General sequence control algorithm used in programmable logic controller

A programming controller and sequence control technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as organizational structure, different address configuration, irregular modification process, parasitic logic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

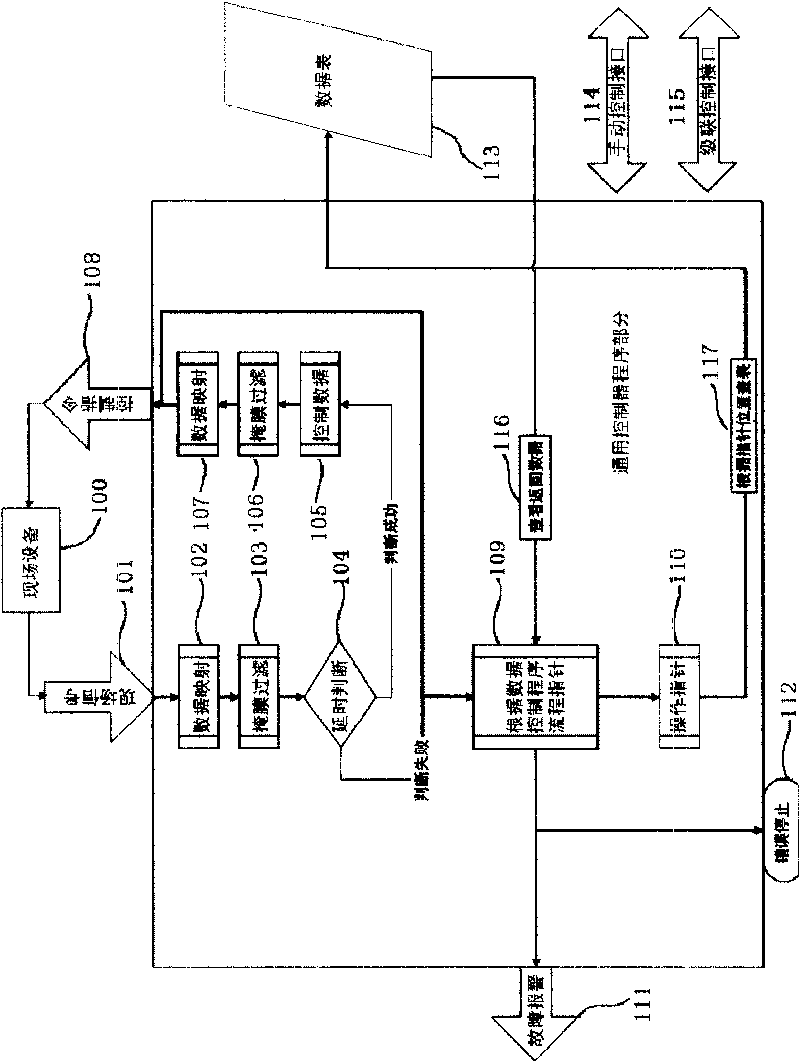

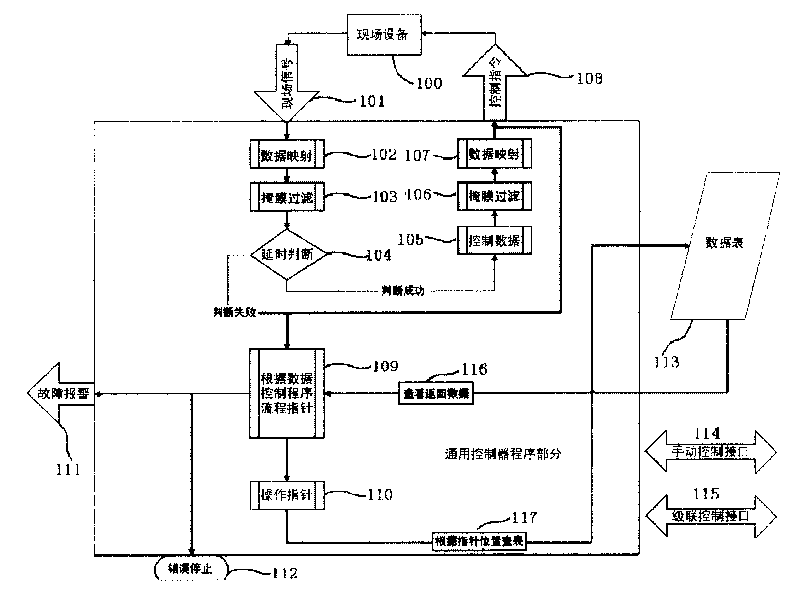

[0039] Such as figure 1As shown, the switching or analog input signal 101 from the field device 100 is connected to the input interface of the programmable controller, and the programmable controller converts the switching or analog input signal 101 into a switching signal, and converts the switching signal according to The bit is assigned to the storage register, and the switching signal assigned to the storage register forms an input status word related to the input signal bit to complete the data mapping step 102 . That is to say, each bit of the status word of the controller corresponds to one field signal, and each bit of the status word maps one field signal. The data mapping step 102 is actually to establish an address conversion rule between the I / O address and the input and output interfaces of the controller under the condition of determining the specific hardware I / O input and output addresses of the controller. After completing the data mapping step 102, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com