Electric equipment protective device

A technology of electrical components and protection devices, applied in variable capacity pump components, pump components, liquid variable capacity machinery, etc., can solve problems such as bad, small gaps, leakage insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

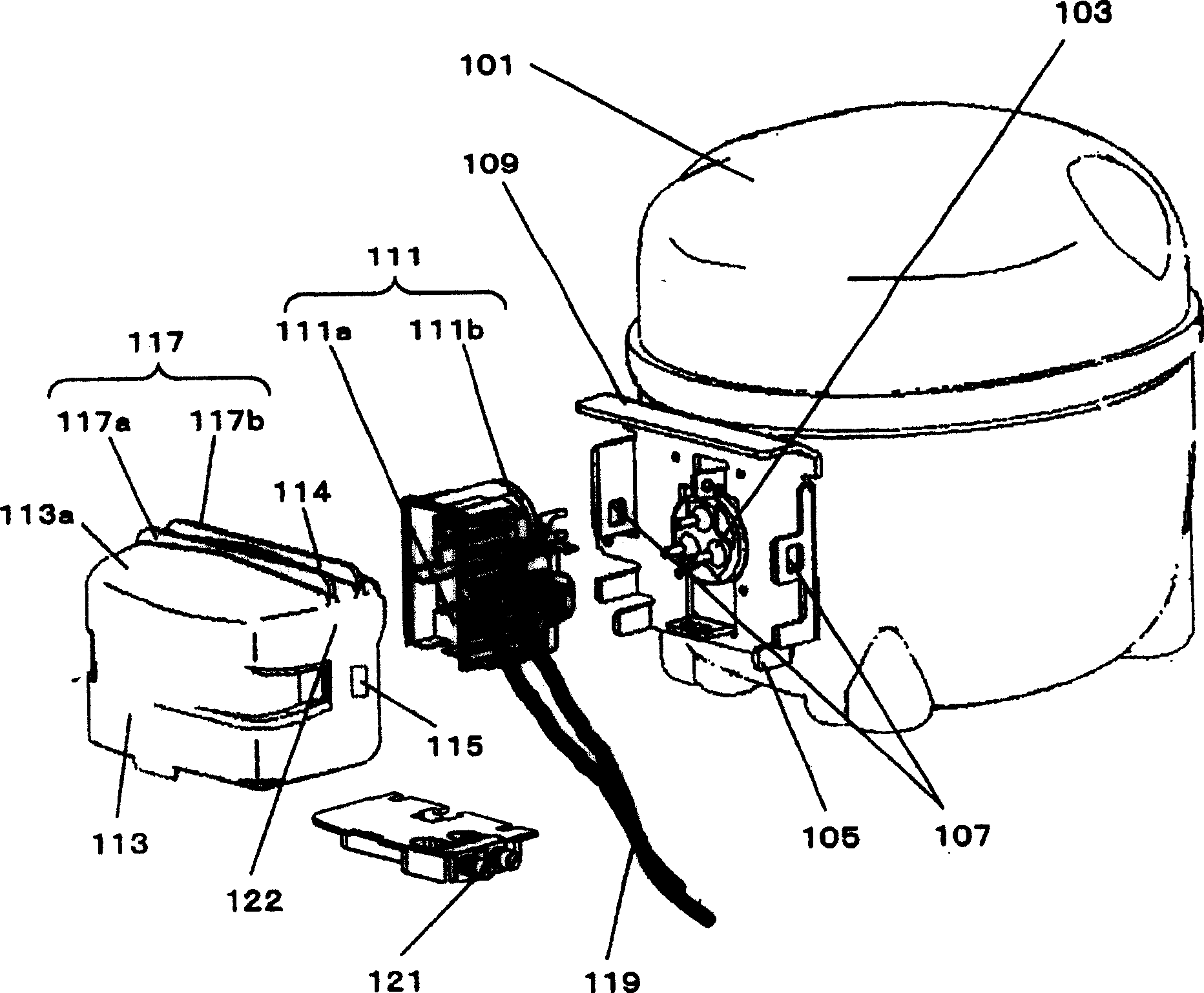

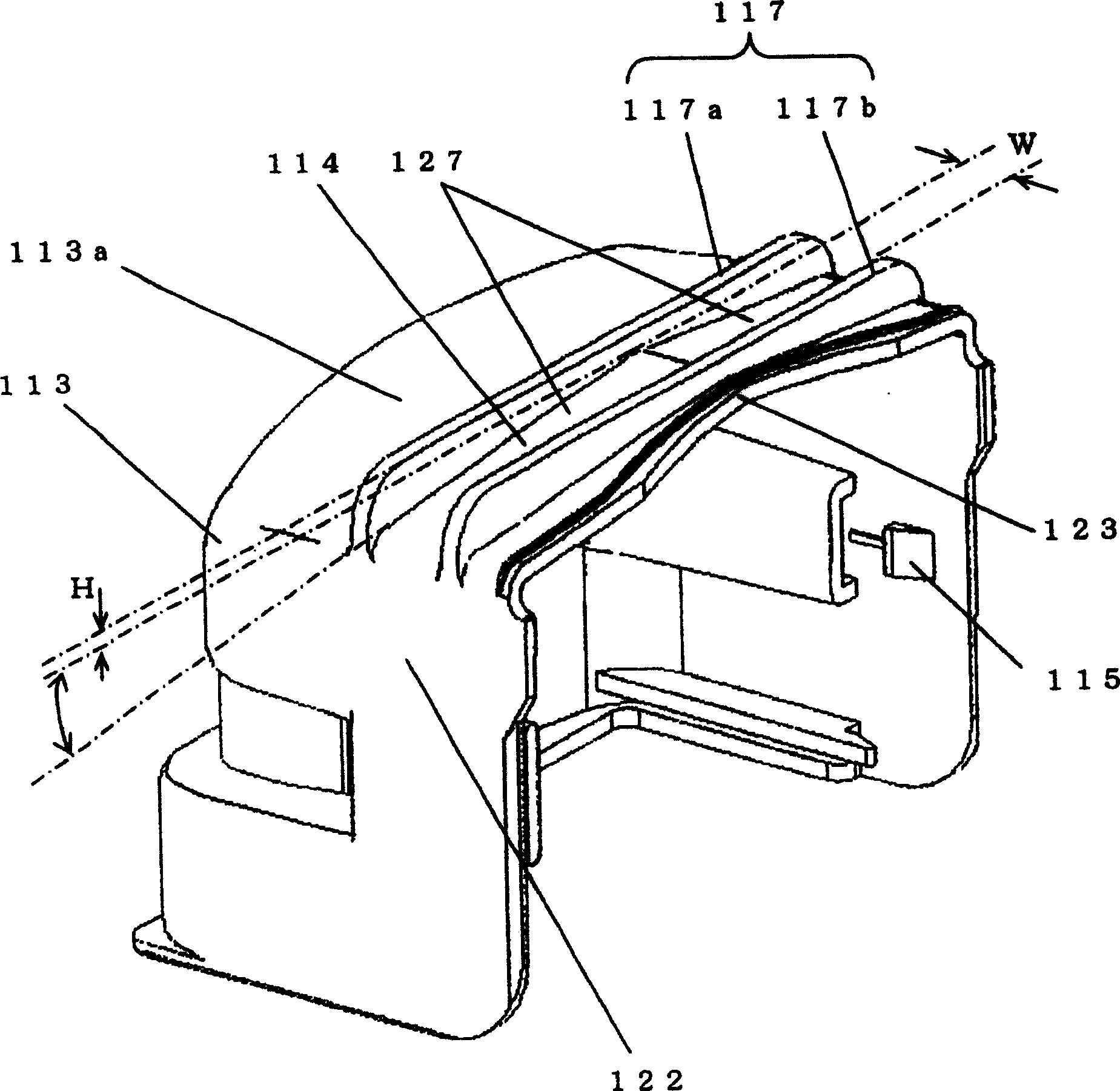

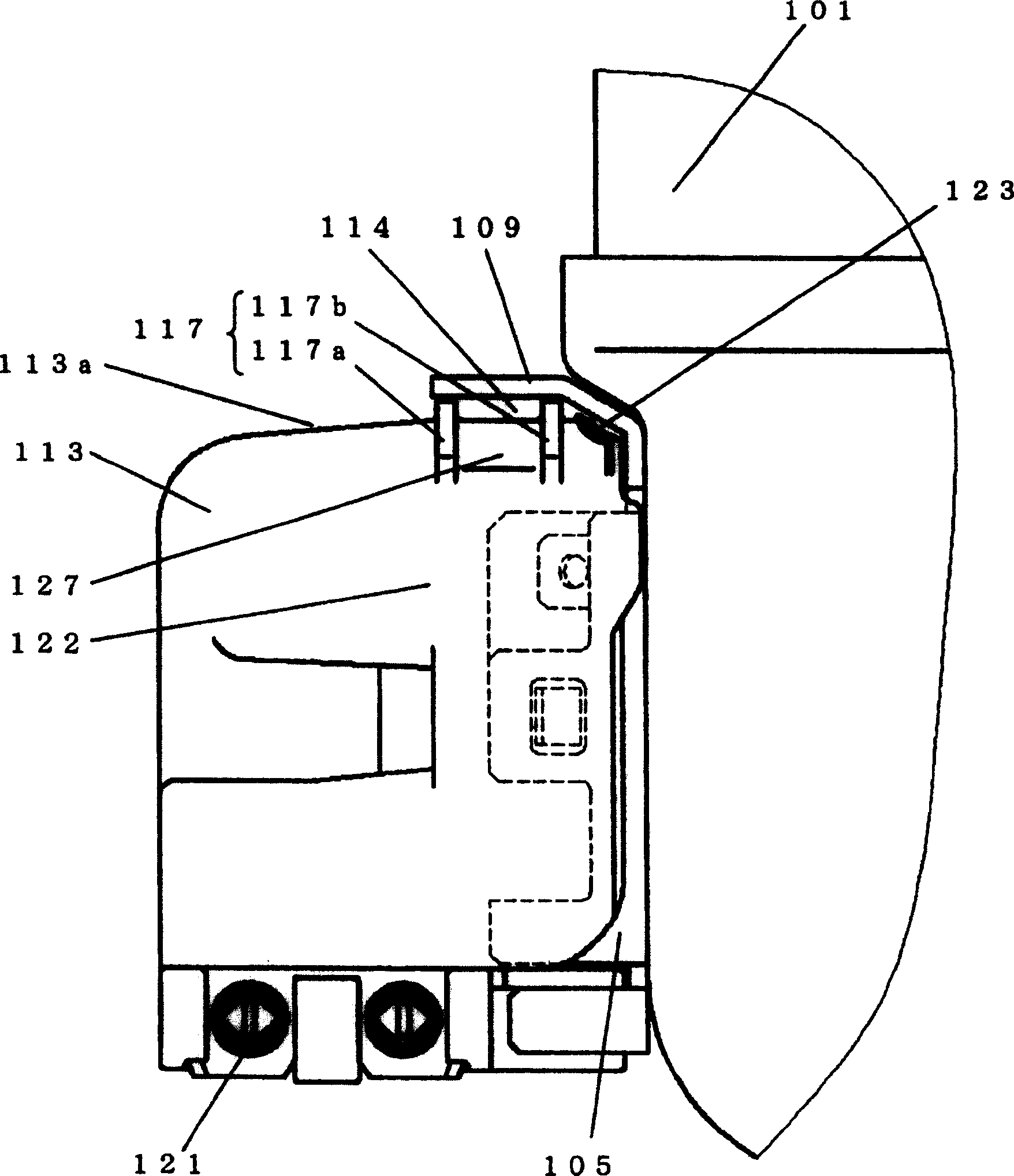

[0042] figure 1 It is an exploded oblique view of the electrical component protection device in Embodiment 1 of the present invention, figure 2 is an oblique view of the electrical parts cover, image 3 It is an enlarged schematic diagram of the electrical component protection device in the installed state, Figure 4 It is the experimental result graph of the second experiment.

[0043] A motor mechanism (not shown in the figure) and a compression mechanism (not shown in the figure) driven by the motor mechanism are installed inside the compressor casing 101 .

[0044] Such as Figure 1 to Figure 3 As shown in , the electrical components 111 include a starting relay 111a and a motor protector 111b. The purpose of using the starting relay 111a is to control the energization of the motor mechanism, so as to prevent the motor mechanism from being burned due to excessive current flowing.

[0045] Specifically, the motor mechanism is provided with a main winding (not shown i...

Embodiment 2

[0081] Figure 5 It is an exploded oblique view of the electrical component protection device according to Embodiment 2 of the present invention, Figure 6 is an oblique view of the electrical parts cover, Figure 7 It is an enlarged schematic diagram of the electrical component protection device in an installed state, Figure 8 It is a schematic diagram of the experimental results of the second experiment.

[0082] exist Figure 5 to Figure 7 Among them, an electric motor mechanism (not shown in the figure) and a compression mechanism (not shown in the figure) driven by the electric motor mechanism are installed inside the compressor casing 201.

[0083] The electrical components 211 include a starting relay 211a and a motor protector 211b. The purpose of using the starting relay 211a is to control the energization of the motor mechanism, so as to prevent the motor mechanism from being burned due to excessive current flowing.

[0084] Specifically, the motor mechanism is...

Embodiment 3

[0119] Figure 9 It is an exploded oblique view of the electrical component protection device in Embodiment 3 of the present invention, Figure 10 is an oblique view of the electrical parts cover, Figure 11 It is an enlarged schematic diagram of the electrical component protection device in the installed state, Figure 12 for along Figure 11 The cross-sectional view of line A—A in Figure 13 It is a schematic diagram of the experimental results of the second experiment.

[0120] exist Figure 9 to Figure 12 In the compressor casing 301, an electric mechanism (not shown in the figure) and a compression mechanism (not shown in the figure) driven by the electric mechanism are arranged inside the compressor housing 301.

[0121] The electrical components 311 include a starting relay 311a and a motor protector 311b. The purpose of using the starting relay 311a is to control the energization of the motor mechanism, so as to prevent the motor mechanism from being burned due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com