Three-shaft high-low temperature speed turntable

A speed turntable and low temperature technology, applied in the direction of rotating gyroscopes, measuring devices, instruments, etc., can solve the problems of product frost and condensation, low safety, damaged products, etc., to reduce the deformation of the frame and shafting, and improve the measurement Accuracy, eliminate the effect of water condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

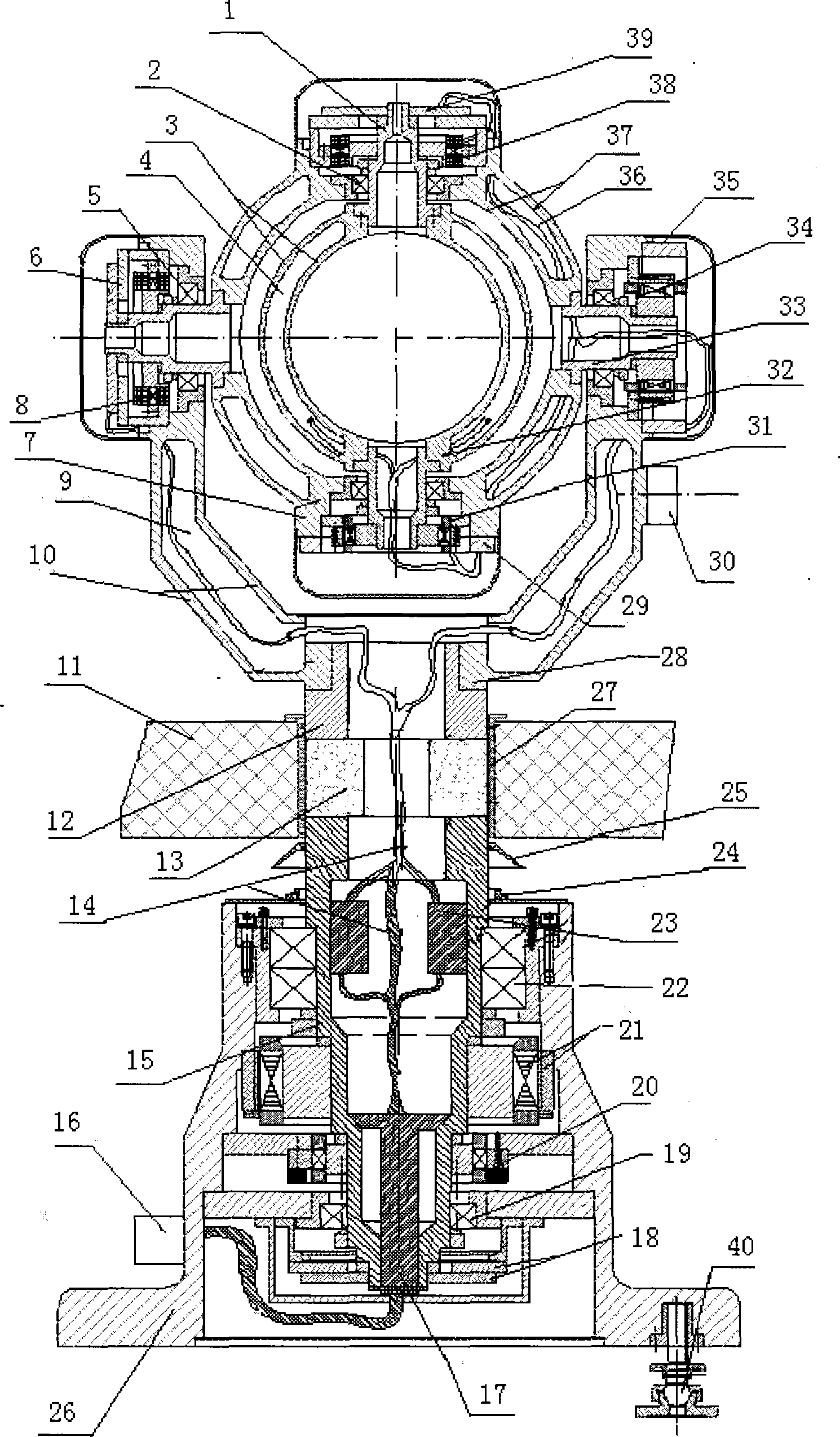

[0025] Such as figure 1 Described, a kind of three-axis high-low temperature rate turntable, comprises turntable base 26, is positioned at the thermostat above turntable base 26 (the figure only shows thermostat bottom plate 11) and is installed in the outer frame 28 in thermostat, Middle frame 7, inner frame 32; the thermostat is a square box heated by fluorine refrigeration resistance wire;

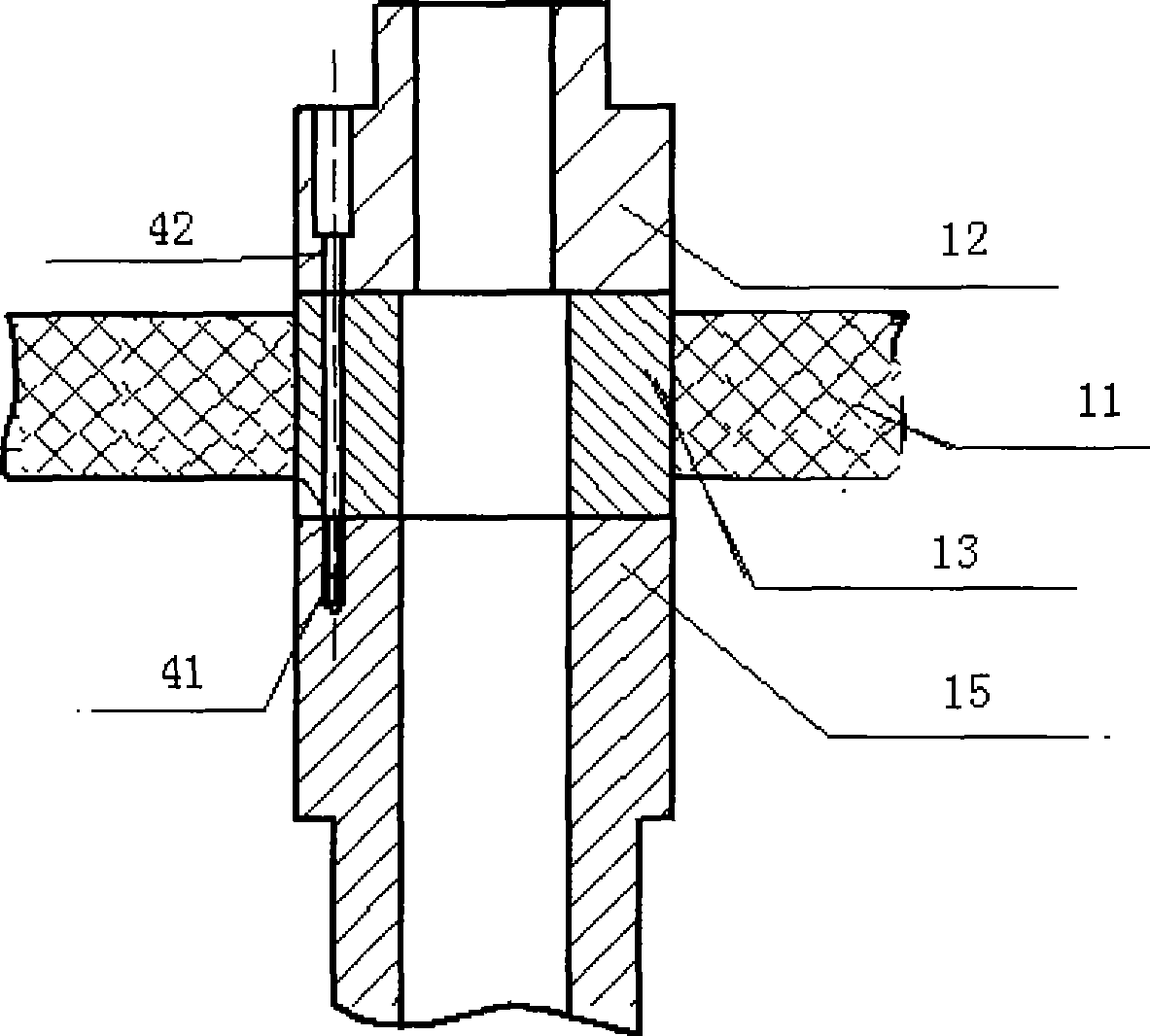

[0026] The center of the turntable base 26 is equipped with a hollow and stepped outer frame main shaft 15, and the outer frame main shaft 15 is sequentially set with an outer frame angle measuring code disc 18, an outer frame auxiliary bearing 19, an outer frame speed measuring machine 20, and an outer frame from bottom to top. Frame driving motor 21, outer frame bearing 22;

[0027] The upper part of the outer frame main shaft 15 protrudes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com