Water tightness test device for electronic equipment case

A test device and electronic equipment technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of cumbersome, labor, and unstable placement of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

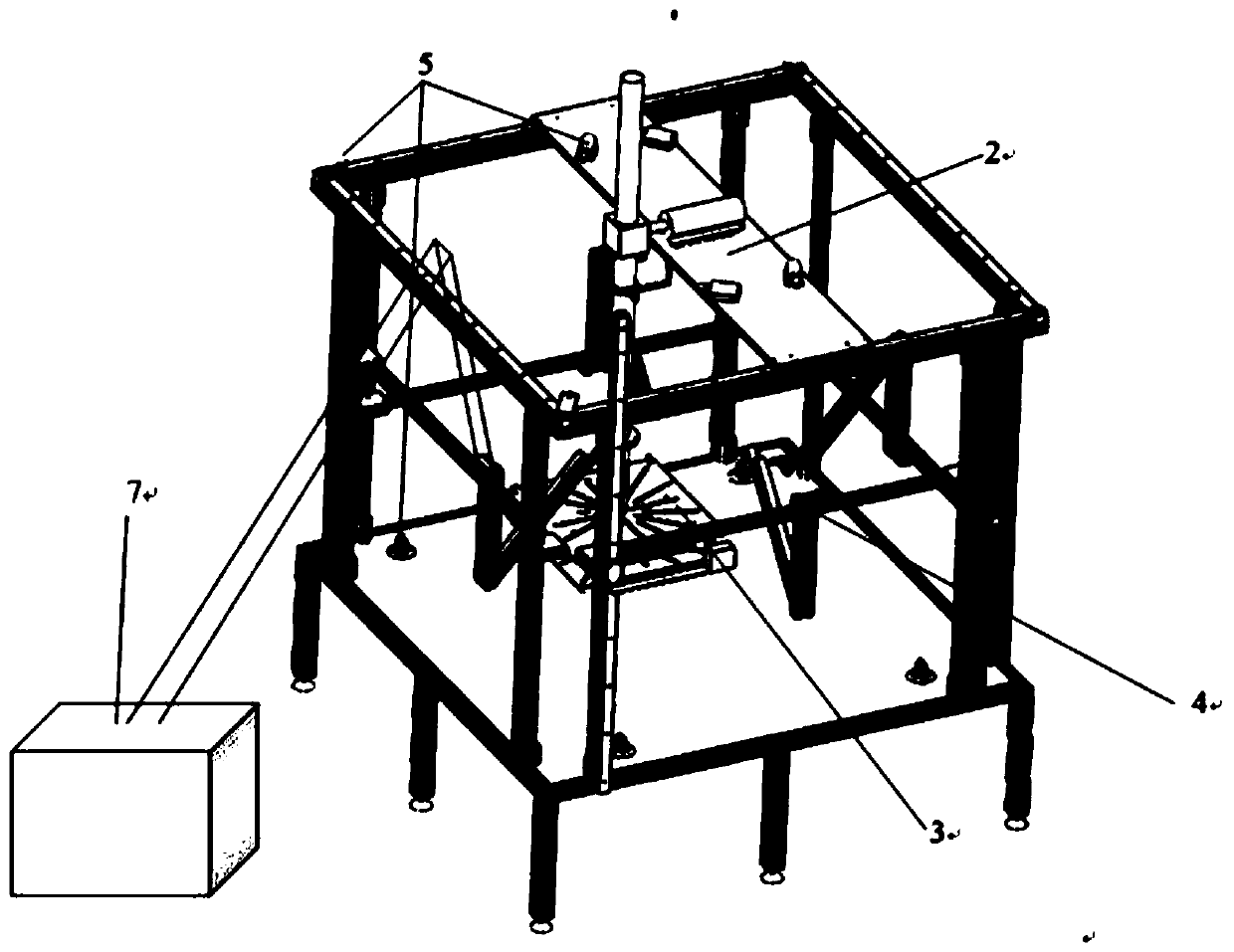

[0027] According to the attached Figure 1-5 The present invention is described further:

[0028] The overall test conditions of the watertightness test device for electronic equipment chassis are divided into dripping, flushing and submerged working states. The specific implementation plan is as follows:

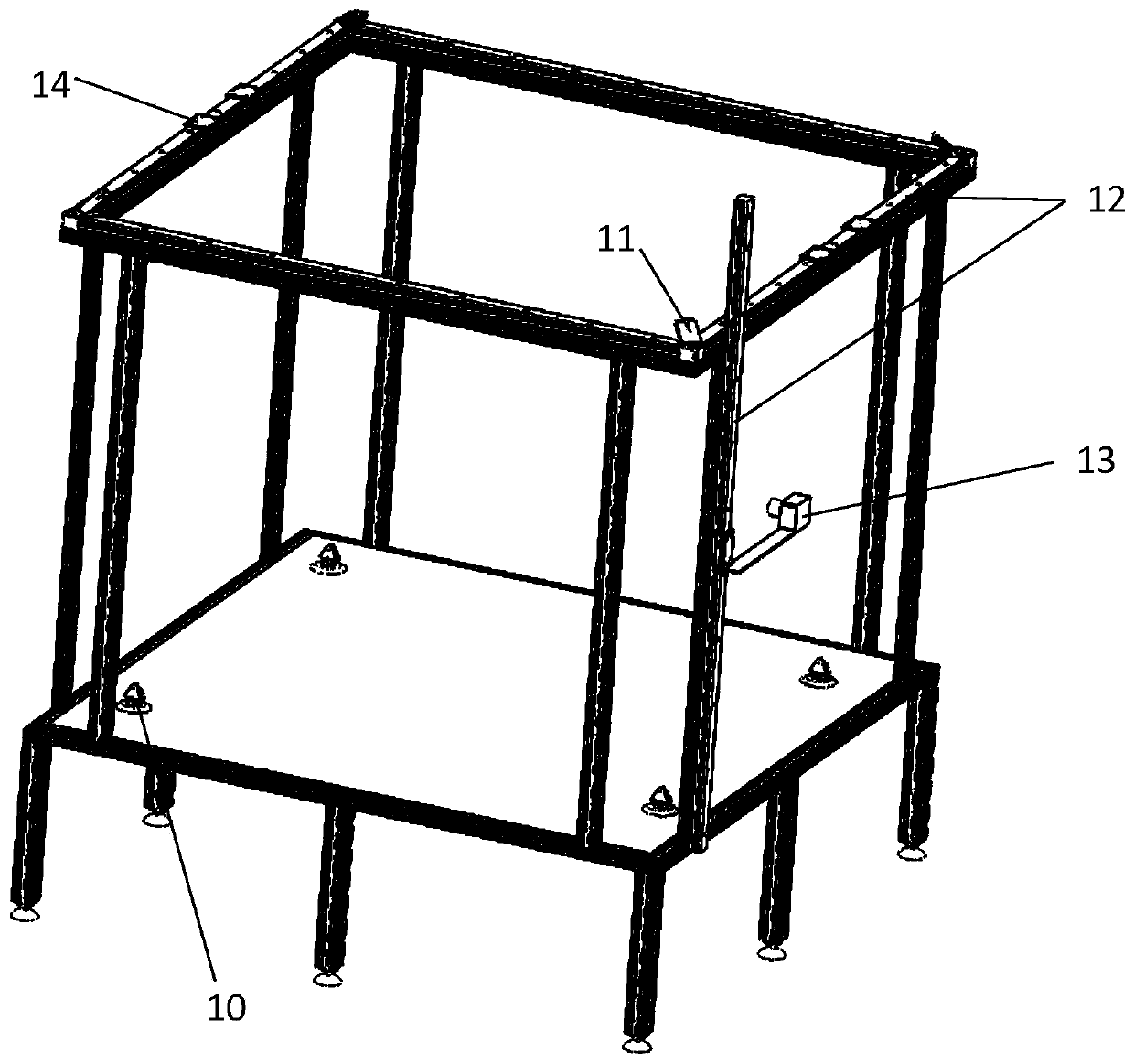

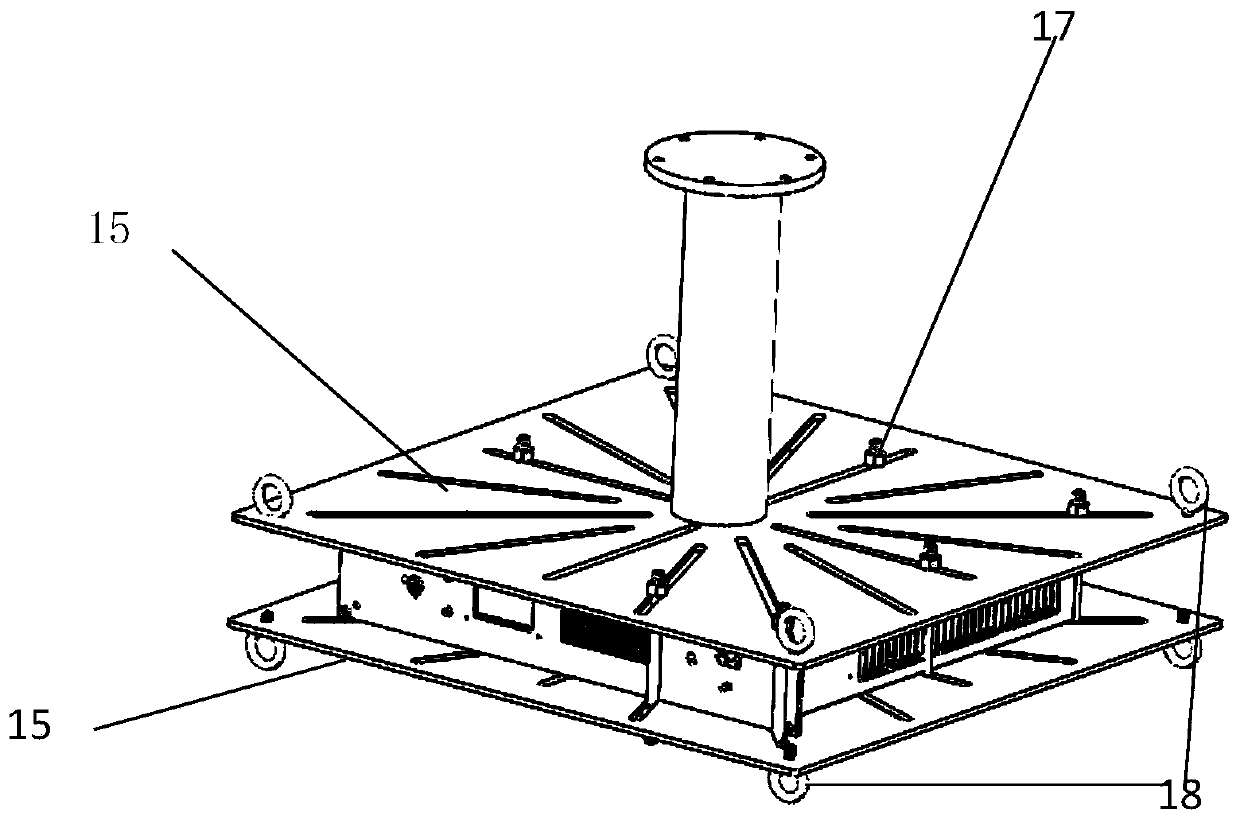

[0029] A watertight test device for an electronic equipment case, comprising a water tank and a lifting structure, the lifting structure includes a lifting rod extending into the water tank, a driving motor arranged on the water tank for driving the movement of the lifting rod, and a lifting rod arranged at the bottom of the lifting rod A platform for placing the chassis to be tested at the end;

[0030] The platform is also connected with multiple groups of suspension assemblies for maintaining the levelness of the platform, and each group of suspension assemblies includes a horizontal motor located above the platform, a first pulley located on the bottom surface of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com