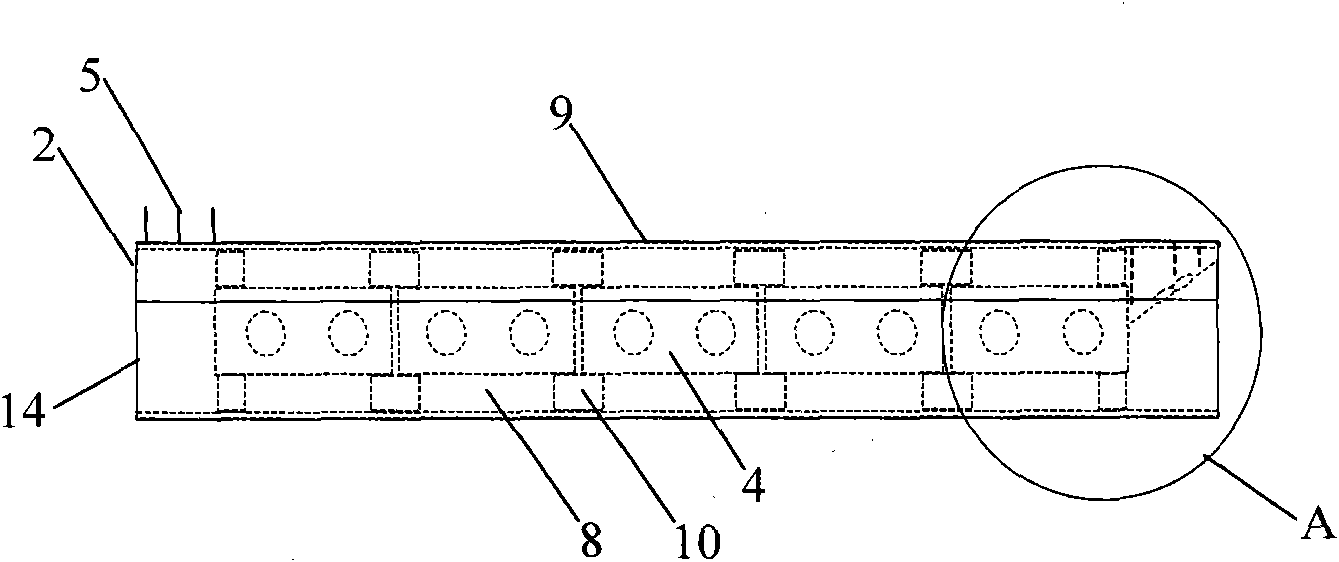

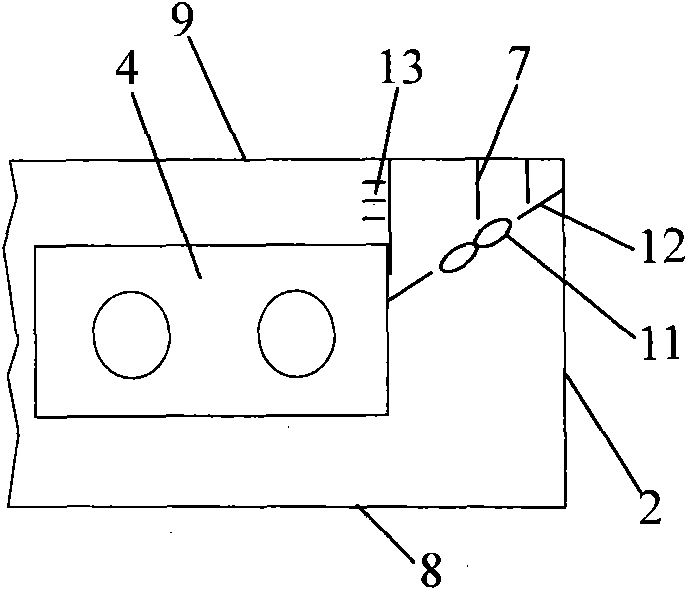

[0055] See Figure 1a-1d As shown, a specific embodiment of the power battery box heat exchange structure of the present invention includes a battery box 1, at least one battery pack 4, a first damper 5, a second damper 7, at least one air driving element 11, and at least one heating element 13 , a control unit (not shown) and a temperature monitoring element (not shown), the battery pack 4 includes several battery modules (not shown one by one) arranged side by side, as Figure 1a As shown, the battery pack 4 is composed of 2 rows of battery modules, each row includes 5 battery modules arranged side by side, the temperature monitoring element is arranged in each battery module of the battery pack 4, and the battery pack 4 In the middle of the battery box 1, the upper surface (not marked), the lower surface (not marked) and the side (not mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com