High-speed array chip mounter

An array type, placement machine technology, applied in electrical components, electrical components and other directions, can solve the problems of multi-time, overall placement efficiency reduction, waste, etc., to achieve high adjustment accuracy, improve debugging speed, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

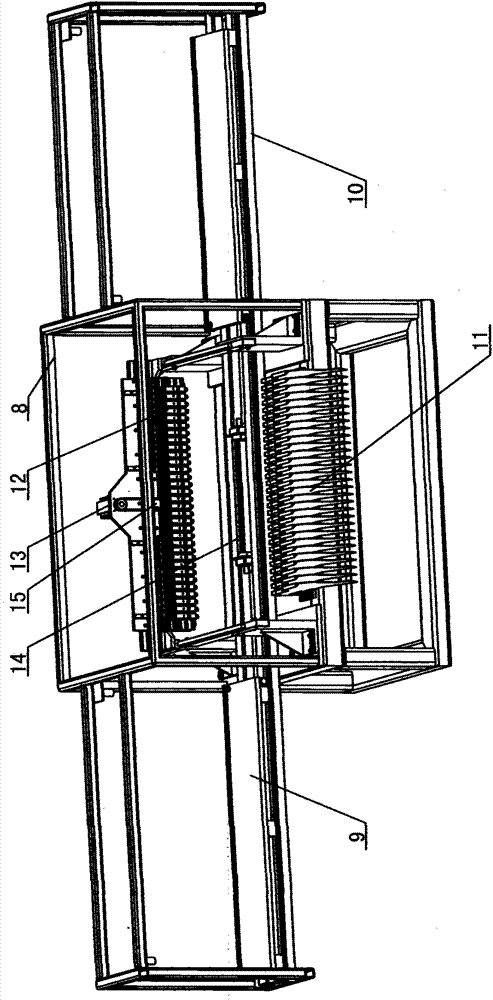

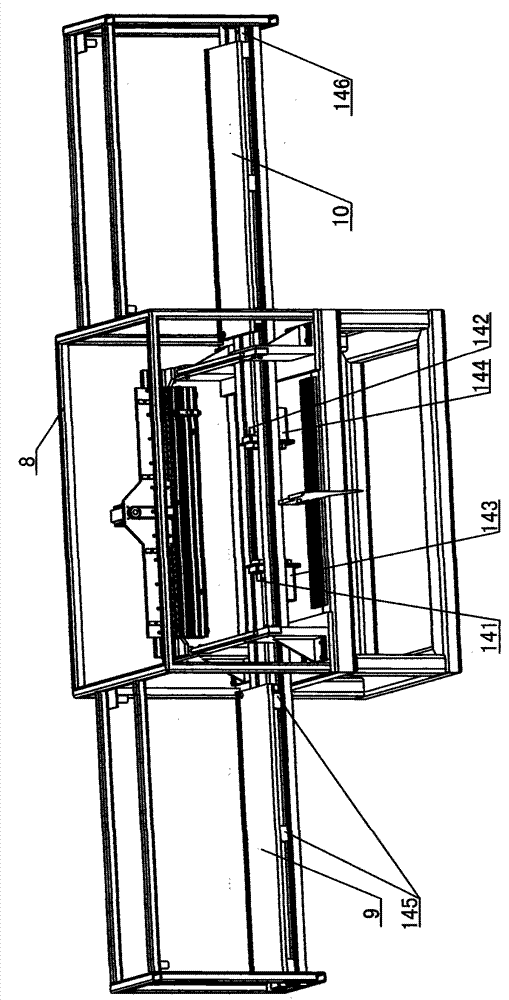

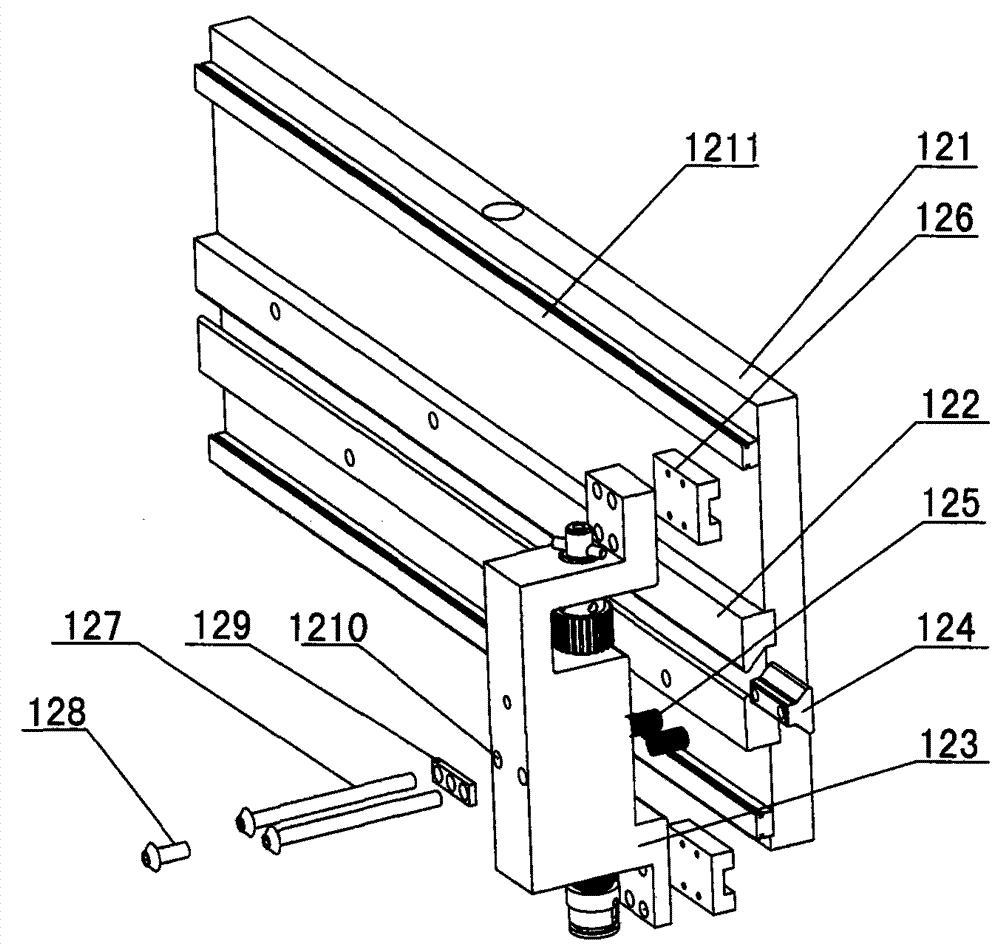

[0033] like figure 1 , Figure 4 As shown, the high-speed array placement machine described in the embodiment of the present invention includes a placement frame 8, and a left pallet 9 and a right pallet 10 are laid horizontally on both sides of the chip frame 8 respectively, located on the left Camera III6 is installed above the connecting position of pallet platform 9 and placement frame 8, and camera IV7 is installed on the frame above the outer end of pallet platform 9 on the left side, and the diagonal reference point of the circuit board is picked up diagonally downwards (can be opposite to Find a pad at the corner) After aligning with the cross coordinate line of the camera, fix the position of the circuit board and send it to the machine for placement, so as to ensure that the position of each circuit board sent into the machine is consistent and achieve accurate placement;

[0034] Two cameras are arranged at the position where the right supply pallet 10 meets the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com