Testing and verifying system appropriate for intelligent transformer substation and verifying method

A technology of intelligent substation and verification method, which is applied in the field of detection/verification of intelligent substations of power systems and digital substations, and achieves the effects of good safety, convenient operation and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

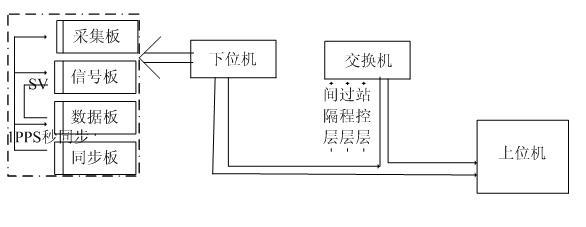

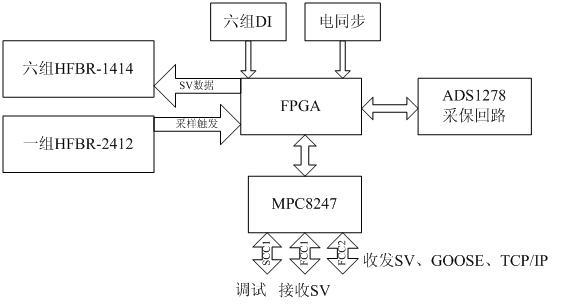

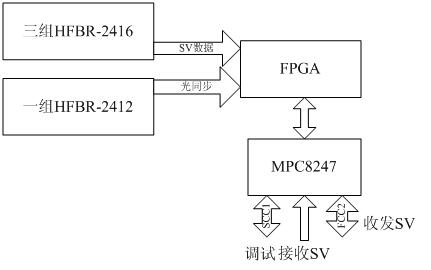

[0034] The lower computer of the embedded system adopts a standard 4U industrial chassis, and the acquisition board, signal board, data board, and synchronization board are arranged horizontally in layers. The front end of the device is equipped with input or receiving terminals, power switch, test function selection dial code and device operation status indication, and the rear end is equipped with FT3, optical fiber Ethernet, and synchronous pulse output terminals. The lower computer of the embedded system is connected to the upper computer of the PC through an industrial switch through an RJ45 twisted pair. The acquisition board exchanges sampling data and obtains working power with the PC h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com