Special-shaped cantilever hyperboloid wood veneer installation structure

A wood veneer and hyperboloid technology, which is applied in the field of special-shaped cantilevered hyperboloid wood veneer installation structure, can solve the difficulty of installation, positioning and setting out of wood veneer in large-span spaces, the difference in joint height and base, and the large deviation of curved surface radians. Accuracy and quality are difficult to control and other issues, to achieve the effect of facilitating standardized operations, meeting tight construction schedules, and solving difficulties in laying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

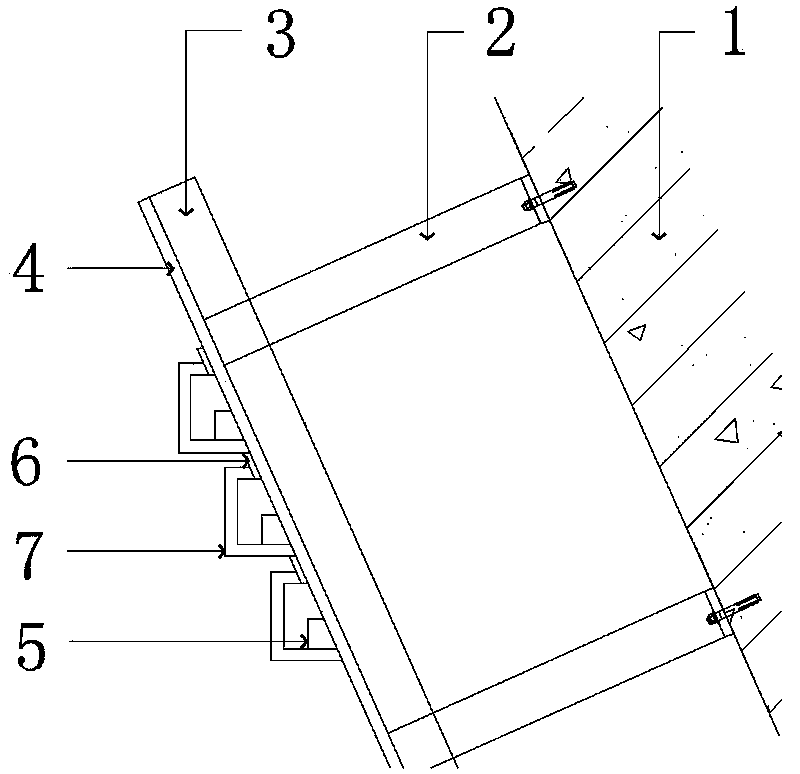

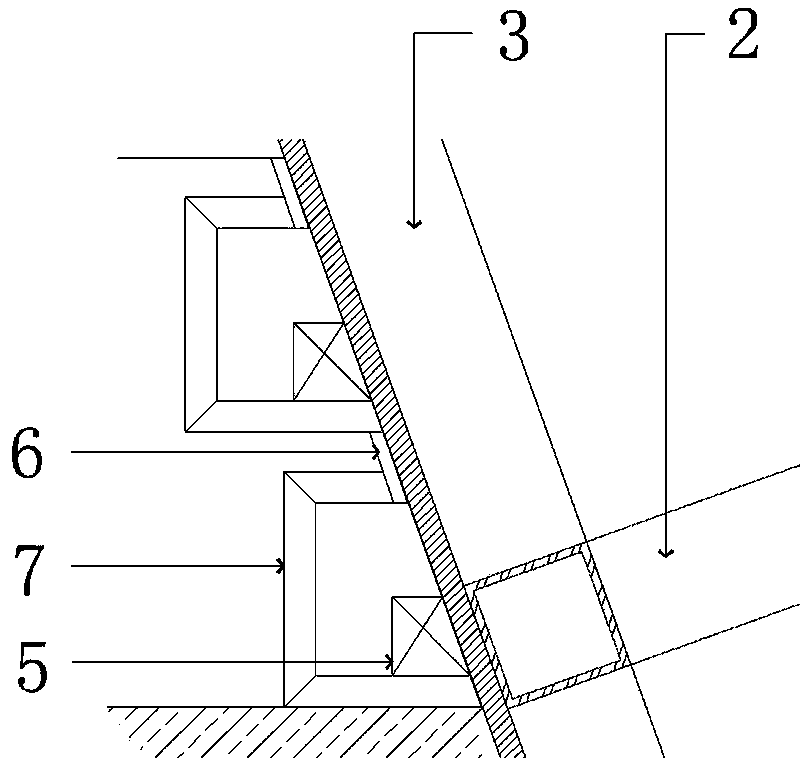

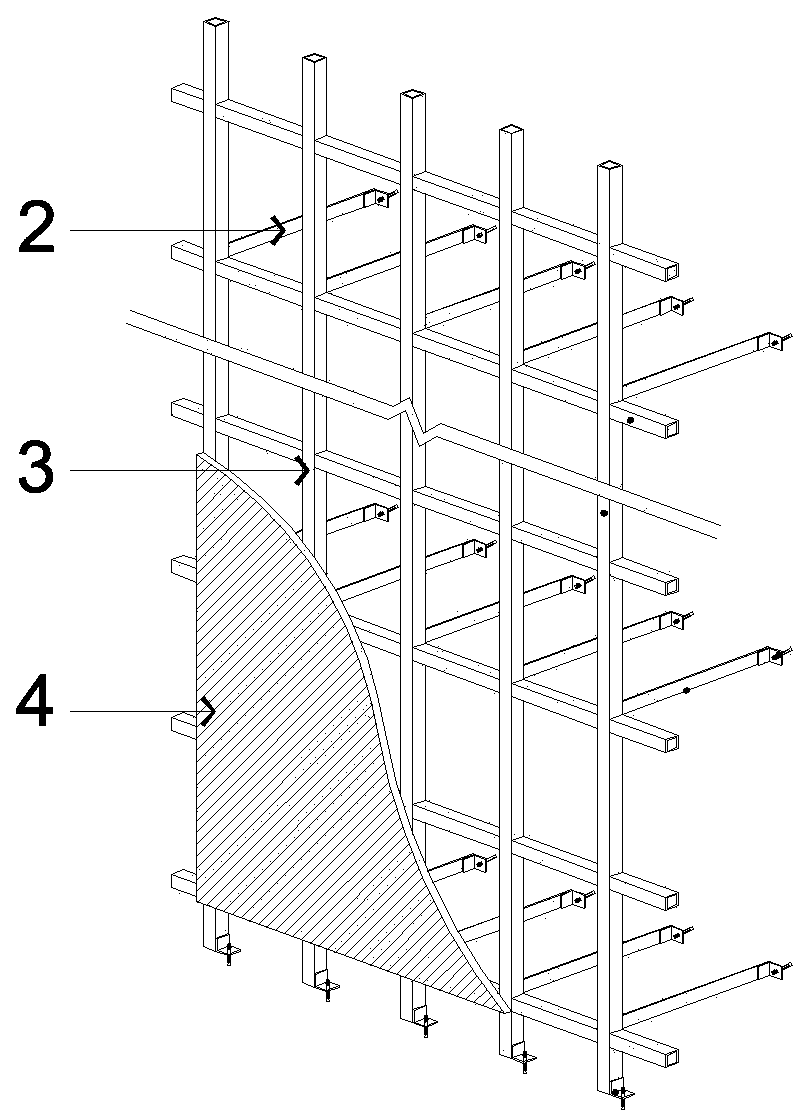

[0019] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a special-shaped cantilevered double-curved wooden veneer installation structure, which includes a base steel frame, a multi-layer board base 4, a right-angled trapezoidal wooden square 5, wooden moldings 6, and a U-shaped curved wooden veneer 7.

[0020] The base steel frame is stably connected to the civil wall 1 by cable-staying chemical bolts. The base steel frame includes a surface steel frame composed of square pipes 3, and the surface steel frame is fixed to the civil wall 1 through angle steel 2.

[0021] Angle steel 2 adopts hot-dip galvanized angle steel. The material of angle steel 2 should meet the specifications. The specification selection is determined according to the wall area, and the design should meet the bearing requirements. The angle steel 2 is cable-stayed and fixed with the civil wall 1 by chemical bolts, and the cable-stay angle is adjusted according to the angle of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com