Convenient and fast installation method for bridge crane slide wire supports

A bridge crane and installation method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of frequent handling and suspension of hanging baskets, poor construction stability of hanging baskets, and easy formation of safety hazards, etc., to achieve lifting installation and welding Work efficiency, manpower saving, and the effect of improving installation work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

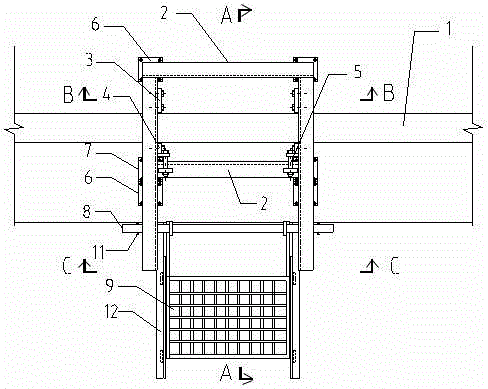

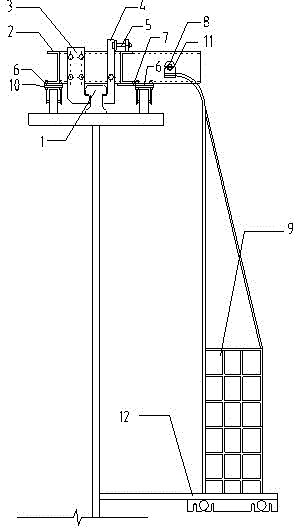

[0023] Such as Figure 1-Figure 4 Shown: a convenient installation method for the bridge crane sliding wire support, including the following steps:

[0024] Step 1: Adjust the bridge crane track 1, which is located in the middle of the top of the crane beam;

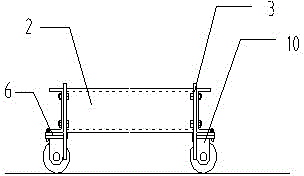

[0025] Step 2: Install the base car, which includes a car frame 2, wheels 10, spare wheel connecting plates 7 and wheel connecting plates 6, the car frame is built from at least four channel steels, and the wheels are arranged on the wheel through the wheel connecting plates. At the bottom of the car frame, the spare wheel connecting plate is set on one side of the wheel connecting plate; the base car is placed on the upper part of the track at the top of the crane beam, the car frame is connected to the track through the fixed limit plate 3 and the movable limit plate 4, and the fixed limit plate and the movable limiting plate are connected with the car frame through fastening bolts 5 and are respectively stuck in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com