Method for recycling water-containing sump oil by utilizing delayed coking device

A technology for delayed coking and water slop oil, applied in cracking, petroleum industry, non-catalytic thermal cracking, etc., can solve the problems of electricity consumption or cooling water, waste of high temperature heat, increase energy consumption of equipment, etc., to achieve energy saving and emission reduction, The effect of increasing processing capacity, reducing cooling load and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

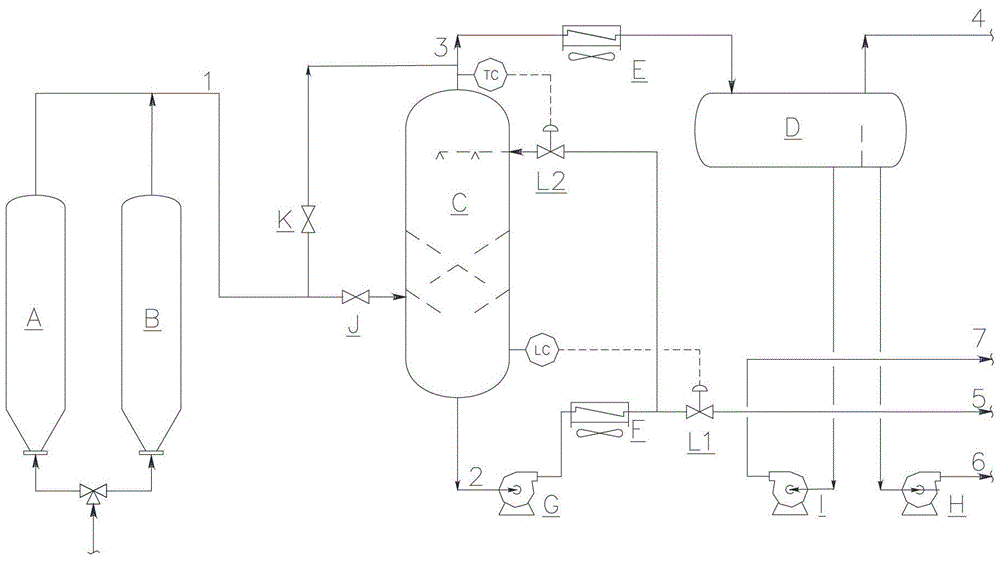

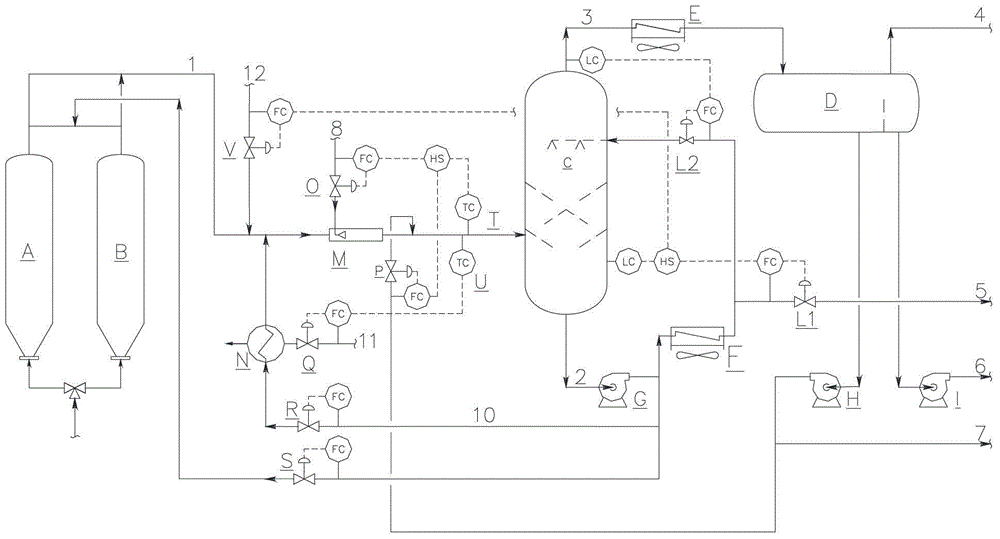

[0035] Such as figure 2 As shown, a schematic flow chart of a method for refining water-containing waste oil by using a delayed coking unit.

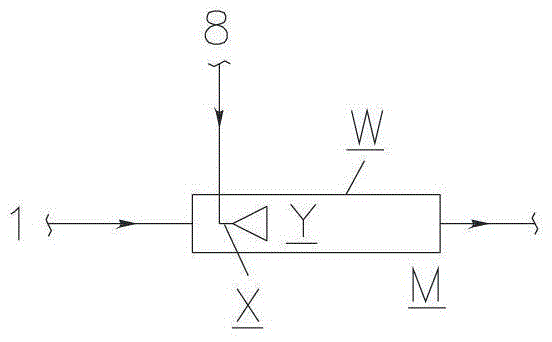

[0036] When the decoking coke tower A or B reaches the steam blowing and water supply steps, the oil gas 1 is vented into the vent tower C. When the vapor phase thermometer T of the stream behind the water-containing waste oil atomizer detects that the oil gas temperature is greater than 200°C, the water-containing waste oil refining flow control valve O is opened, and the water-containing waste oil 8 enters the water-containing waste oil atomizer M to mix with the vented oil and gas 1. The gas-phase temperature of the gas-liquid mixed-phase flow formed by mixing is controlled by the flow control valve O of the water-containing sewage oil 8. When the temperature of the vented oil gas 1 increases, the flow rate of the water-containing sewage oil 8 is increased. If the water-containing sewage oil 8 cannot make the atomizer M When the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com