Patents

Literature

83results about How to "Fast debugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Testing and verifying system appropriate for intelligent transformer substation and verifying method

ActiveCN102608450ADigital real-time simulation with high precisionHigh precisionCircuit interrupters testingSmart substationTransformer

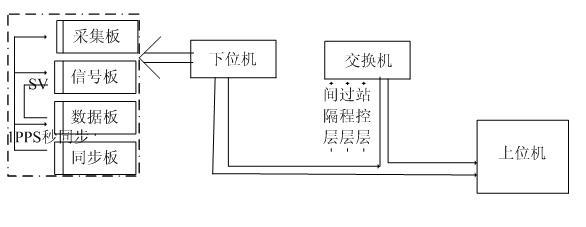

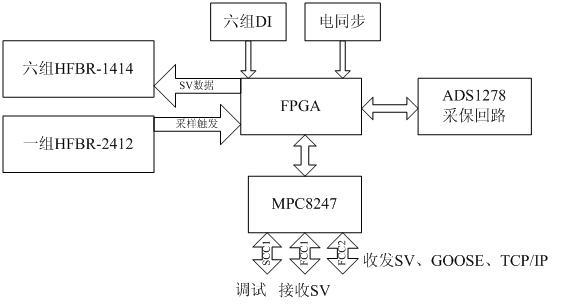

The invention discloses a testing and verifying system appropriate for an intelligent transformer substation and a verifying method. The system comprises an upper computer and an embedded system lower computer that comprises a collecting plate, a signal plate, a data plate and four sub-plates of a synchronization plate. The signal plate, the data plate and the synchronization plate are supplied with power by an external adapter DC5V. The synchronization plate provides synchronization pulse signals to other sub-plates. Ethernet of the upper computer is connected with the signal plate of the upper computer, the intelligent transformer substation, and a process layer, an interval layer and a station layer network of a digital transformer substation by an RJ45 twisted-pair through an industrial switchboard. The testing and verifying system appropriate for the intelligent transformer substation is convenient to detect and verify the electrical capacity of current intelligent transformer substation and digital transformer substation and improves the debugging speed of the intelligent transformer substation and digital transformer substation greatly so as to provide good technical assurance to construction of the intelligent transformer substation and digital transformer substation and lay a solid foundation for safe and stable operation of the intelligent transformer substation and digital transformer substation.

Owner:江苏凌创电气自动化股份有限公司

Debugging method for +/- 800 kV ultra-high voltage direct-current transmission project system

ActiveCN103296673AComprehensive scope of commissioningIncrease operating voltageDc network circuit arrangementsElectrical testingEmbedded systemTransmission line

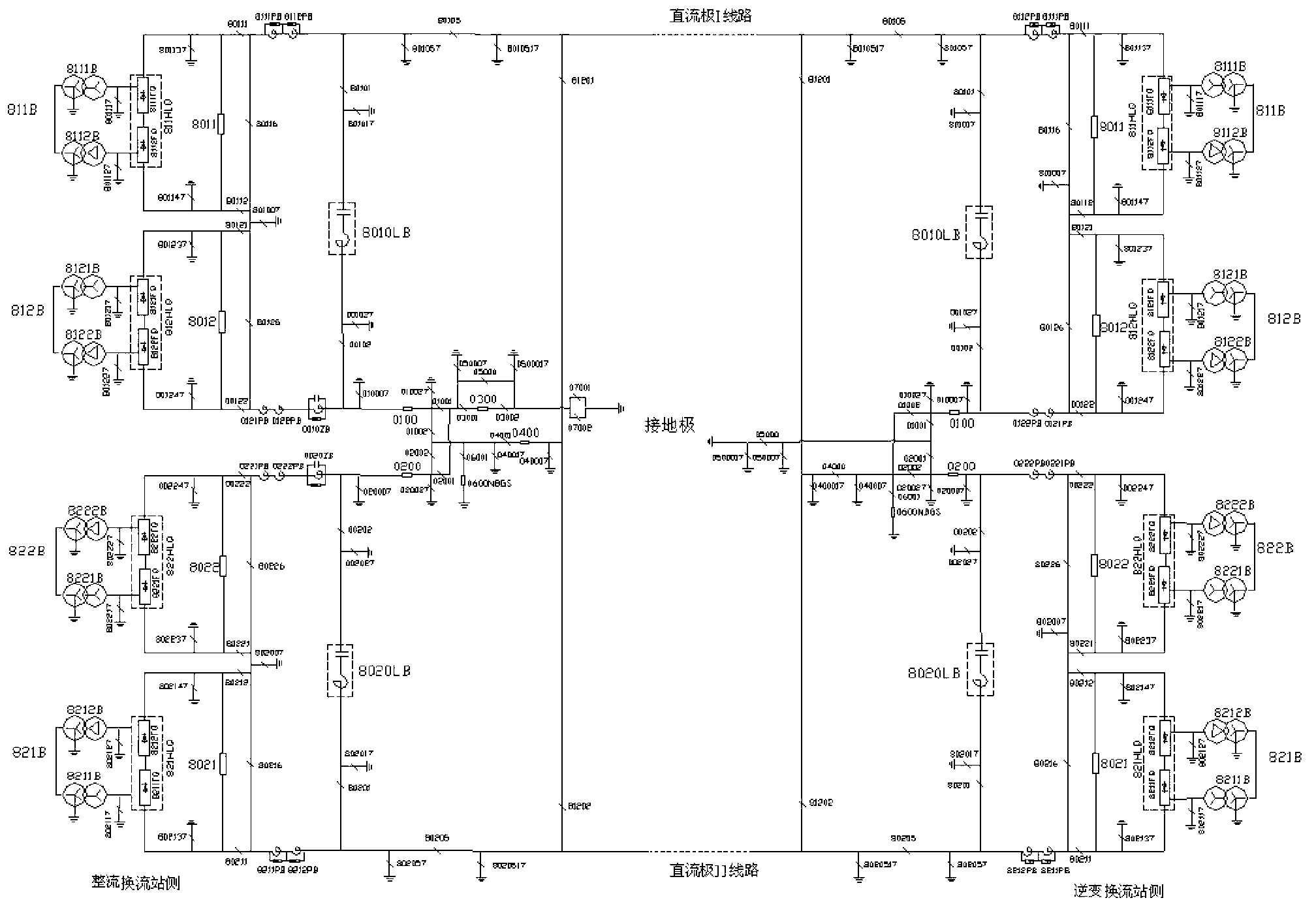

The invention relates to a debugging method for a + / - 800 kV ultra-high voltage direct-current transmission project system. The system comprises convertor stations at two ends and a direct-current transmission line. The debugging method for the + / - 800 kV ultra-high voltage direct-current transmission project system comprises the following steps that (I) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to calculation and analysis; (II) a debugging scheme for the + / - 800 kV ultra-high voltage direct-current transmission project system is formed; (III) a debugging plan for the + / - 800 kV ultra-high voltage direct-current transmission project system is made; (IV) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a field debugging test; (V) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a pilot run; (VI) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a debugging summary. According to the debugging method for the + / - 800 kV ultra-high voltage direct-current transmission project system, a single current converter and a monopolar and bipolar system debugging test are combined for the first time, therefore, the efficiency of a system debugging test is improved, the system debugging speed is increased, good conditions are created for finishing system debugging in advance, and experience and reference are provided for the debugging of a direct-current transmission project system in future.

Owner:STATE GRID CORP OF CHINA +1

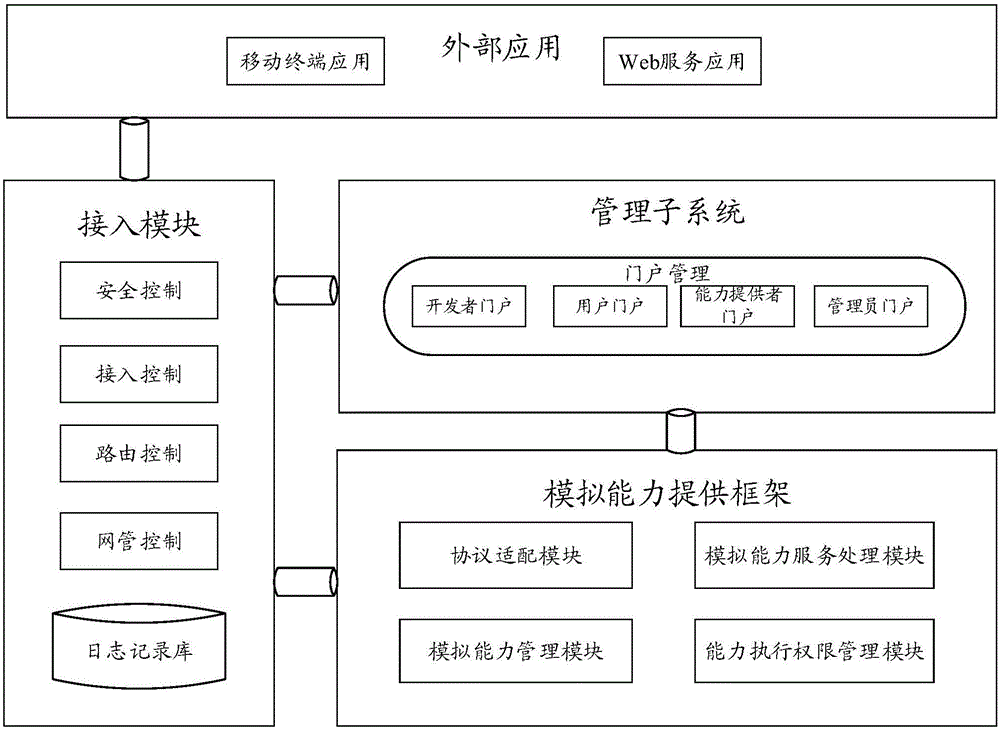

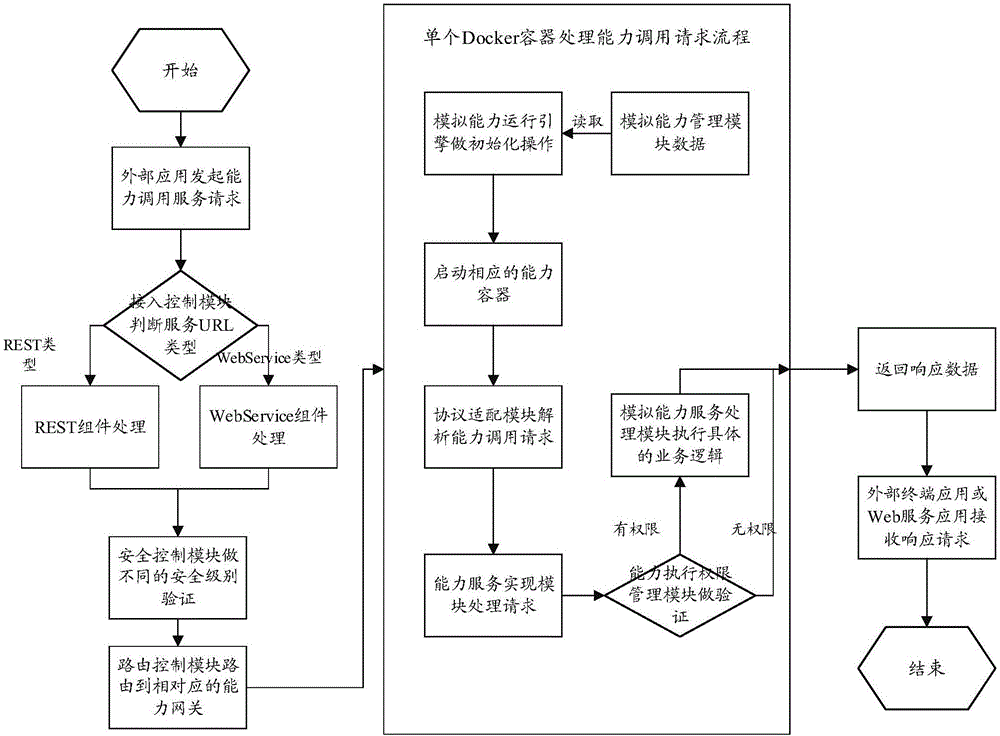

System and method for realizing analog whole network capacity open platform based on cloud computing system

InactiveCN106550033AEfficient managementReliable managementData switching networksExternal applicationOpen platform

The invention relates to a system and method for realizing an analog whole network capacity open platform based on a cloud computing system. The system comprises an open platform access module, an analog capability providing module and a capability open management module. The open platform access module is connected with the analog capability providing module, the capability open management module and an external application. The analog capability providing module is connected with the capability open management module. Through adoption of the system and the method of the structure, physical complexities of various networks are shielded; a plurality of capability open technologies are integrated together; various capabilities in a whole network are simulated; abundant convergence services are established and managed efficiently and reliably with relatively low average operation costs; the capability efficiency of employing the open platform by enterprise applications is effectively improved; and the system and the method have a wide application range.

Owner:PRIMETON INFORMATION TECH

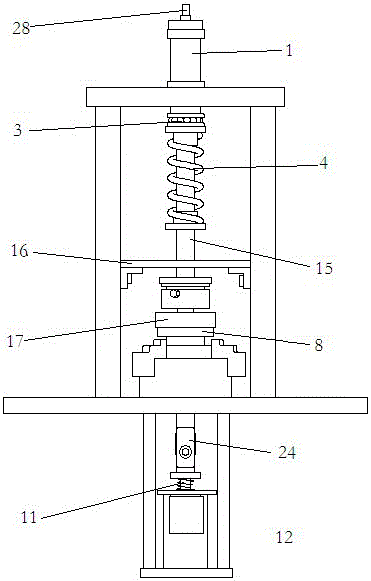

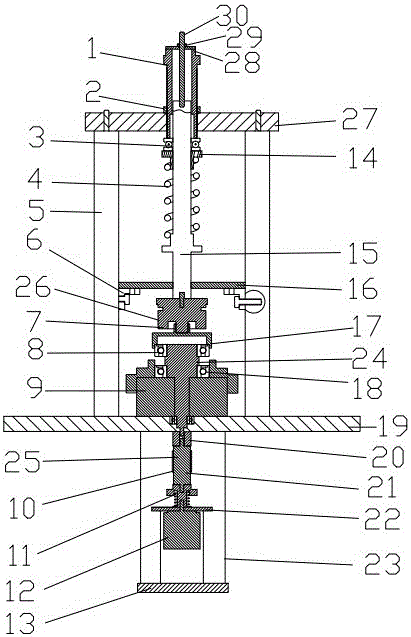

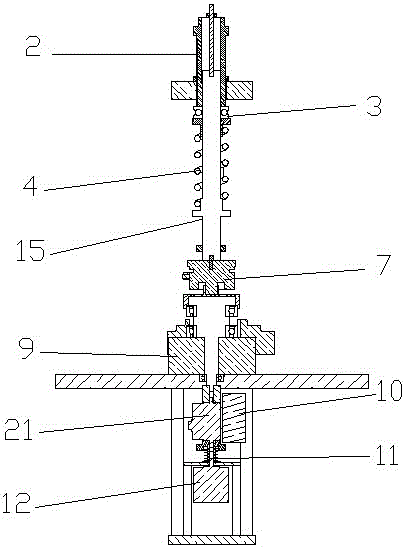

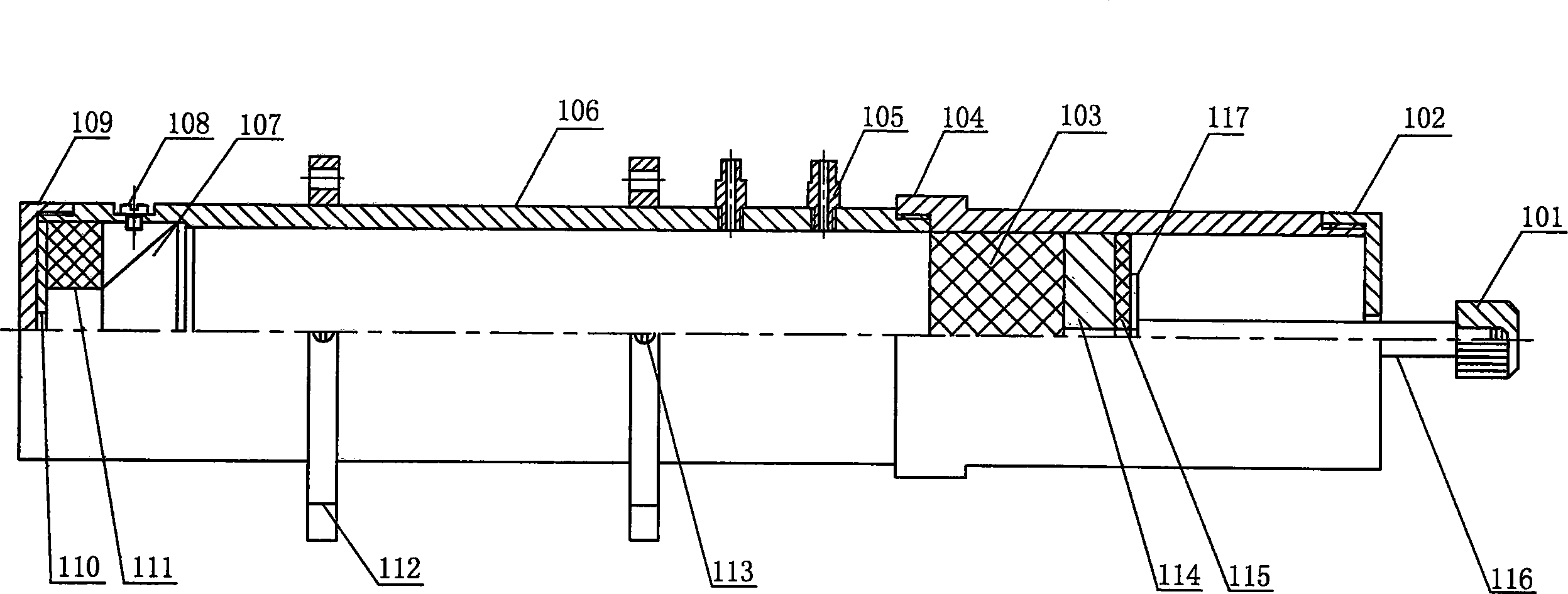

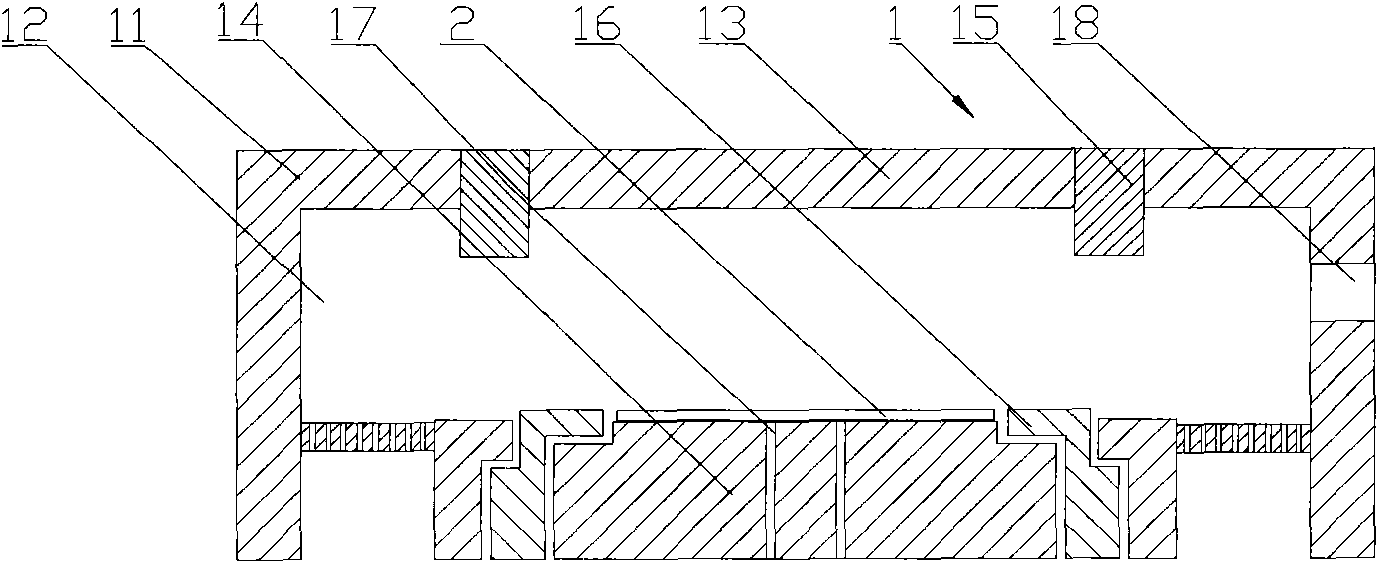

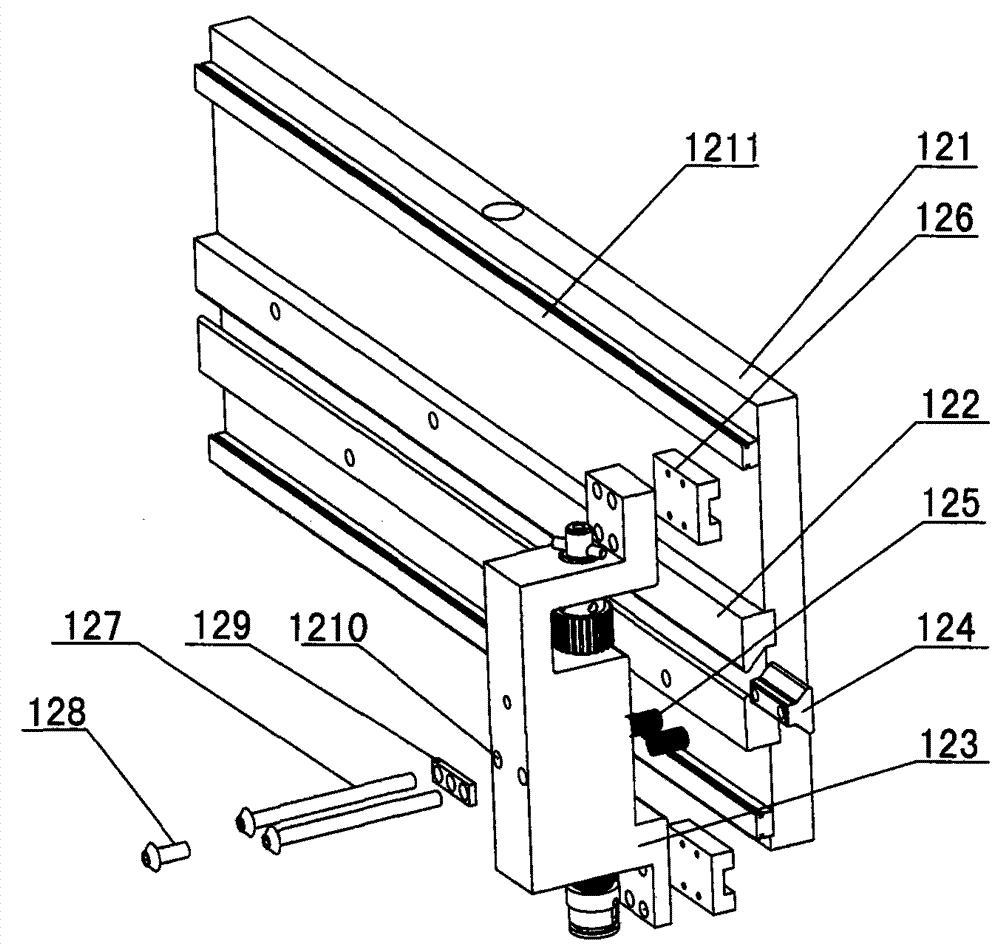

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

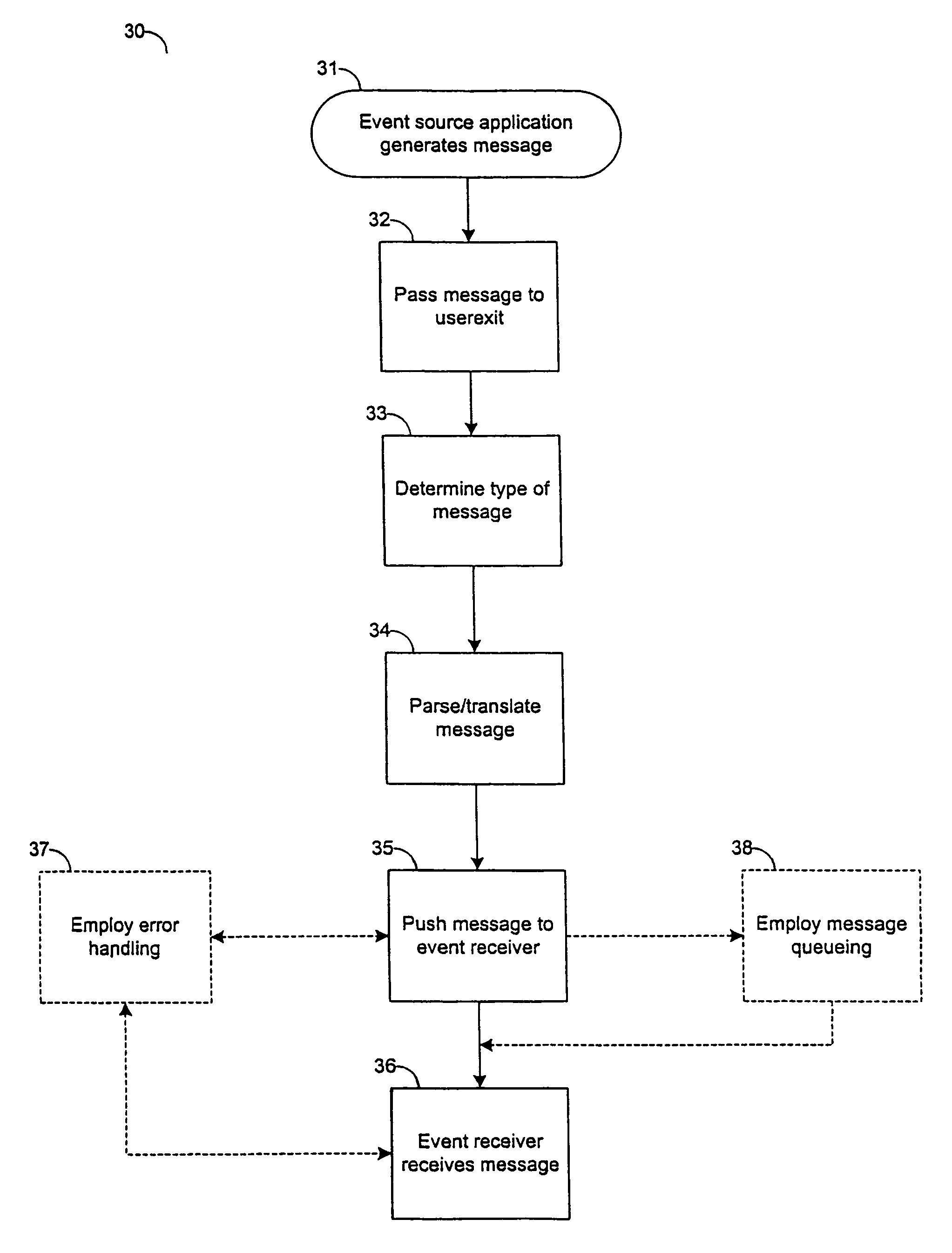

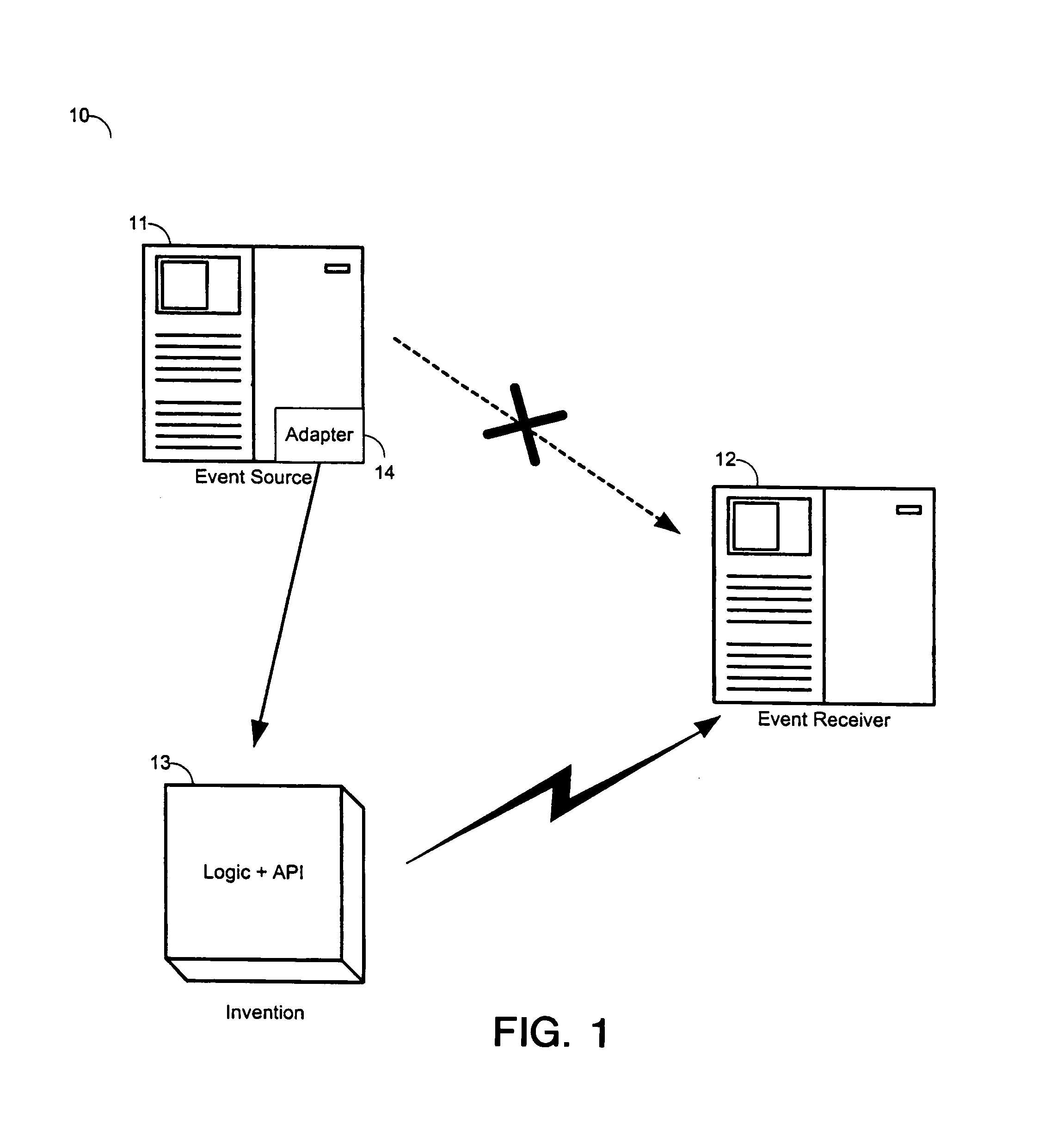

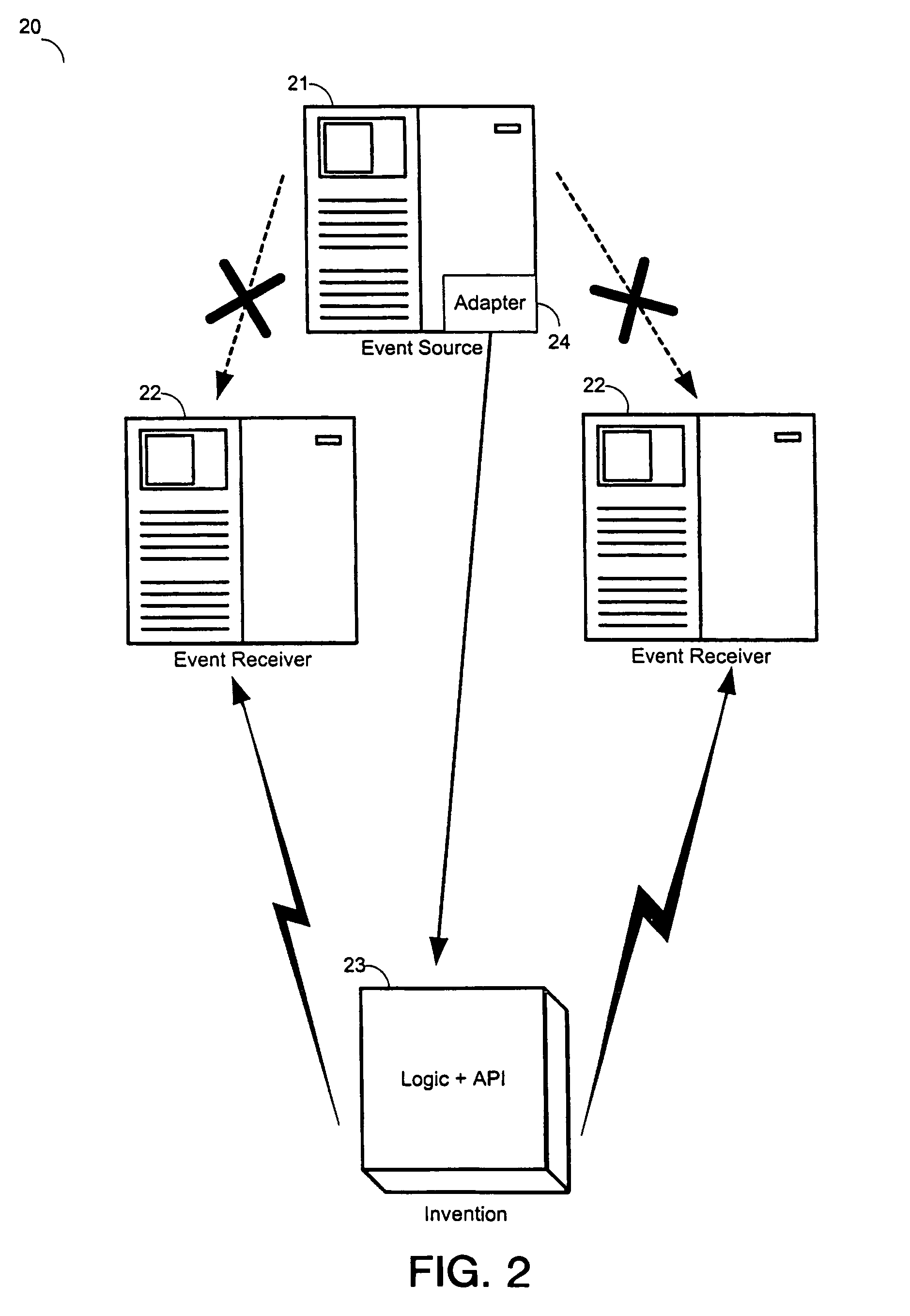

Message bridging system and method for singular server to singular or multiple event reception engines

InactiveUS7080381B2Facilitate communicationFast debuggingMultiprogramming arrangementsProgram code adaptionComputer hardwareApplication software

The present invention provides a system and method for facilitating communications between different systems requiring different event message techniques. In one embodiment, a method for bridging messages between a first and at least a second application having differing message formats comprises receiving message data from the adapter of a first application in a first format, translating and / or parsing the received message data into at least a second format and outputting the translated and / or parsed message data to at least the second application.

Owner:IBM CORP

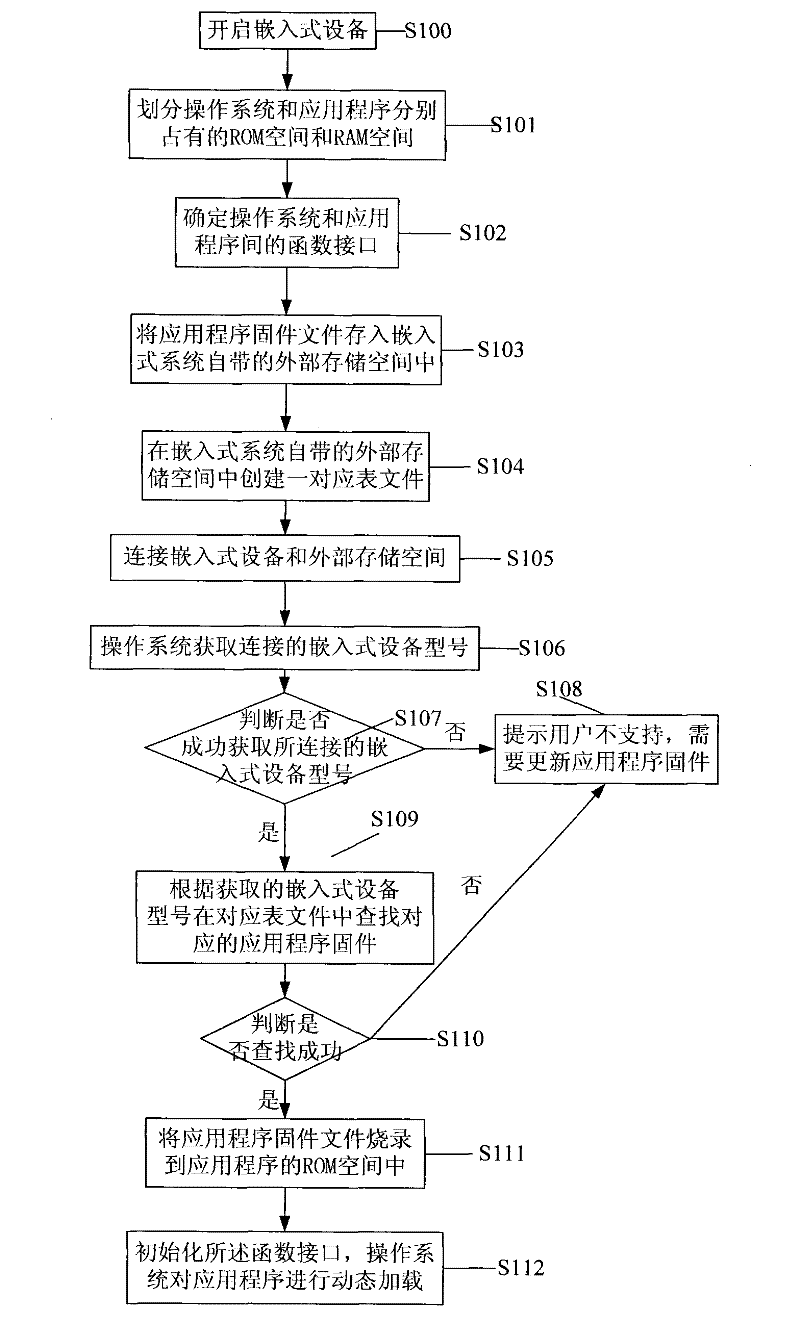

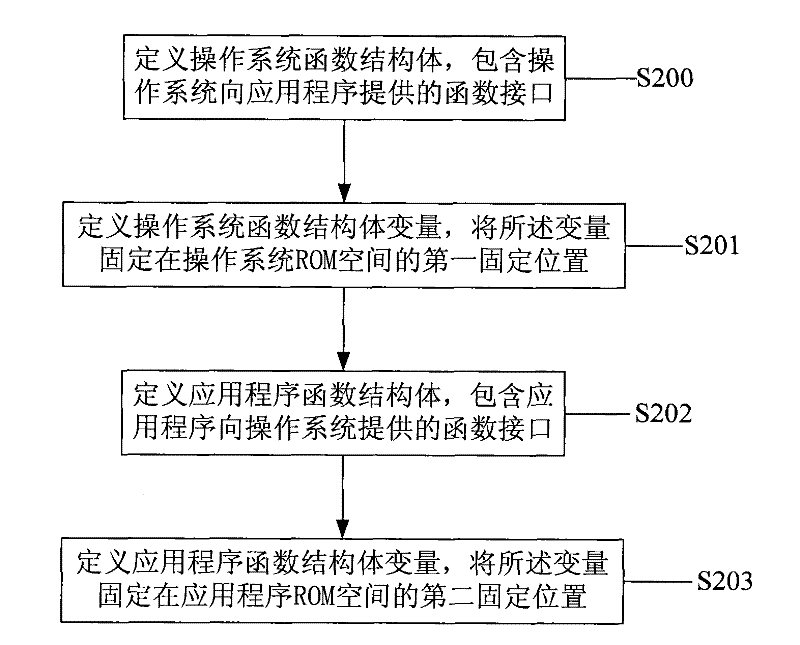

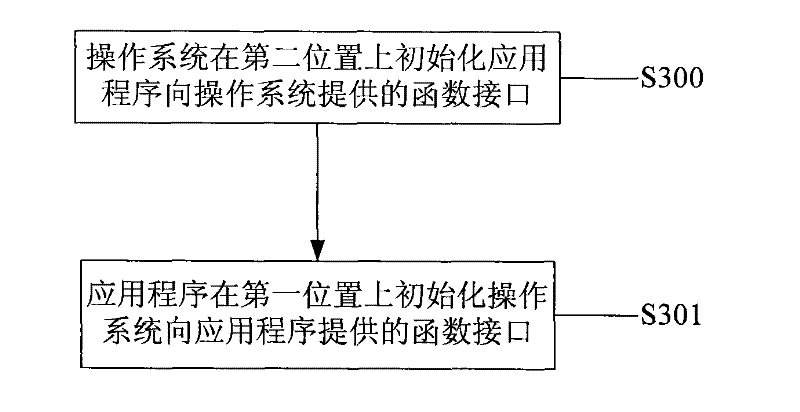

Method for dynamically loading application program of embedded system

InactiveCN102541579AReduce demandReduce R&D costsProgram loading/initiatingExternal storageOperational system

The invention discloses a method for dynamically loading an application program of an embedded system, which comprises the following steps: S1, starting an embedded device and dividing an ROM (read only memory) space and an RAM (random access memory) space respectively occupied by the operating system and the application program; S2, determining the function interface between the operating system and the application program; S3, storing a firmware document of the application program in a built-in external storage space of the embedded device, and connecting the embedded device; S4, burning firmware document of the application program to the ROM space of the application program; and S5, initializing the function interface, wherein the operating system loads the application program dynamically. The method of the invention stores the firmware document of the application program in the own external storage space of the embedded device and dynamically loads the function interface between the operating system and the application program so that the ROM space of a chip is low in demand, and the research and development cost is reduced. In addition, the burning time is shortened and the debugging speed is improved.

Owner:沈阳新邮通信设备有限公司

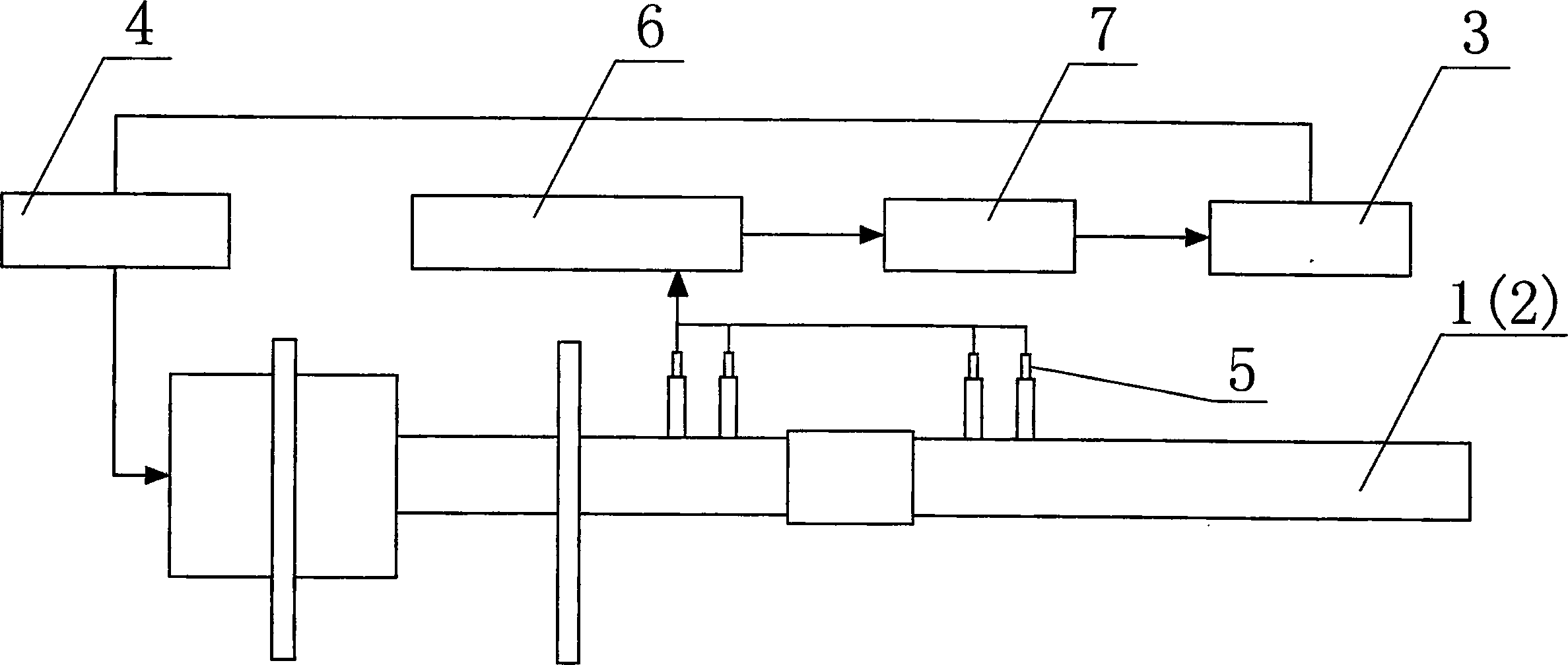

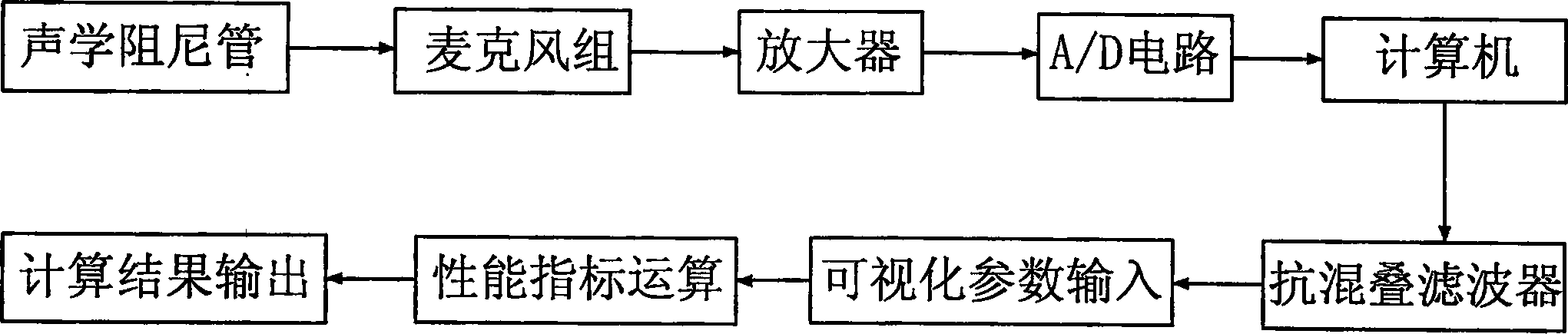

Comprehensive test instrument for performance of accoustic material

ActiveCN1873406AImplement real-time performance testingImprove business efficiencyMaterial analysis using sonic/ultrasonic/infrasonic wavesCombined testAudio power amplifier

The invention relates to acoustical material performance synthesis tester. It includes computer, double-microphone standing wave tube, four-microphone standing wave tube, and four-microphone sets. The double-microphone standing wave tube is made up of front and back standing wave tubes, loudspeaker, two microphone clams, piston rod lid support, piston rod, piston, and handle nut. The four-microphone standing wave tube is made up of front and back standing wave tubes, front and back end cover, loudspeaker, and microphone clam. The audio frequency output of the computer is connected with the loudspeaker. And the four-microphone sets are respectively connected with the signal input of the computer.

Owner:王岩松

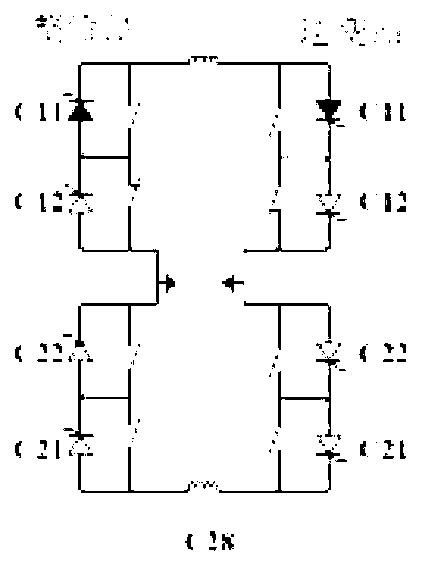

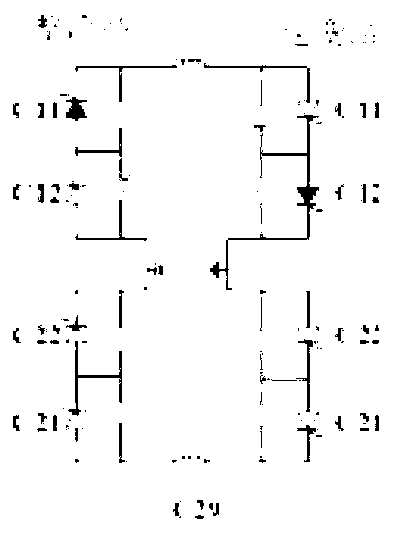

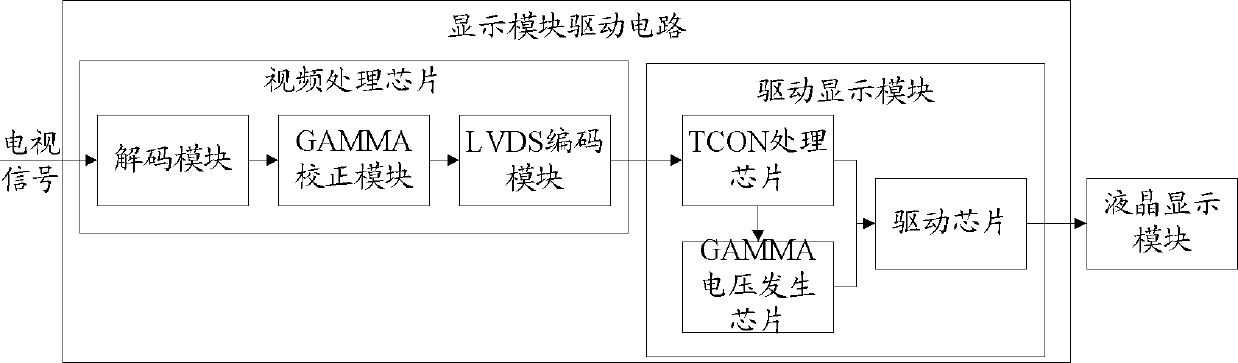

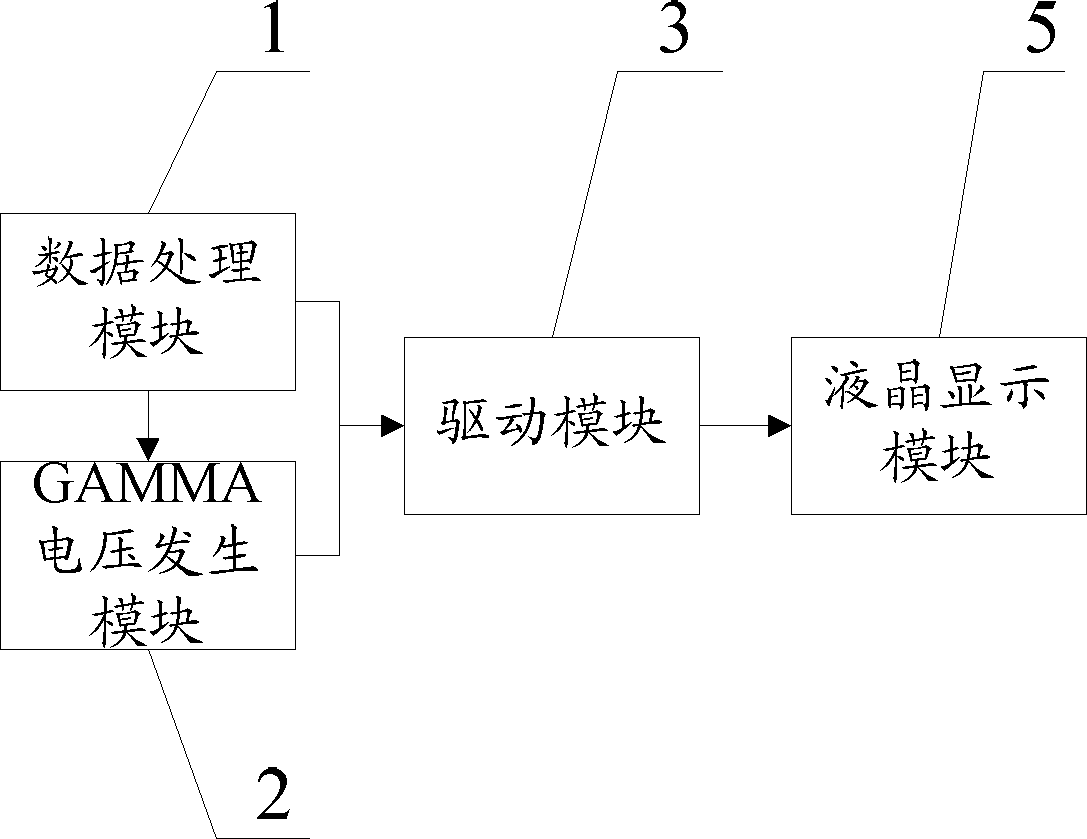

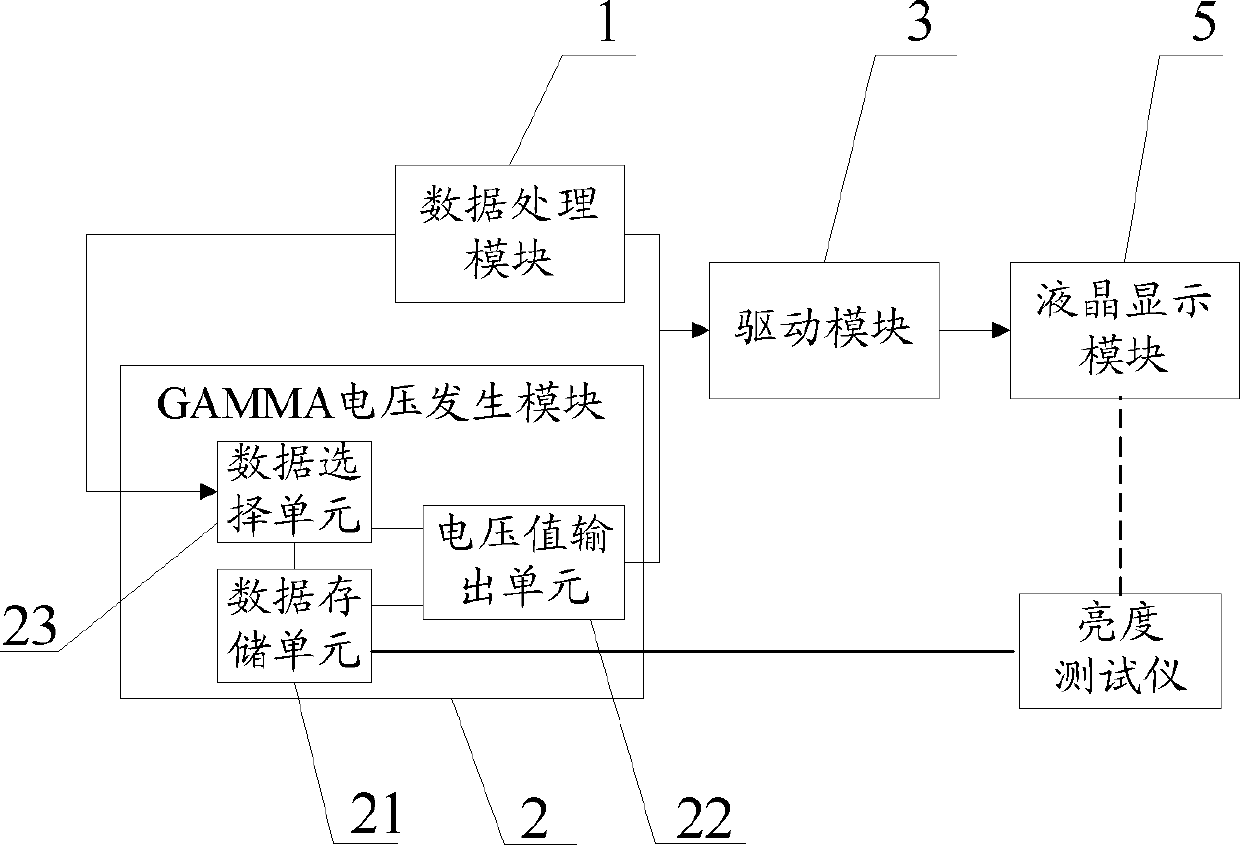

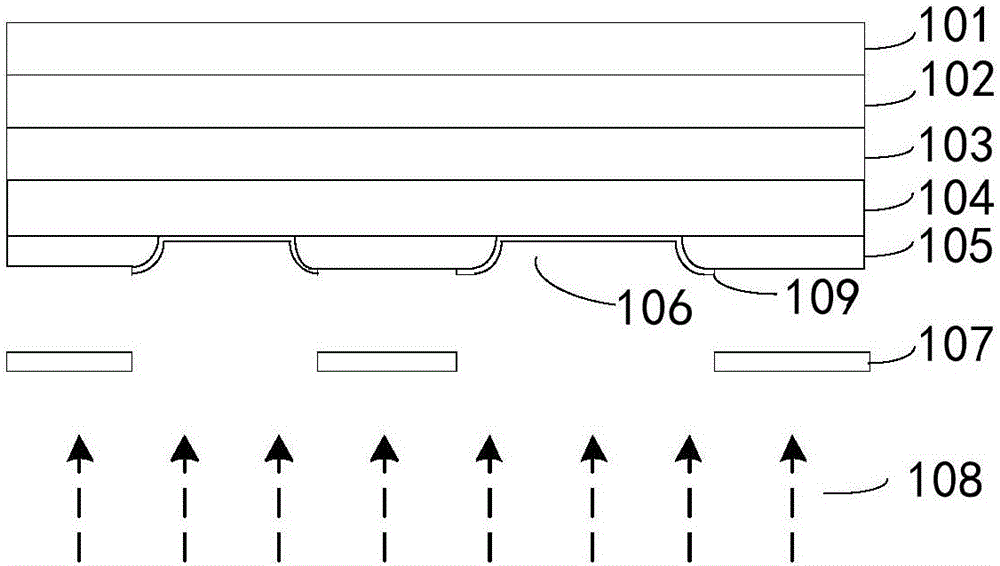

Display module driving circuit, driving method and liquid crystal television

ActiveCN102750914AControl display effectControl light transmittanceColor signal processing circuitsStatic indicating devicesVideo processingComputer module

The embodiment of the invention provides a display module driving circuit, a liquid crystal television and a display module driving method, relates to the field of electronic technology, and solves the technical problem in the prior art that a video processing chip is debugged with a heavy workload. The display module driving circuit comprises a data processing module, a GAMMA voltage generating module and a driving module, wherein the data processing module is used for processing an image displaying signal into a line synchronization signal, a field synchronization signal, a data driving signal and a scanning driving signal; the GAMMA voltage generating module is used for transmitting a GAMMA voltage corresponding to the GAMMA voltage value which is corrected according to a preset GAMMA curve to the driving module after receiving the line synchronization signal; and the driving module is used for generating a driving voltage by using the GAMMA voltage as the reference voltage according to the line synchronization signal, the field synchronization signal, the data driving signal and the scanning driving signal, and loading the driving voltage on pixels on a liquid crystal display module and corresponding to the line synchronization signal, the field synchronization signal and the scanning driving signal. The display module driving circuit, the liquid crystal television and the display module driving method are applied to improvement of the display effect of the liquid crystal television.

Owner:HISENSE VISUAL TECH CO LTD

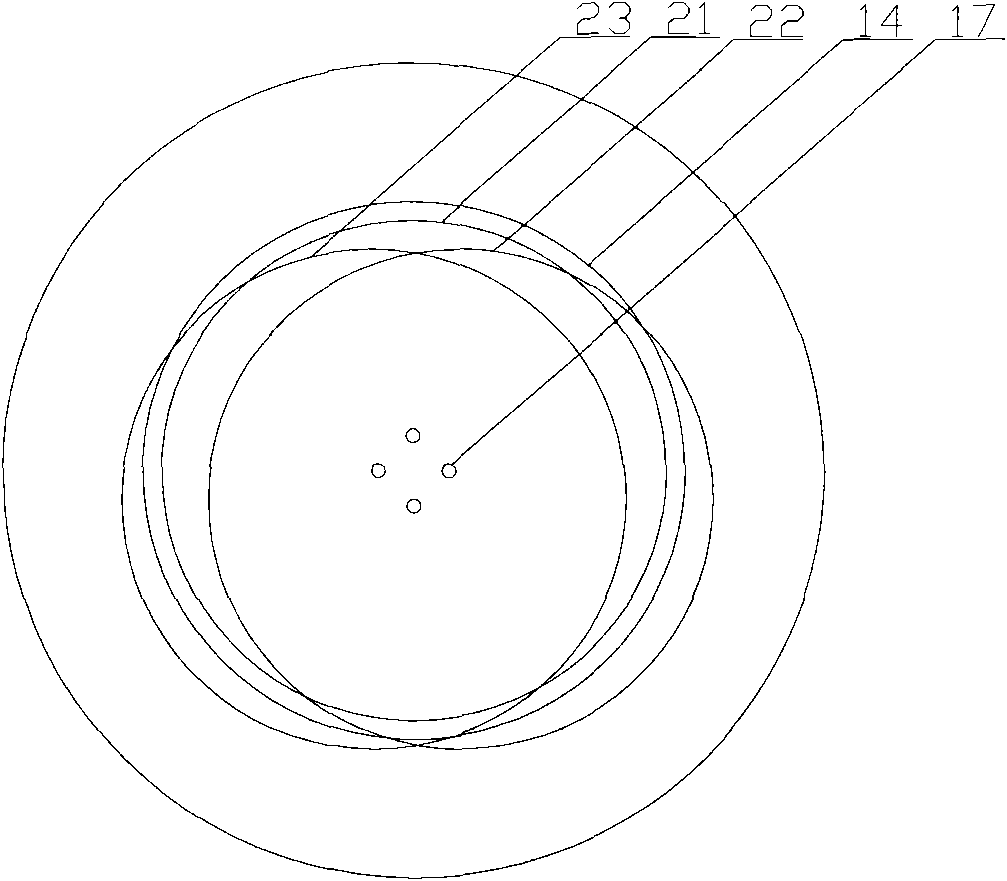

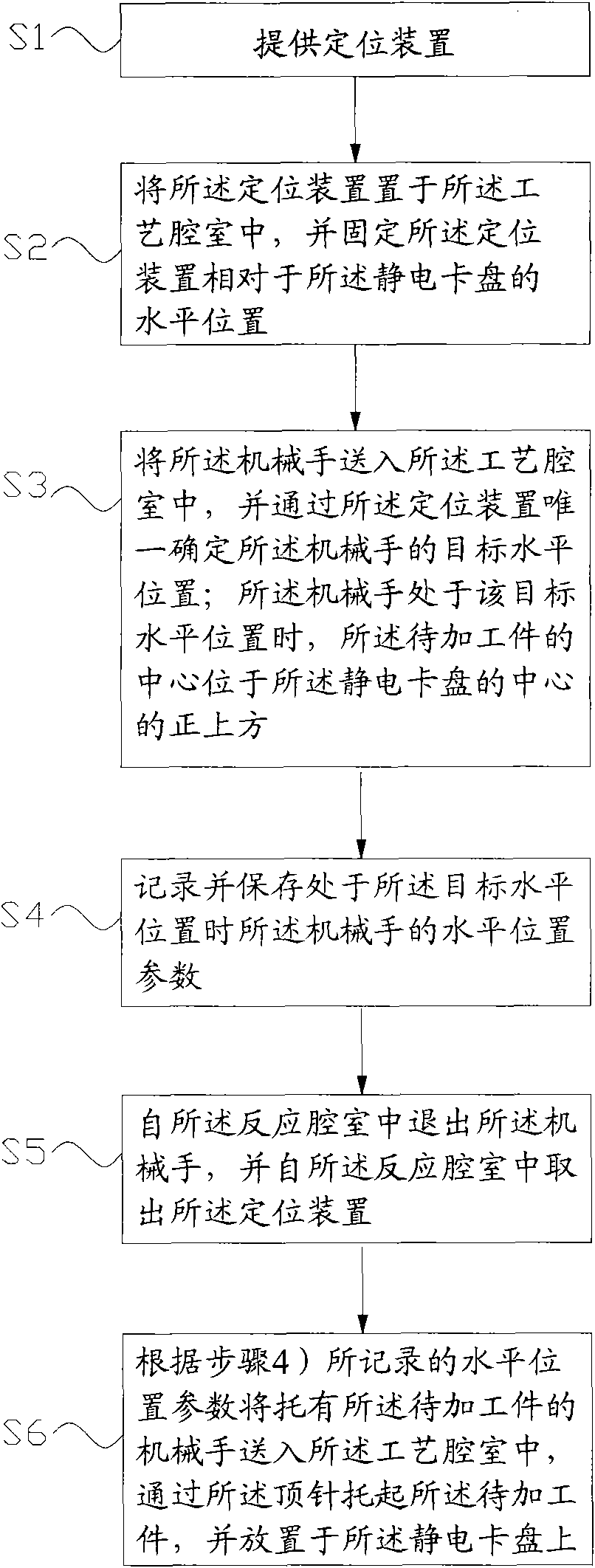

Plasma processing equipment and method for placing workpieces to be processed on static chuck thereof

ActiveCN101866823AImprove accuracyAvoid repeated debuggingSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention discloses a method for placing workpieces to be processed on a static chuck, which is characterized in that the wafer transfer position of a manipulator is determined by a locating device so that the workpieces to be processed can be quickly and accurately placed on the static chuck. The invention also discloses plasma processing equipment capable of using the method. The method or the device can finish the adjustment process in one step and avoid the repeated adjustments through the combination of naked eyes and manual operations, thereby greatly improving adjustment speed, saving a lot of adjustment time, and greatly enhancing the accuracy that the workpieces to be processed fall on the position of the static chuck; furthermore, the adjustment of a technical chamber can be finished without using the workpieces to be processed, thereby further improving working efficiency.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

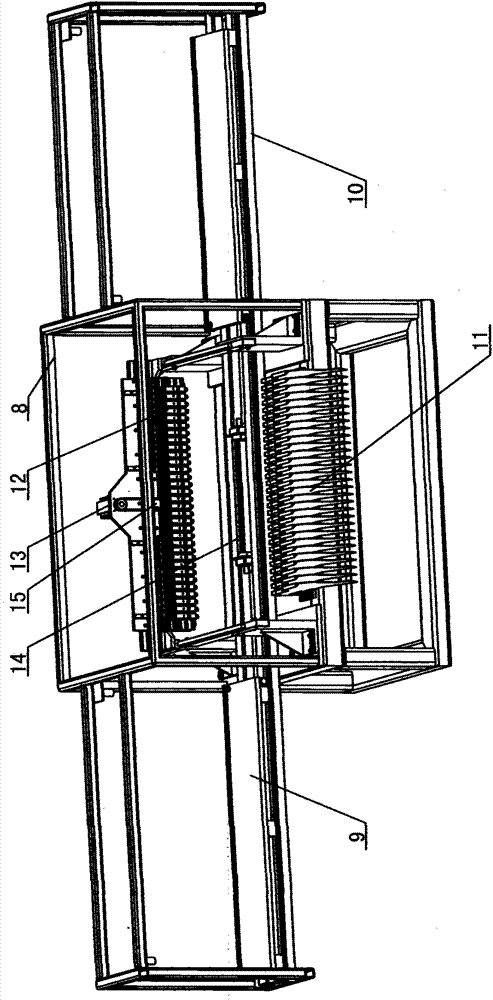

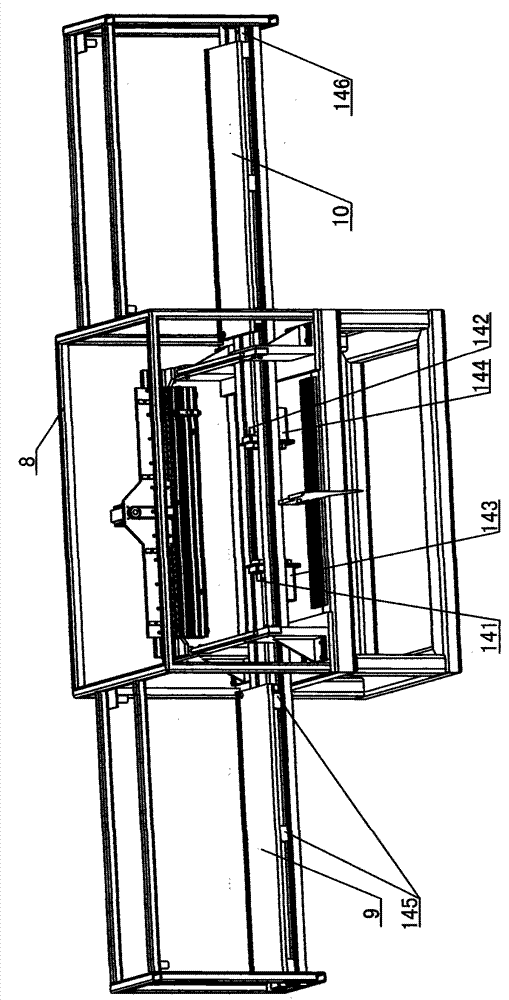

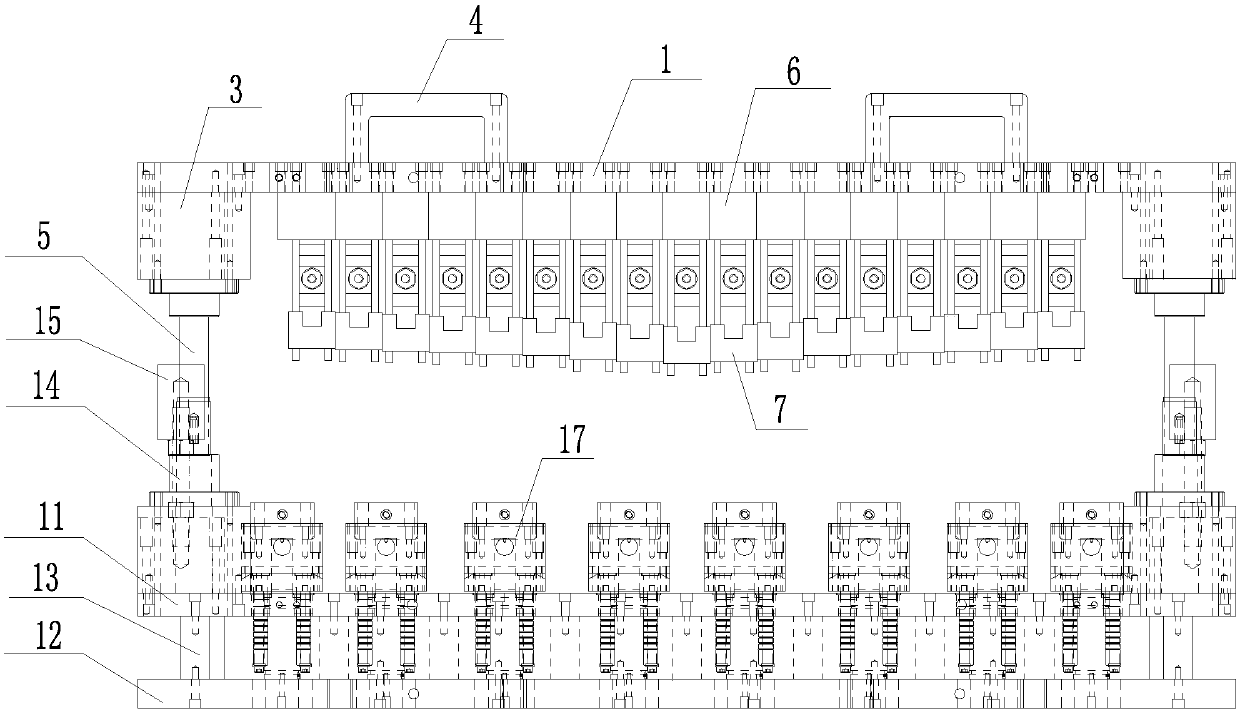

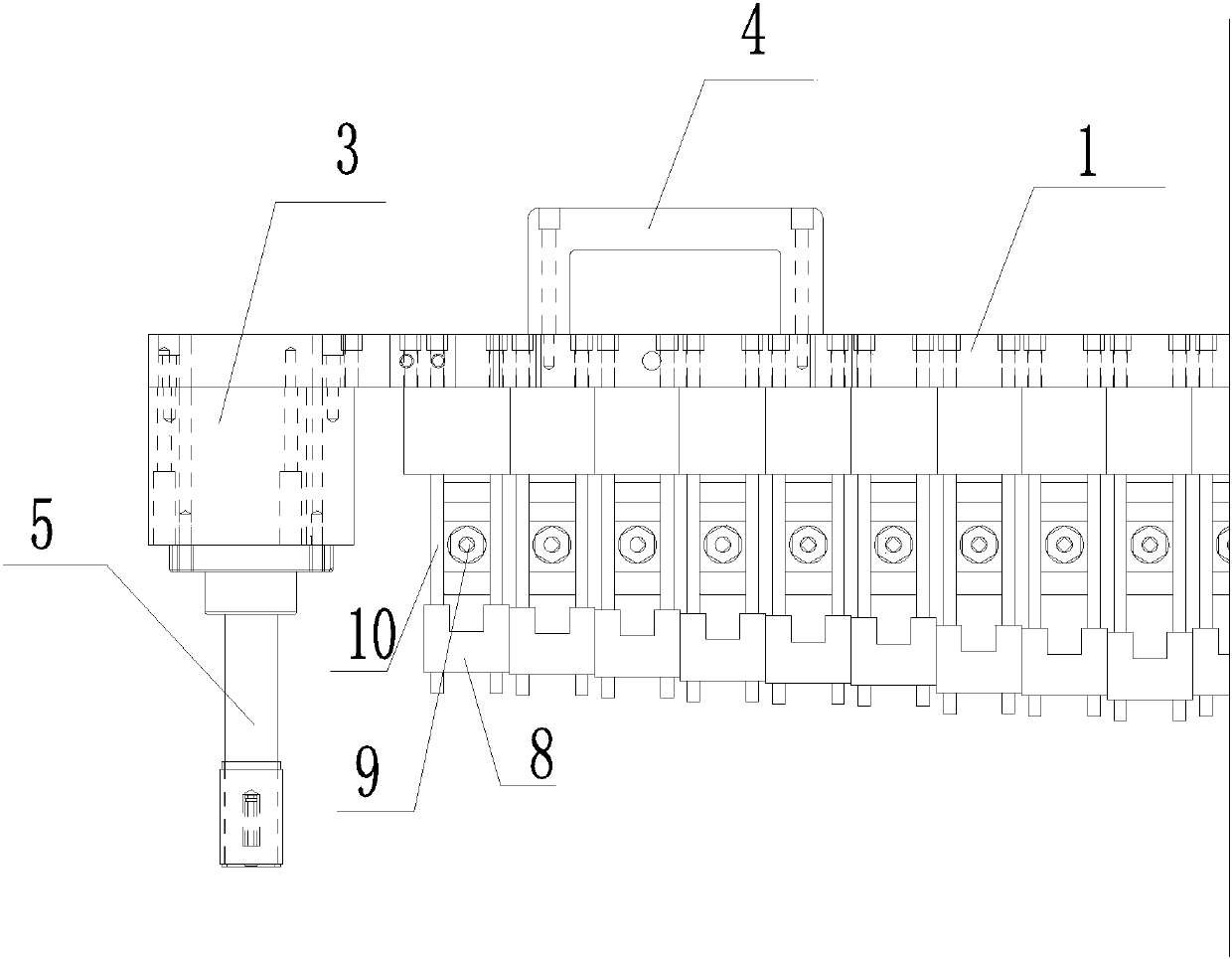

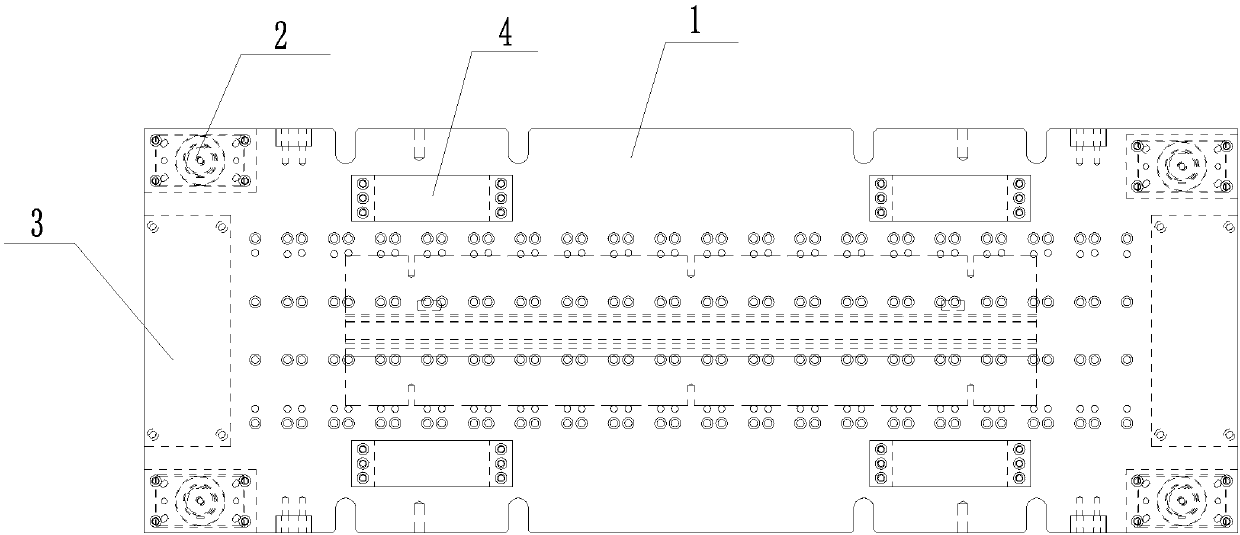

High-speed array chip mounter

ActiveCN103596416ATake advantage ofHigh adjustment accuracyElectrical componentsDisplay deviceForward looking

The invention relates to a high-speed array chip mounter. The chip mounter comprises a chip mounter rack, wherein a left board feeding platform and a right board feeding platform are laid horizontally on the two sides of the chip mounter rack respectively, a forward looking camera is arranged on the front side of the right board feeding platform, an up looking camera is arranged on the upper surface of the right board feeding platform, array mounting heads are arranged on a beam in the chip mounter rack, and a down looking camera is installed at the bottoms of the array mounting heads. An up-down movement mechanism is arranged on the back faces of the array mounting heads, a board feeding mechanism is horizontally laid between the left board feeding platform and the right board feeding platform, and array feeders are installed on one side of the chip mount rack. The high-speed array chip mounter has the advantages that the thirty array mounting heads are adopted for synchronously moving to the corresponding thirty feeders, meanwhile, the cameras are arranged in the area of the left board feeding platform and the area of the right board feeding platform, the cross line on a displayer plays a role in positioning circuit boards, it can be ensured that the fed circuit boards to be mounted are uniform in position, staff are used sufficiently, and high-speed high-efficiency production is achieved.

Owner:浙江华企正邦自动化科技有限公司

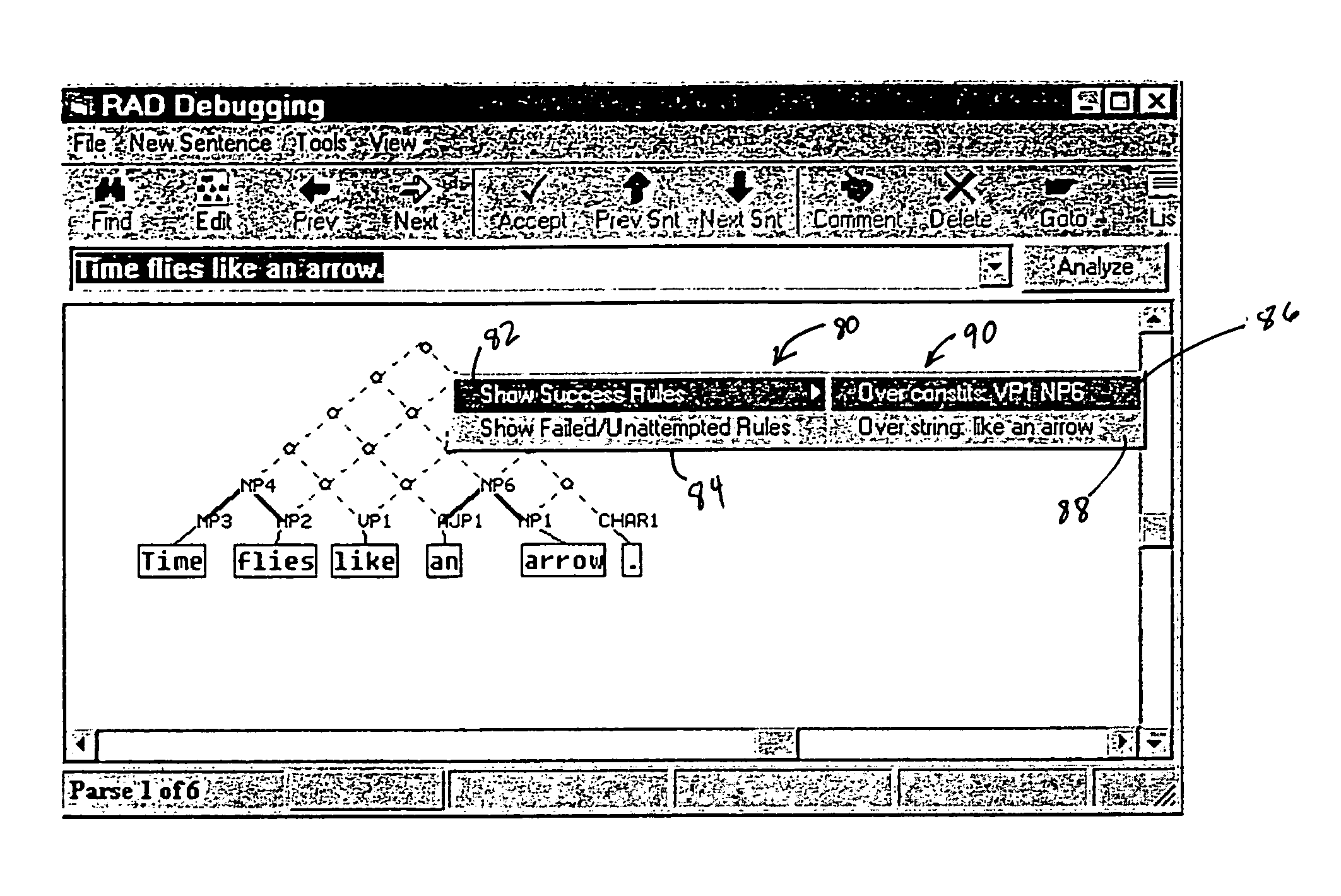

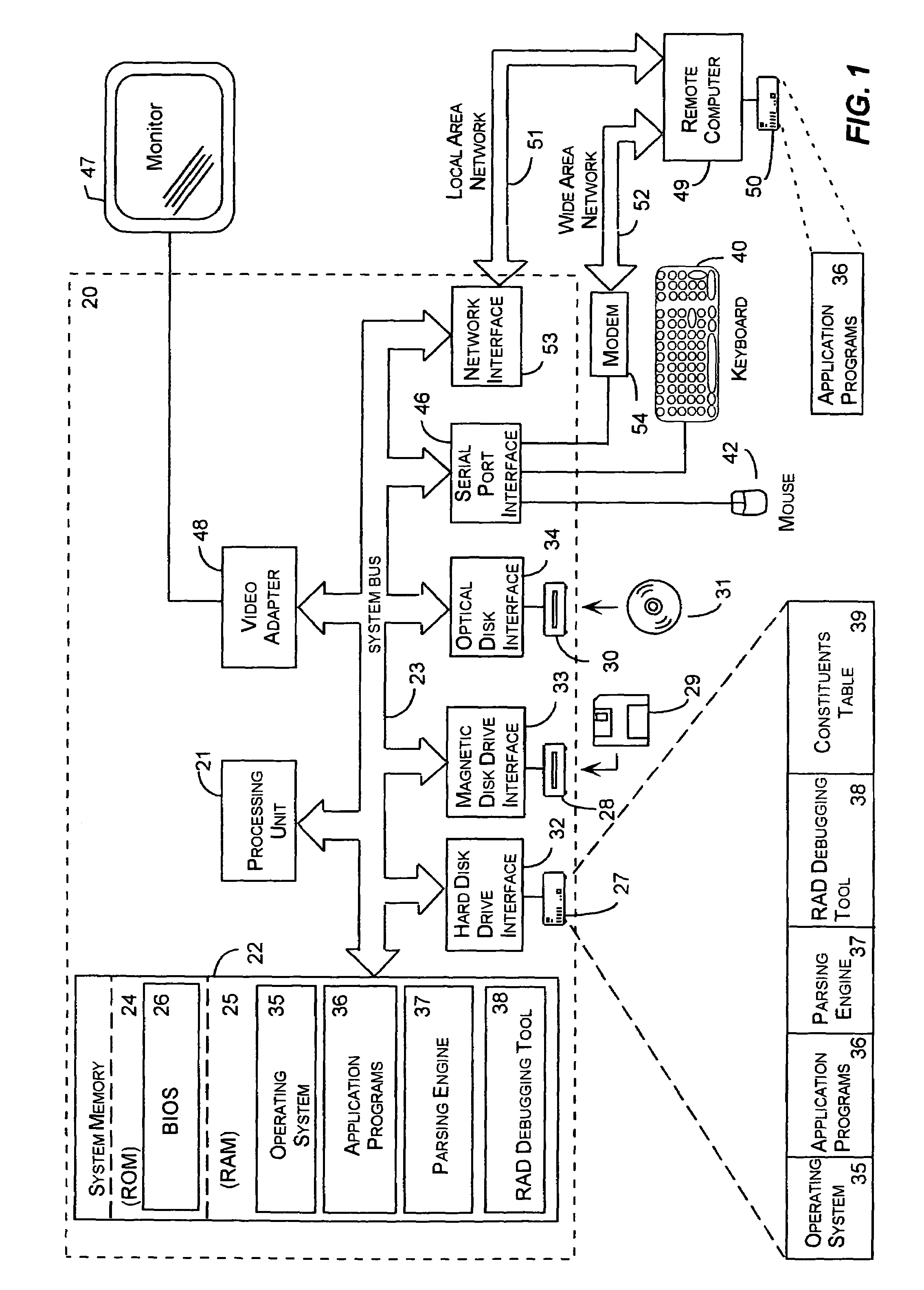

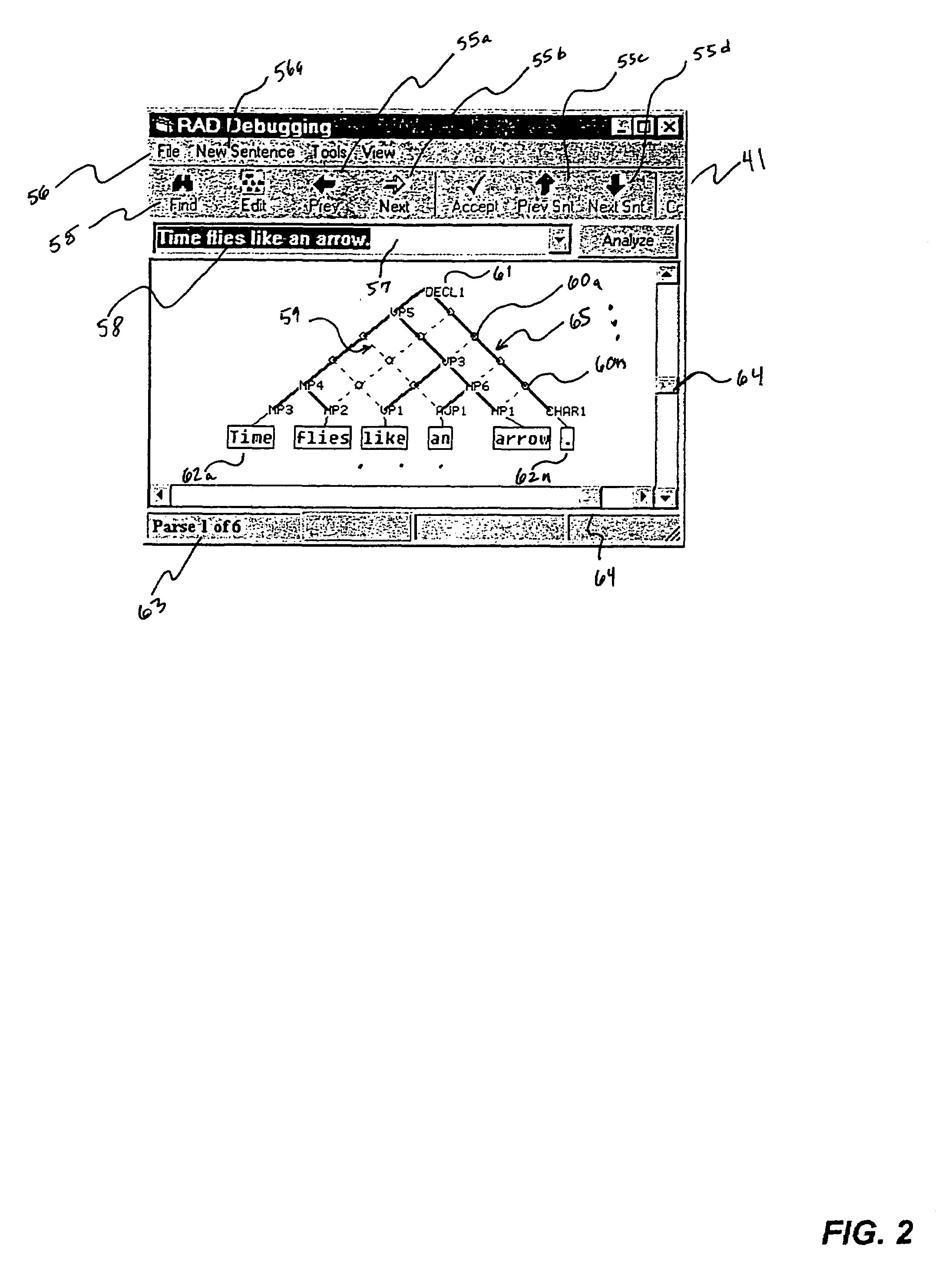

Method and apparatus for analyzing and debugging natural language parses

InactiveUS7379862B1Fast debuggingGood utilizationNatural language data processingProgram controlNatural languageMesh grid

A method and apparatus for analyzing and debugging natural language parses is provided. An input sentence is received and parsed by a parsing engine. A table of constituents is retrieved from the parsing engine and a grid tree is drawn representing the input sentence. Nodes of the tree, or connecting points, appear at intersections of the tree “branches.” Once the grid has been drawn, the first syntactically correct parse of the sentence is mapped to the grid in a tree-like manner (the “parse tree”). Input is then received for selecting one of several graphical buttons, for selecting a node that is in the parse tree, for selecting a node that is not in the parse tree, or for selecting options from one of several “pull-down” menus. If a connecting point that is not contained in the parse tree is selected, a group of menu options may be displayed adjacent to the selected connecting point. The user may select menu options for displaying successful rules applied at the connecting point, or for displaying unattempted and failed rules for the connecting point. If a connecting point that is contained in the parse tree (i.e. a constituent was formed at the connecting point) is selected, a second group of menu options may be displayed adjacent to the selected connecting point. The menu options may include displaying the name of the connecting point and the name of the rule that was applied at the connecting point to form the constituent.

Owner:MICROSOFT TECH LICENSING LLC

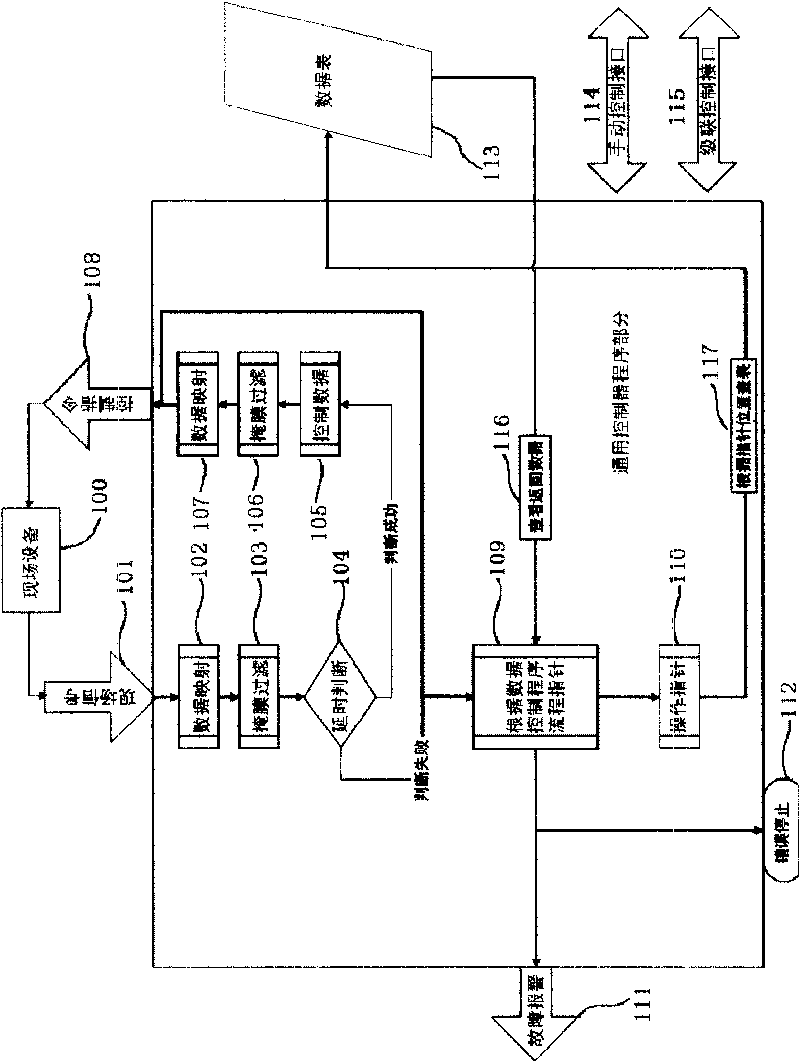

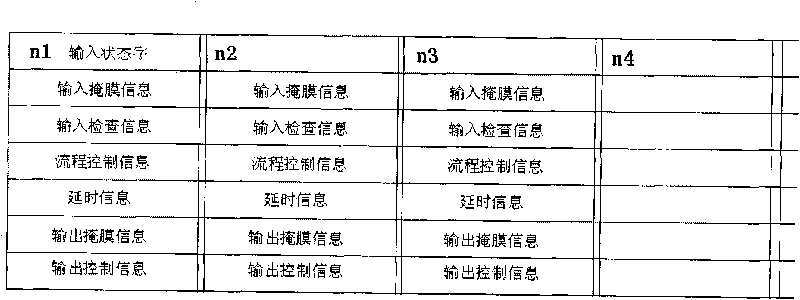

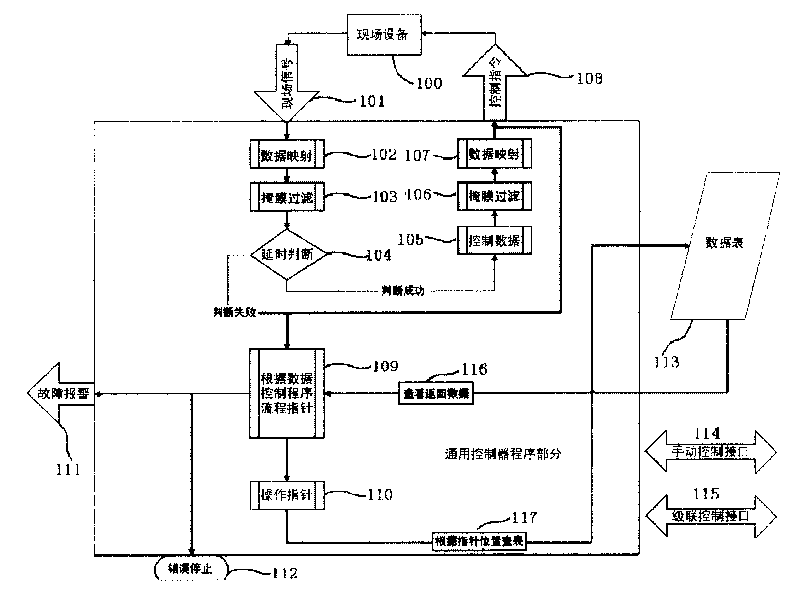

General sequence control algorithm used in programmable logic controller

ActiveCN101750992AMeet the complexityFulfil requirementsProgramme control in sequence/logic controllersDatasheetProgrammable logic controller

The invention relates to the programming of a programmable logic controller (PLC), in particular to a general sequence control algorithm used in the programmable logic controller. The method is that the programmable logic controller repetitively digitalizes the current input signal, the digitalized data is used as an input parameter for indirect addressing, information required for the next operation and control output of the programmable logic controller is obtained from a datasheet and a corresponding operation is conducted according to the information. The general sequence control algorithm used in the programmable logic controller is not limited by a controller master program (i.e. a controller master scheduling program) and a hardware, and can independently maintain the progress of a customer program (i.e. control program), a customer program algorithm for inputting and outputting signal status, the definition of a supportive data storage structure and the specific implementation method.

Owner:江苏普泰自动化技术有限公司

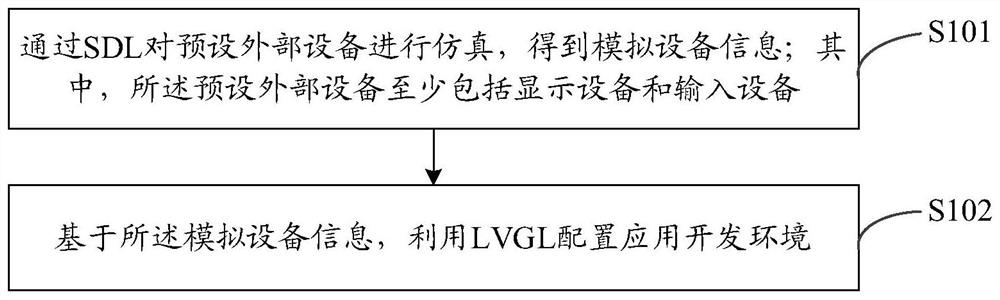

Application development environment configuration method, device and equipment and storage medium

PendingCN112199087AReduce development costsReduce development difficultyVersion controlSoftware testing/debuggingSoftware engineeringOpen source

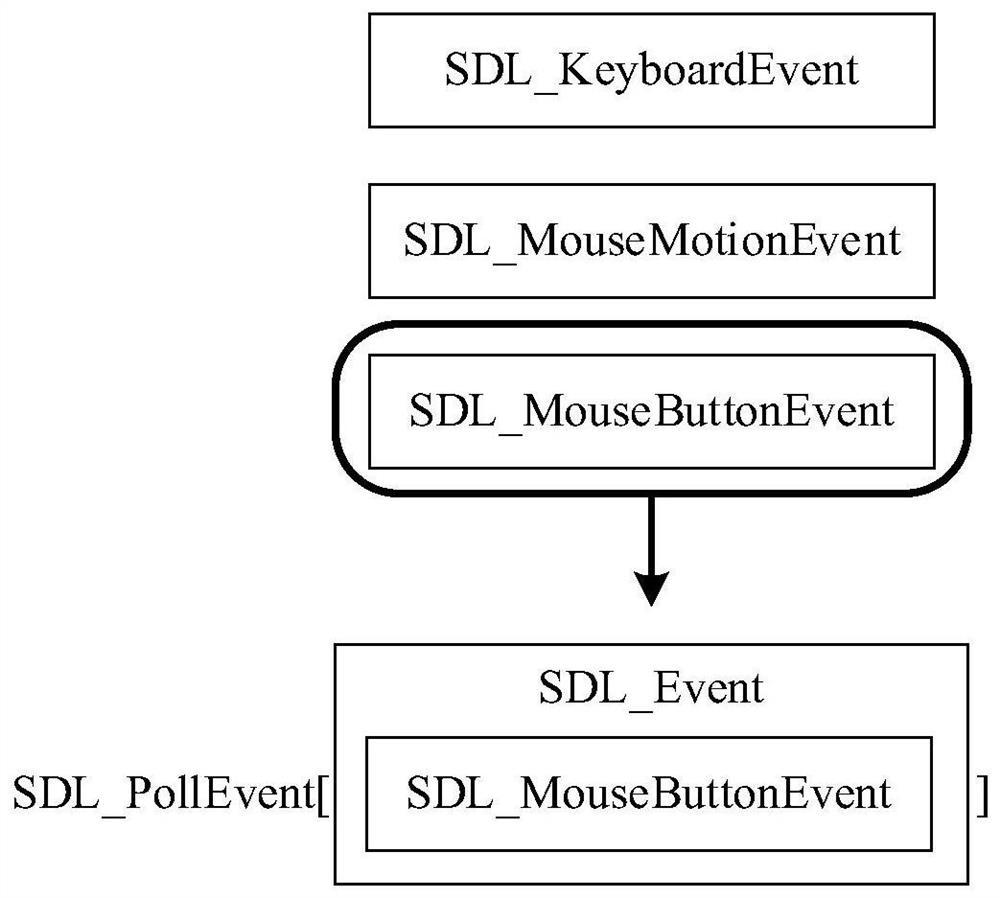

The embodiment of the invention discloses an application development environment configuration method, device and equipment and a storage medium, the method is applied to computer equipment, the computer equipment is provided with a preset operating system, the preset operating system supports a cross-platform multimedia library SDL, and the method comprises the following steps: simulating the preset external equipment through the SDL, obtaining simulation equipment information, wherein the preset external equipment at least comprises display equipment and input equipment; and based on the simulation equipment information, configuring the application development environment by utilizing an embedded open source graphics library LVGL. Thus, the application development cost based on the LVGLcan be reduced, by matching with the SDL, a peripheral driving program of a development board does not need to be transplanted, decoupling from a driving problem is achieved, therefore, the development efficiency can be improved, and meanwhile applications developed based on the application development environment have transportability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for debugging high configuration and power supply interface module in basic inputting and outputting system

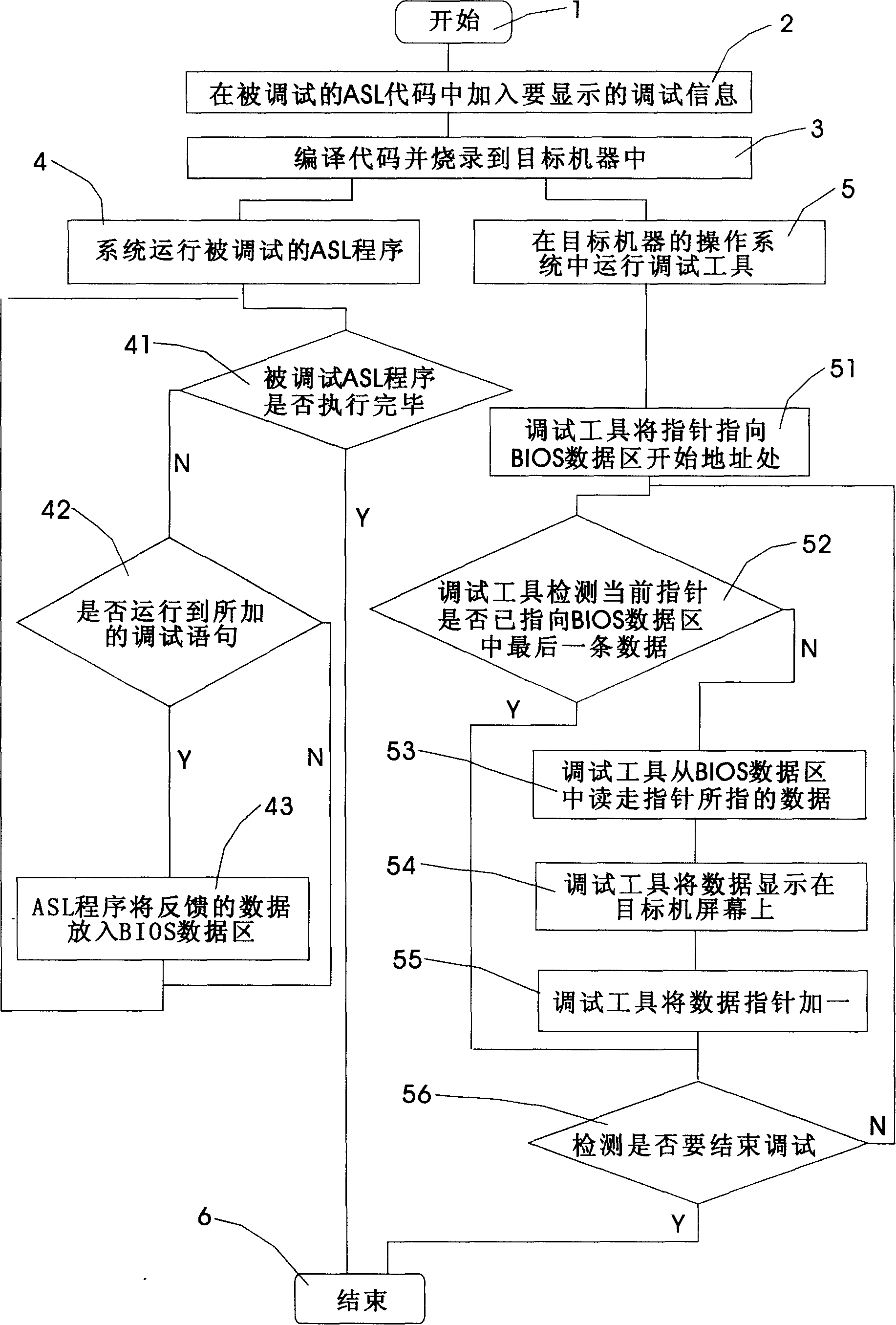

InactiveCN1848093AAffect the working environmentPerform synchronizationSoftware testing/debuggingEmbedded systemInput/output

The present invention discloses a debugging method of high-level configuration and power supply interface module in basic input / output system. Said method includes the following steps: adding debugging information into the high-level configuration and power supply interface module code to be debugged; compiling the code containing debugging information and reading it into object machine; on the object machine operating debugging tool; after the debagging tool is operated, utilizing said debugging information displayed on object machine to make debugging work.

Owner:SHENZHEN TOPSTAR DIGITAL TECH

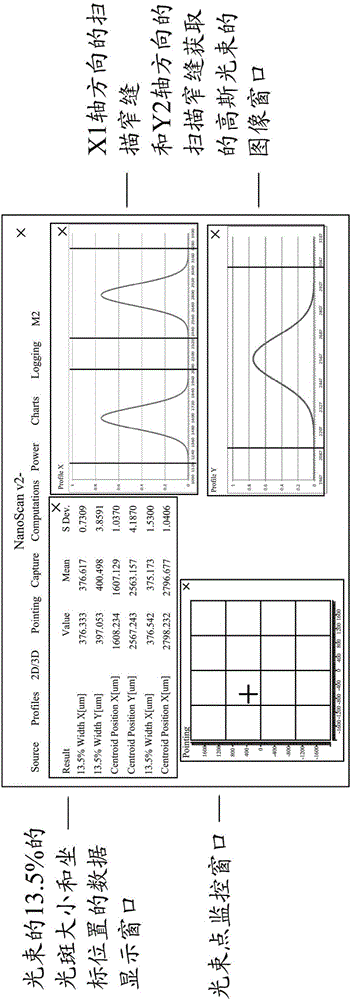

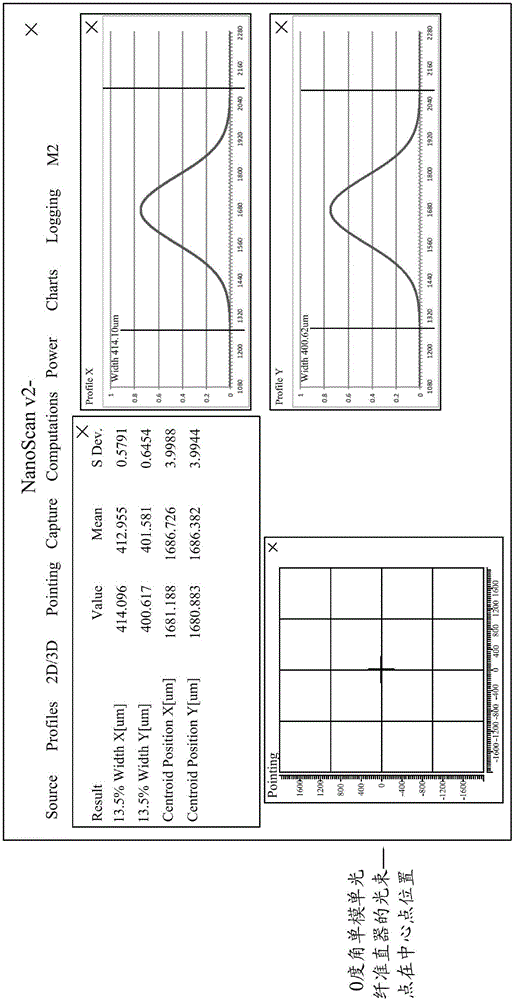

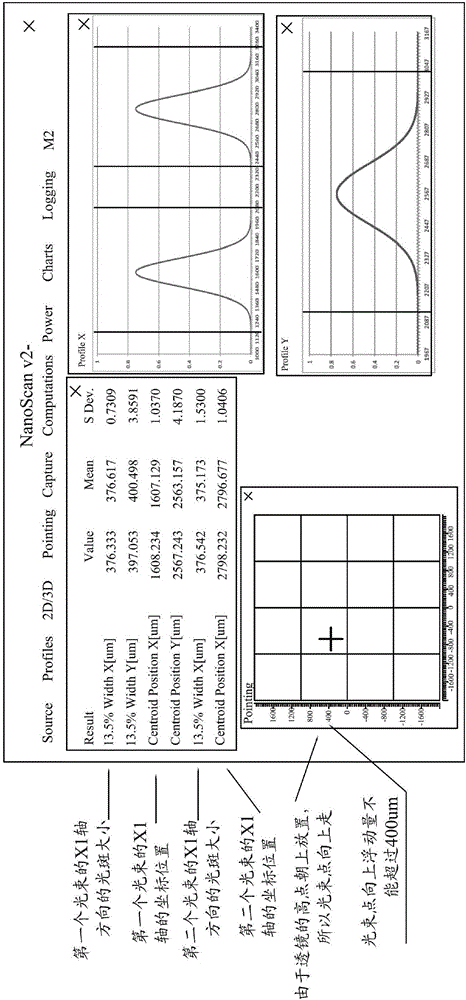

System and method for debugging single-mode broadband double-fiber collimator and thereof

The invention relates to a system and method for debugging a single-mode broadband double-fiber collimator. The system for debugging the single-mode broadband double-fiber collimator comprises an FP-LD laser light source with a wavelength of 1550nm, a Photon Nano Scan spot device, a one-dimensional adjusting bracket, a five-dimensional adjusting bracket, a computer and a to-be-debugged single-mode broadband double-fiber collimator, wherein the FP-LD laser light source with a wavelength of 1550nm is arranged at one end of the single-mode broadband double-fiber collimator; the to-be-debugged single-mode broadband double-fiber collimator is arranged on the one-dimensional adjusting bracket on the five-dimensional adjusting bracket; the one-dimensional adjusting bracket is used for adjusting a clearance between a single-mode double-fiber pigtail and a lens in the single-mode broadband double-fiber collimator; the Photon Nano Scan v2 spot device is interconnected with the computer; the debugging of the single-mode broadband double-fiber collimator is realized by debugging the five-dimensional adjusting bracket; the spot device is used for double beam debugging. The debugging method according to the invention is simple and convenient in operation, high in debugging result consistency, low in insertion loss and high in yield, and can be widely applied to the field of optical fiber communication.

Owner:上海中科光纤通讯器件有限公司 +2

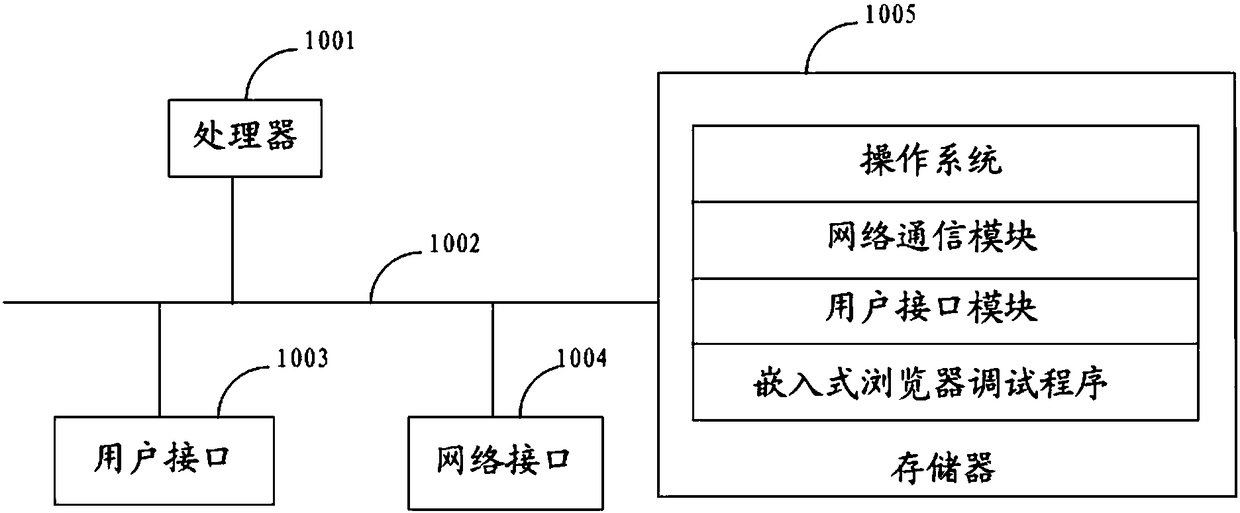

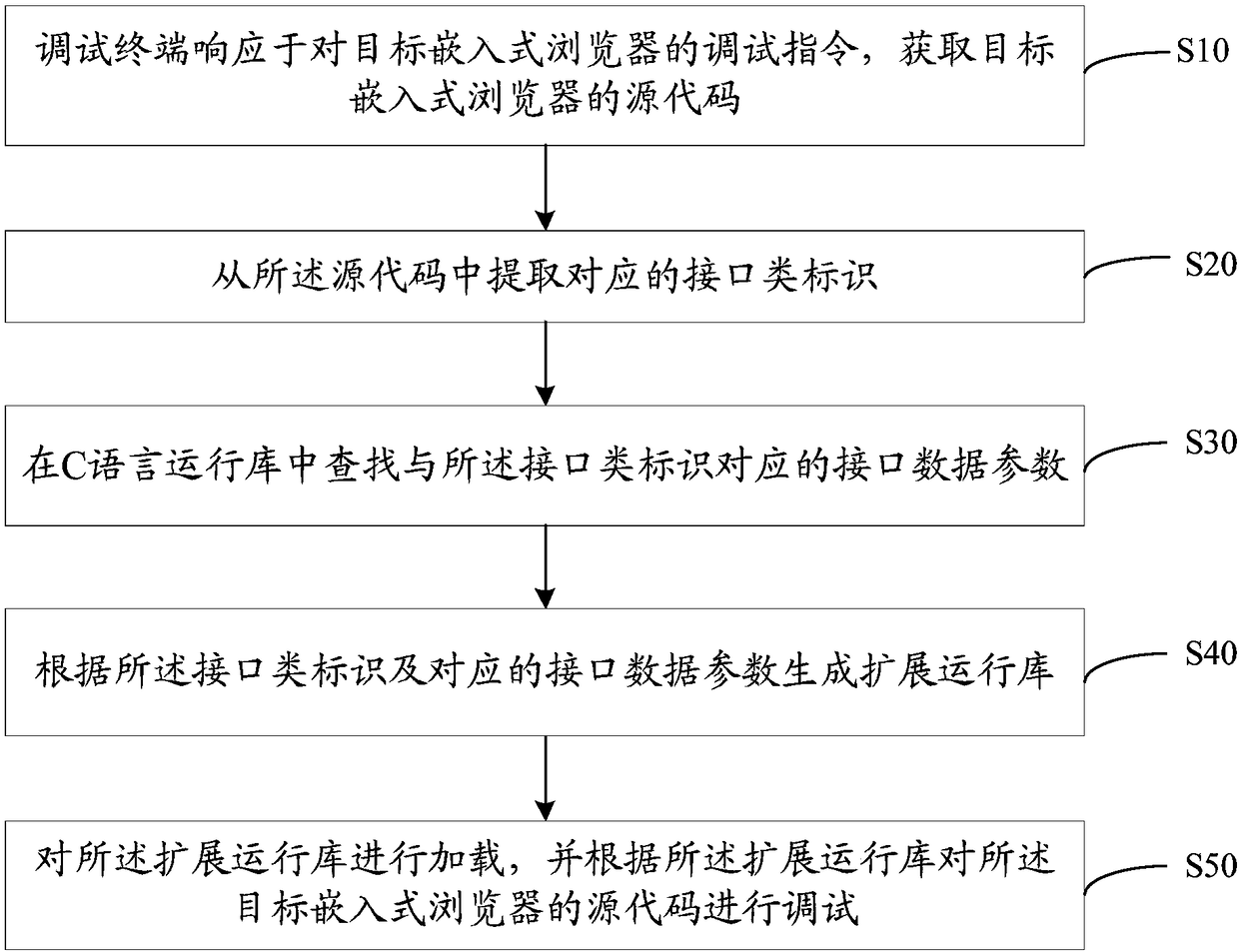

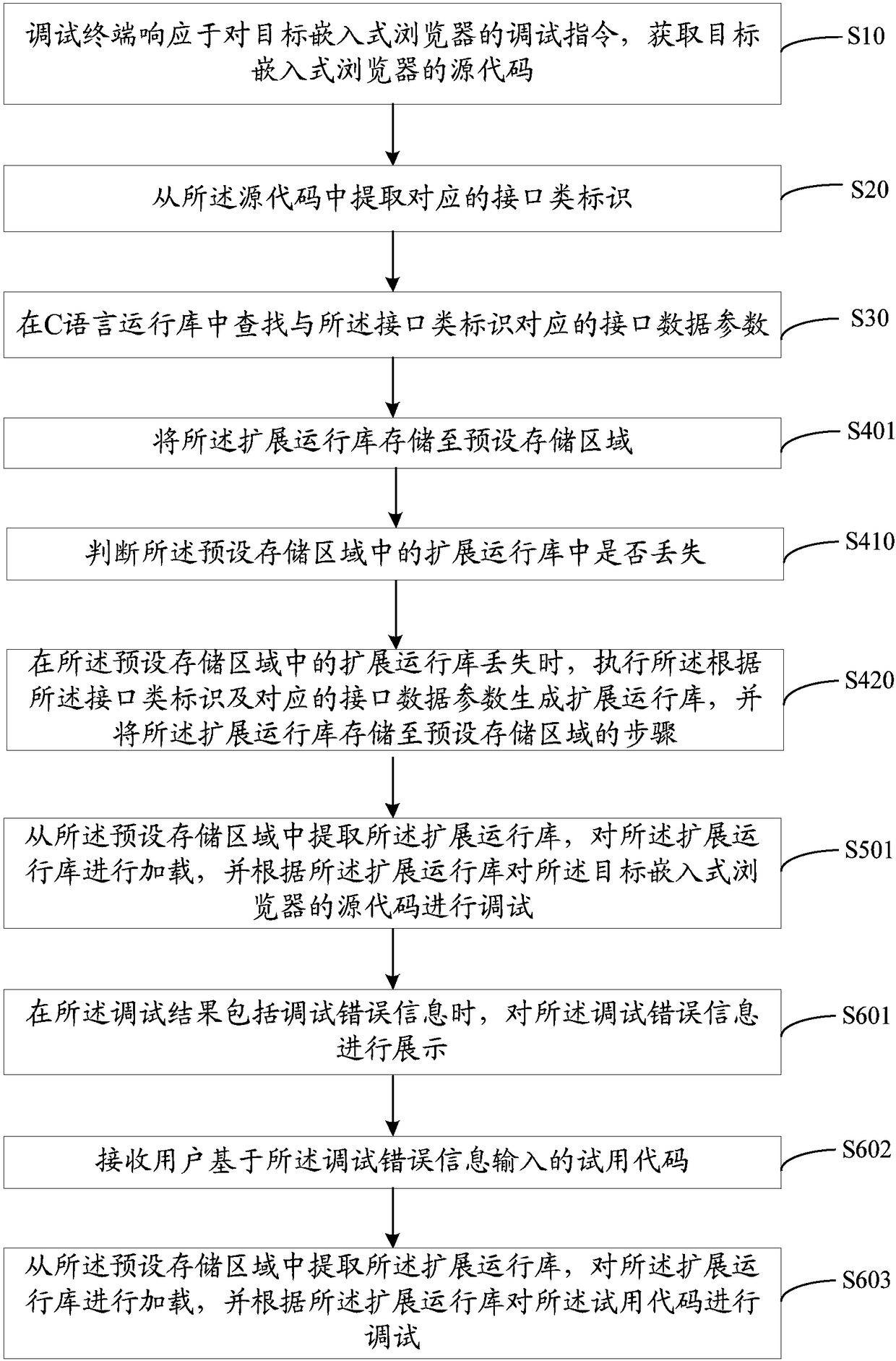

Embedded-browser debugging method, debugging terminal and computer-readable storage medium

ActiveCN108197024AReduce memory consumptionFast debuggingSoftware testing/debuggingSource codeHuman language

The invention discloses an embedded-browser debugging method, a debugging terminal and a computer-readable storage medium. The debugging terminal of the invention acquires source code of a target embedded-browser in response to a debugging instruction for the target embedded-browser; extracts corresponding interface class identifiers from the source code; finds interface data parameters, which correspond to the interface class identifiers, in a C-language running library; generates an extension running library according to the interface class identifiers and the corresponding interface data parameters; and loads the extension running library, and debugs the source code of the target embedded-browser according to the extension running library. Extension running determines a range of interface classes needed for debugging a running environment, the debugging terminal is enabled to not need to load the original C-language running library in debugging the source code of the target browser,consumption of memory is reduced on the basis of not impacting accuracy of embedded-browser debugging results, and debugging speed is increased.

Owner:SHENZHEN TCL DIGITAL TECH CO LTD

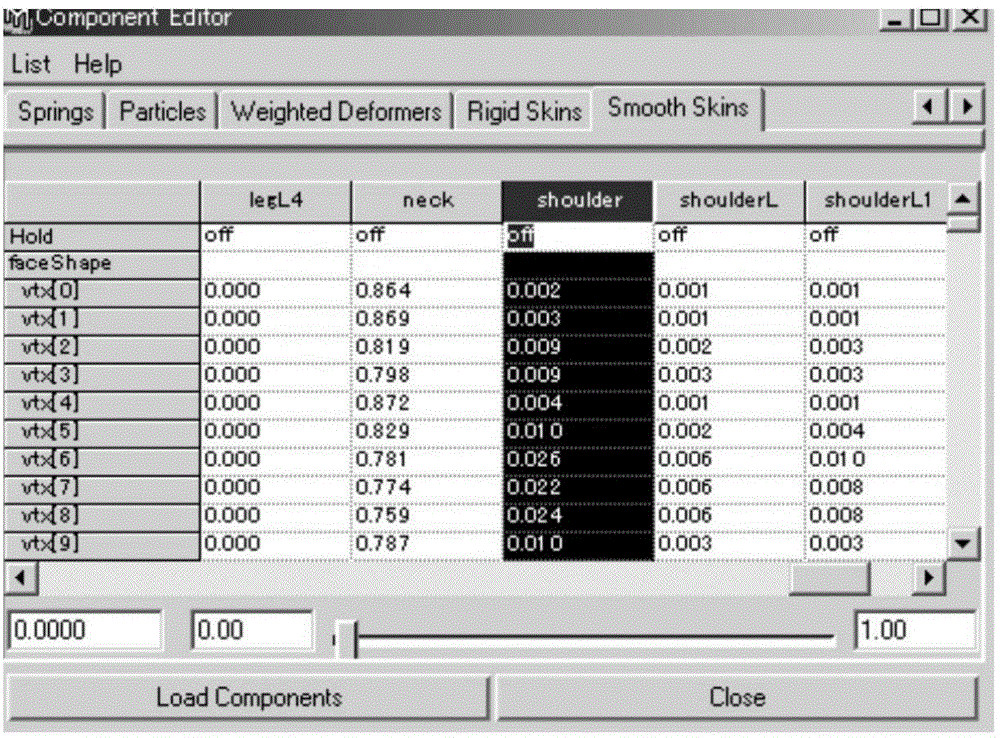

Fine animation manufacturing method based on secondary controllers

ActiveCN104574475AFast debuggingAchieve fine animation effectsAnimationProcessor architectures/configurationAnimationSoftware

The invention discloses a fine animation manufacturing method based on secondary controllers. A polygon where all the secondary controllers are located and local coordinates in the polygon are determined; weight data of all the secondary controllers are exported and combined into a single weight system, and thus the speed of debugging an animation can be increased; meanwhile, after the animation is bonded through a skeleton, a displacement rotation transformation matrix M of the secondary controllers relative to the local coordinate system of the secondary controllers is recorded, then the transformation effects of all the secondary controllers are accumulated according to the weight of the secondary controllers to all vertexes on the polygon model, and the fine animation effect controlled by the secondary controllers is achieved. Compared with secondary controllers in existing three-dimensional software, nodes for updating positions of the controller and nodes for the controllers to adjust the positions of the vertexes of the polygon model are established, and otherwise directed annulate images can be formed. Thus, the method further solves the problem that role animation debugging becomes slow after the multiple secondary controllers are added in the existing three-dimensional software.

Owner:北京春天影视科技有限公司

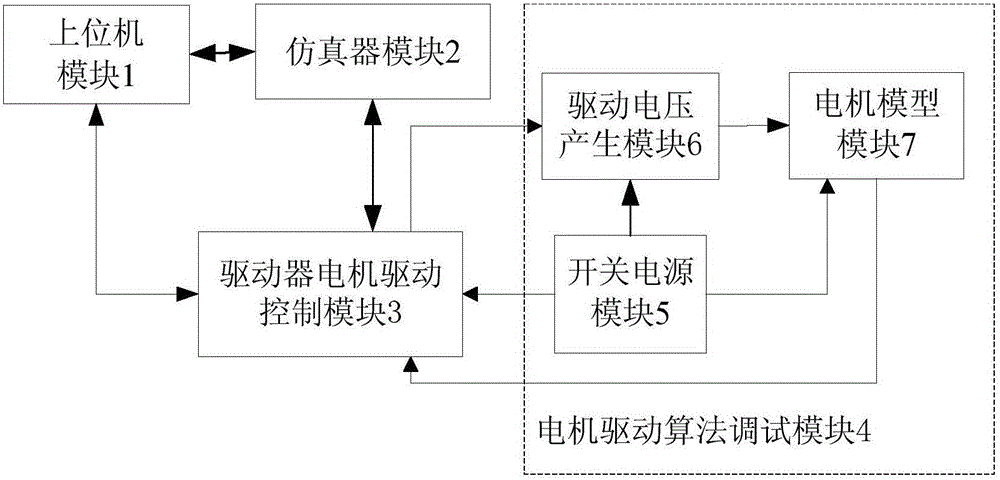

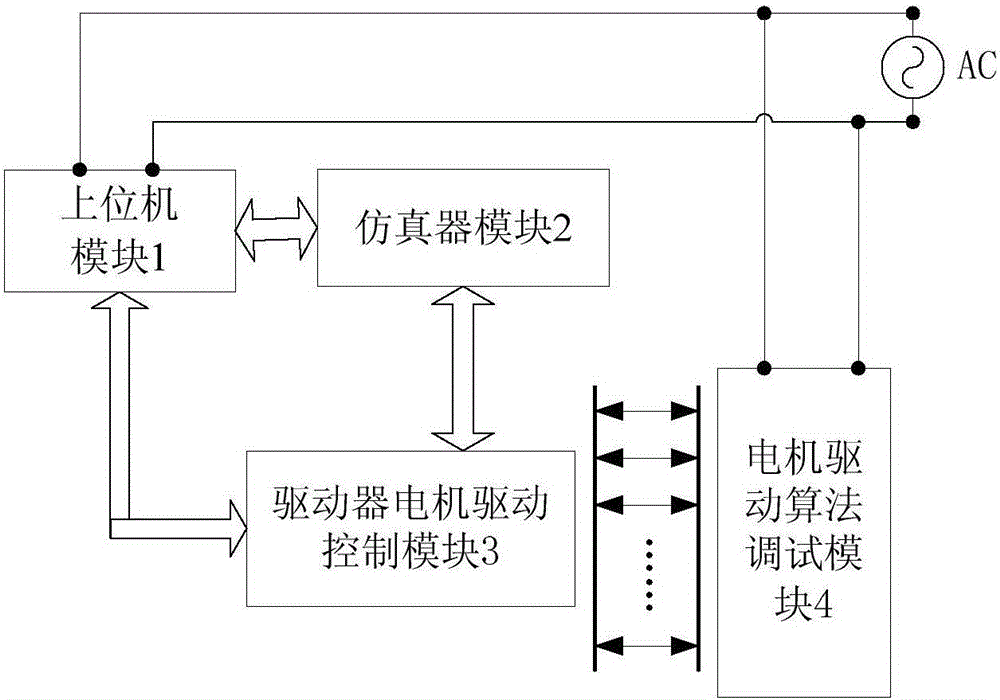

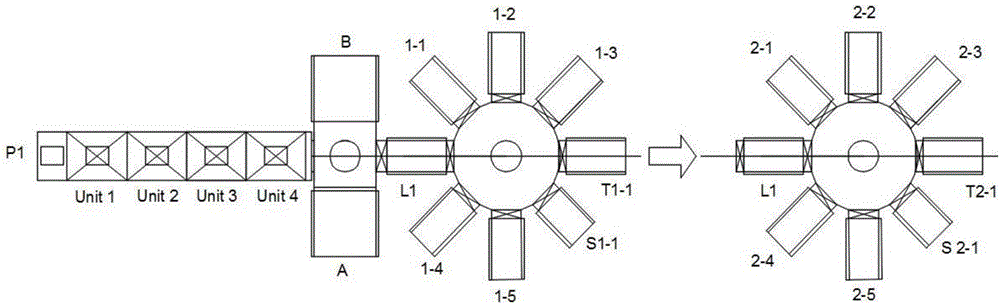

Motor driving algorithm debugging system and debugging method of electric vehicle driver

InactiveCN105938363ALow costFast debuggingElectric testing/monitoringCommunication interfaceElectric vehicle

The invention belongs to the debugging technical field and discloses a motor driving algorithm debugging system and debugging method of an electric vehicle driver. The debugging method includes an upper computer module, a simulator module, a driver motor driving control module and a motor driving algorithm debugging module; the signal interface of the motor driving algorithm debugging module is connected with the signal interface of the driver motor driving control module; the simulation interface of the driver motor driving control module is connected with the test interface of the simulator module; the communication interface of the driver motor driving control module is connected with the upper computer module; and the data interface of the simulator module is connected with the upper computer module. With the motor drive algorithm debugging system and debugging method of the electric vehicle driver of the invention adopted, the development, debugging and improvement of the driving algorithm of a motor can be completed in a short time. The debugging system and debugging method have the advantages of low cost as well as convenience and quickness in motor driving algorithm debugging of the electric vehicle driver.

Owner:GUANGZHOU SANJING ELETRIC

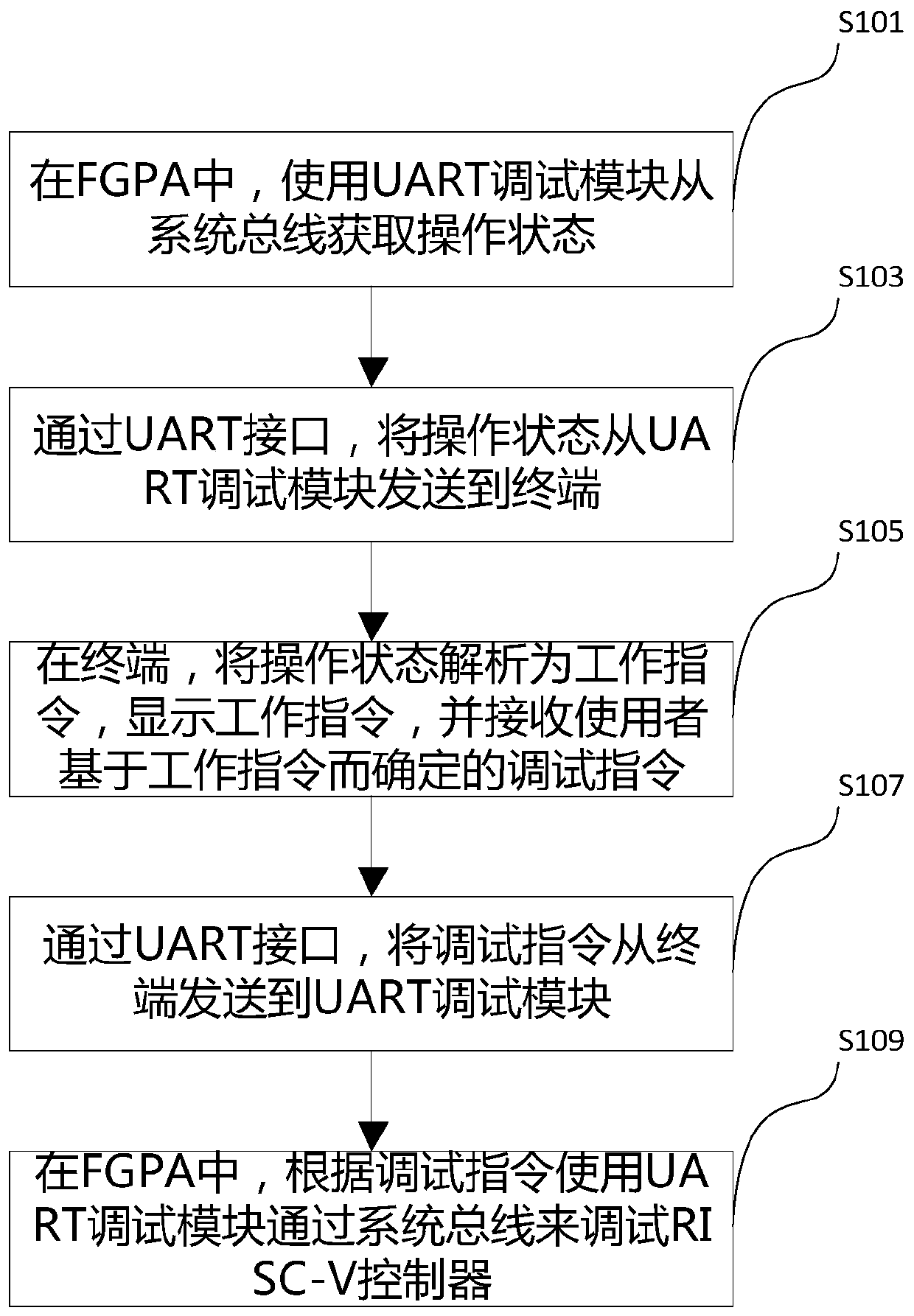

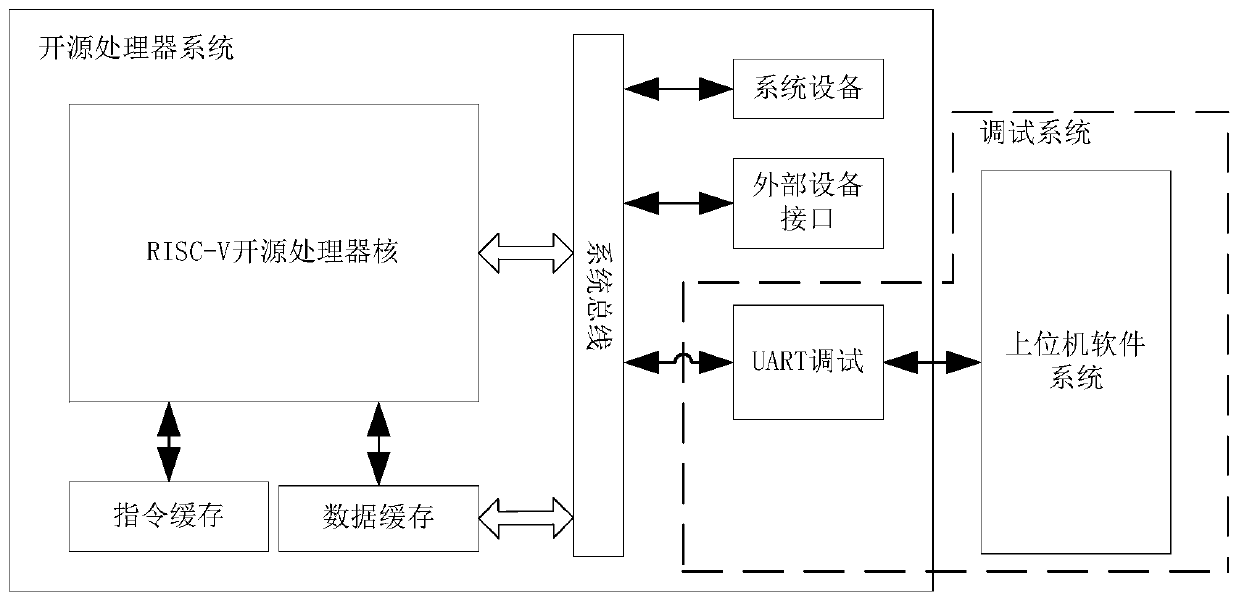

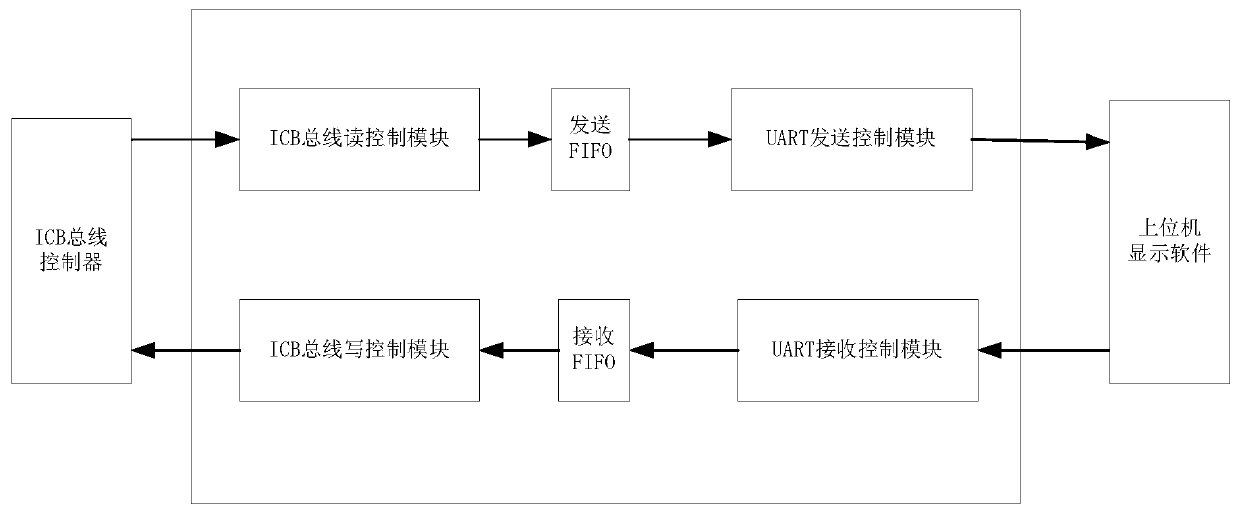

RISC-V controller debugging method and RISC-V controller debugging device based on UART

InactiveCN109783290AReduce the difficulty of debuggingFast debuggingDetecting faulty computer hardwareEmbedded system

The invention discloses a RISC-V controller debugging method and a RISC-V controller debugging device based on a UART. The method comprise: in an FGPA, an UART debugging module is used for obtaining the operation state from a system bus; The operation state is sent to the terminal from the UART debugging module through the UART interface; At the terminal, analyzing the operation state into a working instruction, displaying the working instruction, and receiving a debugging instruction determined by a user based on the working instruction; Sending the debugging instruction from the terminal toa UART debugging module through a UART interface; In FGPA, a UART debugging module is used to debug the RISC-V controller through a system bus according to a debugging instruction. The technical scheme provided by the invention can monitor or debug aiming at different RISC-V controller chips or RISC-V controller chips in different types, so that the debugging difficulty is reduced, and the debugging speed is increased.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

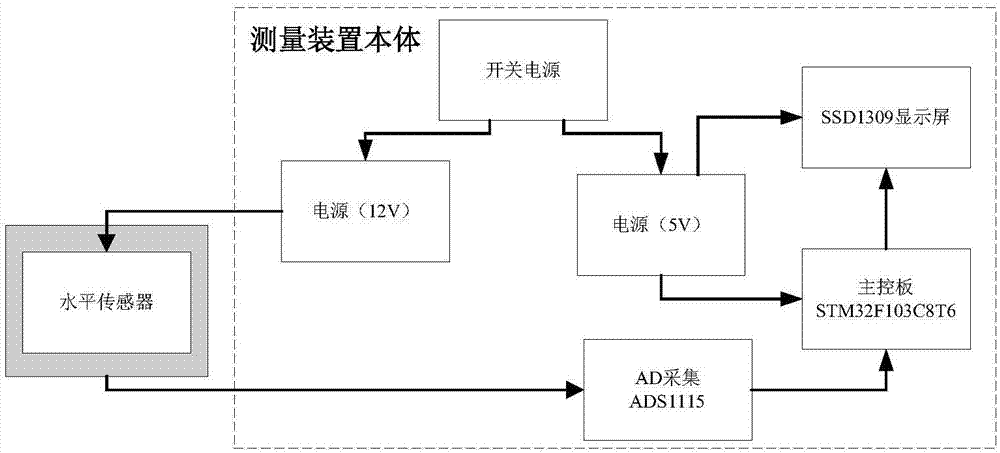

Method and device for detecting dual-axis horizontal precision

The invention relates to a method and device for detecting dual-axis horizontal precision. The method comprises the following steps: selecting measuring components according to leveling accuracy requirements of a measured objected and installation conditions of a measurement reference surface; arranging the selected measuring components, except a horizon sensor, in a housing to form a measurement device body, wherein the measurement device body is connected with the horizon sensor through a cable; and mounting the horizon sensor on a base and placed on the measurement reference surface, wherein the horizon sensor remotely transmits the collected analog signal via a cable to the measurement device body for data processing and display to realize horizontal measurement. The method can realize detection of a double-axis horizontal precision value in real time under severe conditions, and can meet measurement of a narrow space; and when the measurement reference surface is high, operation personnel can measure the horizontal precision of the reference surface without climbing, thereby improving detection speed of horizontal precision of the measured object and improving operation safety.

Owner:BEIJING MECHANICAL EQUIP INST

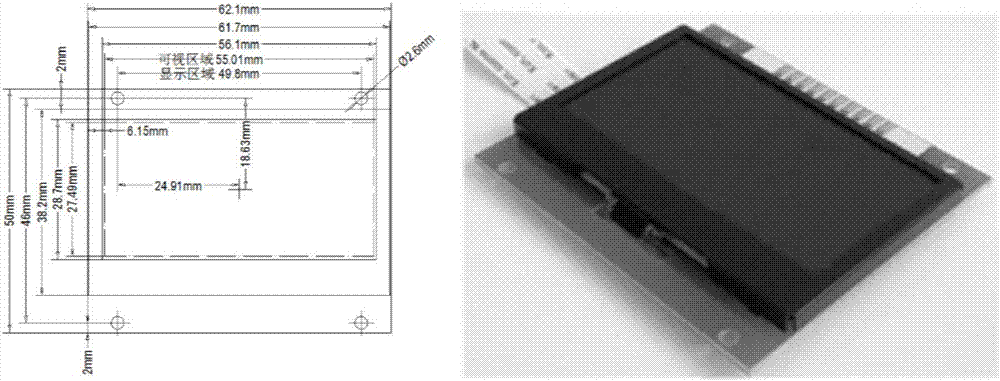

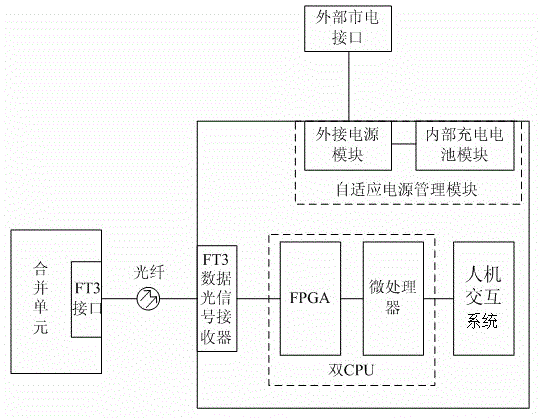

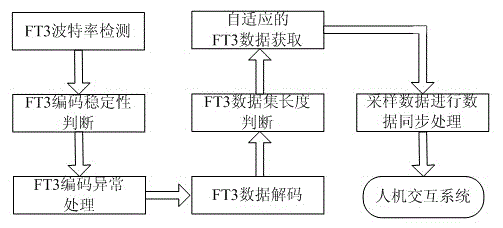

Intelligent substation phase approval device capable of adaptively receiving FT3 transport protocols

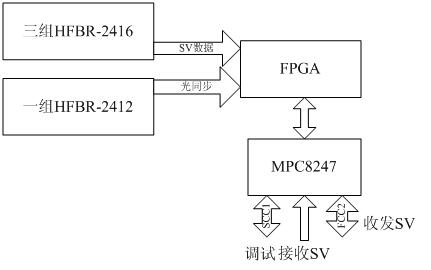

InactiveCN103336176ARealize the sample receiving functionCapable of receivingProgramme controlComputer controlMessage lengthLoop design

The invention discloses an intelligent substation phase approval device capable of adaptively receiving FT3 transport protocols, which comprises an FT3 data optical signal receiver connected with an FT3 interface of a merging unit in an intelligent substation, double CPUs (Central Processing Units) connected with the FT3 data optical signal receiver, a man-machine interactive system, and an adaptive power supply management module connected with an outside electric supply interface. The device has the benefits that 1, compatible hardware loop design is adopted, the FT3 sample data transport protocols at different transport baud rates and message lengths are identified by software automatically, additional configuration of a user is not required, and the device can adaptively perform communication monitoring and decoding on sample data in an FT3 format, and achieves sampling and receiving functions on the FT3 data; 2, the device can receive various sample data in the intelligent substation; and 3, the sample data is accurate and real-time.

Owner:HUNAN XIANGDIAN POWER TEST & RES TECH LTD +2

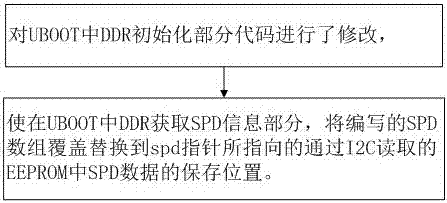

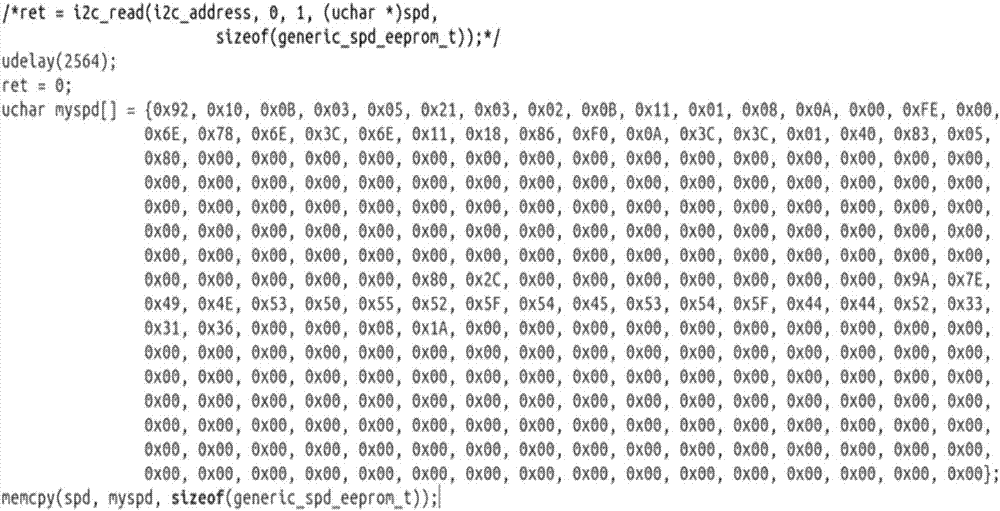

Method for quickly debugging DDR memory grains through U-Boot

InactiveCN107122279ASimplify the commissioning processFast debuggingFunctional testingFaulty hardware testing methodsArray data structureComputer engineering

The invention discloses a method for quickly debugging DDR memory grains through U-Boot, and relates to the relevant technical field of memory debugging. The method modifies initialization part codes of the DDR in the U-Boot so as to obtain the SPD information part by the DDR in the U-Boot, and overlay and replace the written SPD array to the SPD-pointer-pointing and read-by-I2C save position of the SPD data in EEPROM, so as not to conduct programme on the EEPROM every time, thereby accelerating the debugging speed.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

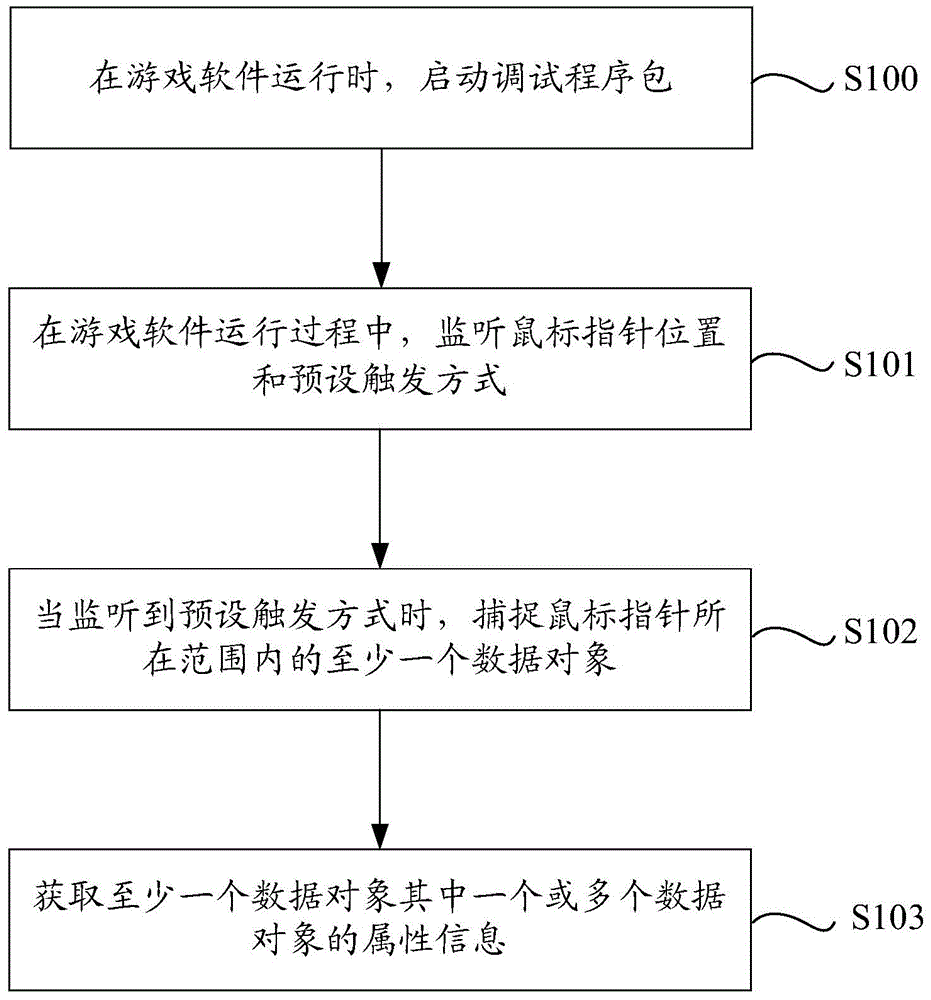

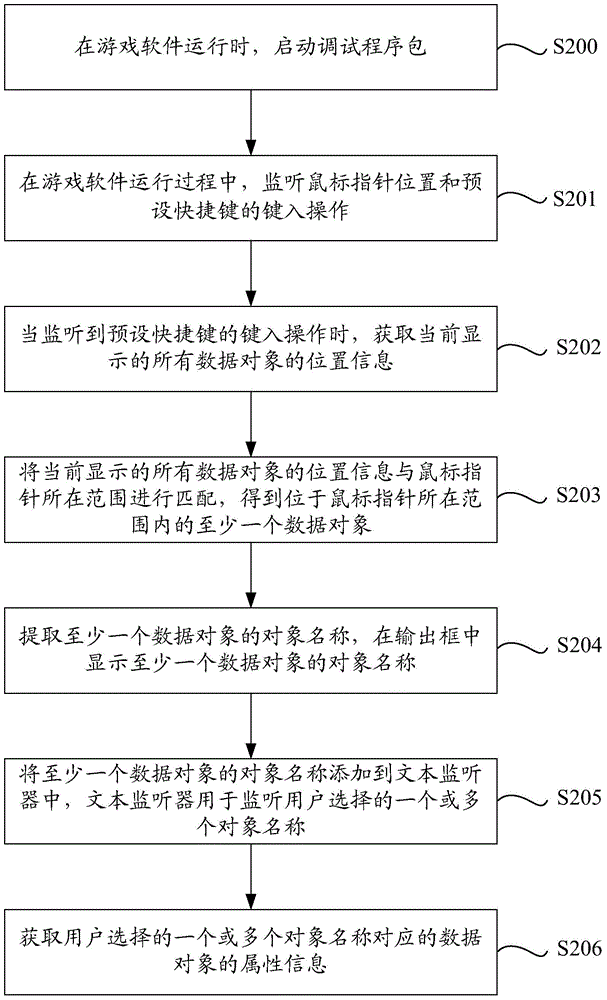

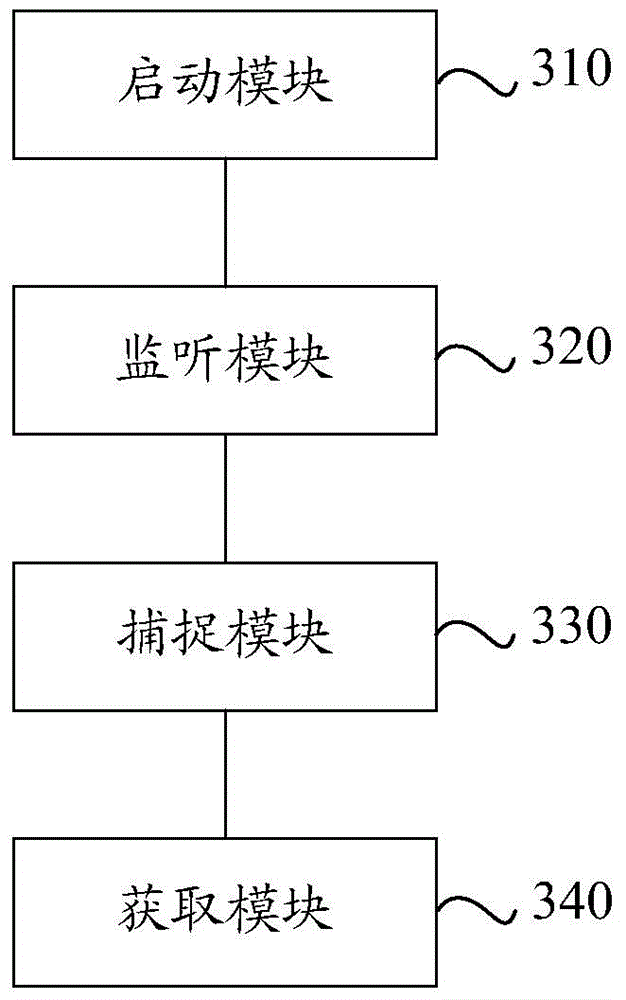

Game data dynamic object capture method and device

InactiveCN104899148AFast debuggingOptimize debugging methodHardware monitoringSoftware testing/debuggingData objectsSoftware engineering

The invention discloses a game data dynamic object capture method and device. The method is used for capturing data objects in the game software operating process, and a debugging program package is pre-registered in the game software. The method includes when the game software operates, starting the debugging program package; in the game software operating process, monitoring the mouse pointer position and a preset triggering manner; when the preset triggering manner is monitored, capturing at least one data object in the range of the mouse pointer; acquiring the attribute information of one or multiple data objects of the at least one data object. By means of the technical scheme, a user can capture the data object in the range of the mouse pointer dynamically in the game software operating process, the game software debugging speed is increased, and the game debugging method is optimized.

Owner:BEIJING QIHOO TECH CO LTD +1

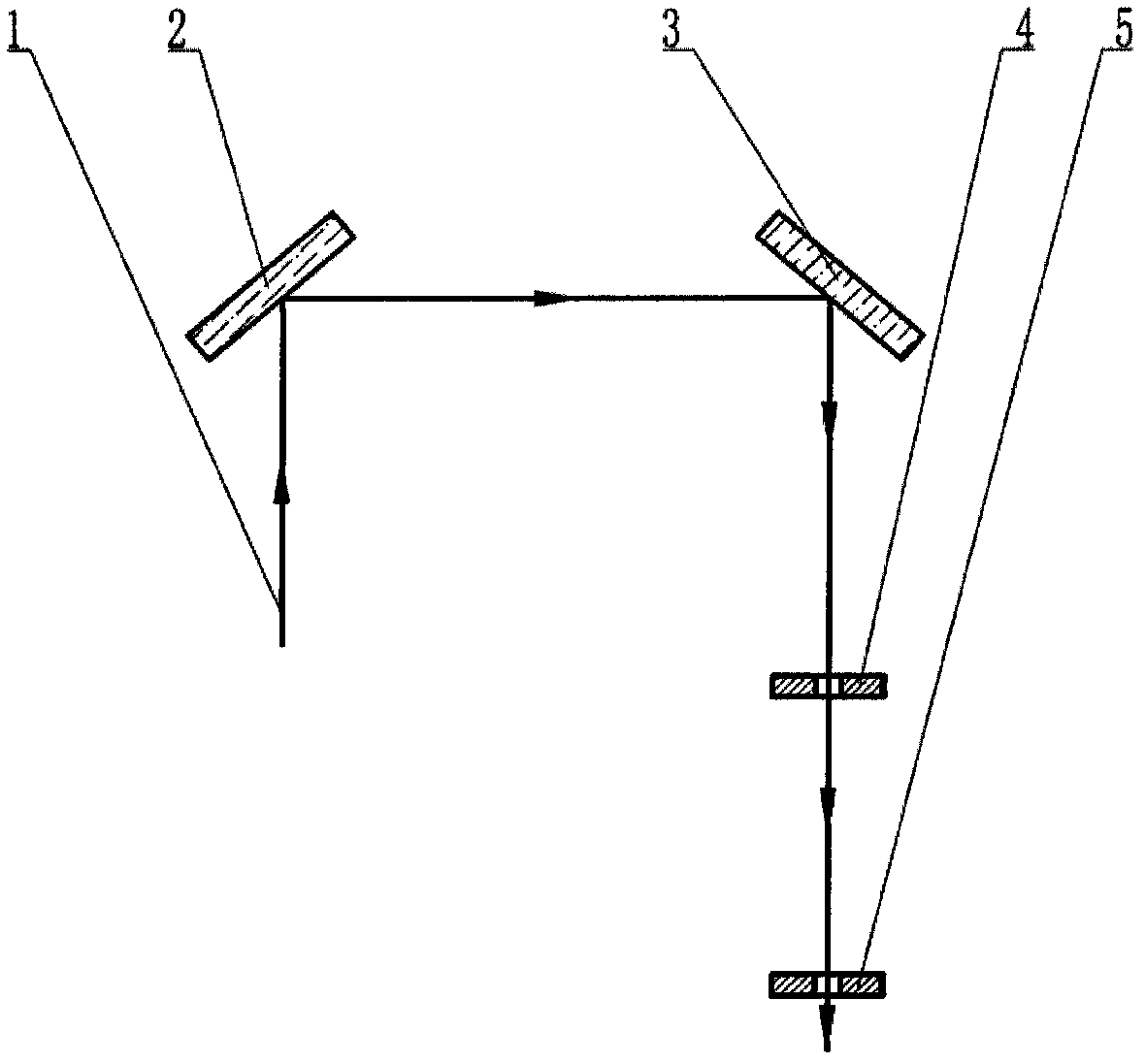

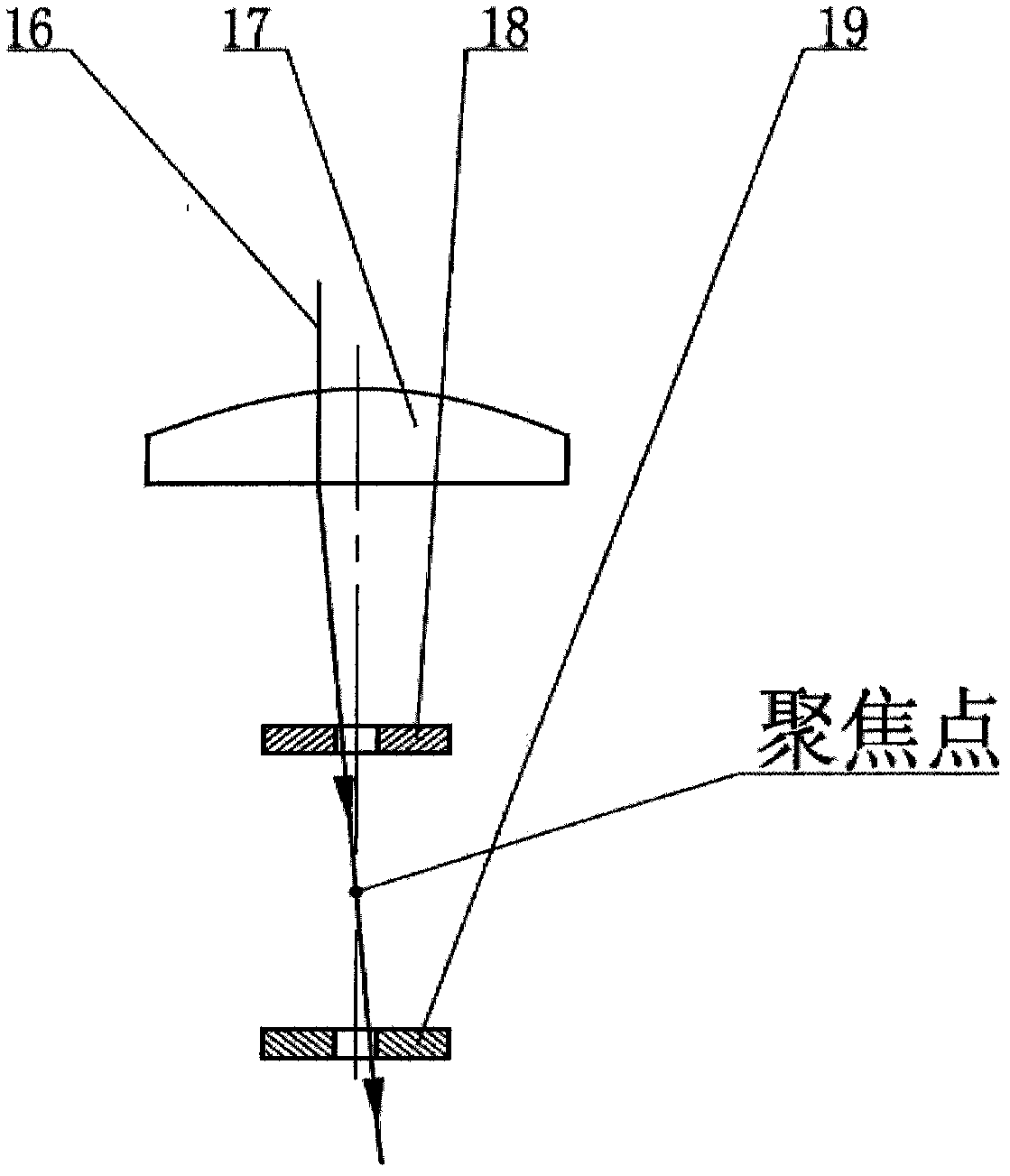

Method for precisely locating laser beam space

ActiveCN102279455AFast debuggingReduce geometric tolerance requirementsMountingsOptoelectronicsLaser beams

The invention relates to a method for precisely locating a laser beam space, wherein at least one laser beam is incident to a first reflector; the first reflector reflects the laser beam to a second reflector; the second reflector reflects the reflected laser beam; therefore, the laser beam reflected by the second reflector passes through a tooling hole in a corresponding tooling set; the preciselocation of the laser beam is realized; the number of the laser beams is same as the number of the tooling sets; the tooling set comprises a first tooling and a second tooling; the hole centre of thefirst tooling and the hole centre of the second tooling are on the same straight line; and the straight line is vertical to the hole bottom surface of the first tooling.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

Panoramic sunroof guide rail arc pressing all-purpose die

PendingCN107790559AFast debuggingStable productionShaping toolsMotor vehicle partStructural engineering

The invention relates to a panoramic sunroof guide rail arc pressing all-purpose die, and belongs to the field of automobile component machining equipment. The panoramic sunroof guide rail arc pressing all-purpose die comprises an upper die body and a lower die body. The upper die body comprises two upper pressing block assemblies, and the lower ends of the upper pressing block assemblies can be adjusted to a certain radian. The lower die body comprises lower die block assemblies matched with the lower die body. By means of the panoramic sunroof guide rail arc pressing all-purpose die, multiple types of automobile sunroof guide rails can be produced, meanwhile, the debugging speed is high, and production is safe and stable.

Owner:SHANGHAI MOBITECH AUTO PARTS

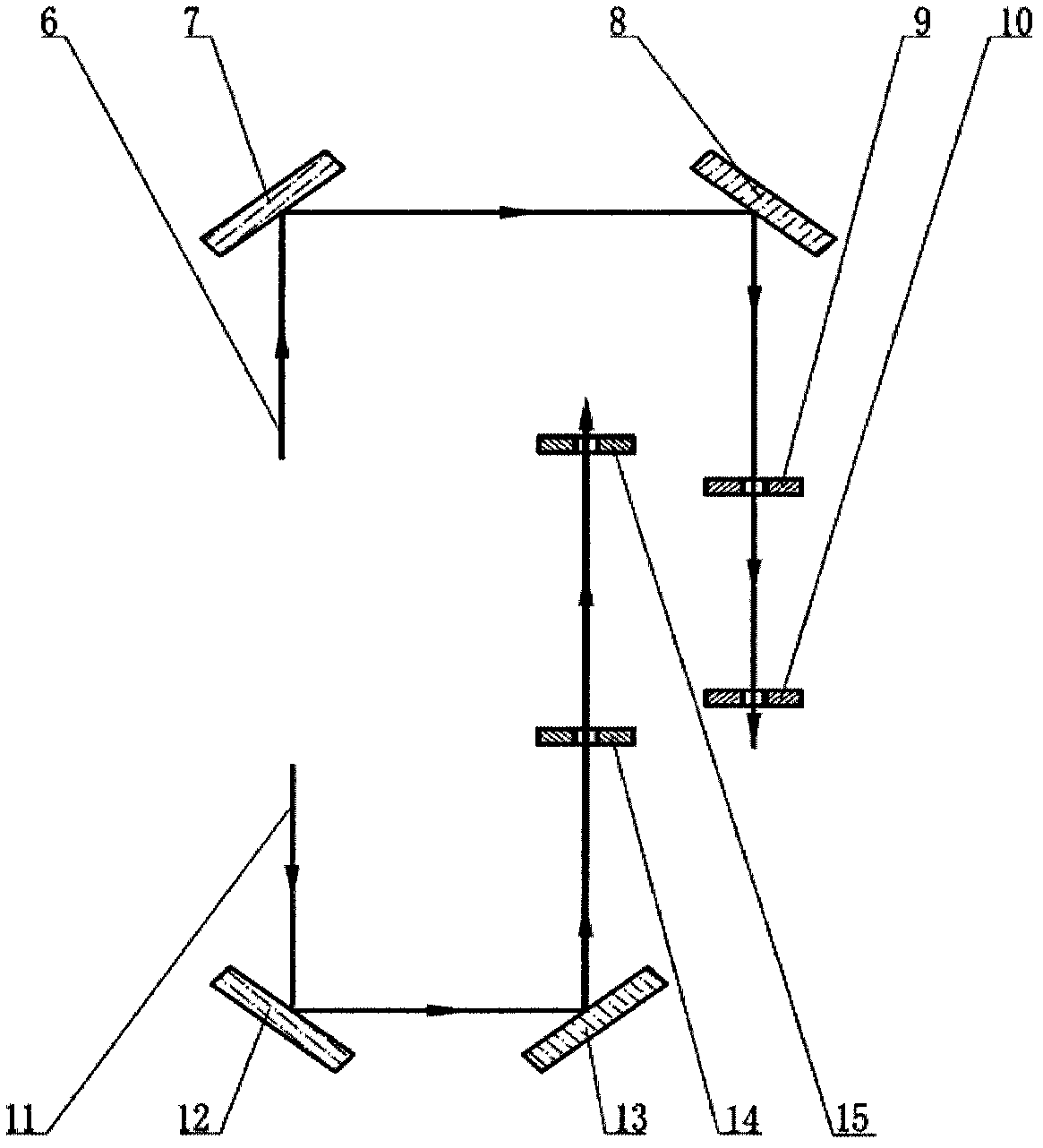

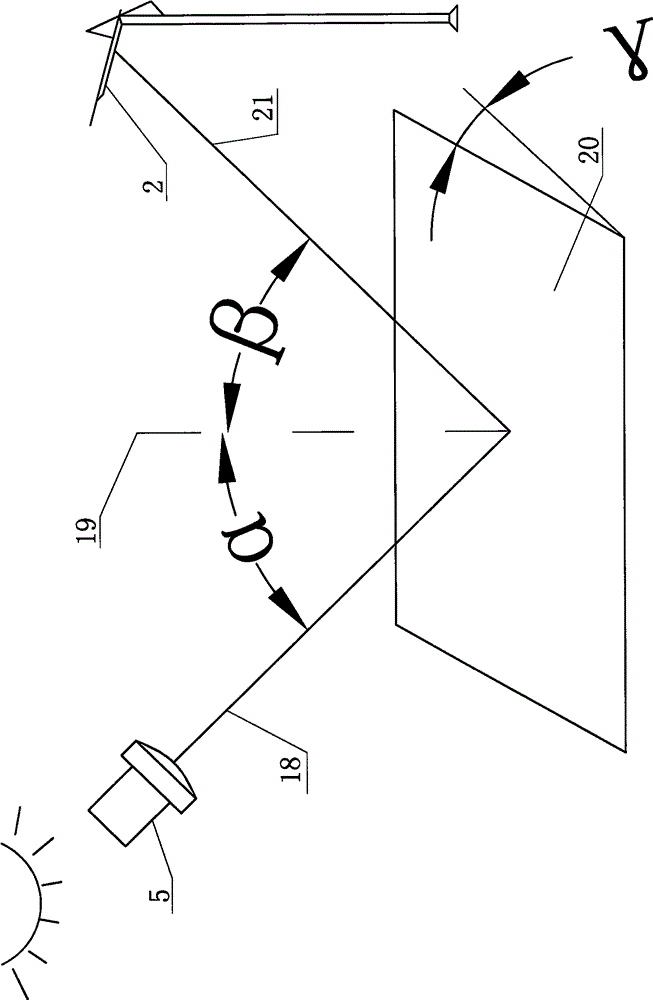

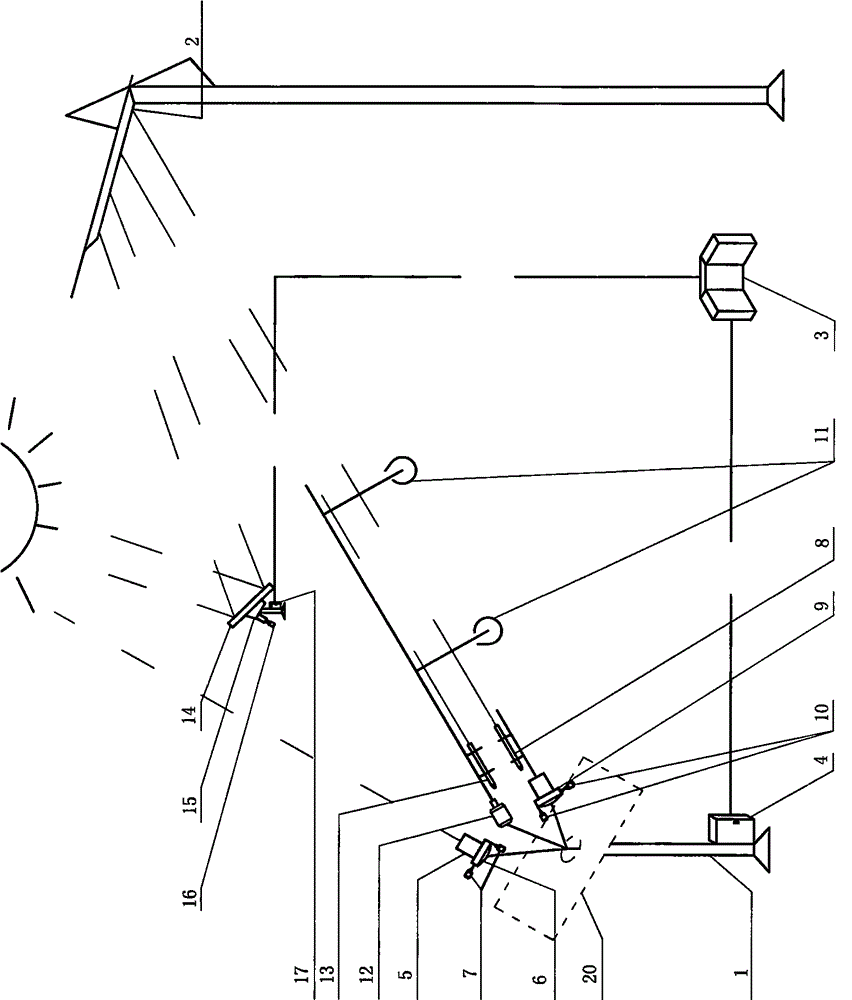

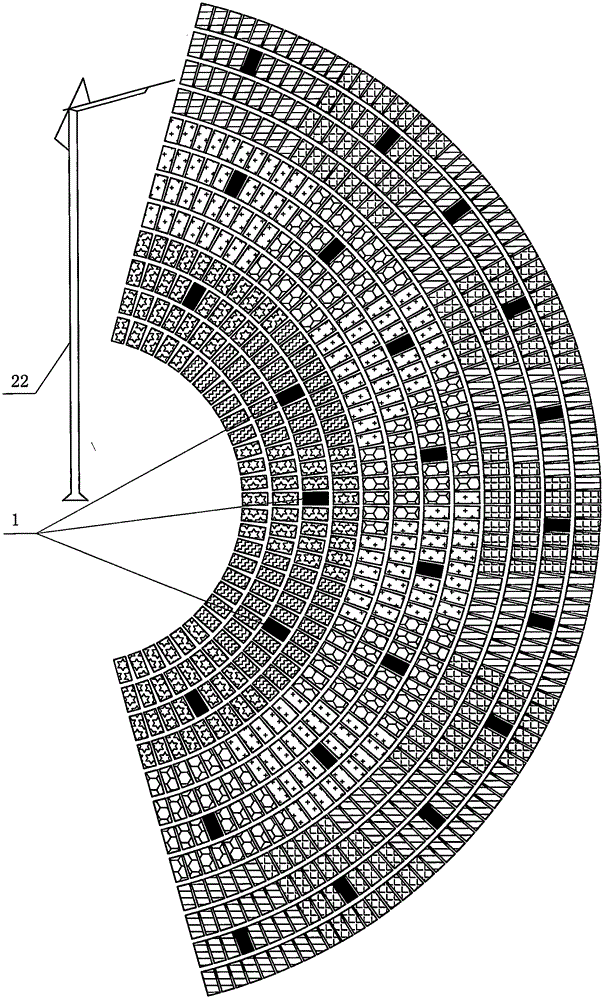

Group-control solar high-temperature thermal power generation thermal-arrest control system

InactiveCN104990284AFast debuggingFast installationSolar heating energySolar heat devicesHeliostatControl system

The invention provides a group-control solar high-temperature thermal power generation thermal-arrest control system, and belongs to the technical field of solar thermal power generation thermal-arrest control. The system mainly comprises a plurality of reference piles (1), a plurality of driven lens groups, a convergence lens (2) used to converge sunshine reflected by a driven lens field, and an upper computer controller (3) receiving information of deflection angle, and solar incidence angle ([alpha]), solar emergence angle ([beta]), and deflection angle ([gamma]) of each holder in real time, the information being uploaded by the reference piles (1), and the information is distributed and transmitted to a controlled driven lens group. The system can determine positions of sunlight on the convergence lens (2), the sunlight being reflected by the reference piles (1), and adjusts angles of the driven lenses according to the position, so that angles of the driven lenses are more accurate. In the control system, a sensing device is not needed to be installed on each heliostat, so cost is reduced, and maintenance ratio is reduced. The heliostat does not need to be installed in high precision, so installation and debugging speed of the lens field is improved.

Owner:王斌

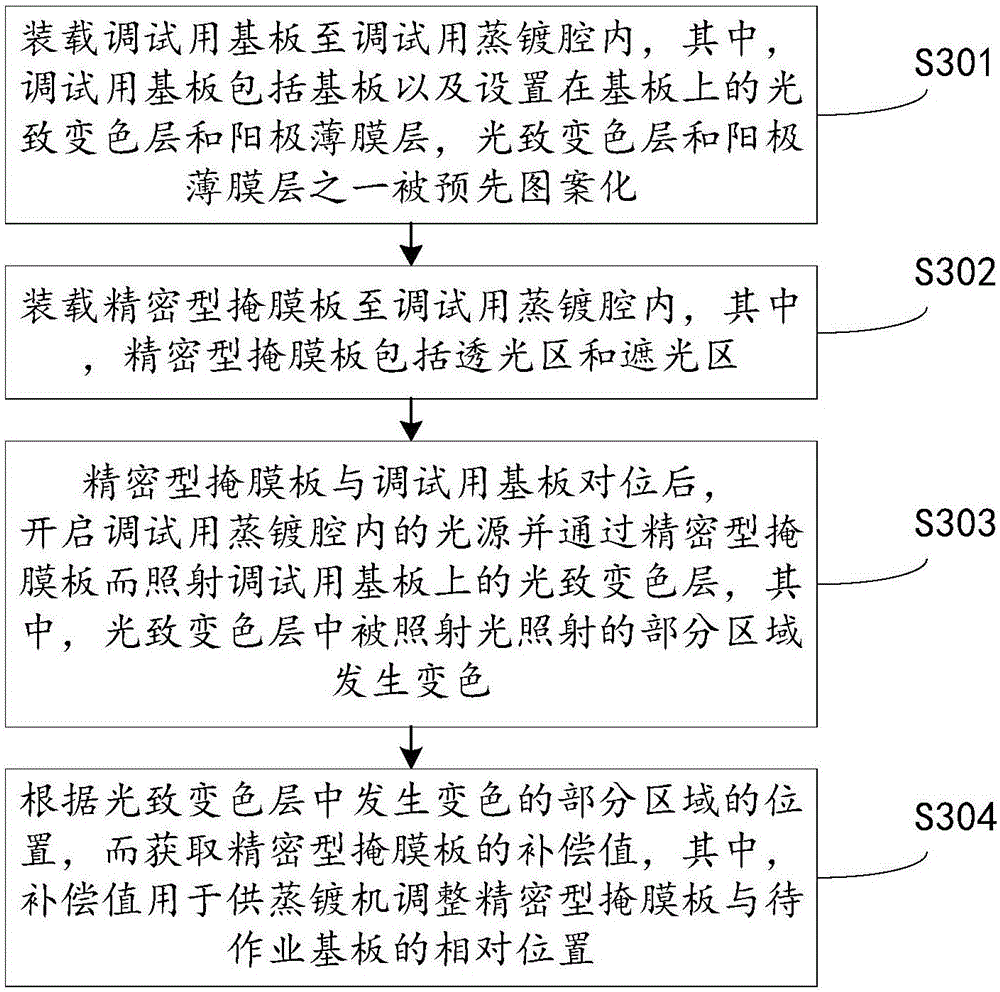

Debugging method and thermal evaporator

The invention discloses a debugging method and a thermal evaporator. The method is used for adjusting the relative position of a precise mask plate and a substrate to be operated and includes the steps that the debugging substrate is loaded into a debugging evaporation cavity; the precise mask plate is loaded into the debugging evaporation cavity; a light source in the debugging evaporation cavity is started and further irradiates a photochromic layer on the debugging substrate through the precise mask plate, and the color of the partial region irradiated by irradiation light in the photochromic layer is changed; and the compensation value of the precise mask plate is obtained according to the position of the partial region with the color being changed in the photochromic layer. By adoption of the method, organic materials can be omitted during adjustment, and the debugging speed is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

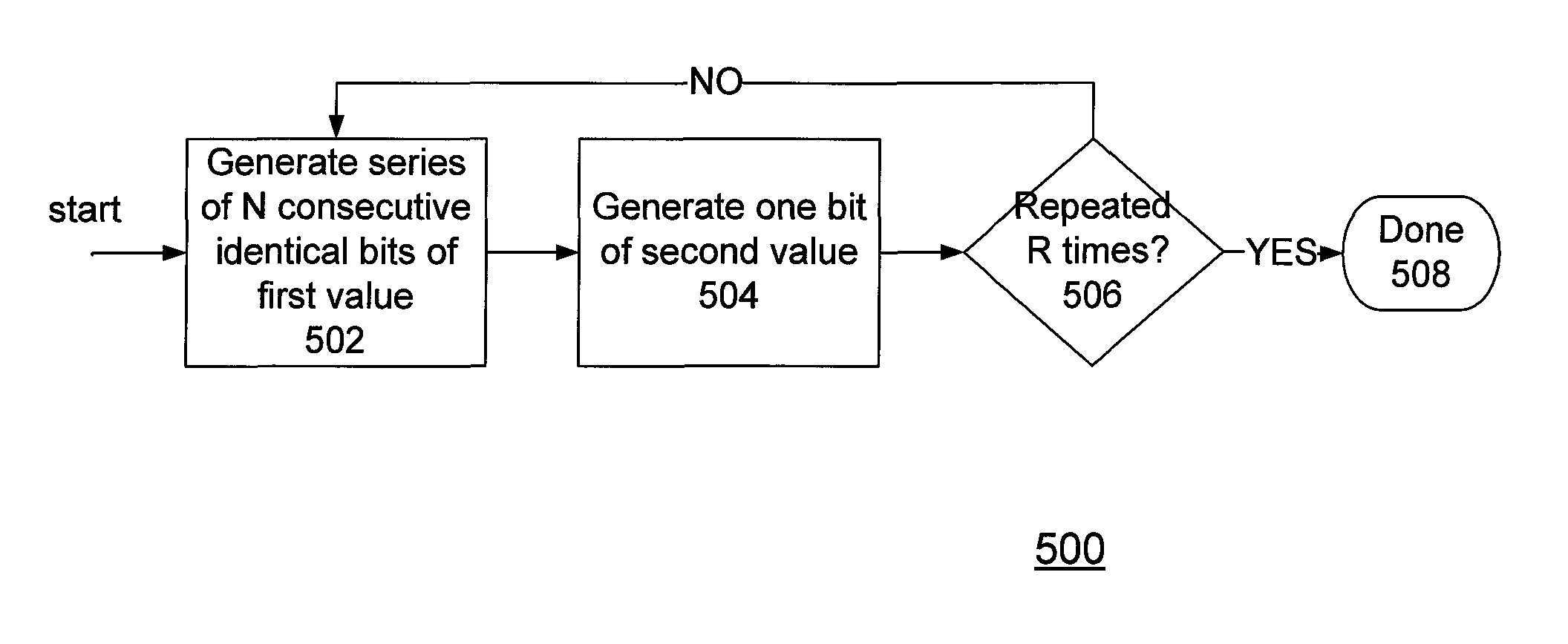

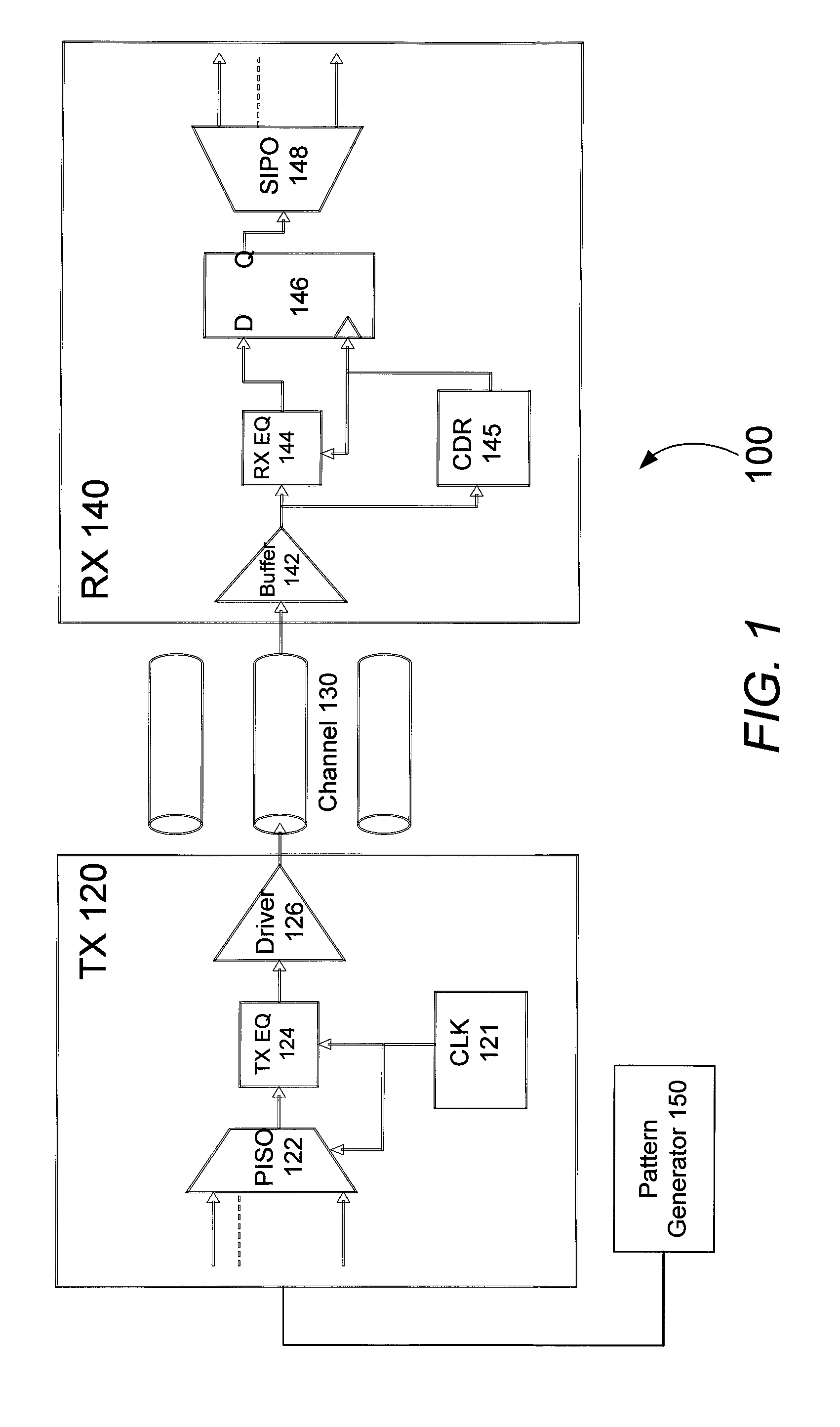

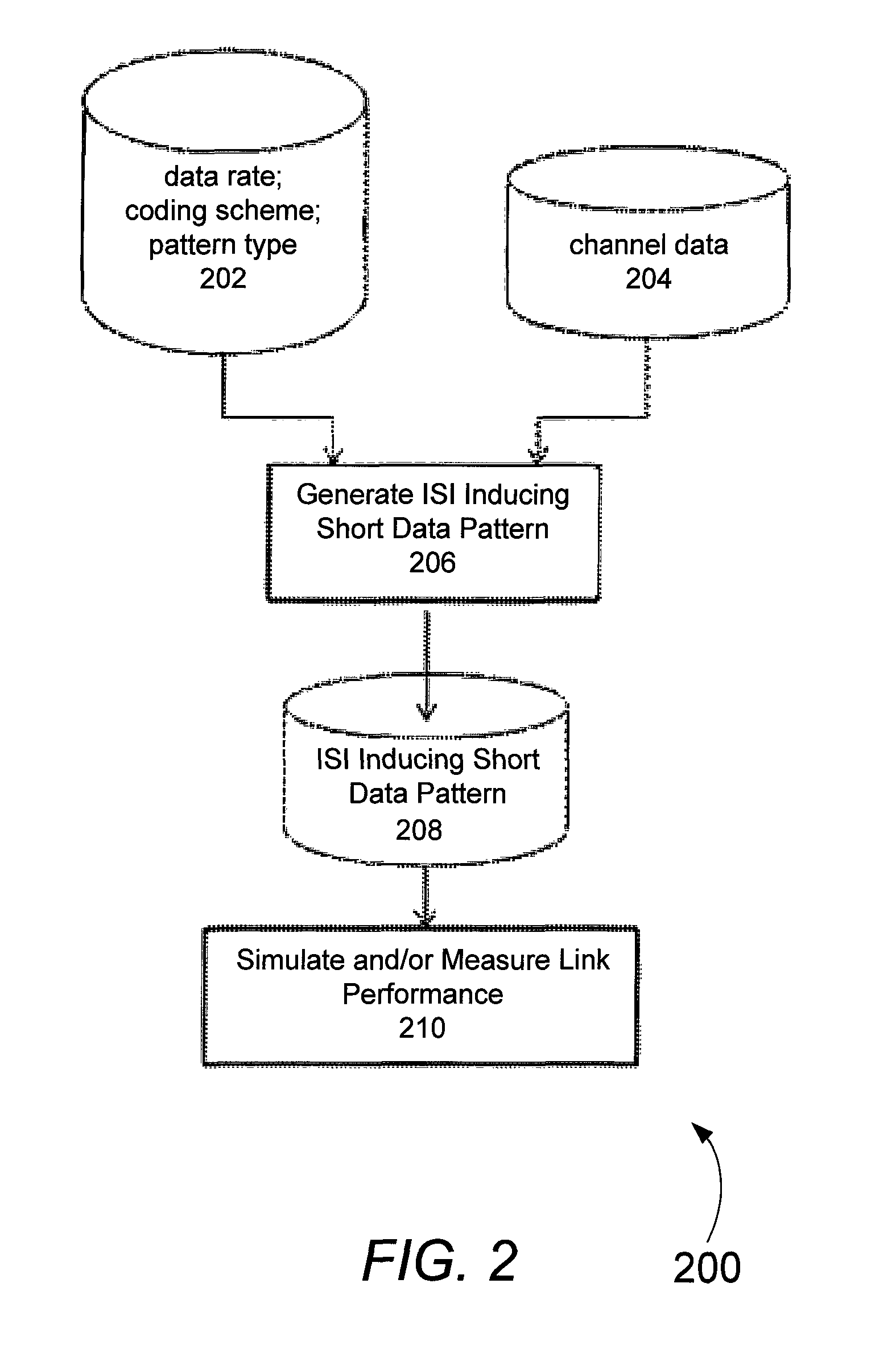

Methods and apparatus for generating short length patterns that induce inter-symbol interference

ActiveUS9177087B1Improve good performanceShort simulationAnalogue computers for electric apparatusCAD circuit designCommunication linkBinary clock

One embodiment relates to a method of generating worst case inter-symbol interference (ISI) inducing short patterns for simulating and / or testing a communication link. The method includes the generation of a binary clock sequence comprising bits of alternating values at the beginning of the pattern. In addition, an ISI inducing binary sequences and its complement are generated after the clock sequence. Another embodiment relates to a pattern generator for generating an worst case inter-symbol interference inducing short pattern for testing a communication link. Other embodiments, aspects, and features are also disclosed.

Owner:ALTERA CORP

Horizontal machining central base plate for quickly replacing fixture

The invention discloses a horizontal machining central base plate for quickly replacing a fixture. The horizontal machining central base plate comprises a base plate body and is characterized in that positioning holes for quick positioning are arranged on the base plate body. The fast positioning holes are added on the base plate positioned by an equipment workbench according to the fixture design principle, and the fixture is quickly positioned according to the fixture design principle of 'six degrees of freedom'. Therefore, a previous coordinate system and length correction of a cutter are used entirely and conveniently for next processing, equipment can be directly started for processing and cutting, a plurality of adjustment procedures are completely omitted, debugging speed of processing is greatly increased, and the first purpose of lean production is typically achieved.

Owner:江苏迅隆科技发展有限公司

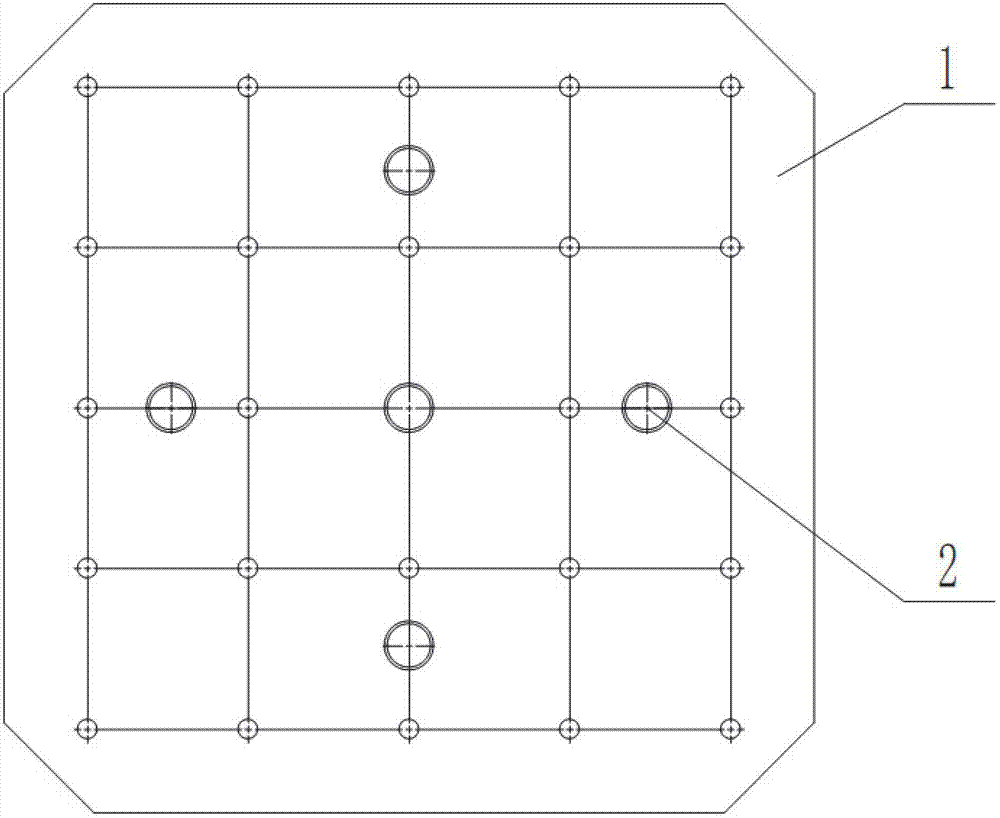

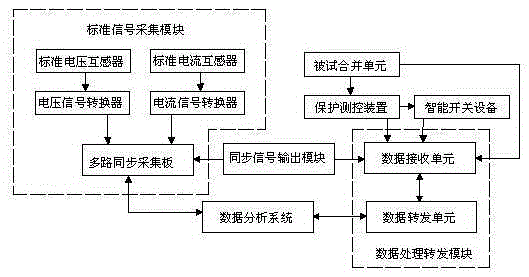

Intelligent transformer substation system grade time characteristic testing device

InactiveCN105376119AFast debuggingSafe and stable operationData switching networksSmart substationTransformer

The invention discloses an intelligent transformer substation system grade time characteristic testing device, comprising a data transmission system and a data analysis system. The data transmission system comprises a standard signal collection module, a data processing forwarding module and a synchronization signal output module; the standard signal collection module and the data processing forwarding module are connected to a data analysis system; and the output terminal of the synchronization signal output module is connected to the input terminals of the standard signal collection module and the data processing forwarding module. The invention can realize the time characteristic test on a merging unit to be tested, a protection measurement control device and an intelligent switch device, greatly improves the conditioning speed of the intelligent transformer substation, provides good technical guarantee to the development of the intelligent transformer station, and lays solid foundation to safety stable operation of the intelligent transformer station.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com