Patents

Literature

99results about How to "Easy to standardize work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

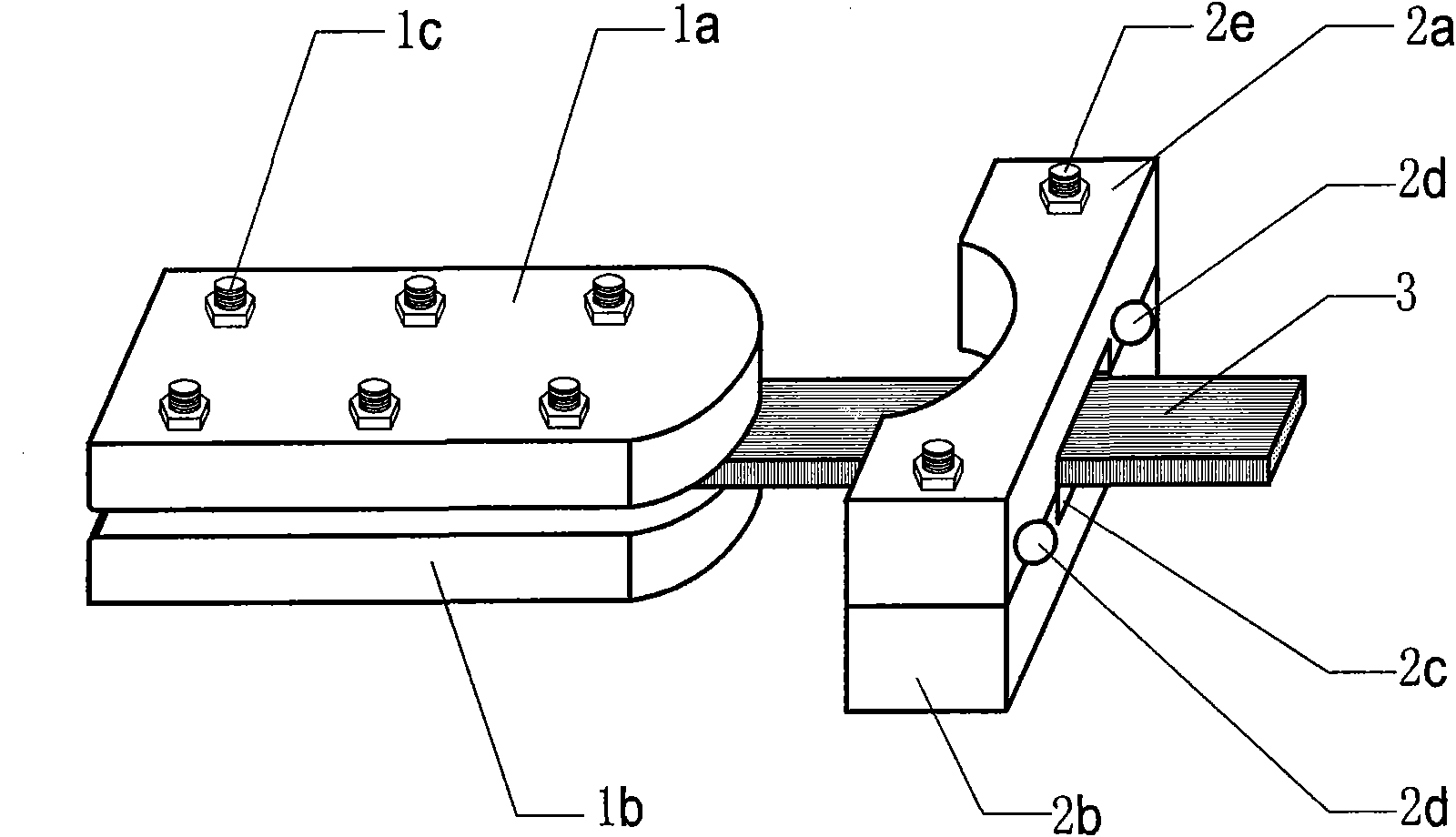

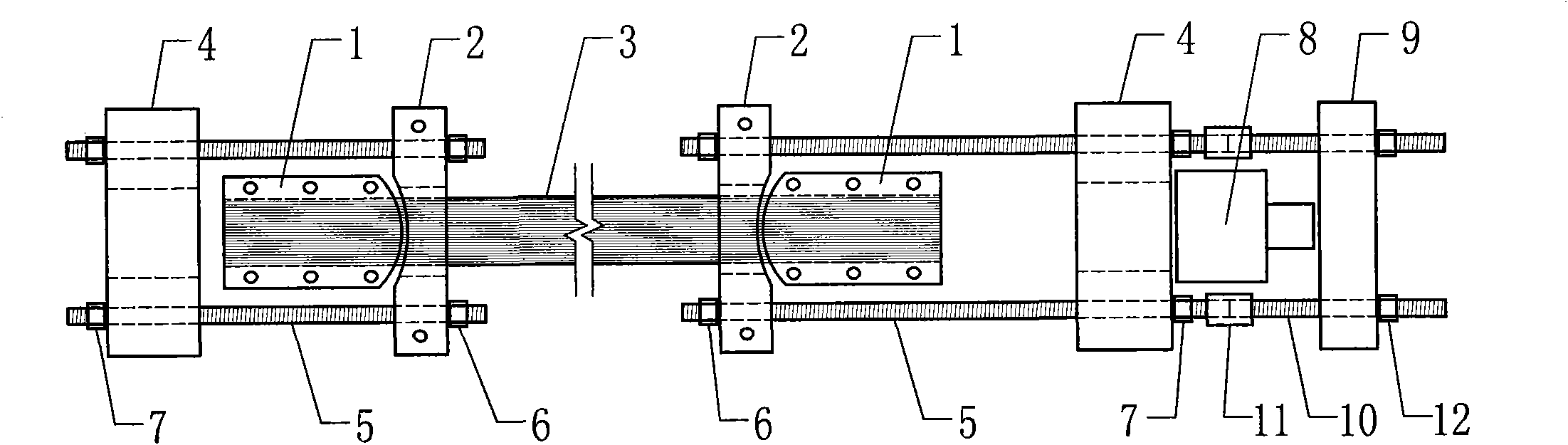

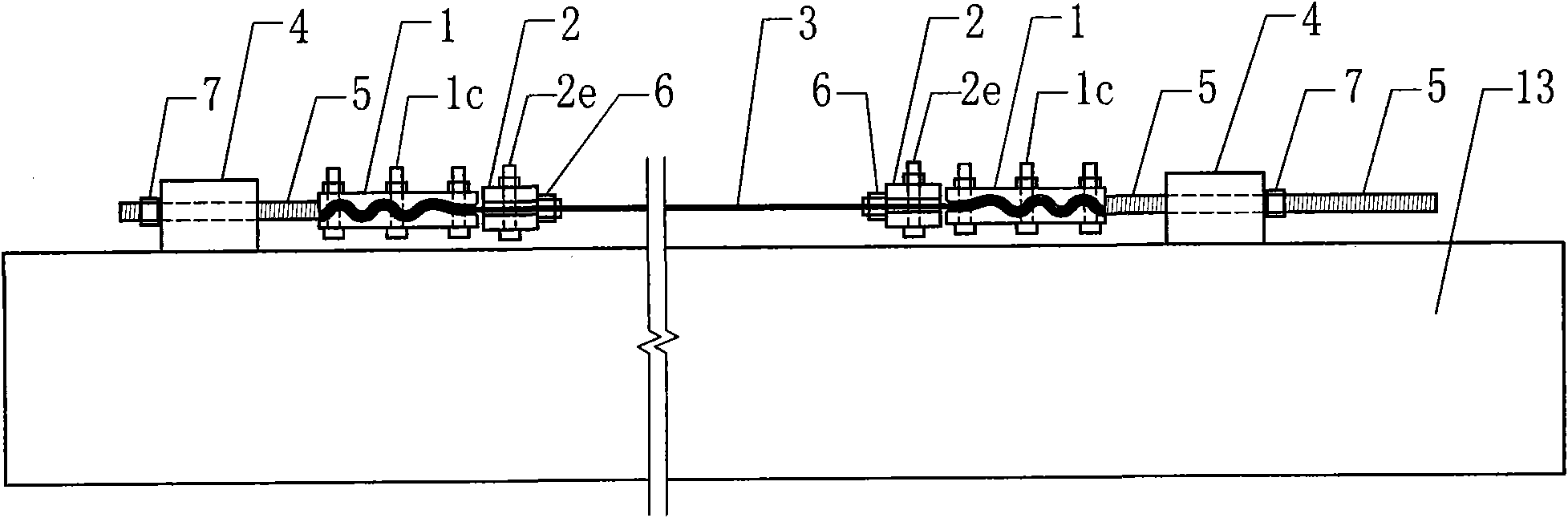

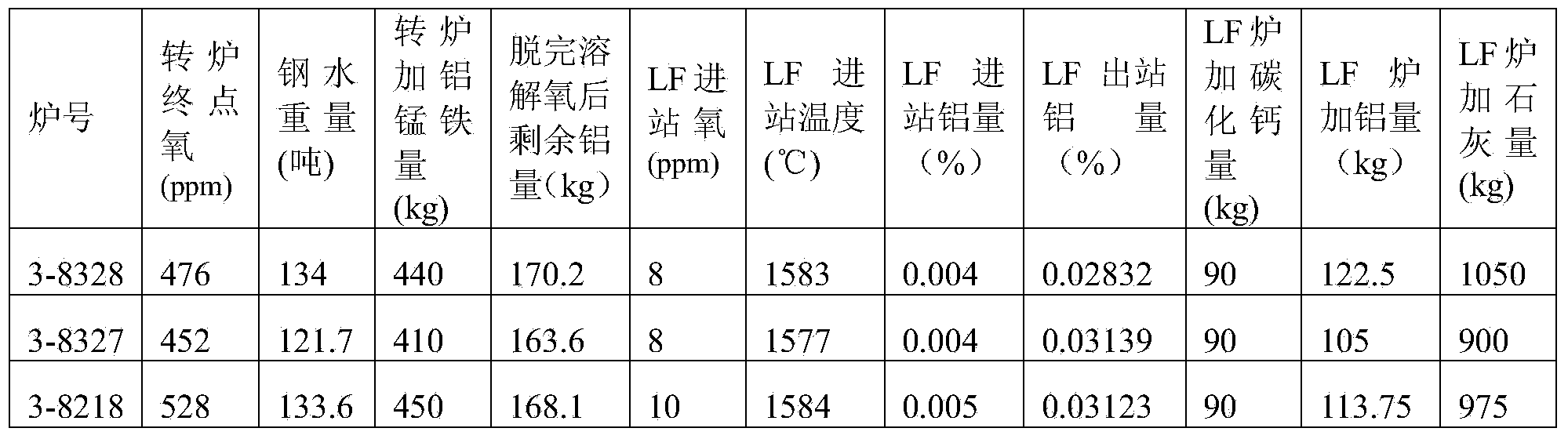

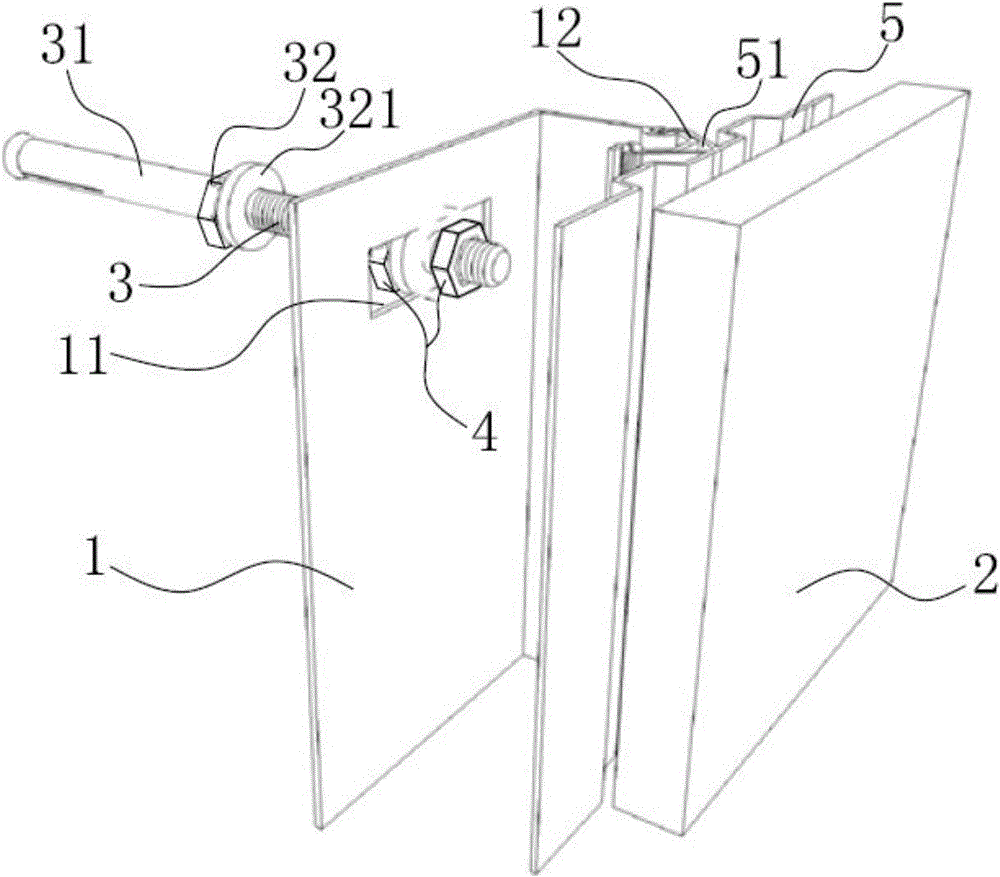

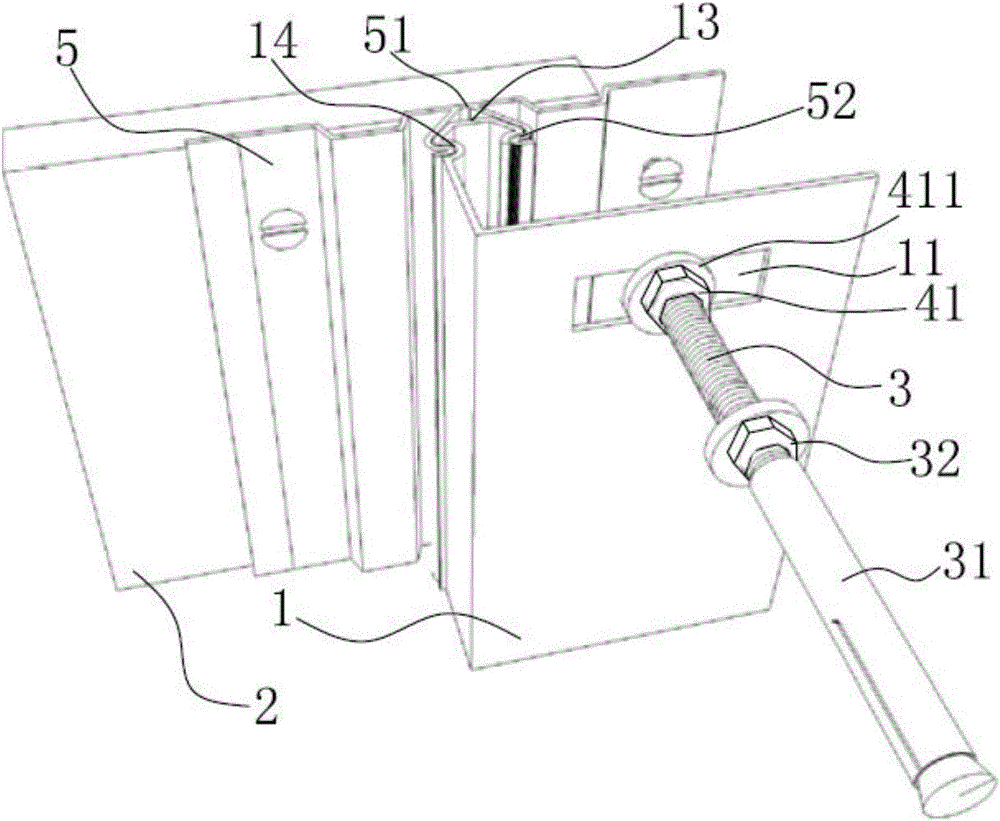

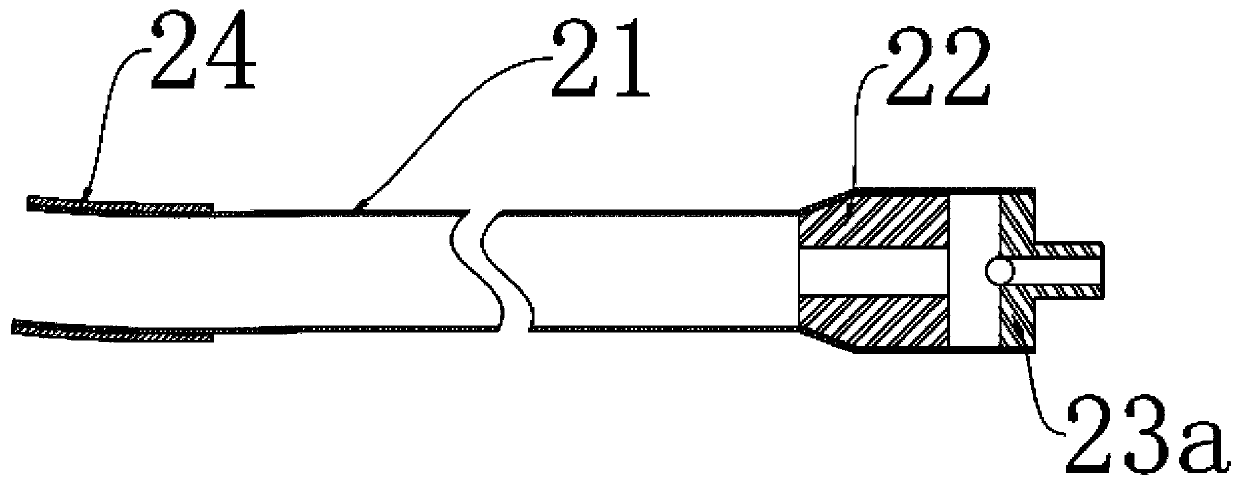

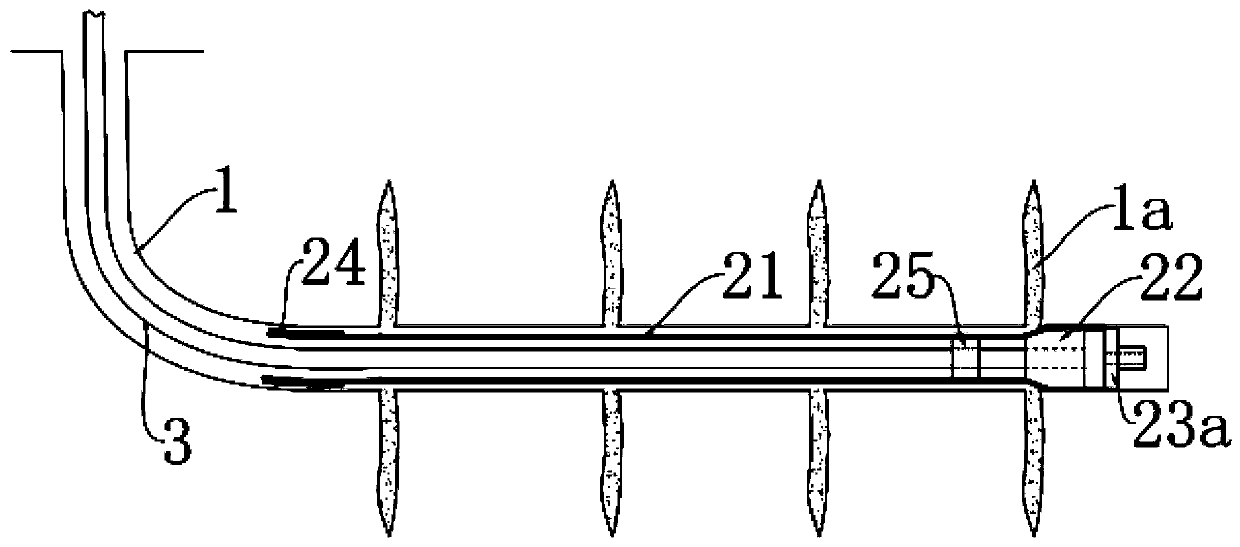

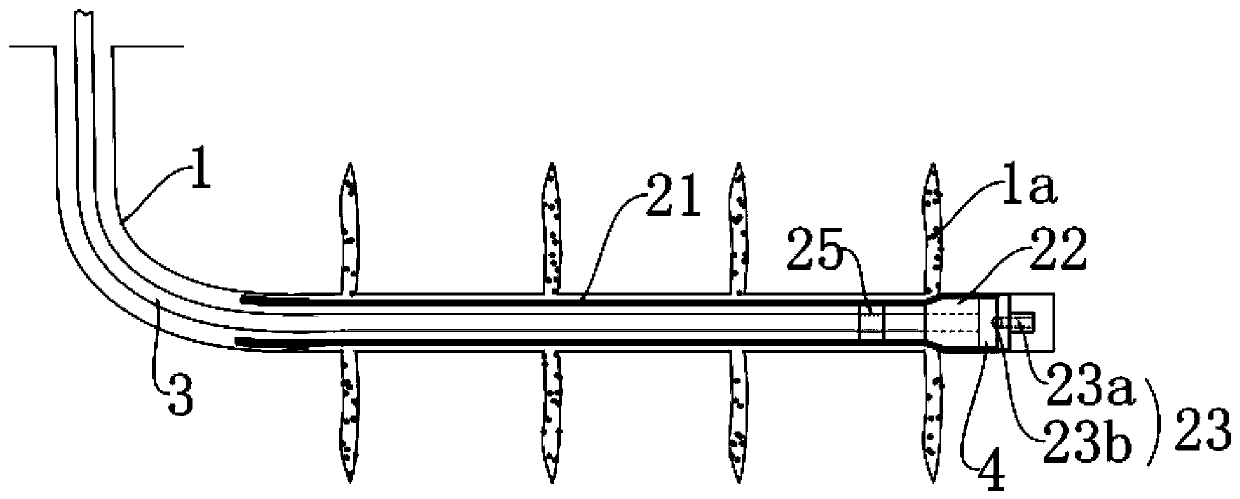

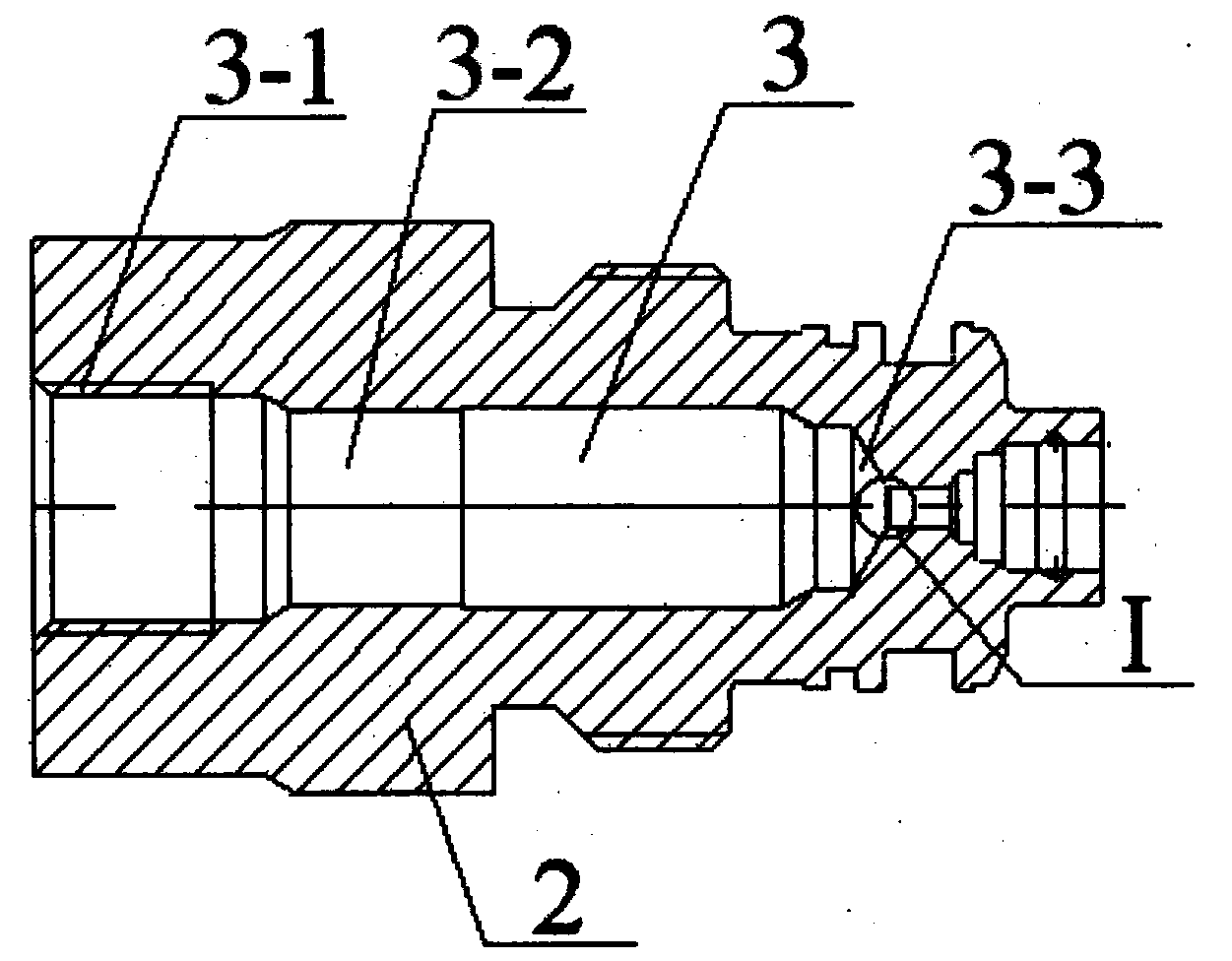

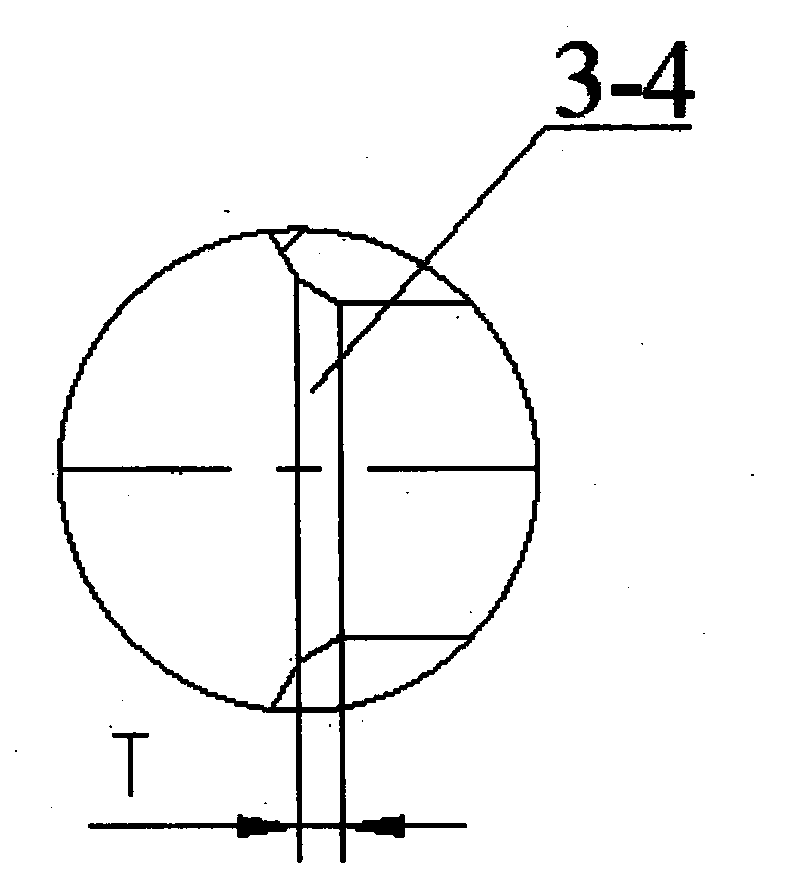

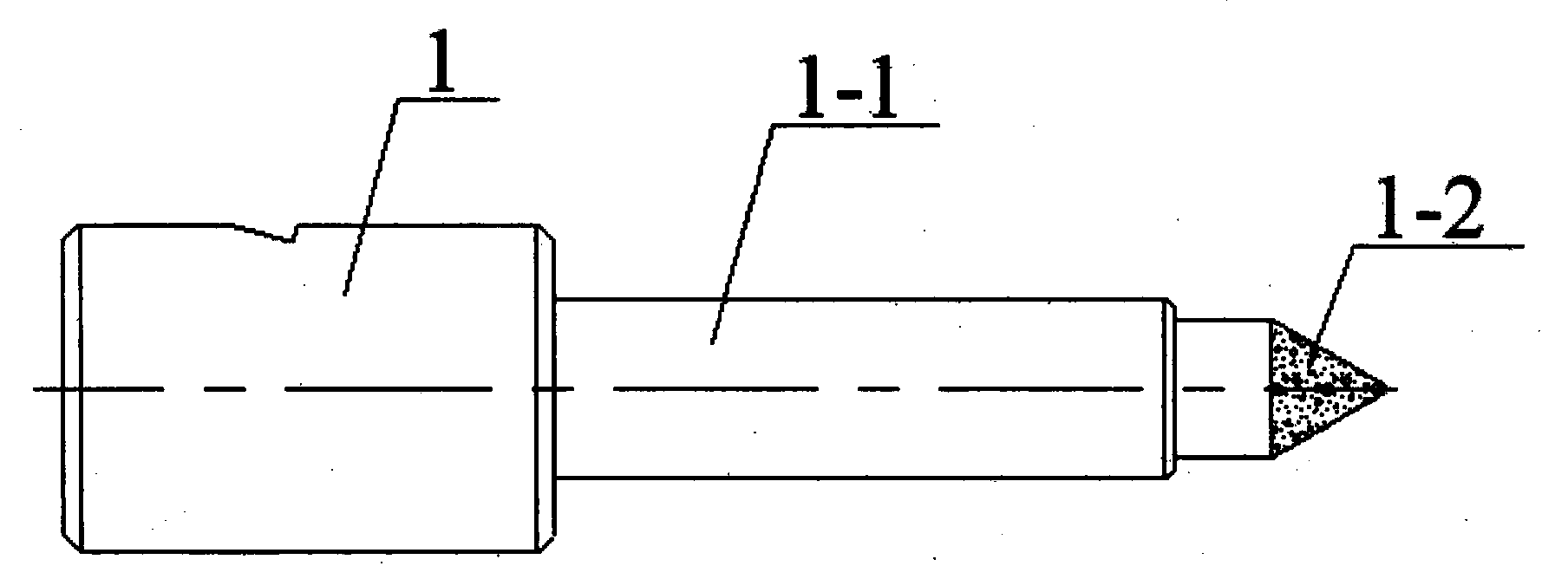

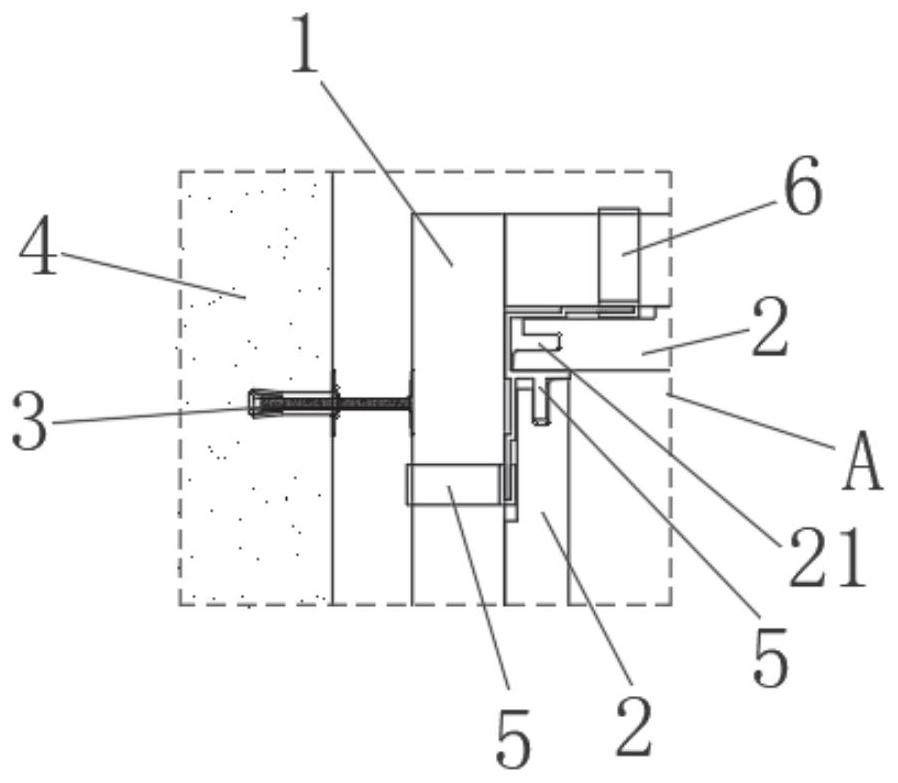

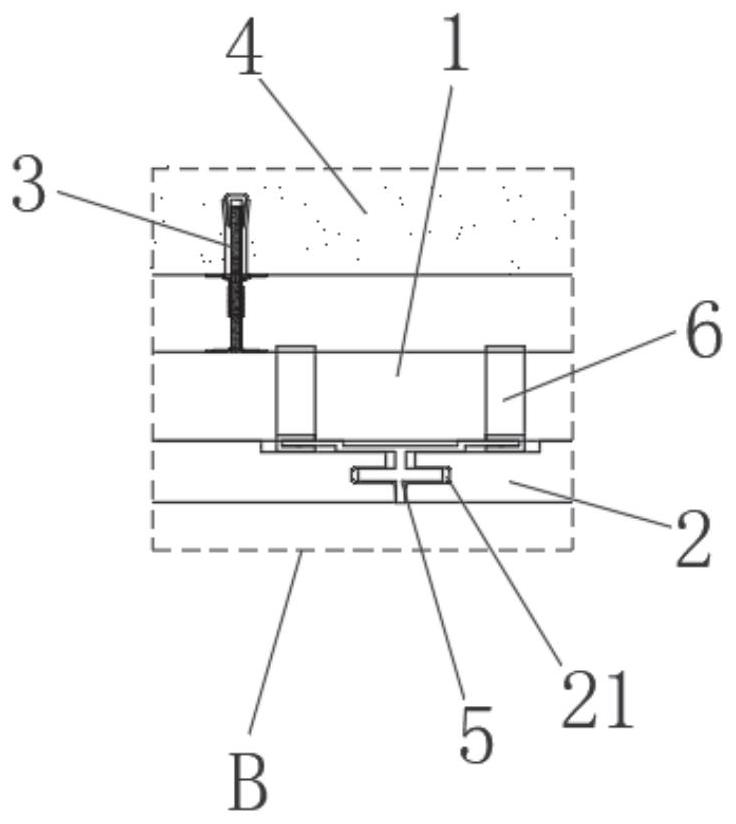

Articulated anchor and prestress tensioning method of high strength fibre composite sheet

ActiveCN101851985AGuaranteed automatic adjustmentGuaranteed uniformityBuilding reinforcementsBuilding material handlingFiberConcrete beams

An articulated anchor and a prestress tensioning method of high strength fibre composite sheet relate to an anchor holder used to perform prestress tensioning to the high strength fibre composite material of the enhancement or reinforcement engineering structure and a method thereof. The articulated anchor of the invention comprises an anchor head and a compression and locking device, and the articulated anchor is characterized in that the anchor head contains a raised head anchor and a concave block. The method of the invention is that the articulated anchor is used to clamp and anchor the two ends of FRP sheet, a jack is used to apply a tension on the concave block and the concave block pushes the raised head anchor to perform prestress tensioning to FRP sheet. The articulated anchor of the invention has simple structure, convenient installation and low cost; and the method of the invention is simple, intuitive and practical, and can ensure the tensioning uniformity of FRP sheet, made full use of the intensity of FRP sheet and effectively increase the bearing capacity of the engineering structure. The articulated anchor of the invention can be widely used to enhance or reinforce the large engineering structures such as bridges or buildings and especially to perform external prestressing reinforcement to longspan concrete beams, longspan concrete slabs and the like.

Owner:卓清

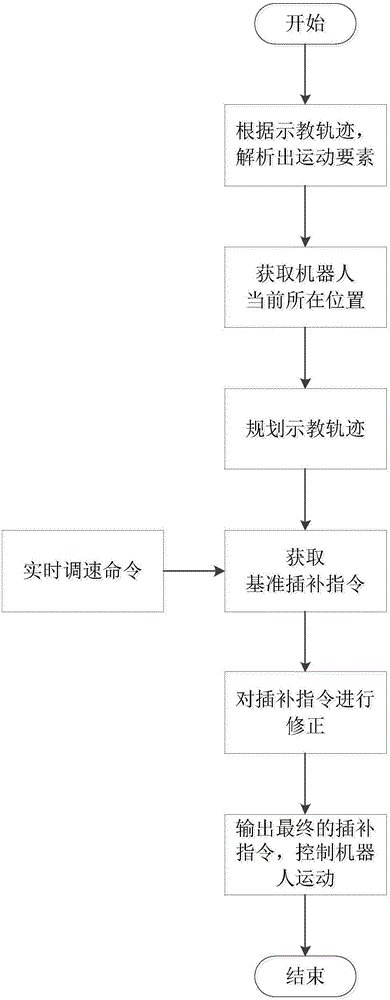

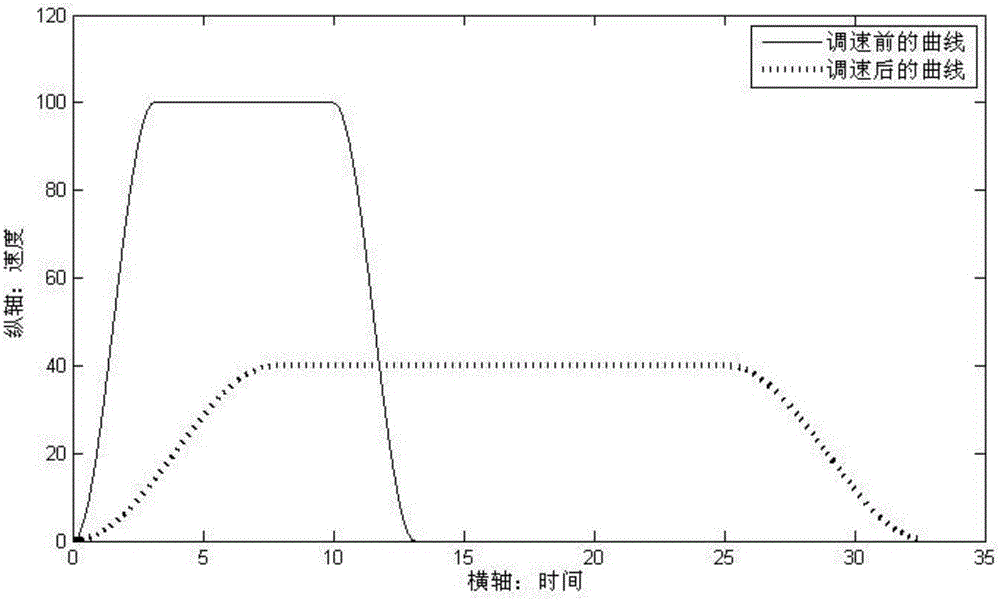

Method for adjusting running speed of robot in real time

ActiveCN106584462AExtend working lifeGuaranteed continuityProgramme-controlled manipulatorPosition/course control in two dimensionsControl systemEngineering

The invention discloses a method for adjusting running speed of a robot in real time. Movement elements are analyzed through a demonstrating track, track planning and interpolation are carried out, and an interpolation command is corrected by inputted speed adjusting parameters to achieve the purpose of adjusting the speed in real time. According to the control command corrected by the method, a curve can be changed smoothly and continuously, so that stress on a mechanical system is not impacted or changed suddenly, a control effect is soft, and loss on moving parts is reduced. Meanwhile, the method is simple in control logic and small in calculated amount, and meets control requirements on instantaneity of a robot control system. When the speed is adjusted, only a standard process requires to be demonstrated according to actual working conditions, then a monitoring terminal is debugged to transmit different speed adjusting commands, a robot control system responds the received speed adjusting parameters so that the effect of changing the running speed of the robot can be achieved, work complexity of operators is greatly simplified, the field processing efficiency is improved, and standardized operation of the robot is facilitated.

Owner:NANJING ESTUN AUTOMATION CO LTD +1

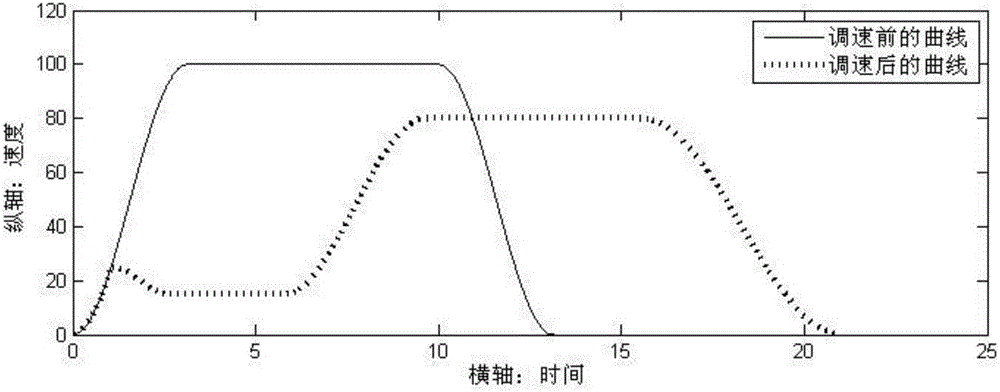

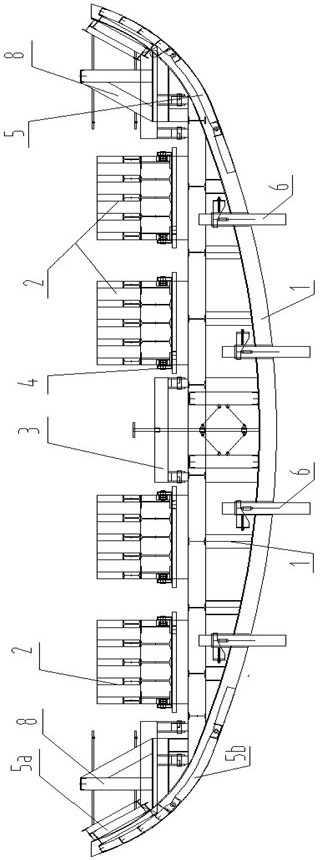

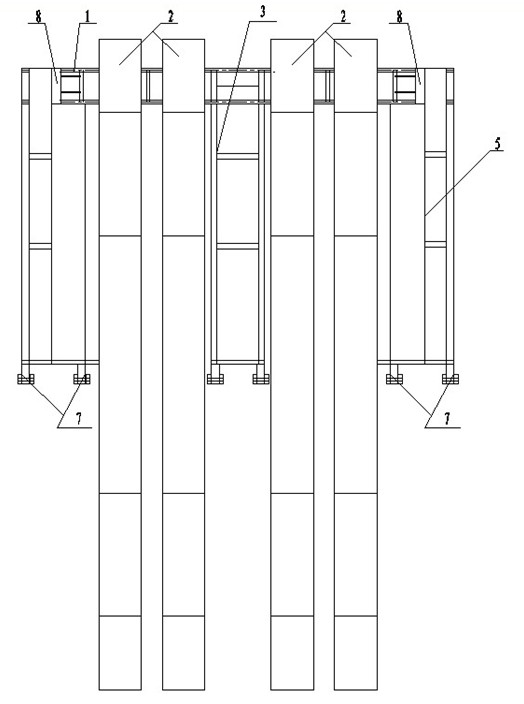

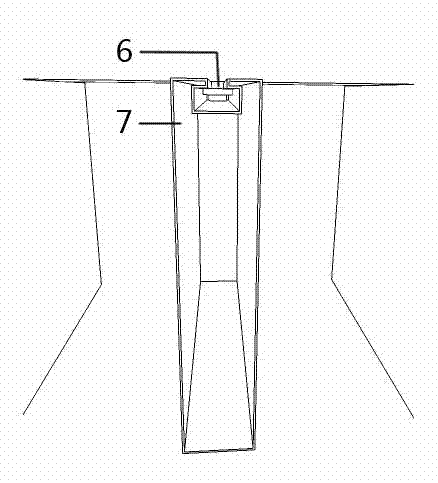

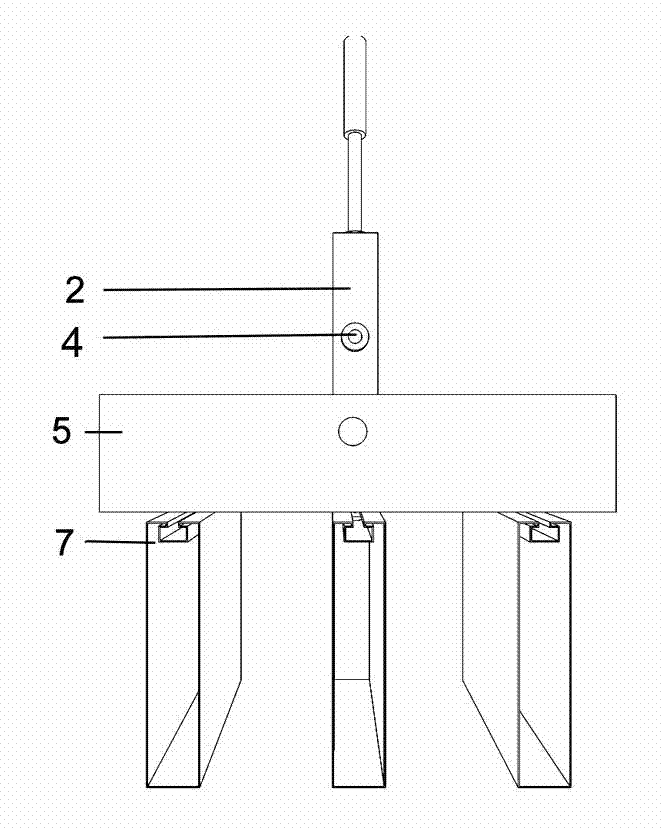

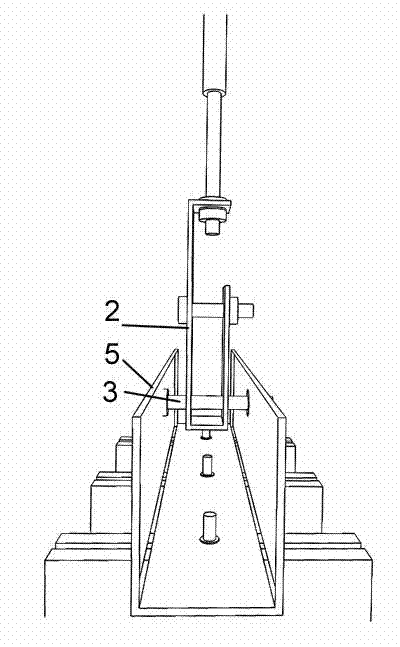

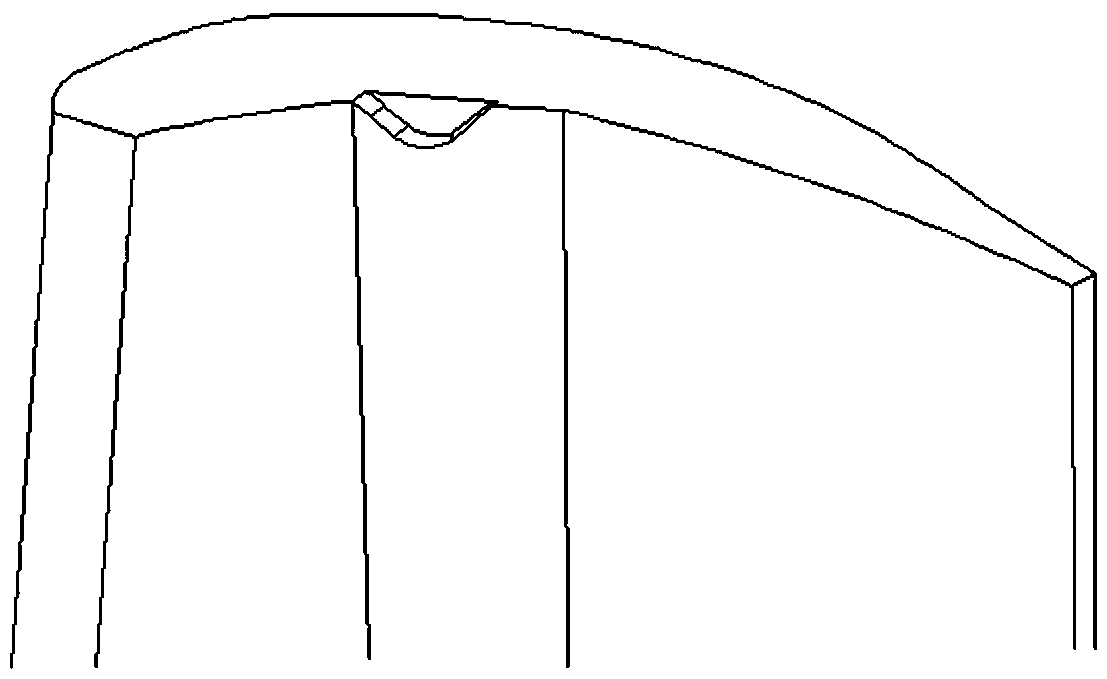

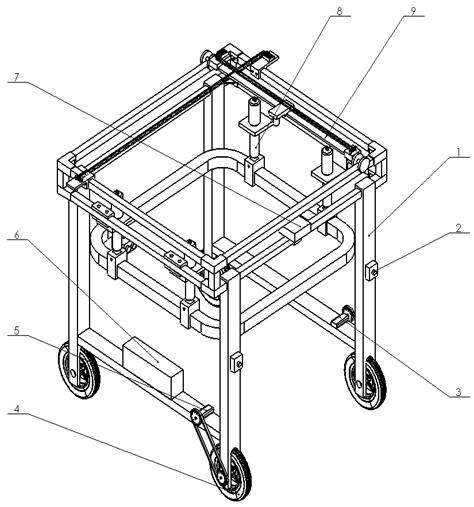

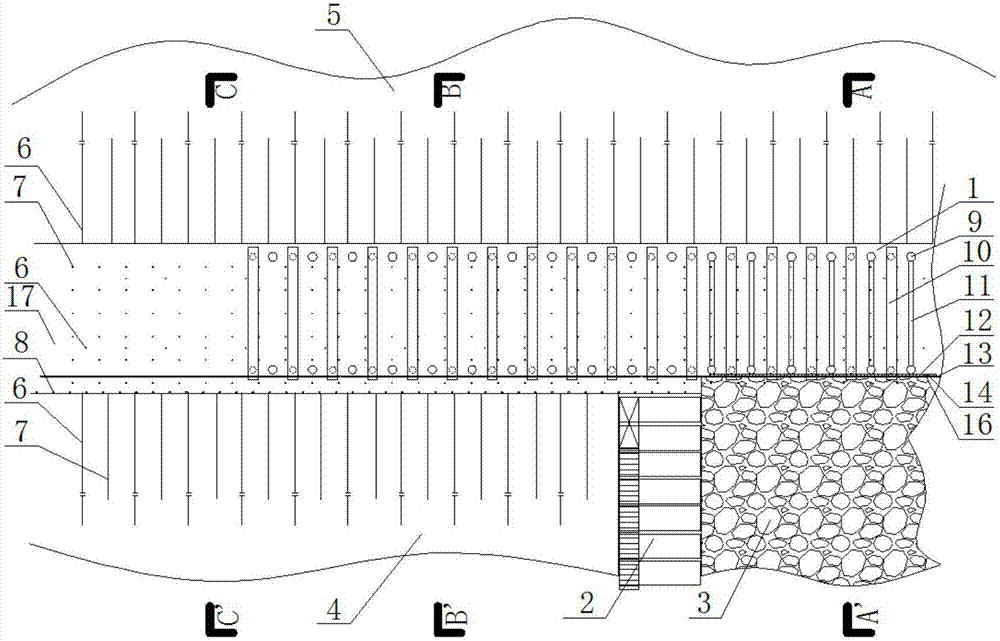

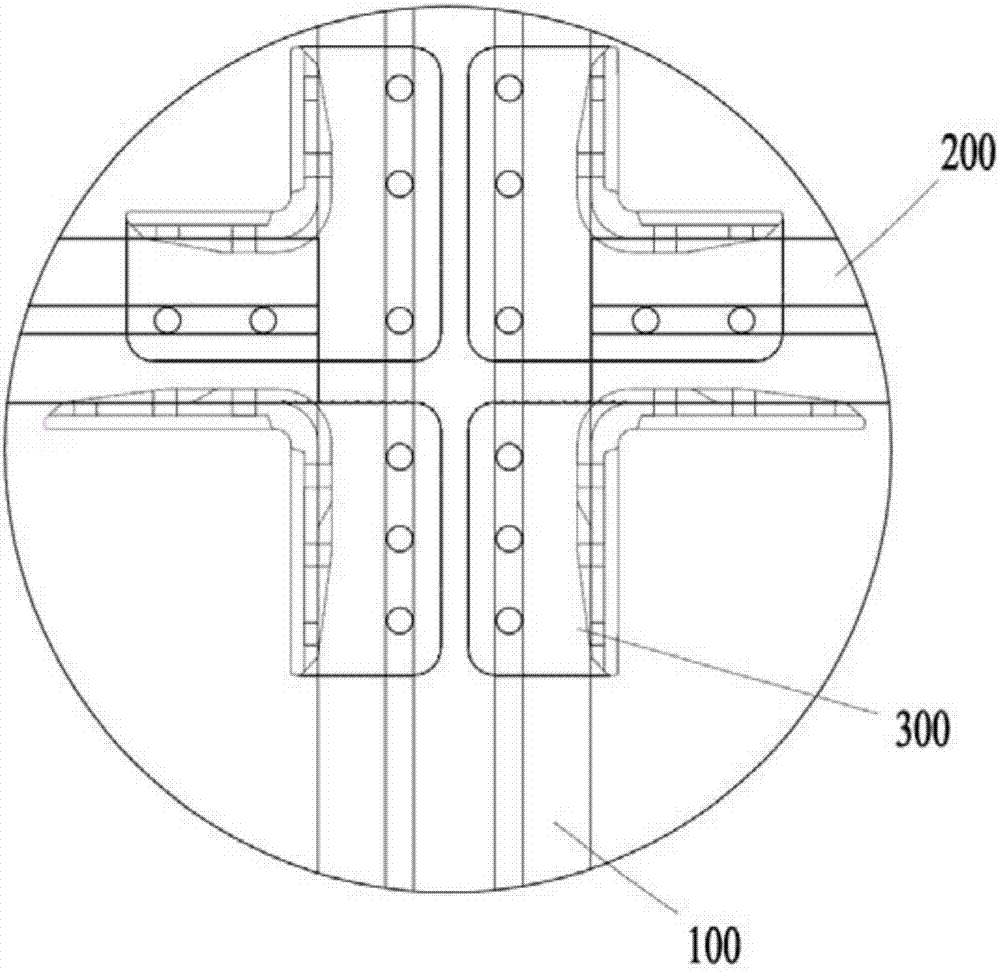

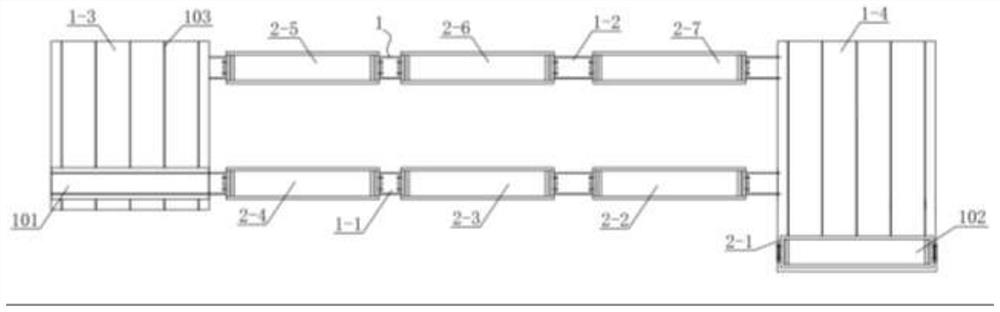

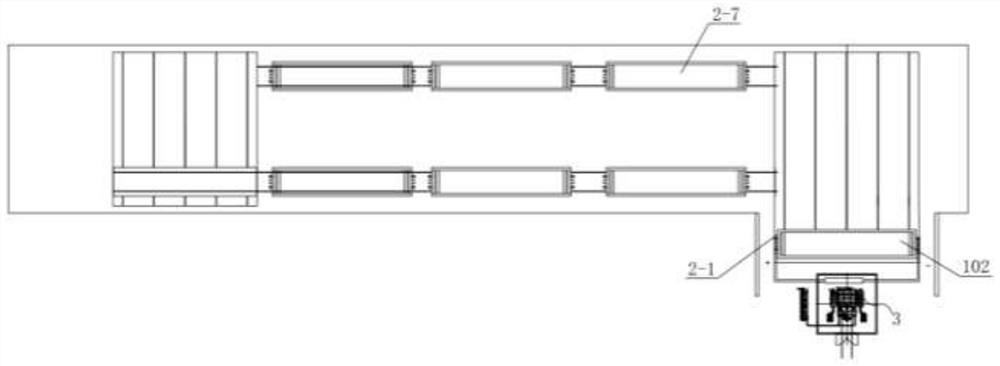

Construction equipment for inverted arch of two-track tunnel of high-speed railway

ActiveCN102146799AIncrease the level of mechanizationPrecise positioningUnderground chambersTunnel liningUltimate tensile strengthMechanization

The invention relates to construction equipment for the inverted arch of a two-track tunnel of a high-speed railway, belonging to the technical field of tunnel construction equipment. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway comprises a trestle, an inverted arch mould frame and a terminal beam, wherein the terminal beam is connected with the inverted arch mould frame to form into a whole; the terminal beam and / or the inverted arch mould frame are / is connected to the trestle; and the terminal beam and the inverted archmould frame autonomously move on the trestle. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway can position accurately, move in place fast and convenient, and has the advantages of high mechanization level, low article labor intensity and low construction cost; the construction equipment can complete the inverted arch through one-time monolithic casting with high construction efficiency and high construction quality, and can provide guarantee for quick tunneling; construction organization and work procedure partition in the tunnel are optimized, thereby being beneficial to standardized operation and safe and civil construction; and the construction operation is convenient and fast, breaks through the traditional inverted arch construction technology and ensures the continuous construction quality of the inverted arch, thus being in favor of popularization and application.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

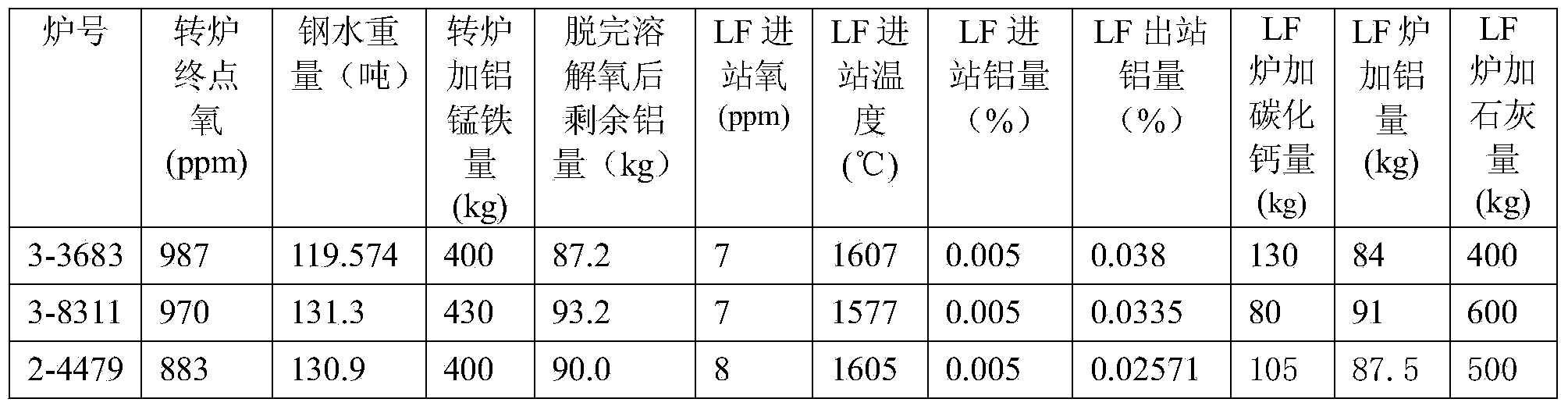

Method for determining amount of slagging material and deoxidized alloy added into LF (Low-Frequency) refining furnace by use of reference heat method

ActiveCN103866088AProcessing data is accurateAvoid instabilityProcess efficiency improvementSlagInstability

The invention relates to a method for determining the amount of a slagging material and deoxidized alloy added into an LF refining furnace by use of a reference heat method. The method comprises the following steps: controlling the amount of slags discharged from a rotary furnace during a refining process, wherein the amount of the added synthetic slags is the same during a steel discharging process of the rotary furnace according to the same type of steel heat number; (1) acquiring data and building a database by use of a computer; and (2) using the database for determining the amount of the slagging material and the deoxidized alloy added into this type of steel LF refining furnace when the acquired data of a certain type of steel in the database is accumulated to be not less than 400 heat number. The method disclosed by the invention comprises steps of acquiring operation data, building the database and using the computer to process the data rapidly and accurately; the reference heat method absolutely can be used for replacing the existing slagging method for manually determining the amount of the added slagging material and has the advantages of solving the instability of manual determination, optimizing the refining effect, stabilizing the quality of refined liquid steel and promoting standardized operation.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

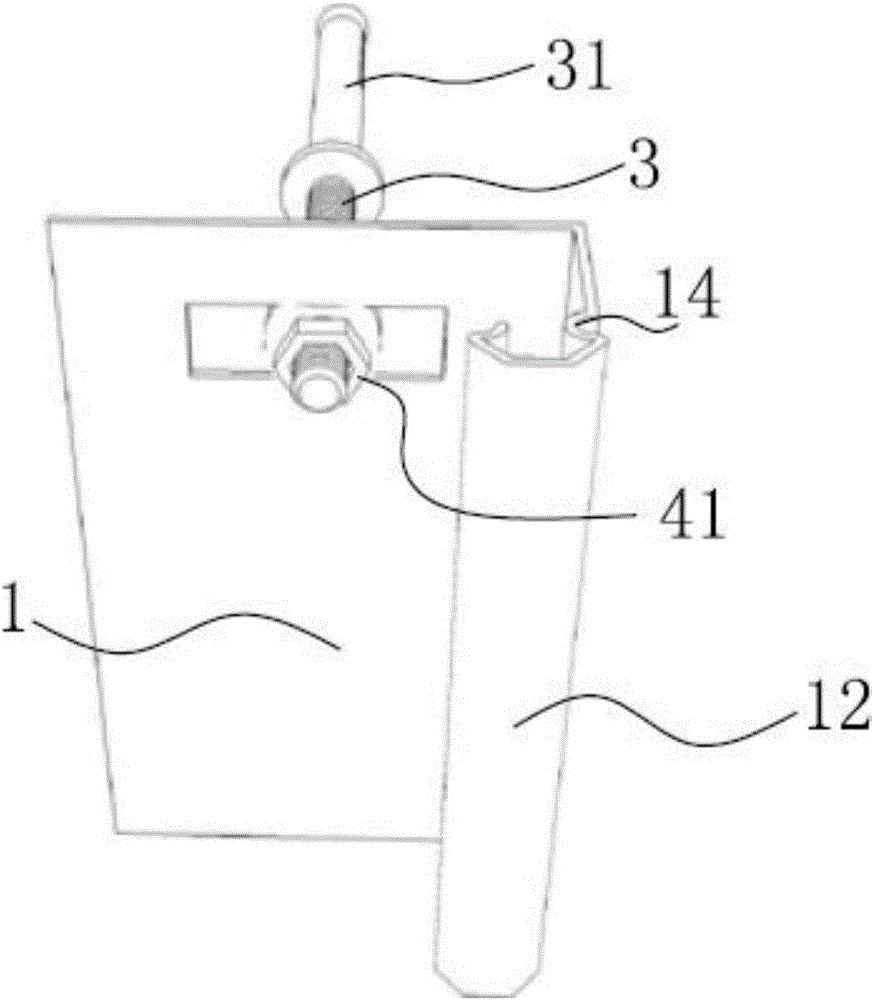

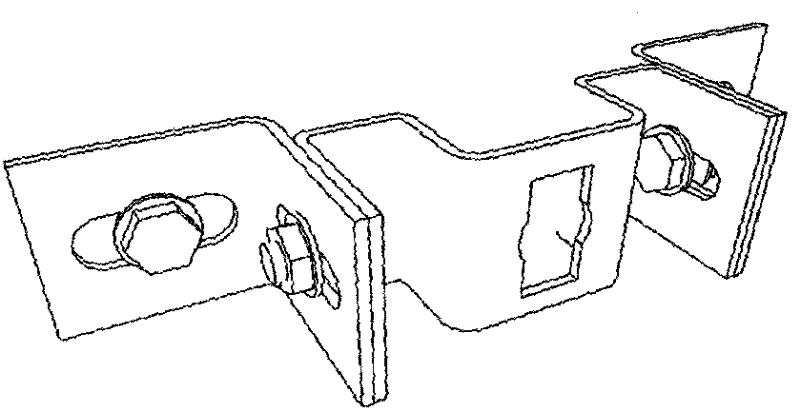

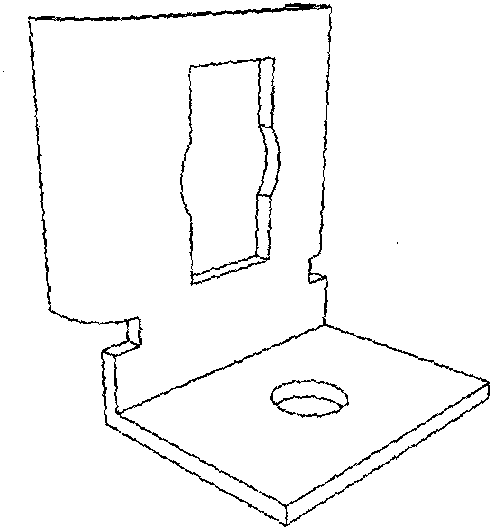

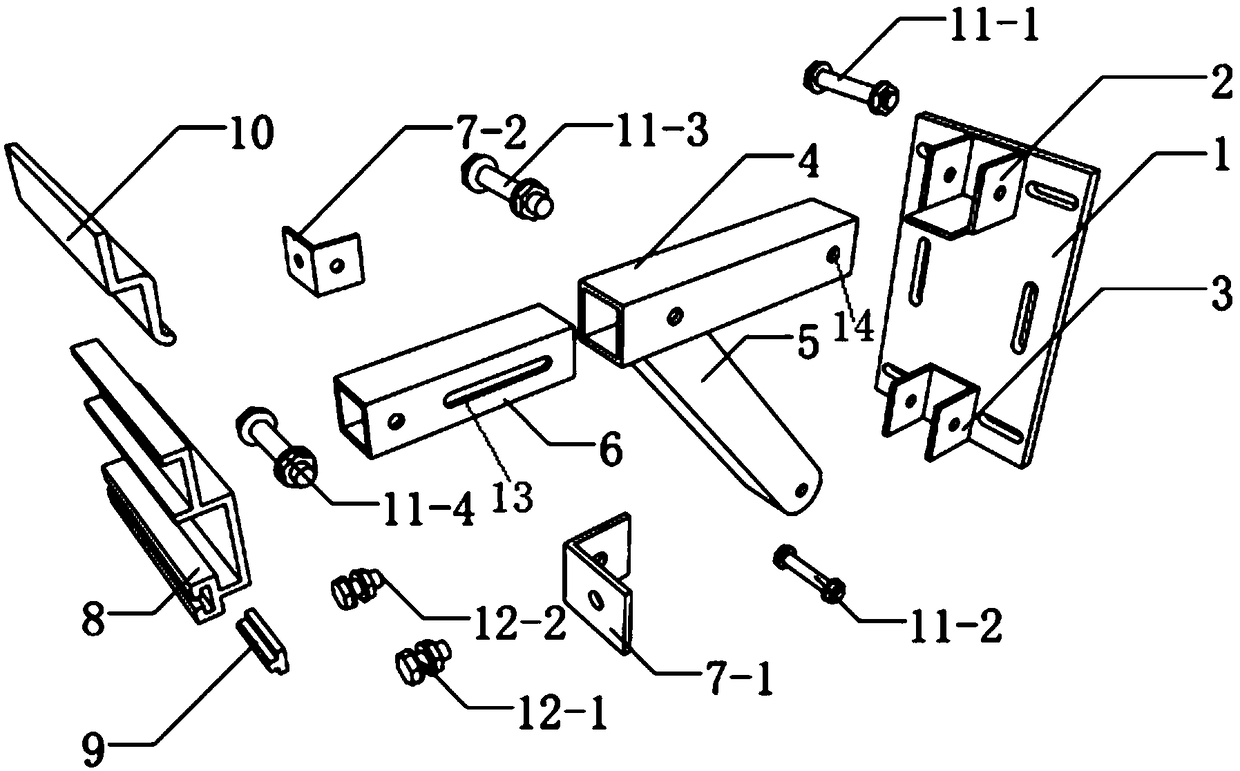

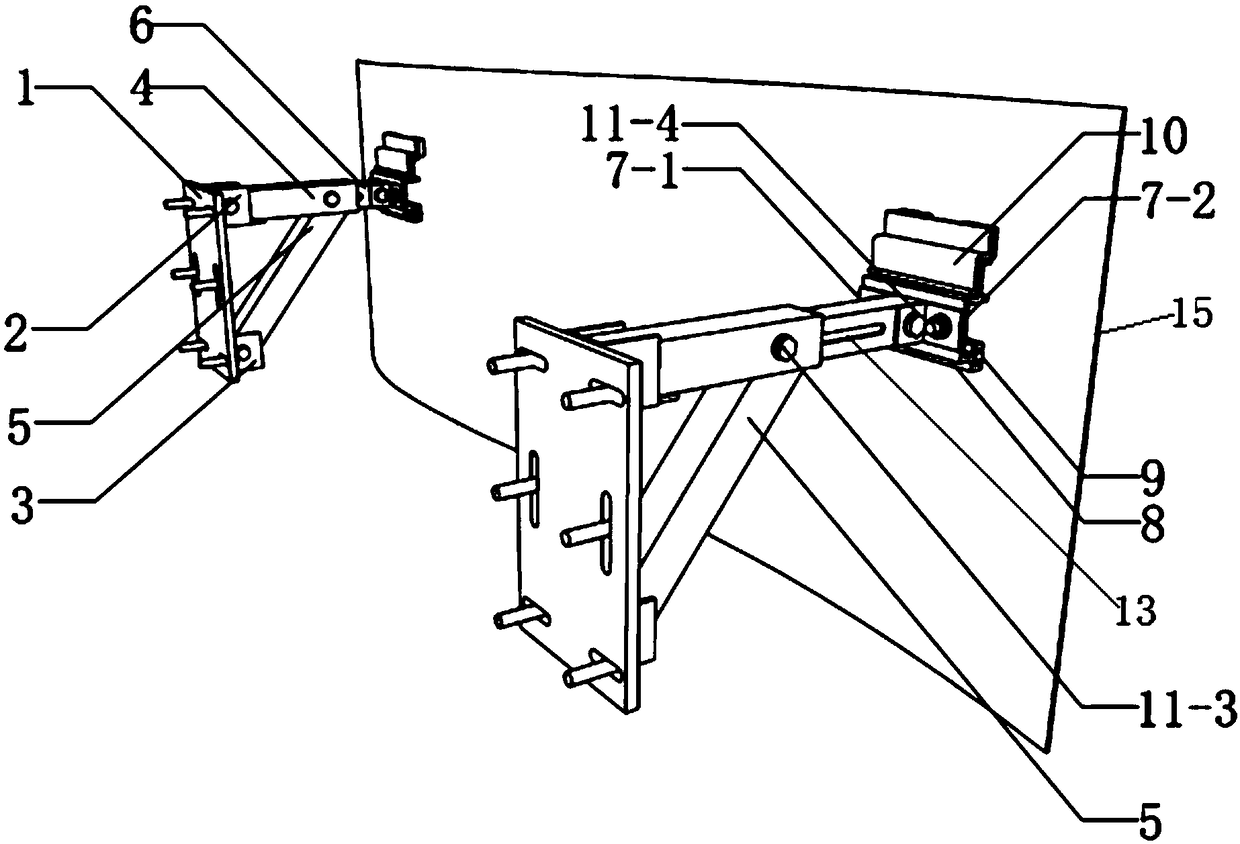

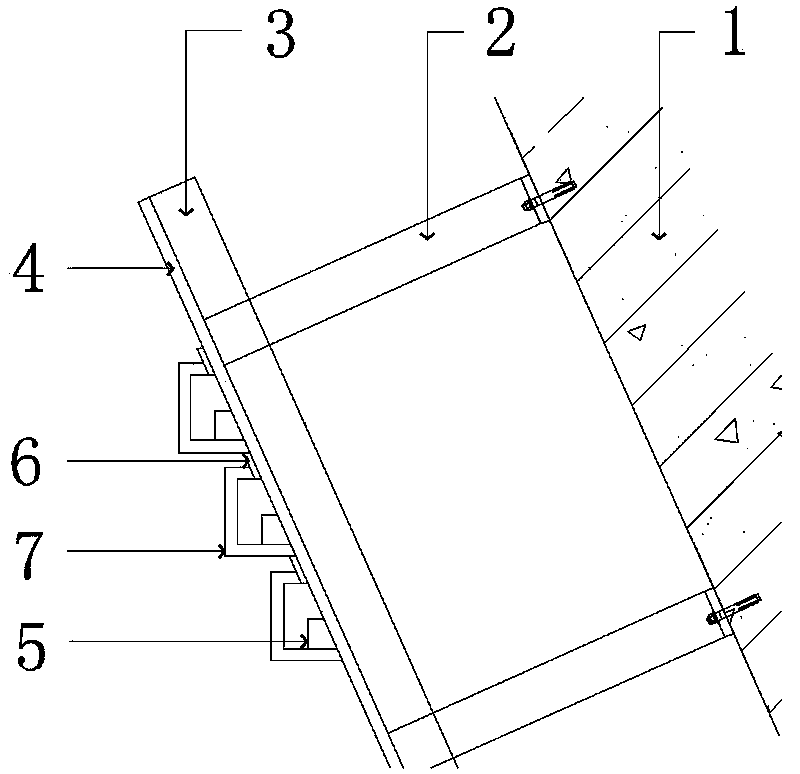

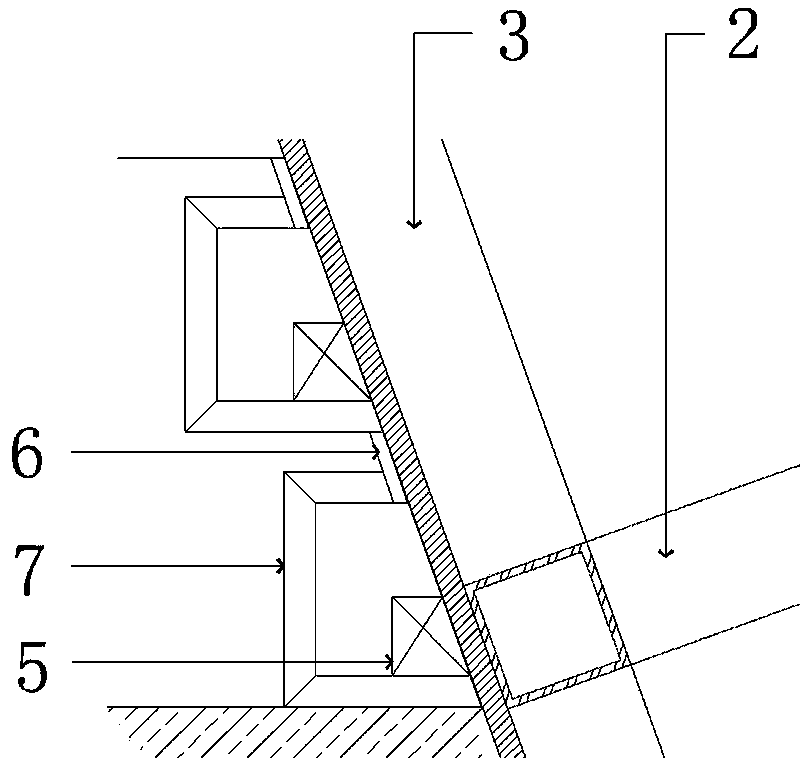

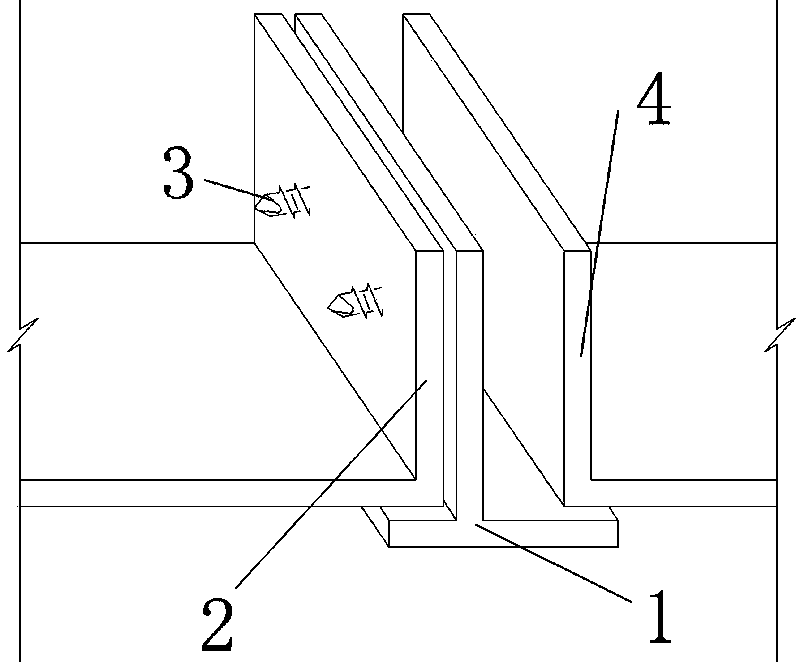

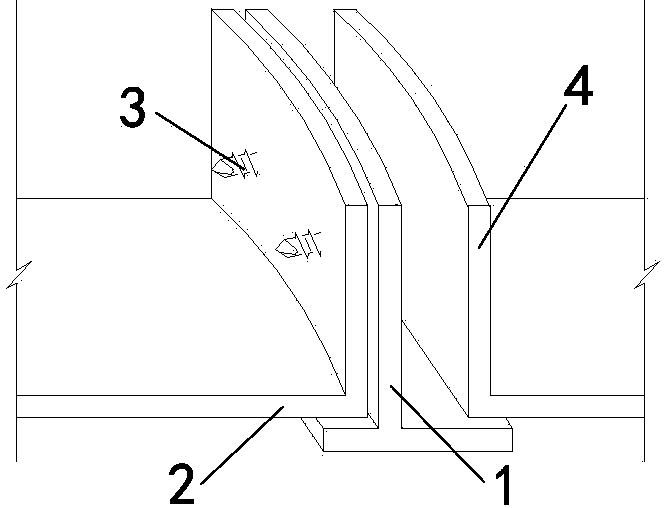

Vertical-face stone dry-hanging mounting structure

InactiveCN102359242AImprove installation efficiencyFast constructionCovering/liningsKeelBuilding construction

The invention discloses a vertical-face stone dry-hanging mounting structure. The vertical-face stone dry-hanging mounting structure comprises a keel, a bridge connecting piece (4), a wall connecting piece (1), a sliding block (5) and a stone dry-hanging piece, wherein the keel is fixed on the wall body by the wall connecting piece (1) and comprises a vertical keel (2) and a transverse keel (3); the vertical keel (2) is connected with the transverse keel (3) by the bridge connecting piece (4); the sliding block is mounted on the keel by an adjustable fixing piece; the sliding block (5) can move along the keel while adjustment is needed; and the stone dry-hanging piece is fixedly connected with the sliding block (5). A keel clamping groove is arranged on the keel (2). The adjustable fixing piece is a waist-shaped fixing piece (8) with bolt property; a spring gasket is arranged in the middle of the waist-shaped fixing piece; and a clamping groove firmly matched with the keel clamping groove is formed at the lower opening of the waist-shaped fixing piece. The vertical-face stone dry-hanging mounting structure disclosed by the invention has the advantages of simplicity in construction, no need of professional operator and high mounting speed; moreover, the division dimension of the vertical-face stone can be freely adjusted without being detached and remade while the division dimension is changed so that the material waste is avoided.

Owner:GOLD MANTIS CONSTR DECORATION

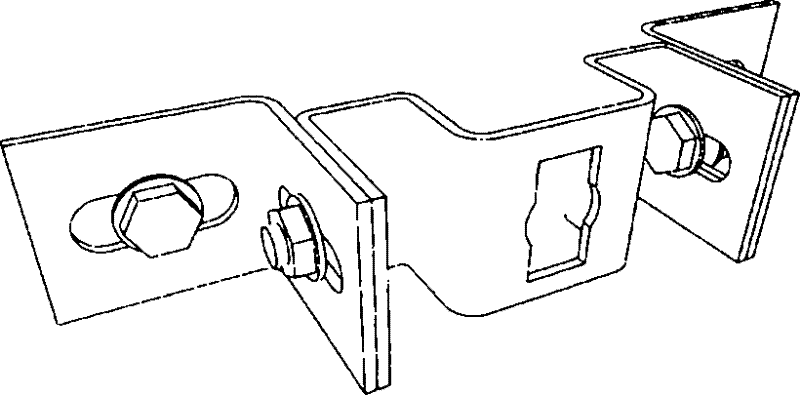

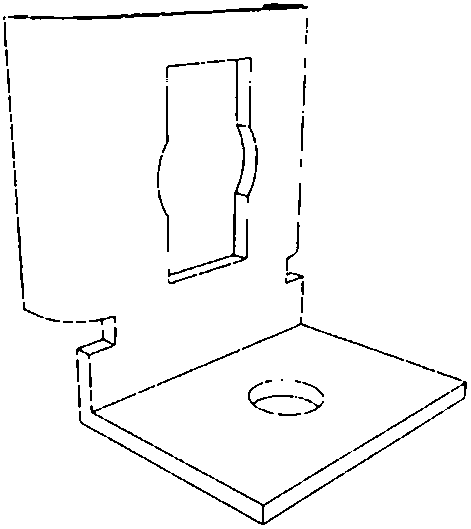

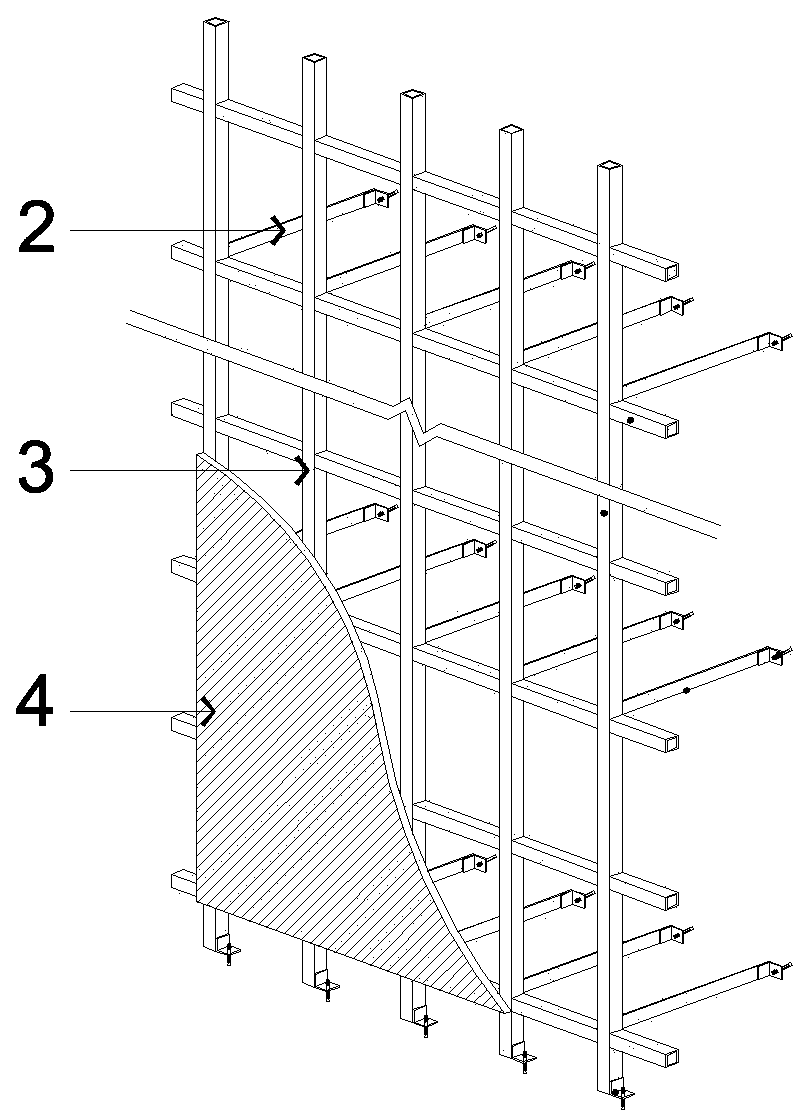

Facing integrated board dry hanging installation structure with adjustable and dismountable facade

ActiveCN105064646AImprove installation efficiencyFast constructionCovering/liningsEngineeringFastener

The invention discloses a facing integrated board dry hanging installation structure with an adjustable and dismountable facade. The facing integrated board dry hanging installation structure comprises a connecting element and a lead screw, wherein one side of the connecting element is detachably connected with the facing integrated board, and the other side of the connecting element is provided with a long strip-shaped hole; and one end of the lead screw is arranged in the long strip-shaped hole and is fixed through a fastener, and the other opposite end of the lead screw is fixedly connected with a wall body. Compared with the prior art, the facing integrated board dry hanging installation structure has the following beneficial effects that 1, the installation of a base layer is avoided, and the installation efficiency of a facing integrated board is improved; 2, the installation adjustment of the facade is fast realized, the construction period is greatly shortened and changed, and the consumable cost is reduced; and 3, the fast dismounting is realized, the dismounting risk due to artificial damage or repair in a later period is avoided, and the peripheral installed boards cannot be influenced by the dismounting of any one board.

Owner:GOLD MANTIS CONSTR DECORATION

Vertical dry-hanging mounting structure of stone

The invention discloses a vertical dry-hanging mounting structure of a stone. The mounting structure comprises a keel (2), a wall connecting piece (1), a sliding block (5) and a stone dry-hanging piece, wherein the keel (2) is fixed on a wall body by virtue of the wall connecting piece (1); the sliding block (5) is mounted on the keel (2) by virtue of an adjustable fixer; when the sliding block (5) needs to be adjusted, the sliding block (5) can move along the keel (2); the stone dry-hanging piece is fixedly connected with the sliding block (5); the keel (2) is provided with a keel clamping groove; the adjustable fixer is a kidney-shaped fixer (8) with the properties of a bolt; a spring washer is arranged in the middle of the adjustable fixer; and the lower opening of the adjustable fixer is provided with a clamping groove which is matched and held with the keel clamping groove. The vertical dry-hanging mounting structure of the stone is simple and feasible to construct, can improve the speed of mounting the stone, does not need the operation of a specialized person, has popular construction, and is beneficial to standard operation; and furthermore, when the division size of a vertical stone changes, the division size can be regulated freely without disassembling and remaking the vertical stone, so as to avoid the waste of materials.

Owner:GOLD MANTIS CONSTR DECORATION

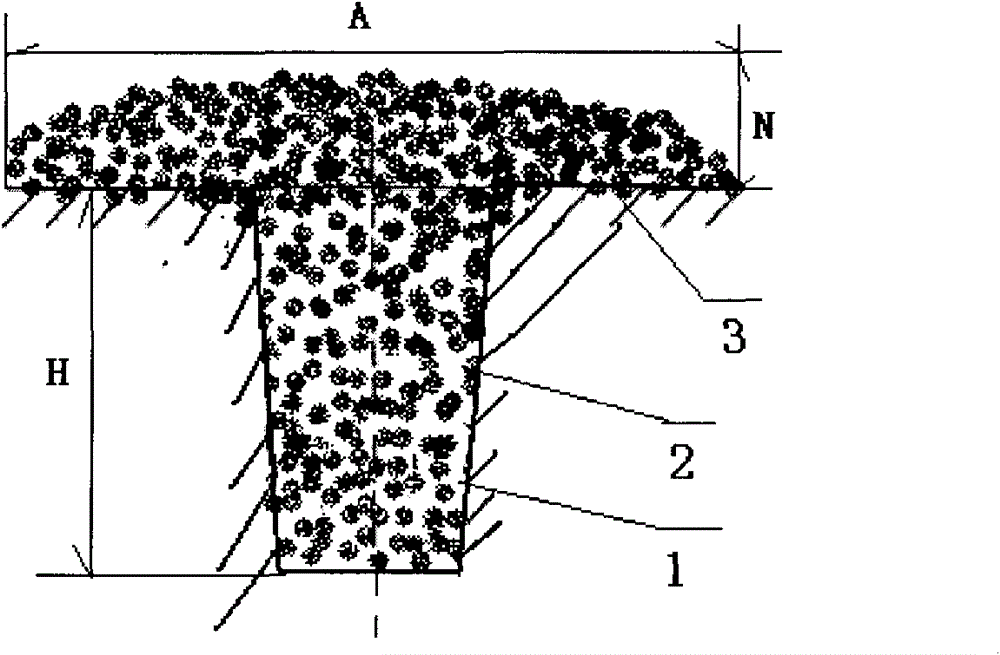

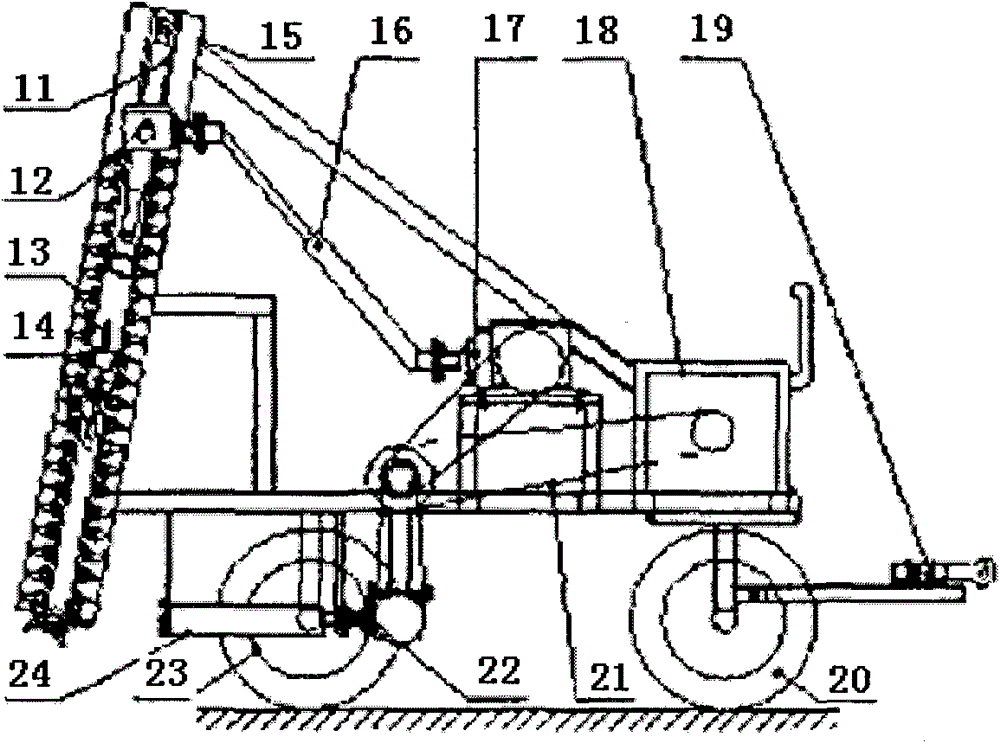

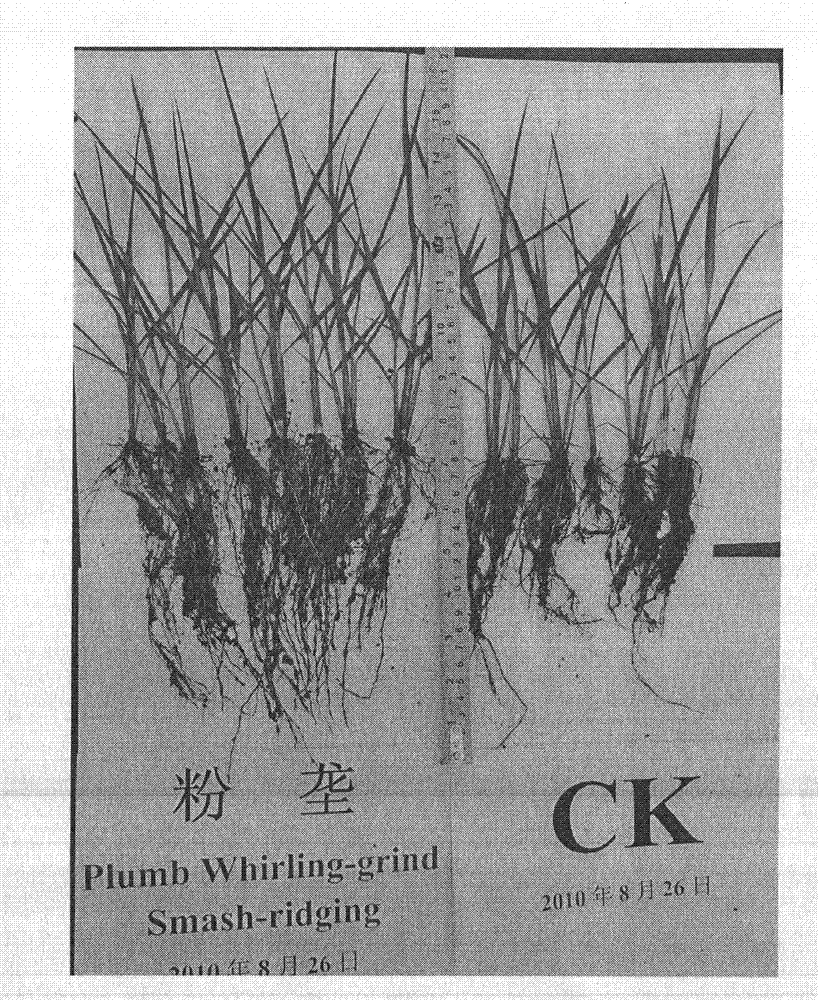

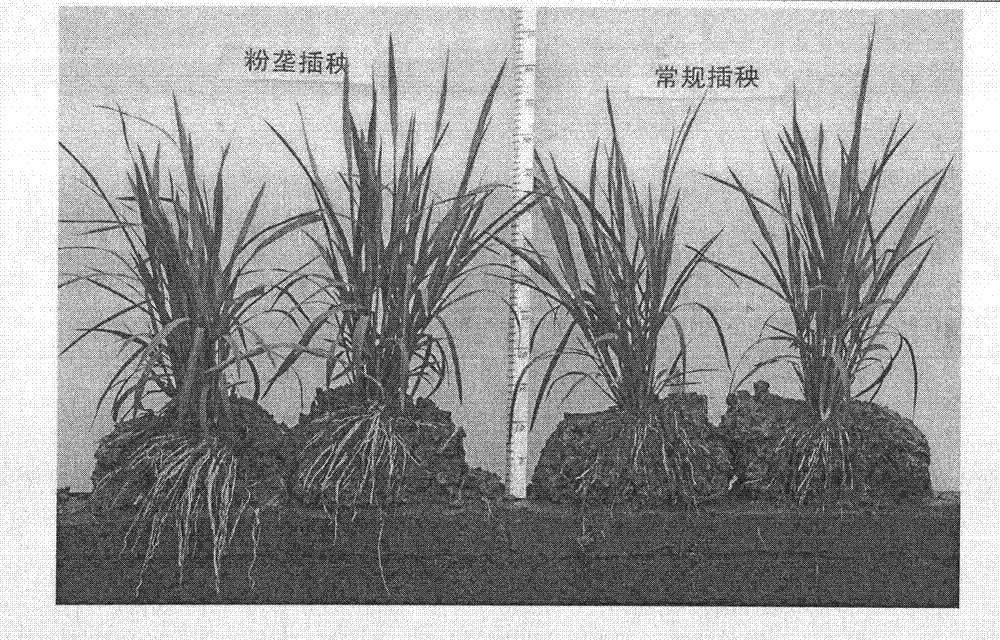

Powder ridge deep-cyclone water-storage seedling-retaining growth promoting and cultivation method in arid and semi-arid regions

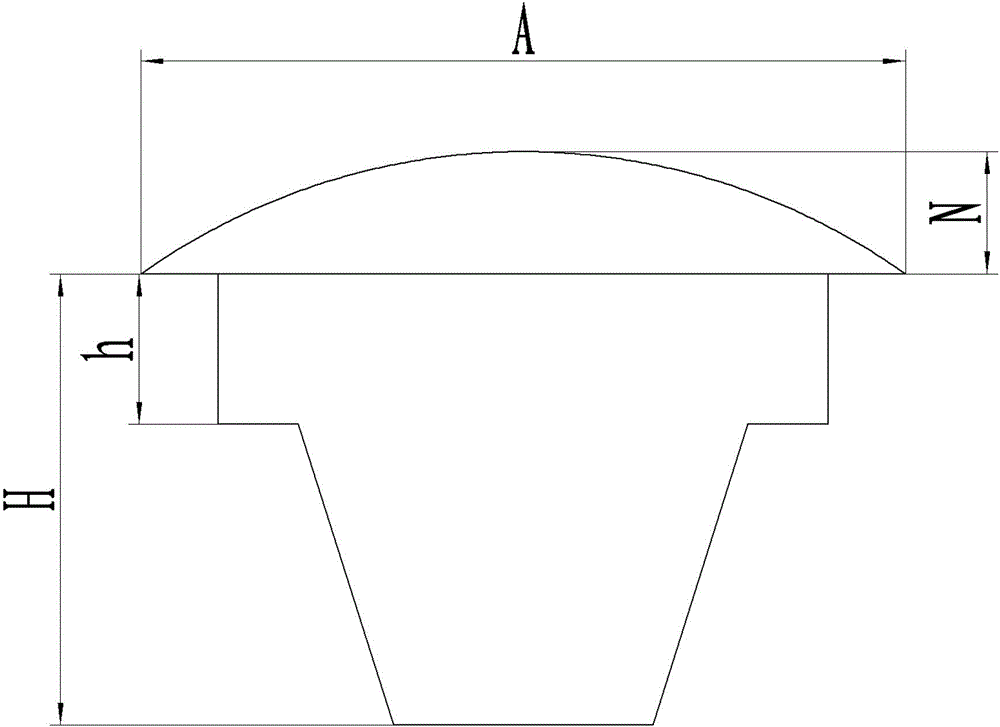

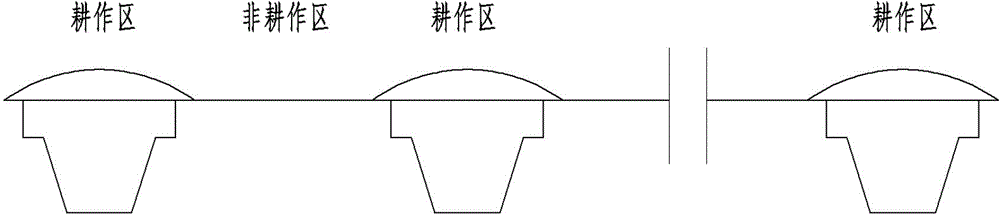

InactiveCN104303635AHighlight substantive featuresSignificant progressPlant protective coveringsSoil-working methodsWater storageSoil science

The invention discloses a powder ridge deep-cyclone water-storage seedling-retaining growth promoting and cultivation method in arid and semi-arid regions. The middle of a cultivating area is deep-ploughed by using a rotary tillage spiral type machine while the two sides of the cultivating area are shallow-ploughed; the soils are milled at the same time; the soils are naturally ridged after the soils are rotated in a deep mode and loosened so as to form a T-shaped ridge land of which the two sides are surrounded by shallow loosening soils and the inclined surfaces have a certain angle. Drainage channels are arranged in a non-cultivation area, a film covers the ridge land, planting holes are formed in the ridge land, and a water-storage tank for storing water and retaining water is established around the planting holes; meanwhile, standardization farm operations such as fertilizer application and pesticide application are carried out, so that the operation is finished mechanically and integrally once, and the labor efficiency is greatly improved; by using the cultivating method, the water content of the soil is effectively increased by more than 30 percent, the production of crops is increased by more than 40 percent, and the economic benefit is obviously increased; moreover, a new ecological balance system is established, and the method has a great popularization value in the northwest arid region.

Owner:广西壮族自治区农业科学院经济作物研究所

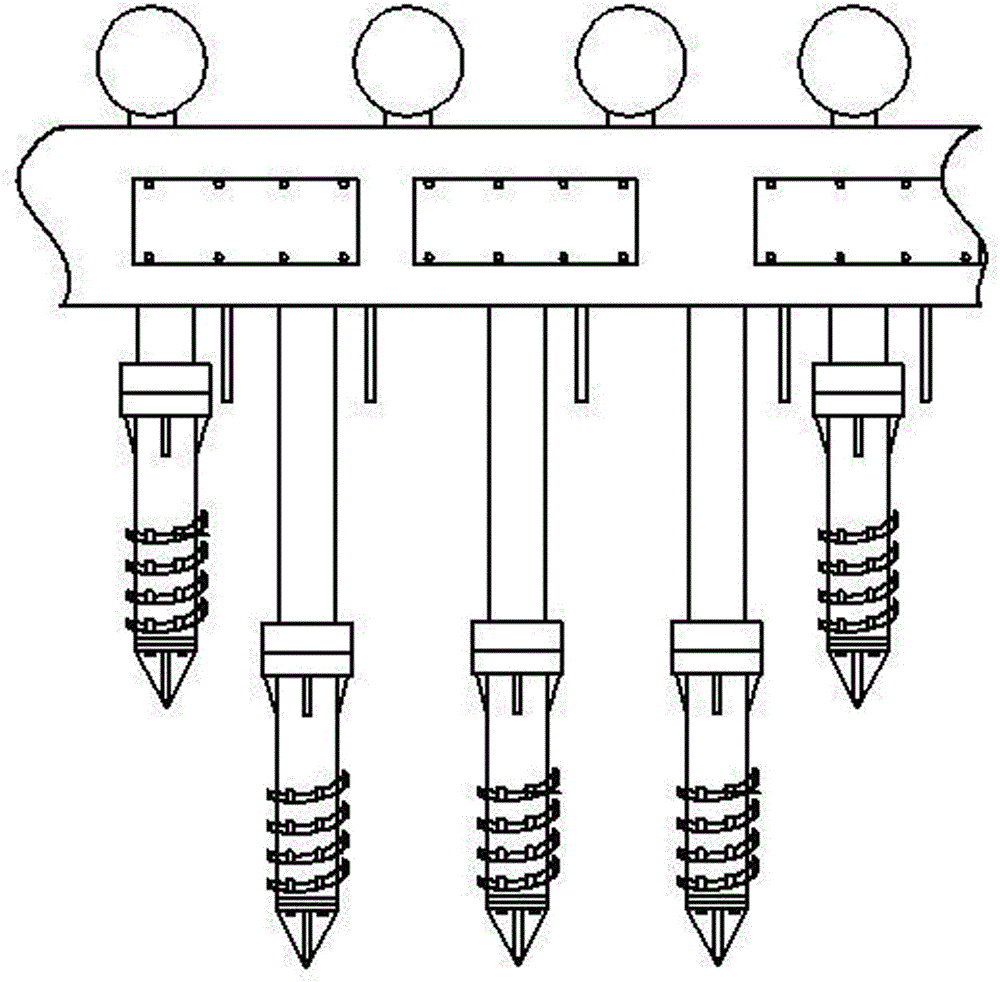

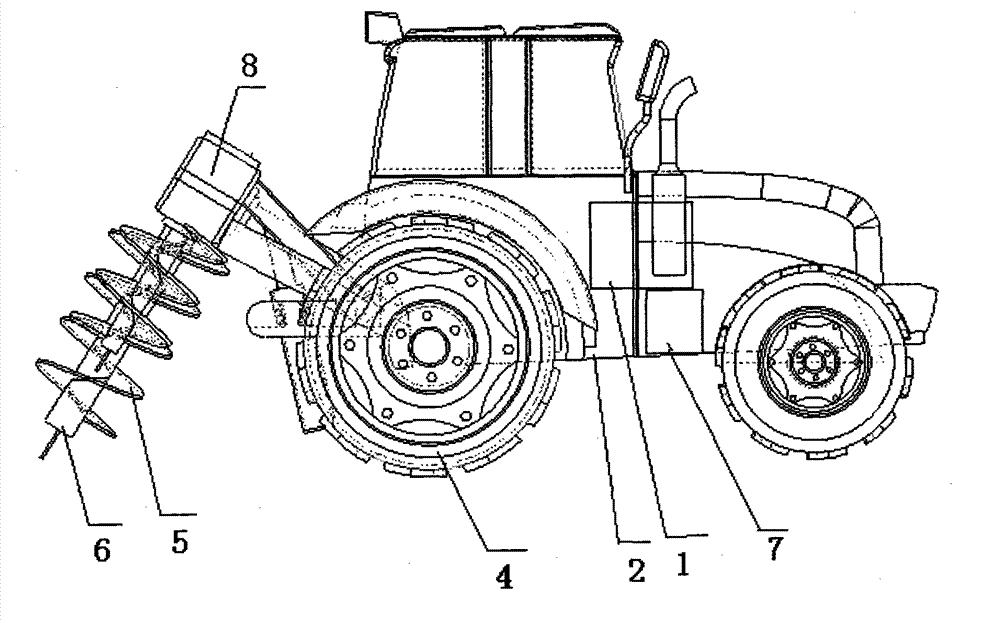

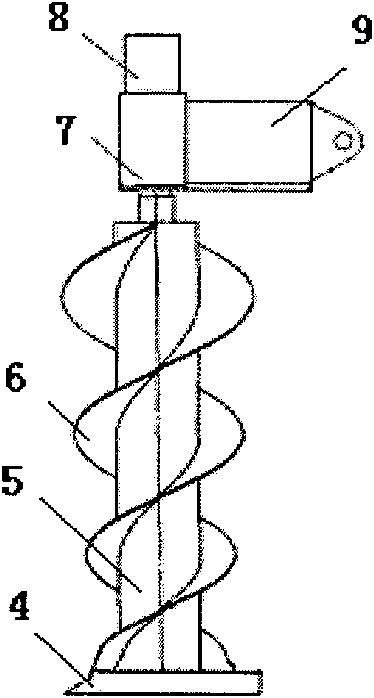

Spin milling type multifunctional machine for deeply ploughing and crushing ridges

InactiveCN101971723BReduce provenanceSignificant progressSpadesTilling equipmentsGear wheelAgricultural engineering

Owner:GUANGXI WUFENG MACHINERY CO LTD

Multi-curve panel adjustable point hook device

The invention discloses a multi-curve panel adjustable point hook device. The device comprises a horizontal sleeve, a diagonal support bracket, an adjustable telescopic rod and a first opposite penetrating bolt, the horizontal sleeve is fixedly connected with the diagonal support bracket, and the adjustable telescopic rod and the horizontal sleeve are connected by the first opposite penetrating bolt; the precision of the installation and splicing of a special-shaped material is improved, a large amount of manpower and material resources are saved for welding and anti-rust treatment, and the labor cost is reduced. Professional staff operation is not required, mass construction is conducted, the construction speed is improved, and the device is conducive to standardization.

Owner:GOLD MANTIS CONSTR DECORATION

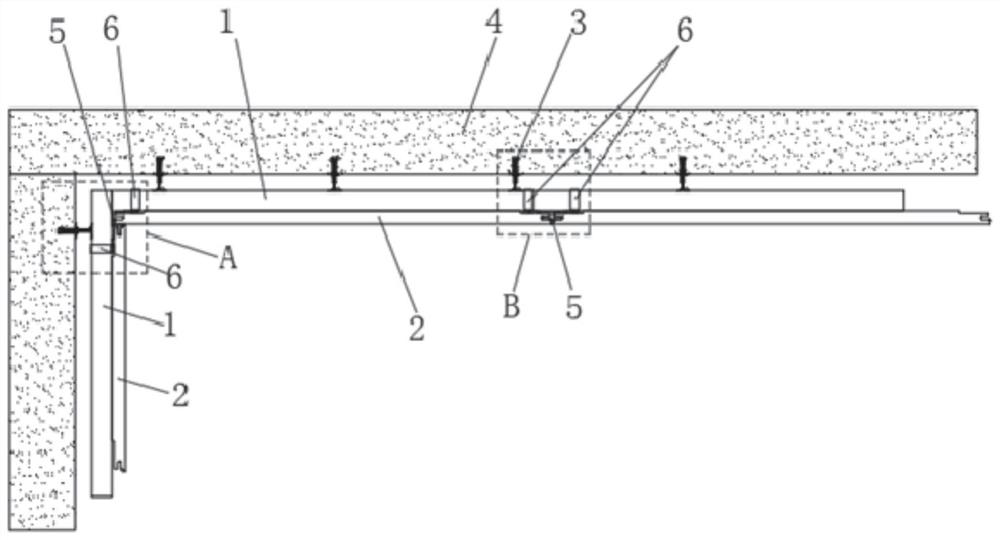

Plastic grid ceiling system

The invention discloses a plastic grid ceiling system, which comprises a primary keel (5), a secondary keel (7), a connecting bolt (6), a split bolt (3), a hanger (2) and a lead screw (1), wherein the lead screw (1) is connected with the hanger (2); the hanger (2) is connected with the primary keel (5) through the split bolt (3); the secondary keel (7) is made of an aluminum grid; the secondary keel (7) is provided with a connecting neck which extends along the length direction of the secondary keel (7); the upper end of the connecting bolt (6) is connected to the primary keel (5); the lower end of the connecting bolt (6) comprises a screw cap; the screw cap is clamped into the connecting neck; and the connecting bolt (6) can move along the connecting neck. The plastic grid ceiling system is suitable for high-end places, the ceiling three-dimension can be enhanced, and diverse shapes of a ceiling and high concealment are achieved; and under the condition of ensuring the working period and complex shapes, a good visual effect is achieved.

Owner:GOLD MANTIS CONSTR DECORATION

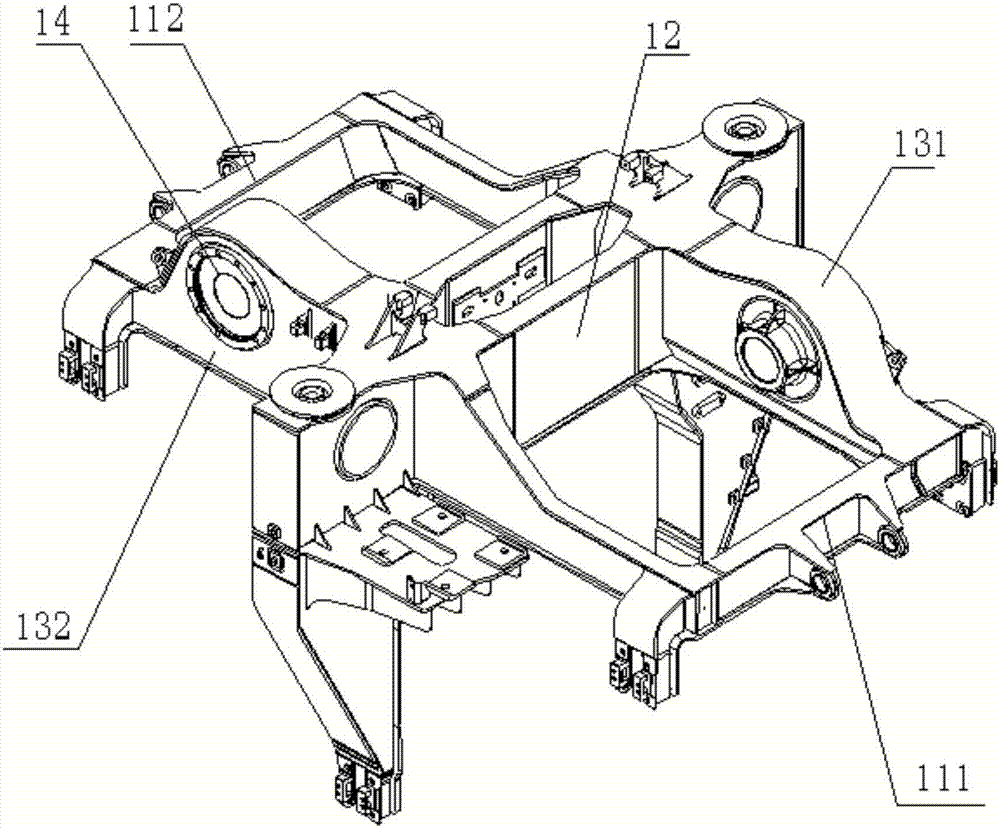

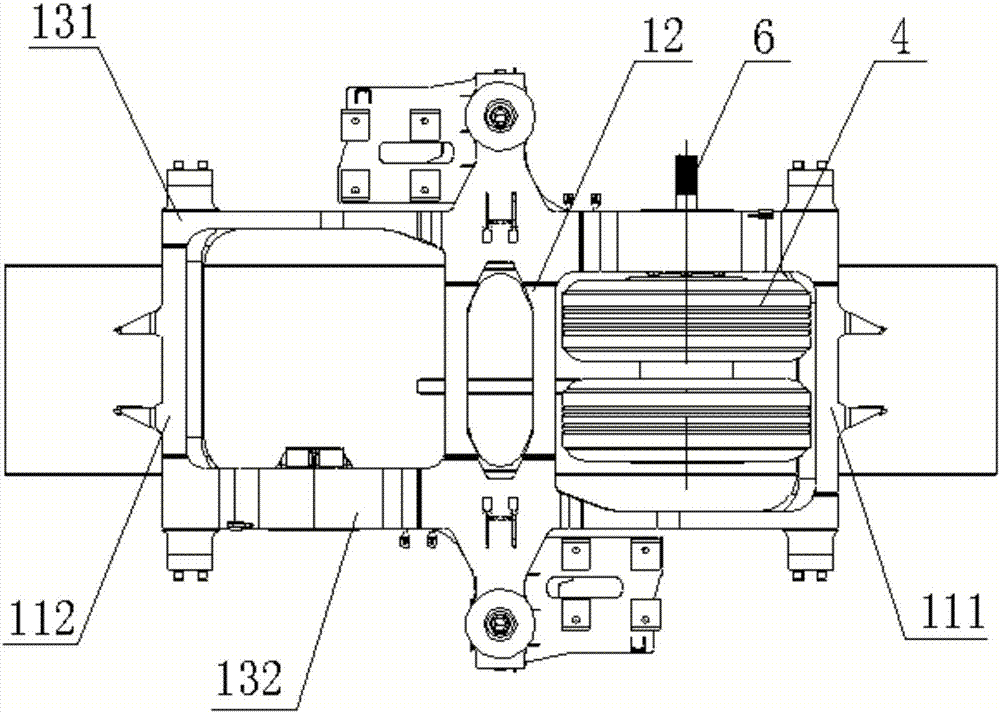

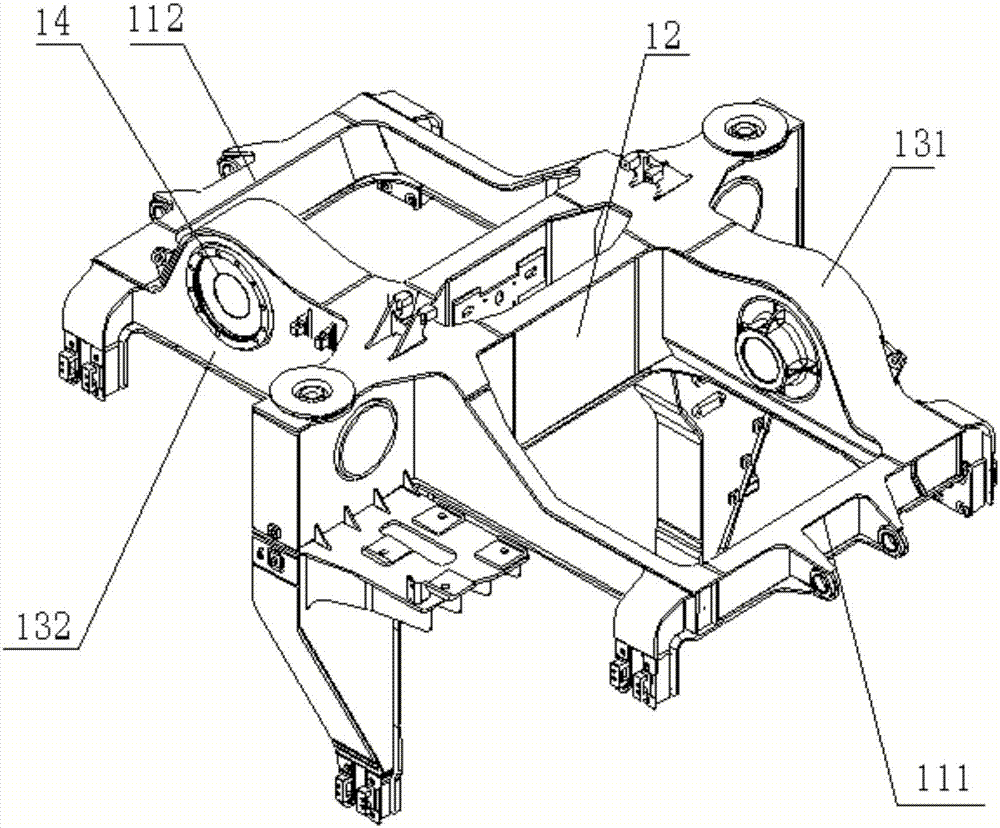

Single-track bogie and track vehicle with single-track bogie

The invention provides a single-track bogie. The single-track bogie comprises a framework, a traction device fixed on the framework, gearbox bases firmly disposed on the framework and a motor base firmly disposed on the framework, wherein the framework comprises two centrally symmetric longitudinal beam modules; and lower cover plates of the longitudinal beam modules are integrated with the motor base. Because of the form of integrating the motor base and longitudinal beams, manufacture is more convenient, time spent on separation installation of the motor base is saved, and operation efficiency is increased. In addition, intensity of parent materials of the integral structure is stronger than intensity of a combined structure. The gearbox bases are disposed inside the longitudinal beam modules, so an integral structure is formed by the gearbox bases and the longitudinal beam modules. In this way, the installed gearbox structure is more stable; the gearbox bases are not shaken easily during gearbox work; and transmission is steadier. The invention also provides a track vehicle.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

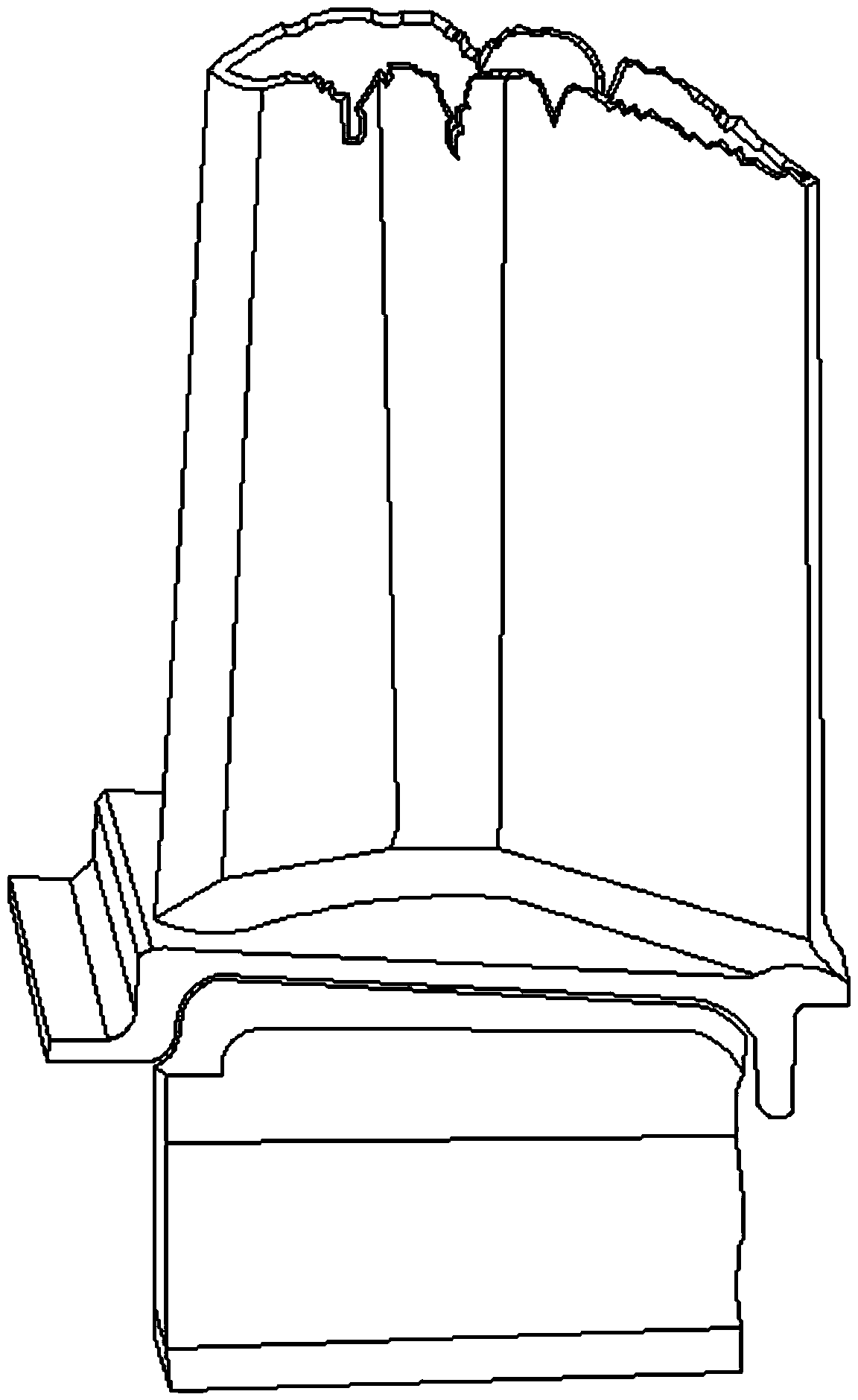

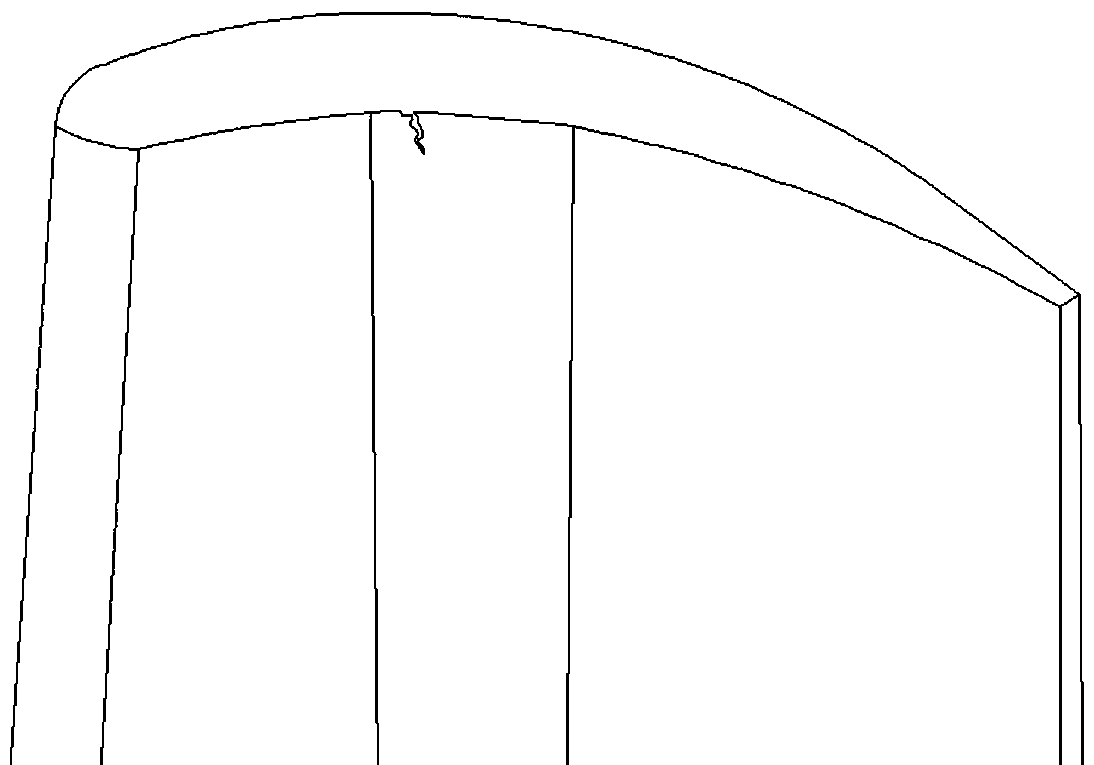

Integral repair method for longitudinal intensive damage of blade crown of aero-engine turbine rotor blade

InactiveCN110202158AReduce the difficulty of operationAvoid crack regenerationAdditive manufacturing apparatusIncreasing energy efficiencyRepair materialNondestructive testing

The invention discloses an integral repair method for the longitudinal intensive damage of a blade crown of an aero-engine turbine rotor blade. The integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade comprises the following steps of firstly mechanically grinding the blade, integrally removing a damaged blade crown, adopting laser for repairing cracks under a casting cover plate, and fixing a blade tip cover plate onto the blade crown of the blade; then adopting an integral type laser solid forming technology for integrally forming the blade crown, manually processing a formed blade crown surface, and recovering a runner type surface; and finally, carrying out nondestructive testing on the repaired turbine blade, and puttinginto use after the blade meets a criterion. According to the integral repair method for the longitudinal intensive damage of the blade crown of the aero-engine turbine rotor blade provided by the invention, the integral repairing method is adopted, so that not only is degradation material removed thoroughly, but also the one-by-one repair process is avoided, and the workload is reduced; and meanwhile, through using a special repair material, a combination property of the crown material is improved.

Owner:PLA NO 5719 FACTORY

Method for planting dryland crops by crashing soil

InactiveCN101779537BImprove permeabilityIncrease productionFertilising methodsSoil-working methodsCrop cultivationPlant disease

The invention discloses a method for planting dryland crops. A rotavator is utilized to deeply loosen and crash the soil in furrows so as to crash the loose soil in a cultivated layer and plough sole and make a portion of foreign soil in the plough sole rise up to be naturally mixed with the soil in the cultivated layer for forming furrows and ridges. The ridges are trapezoidal. Each furrow is 25to 30 cm in width and 80 to 100 cm in depth with loose soil distributed in a T shape, and each loose ridge can be 70 to 80 cm in width and 20 to 25 cm in height; or, each furrow is 50 cm in width and60 to 70 cm in depth, and each ridge is 90 cm in width and 20 cm in height. Crops can be planted right after soil is loosened by the rotavator and formed into ridges. Spacing and furrow depth can be determined according to the planting requirements of different crops. By using the method of the invention, soil in the whole cultivated layer is in a loose state, and foreign soil can be improved during deep rotary tillage, therefore, the water and fertilizer retaining ability and the permeability of the soil are enhanced. The invention has the advantages of helping crops root deeply and utilize water and fertilizer, relatively reducing diseases and weeds, and greatly increasing the yield of crops (usually over 20%, and a maximum of over 100%).

Owner:广西壮族自治区农业科学院经济作物研究所

Refracturing and reconstruction method of oil and gas well

ActiveCN110439524AAchieve full coverageImprove controllabilityFluid removalReconstruction methodControllability

The invention discloses a refracturing and reconstruction method of an oil and gas well. The refracturing and reconstruction method of the oil and gas well includes the following steps that 1, an oldwell is prepared, and it is ensured that the oil and gas well is unobstructed and clean; 2, an expansion tubular column is lowered; 3, the expansion tubular column expands and covers an original casing pipe; 4, pressure is tested; 5, perforation is conducted, a perforation tool is lowered to a pre-perforation position to conduct perforation, and the pre-perforation position avoids an original fracturing section; and 6, fracturing is conducted. Compared with the prior art, the refracturing and reconstruction method has the beneficial effects that an existing subsidy tube technology is creatively applied to old well reconstruction of the oil and gas well, full coverage of the horizontal section of a wellbore is realized by lowering the expansion casing pipe once, subsequent perforation and fracturing only need to be avoided an old fracturing seam and are conduced according to the normal perforation fracturing operational procedures, compared with an existing old well reconstruction technology, controllability of the whole construction process of the refracturing and reconstruction method is good, and standardized operation is easily realized.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hot-working process capable of improving cogging for titanium alloy cast ingot

The invention discloses a hot-working process capable of improving the cogging for a titanium alloy cast ingot. The process comprises the following steps of: 1, scalping the titanium alloy cast ingot and then cutting off a dead head, and then removing the surface defects of the titanium alloy cast ingot by means of grinding; 2, placing the titanium alloy cast ingot in a heating furnace to preheat, and then heating up to 150-200 DEG C above the phase transformation point of a cast ingot beta and preserving heat; 3, placing the heat-preserved titanium alloy cast ingot on a press of greater than 2000 T, and then performing cogging forging, so as to obtain a titanium alloy blank with one end which is forged to process dimensions; and step 4, placing the titanium alloy blank with one end which is forged to process dimensions in the heating furnace, heating, and forging the other end to the process dimensions in the same manner. The hot-working process disclosed by the invention is easy to realize standardized work, and reduce the instability phenomenon of head shrinkage cavity caused by human factors, thus increasing the yield of products; and with the adoption of the process method, the blanks which are less in end-surface shrinkage cavity removal amount and good in surface quality can be produced, thus increasing the yield of products.

Owner:WESTERN TITANIUM TECH

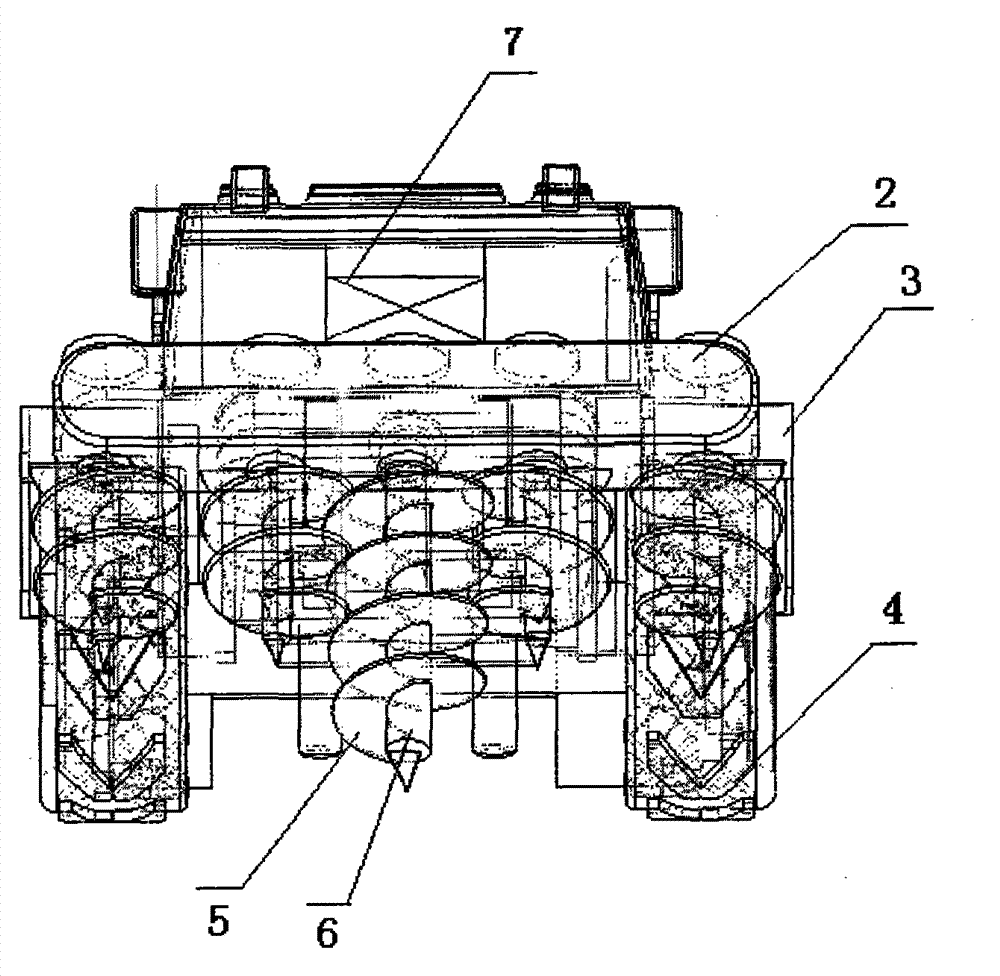

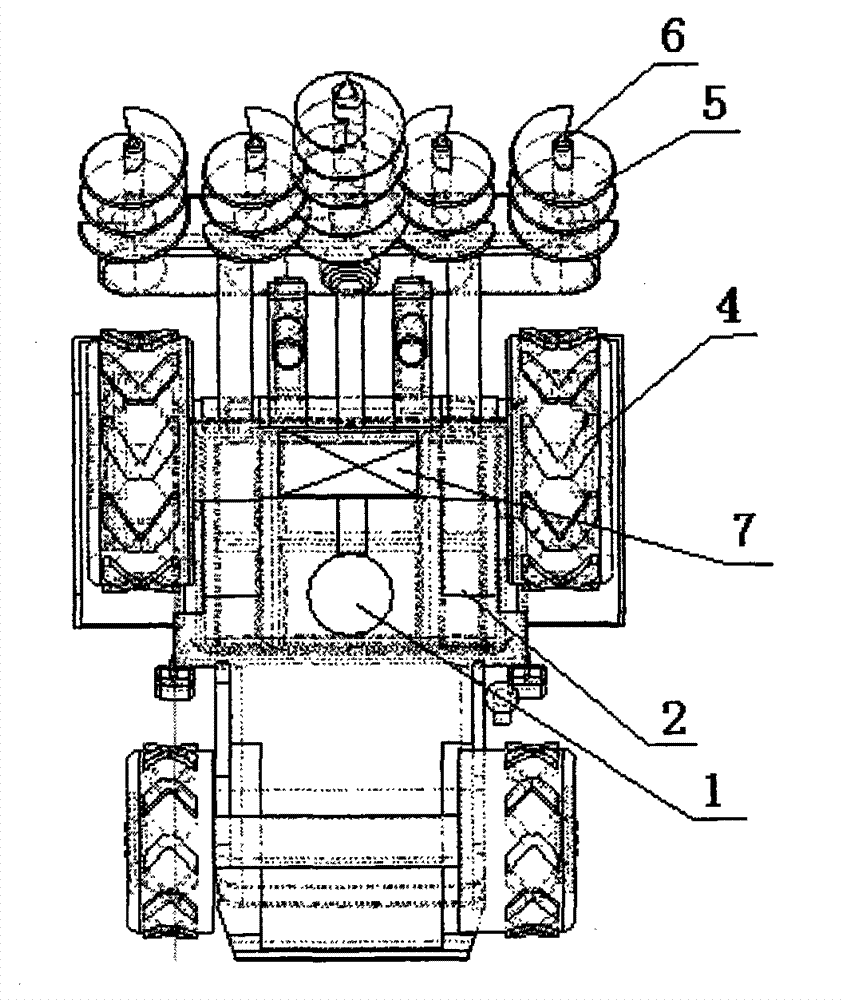

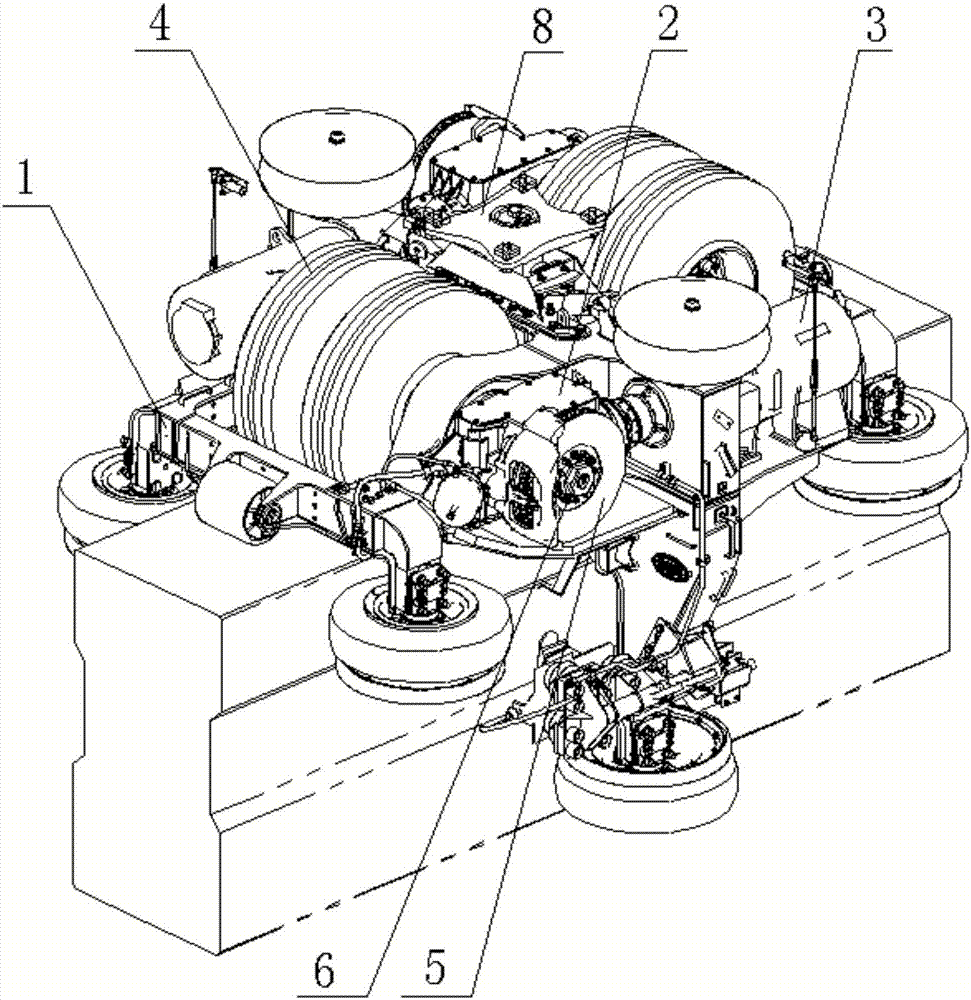

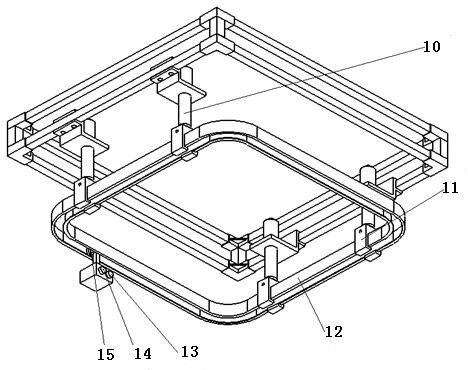

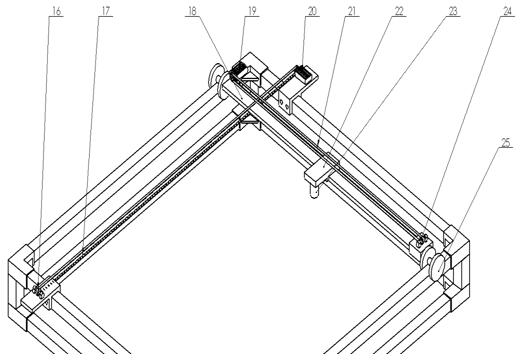

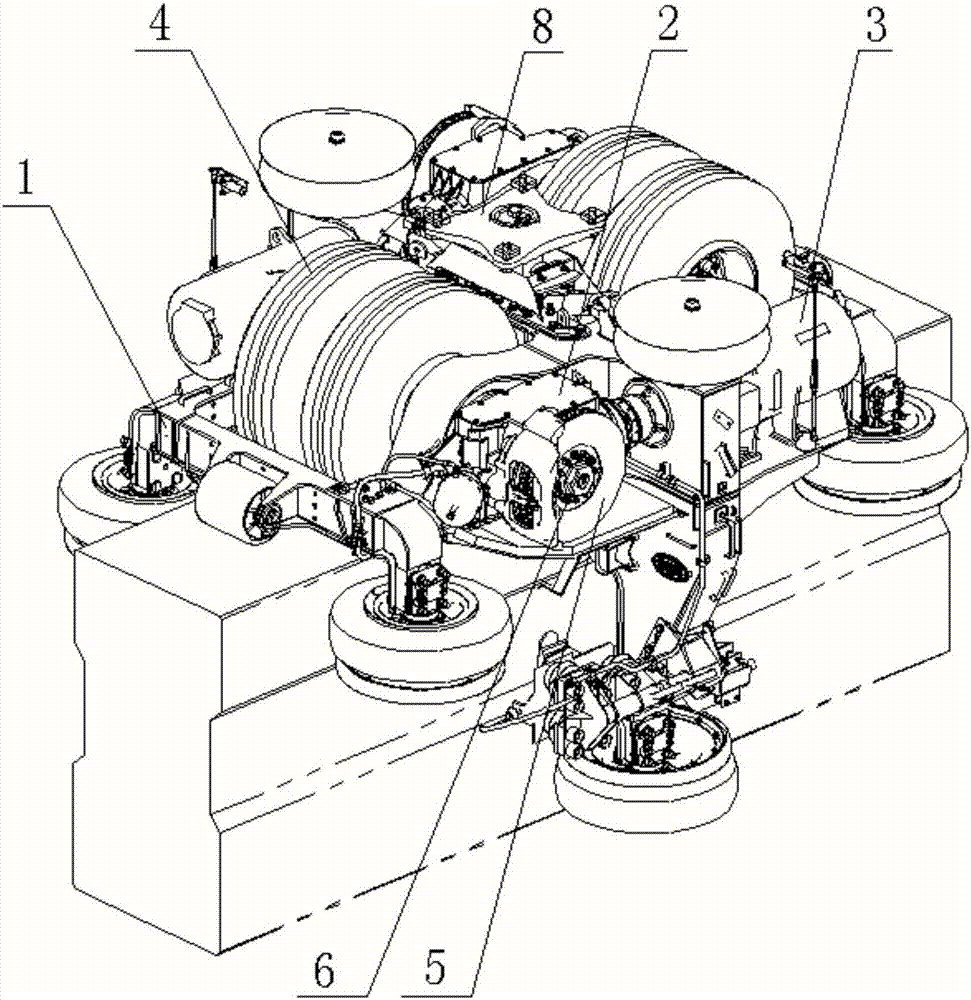

Field-oriented self-propelled crop phenotype acquisition equipment and acquisition method

ActiveCN111637342ARealize all-round photo takingEasy to scanSpectrum investigationStands/trestlesBiotechnologyEngineering

The invention relates to field-oriented self-propelled crop phenotype acquisition equipment and an acquisition method. The field-oriented self-propelled crop phenotype acquisition equipment comprisesa self-propelled navigation vehicle, a translation type phenotype acquisition device, an annular phenotype acquisition device and a telescopic mechanism, wherein the translation type phenotype acquisition device and the annular phenotype acquisition device are mounted on the self-propelled navigation vehicle; the telescopic mechanism drives the annular phenotype acquisition device to move vertically; and the annular phenotype acquisition device is positioned below the translation type phenotype acquisition device. According to the field-oriented self-propelled crop phenotype acquisition equipment and the acquisition method, by the transverse and longitudinal translation of a hyperspectral camera, top ends of plants are photographed in all directions, and therefore, crop canopies are scanned fully; by the telescopic mechanism, the height positions of a near-infrared camera and a depth camera are adjusted; by a self-driven trolley, the near-infrared camera and the depth camera move in the peripheral direction, and therefore, crops are acquired in all directions; and the field-oriented self-propelled crop phenotype acquisition equipment is simple in structure, high in automation degree and good in standardized operation, and the field phenotype data acquisition efficiency and quality are greatly improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

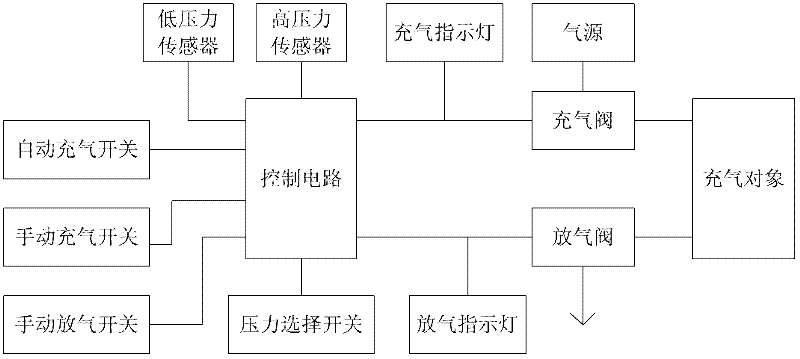

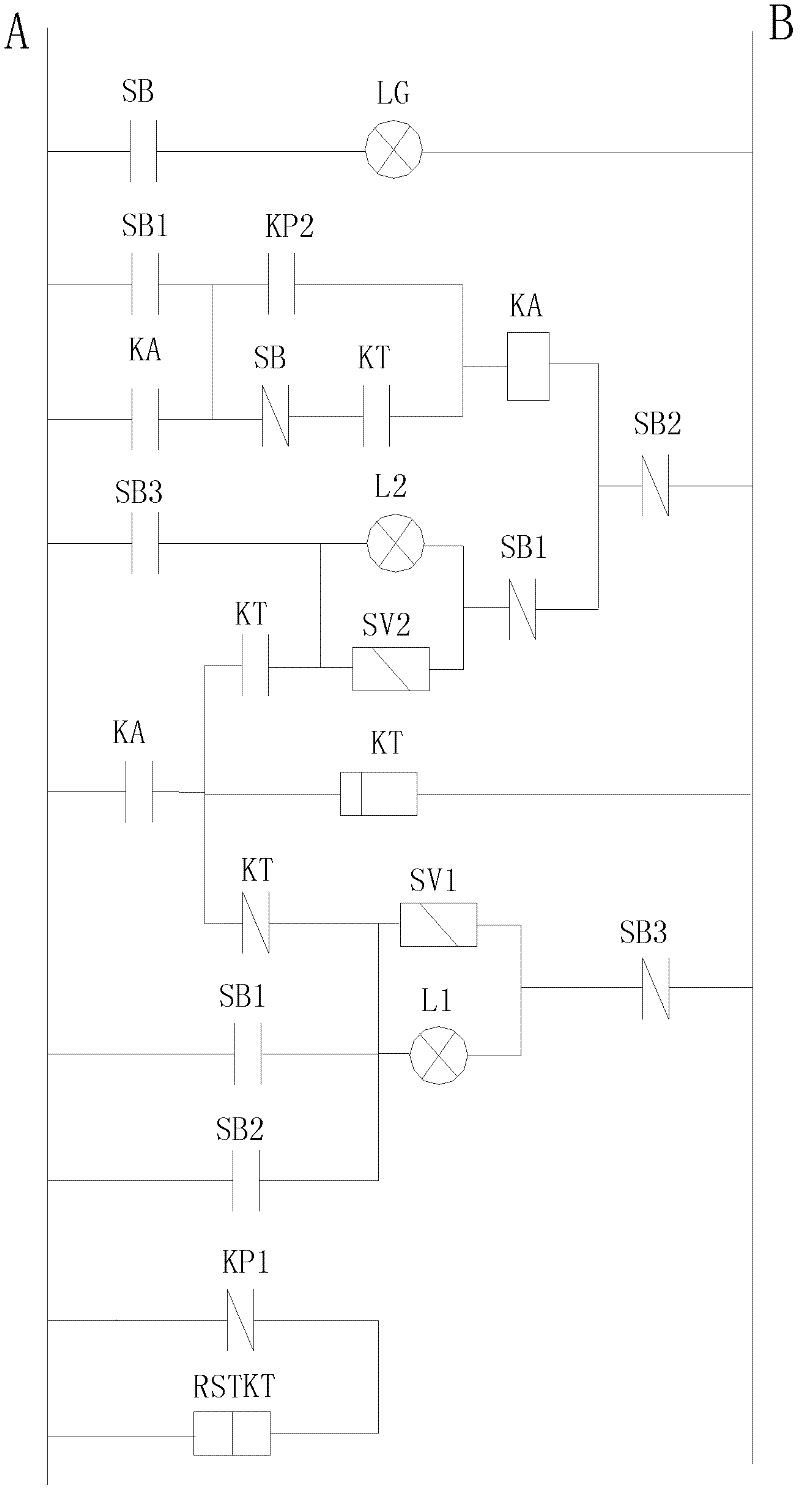

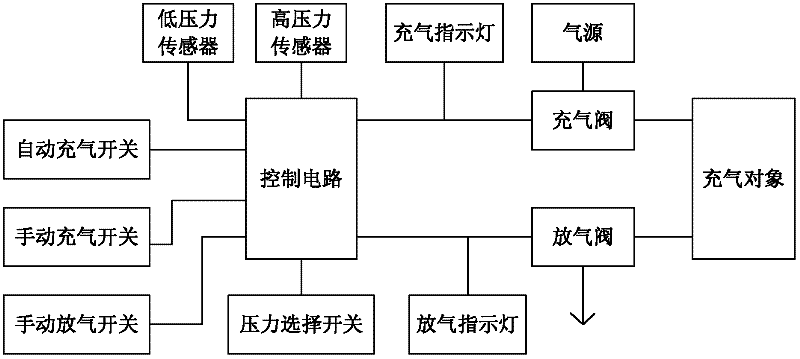

Simple automobile tire automatic inflation device and inflation method

The invention discloses a simple automobile tire automatic inflation device and an inflation method. The automatic inflation device comprises an inflation valve, a deflation valve, a low-pressure sensor which is used for sensing the pressure of an inflated object and is triggered at low pressure, a high-pressure sensor which is used for sensing the pressure of the inflated object and is triggered at high pressure, a pressure option switch for setting an inflation pressure, and a control circuit which is used for correspondingly controlling the inflation valve and the deflation valve according to the state of the pressure option switch and signals of the low-pressure sensor and the high-pressure sensor. The simple automatic inflation device has the advantages of easy manufacture, low cost, strong practicality and convenience in maintenance and use, can be recycled for a long time, and facilitates standard operation. According to the automatic inflation device and method, a mode of inflating before deflating is adopted, and a plurality of objects to be inflated can be inflated at the same time, so that mutual interference is avoided, and working efficiency is increased.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

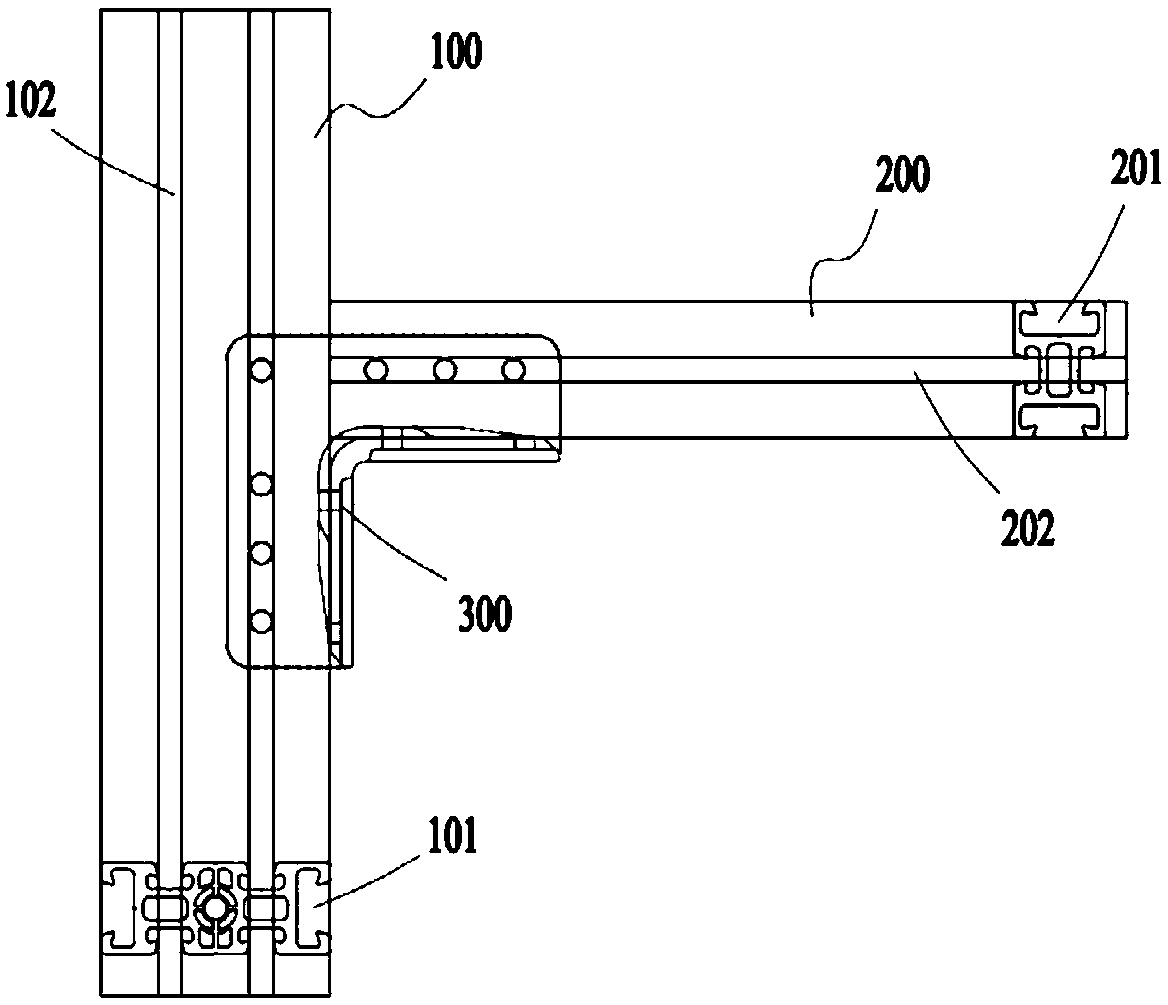

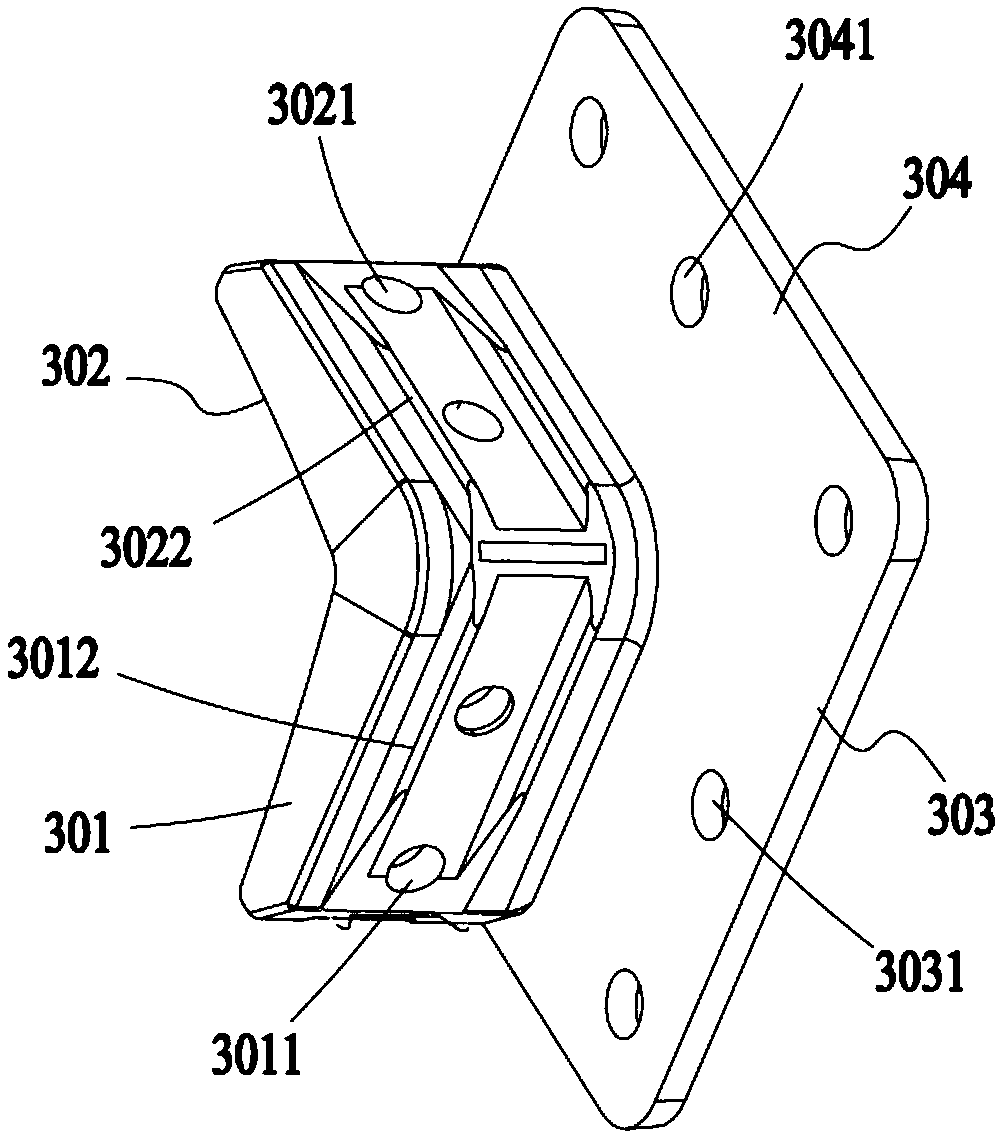

Connector and automobile frame mounting structure

A connector and automobile frame mounting structure is disclosed. The connector includes a first mounting plate and a second mounting plate perpendicular to each other, At least one first mount hole is formed on that first mount plate, the surface of the first mounting plate is convex with two first convex strips arranged side by side, A first mounting hole is positioned between the two first ribs, At least one second mount hole is formed on that second mount plate, the surface of the second mounting plate is convex with two second convex strips arranged side by side, The second mounting holeis located between the two second ribs, and the edge of the first mounting plate vertically extends with a third mounting plate, the third mounting plate is provided with a third mounting hole, and / orthe edge of the second mounting plate vertically extends with a fourth mounting plate, the fourth mounting plate is provided with a fourth mounting hole. Each mounting surface of the present invention is provided with two projections arranged at intervals, and when the mounting hole and the screw are matched, the edge of the support beam can be arranged between the two projections, so that the fixing of the four mounting surfaces can be realized conveniently.

Owner:张家港市宏侣机械制造有限公司

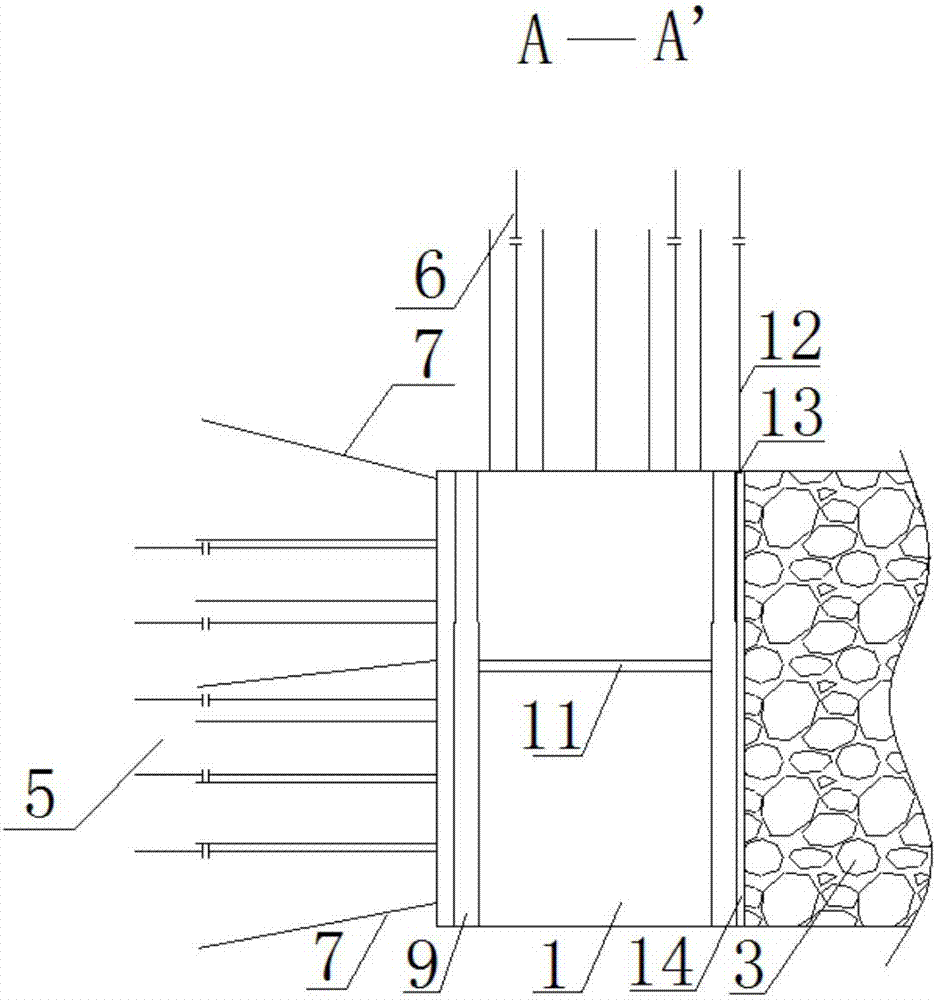

Supporting and protecting device for gob-side entry retaining of ultra-high roadway

PendingCN107956481AHigh recovery rateReduce the amount of excavationUnderground chambersTunnel liningEconomic benefitsStructural engineering

The invention discloses a supporting and protecting device for gob-side entry retaining of an ultra-high roadway. The ultra-high roadway includes a roadway and a front undercutting roadway, negative coal wall spalling is arranged on one sides of the roadway and the front undercutting roadway, and a mined-out area, a working surface and positive coal wall spalling are sequentially arranged on the other sides of the roadway and the front undercutting roadway. Steel pipe concrete pillars and stacking brackets for supporting and protecting are arranged at intervals in the roadway. Transverse strutsteel columns for resisting roadway lateral pressure are arranged on the steel pipe concrete pillars at the mined-out area in the roadway. A roadway top plate is provided with reinforced anchor cables for advance pre-reinforcement. The device has the advantages of reliable support and protection, simple operation, cost saving, improvement of coal recovery rate and improvement of the economic benefit of coal mine, and the application of the ultra-high gob-side entry retaining can reduce the excavation amount of the roadway and alleviate the continuous tension in the mine.

Owner:SHAANXI COAL & CHEM TECH INST

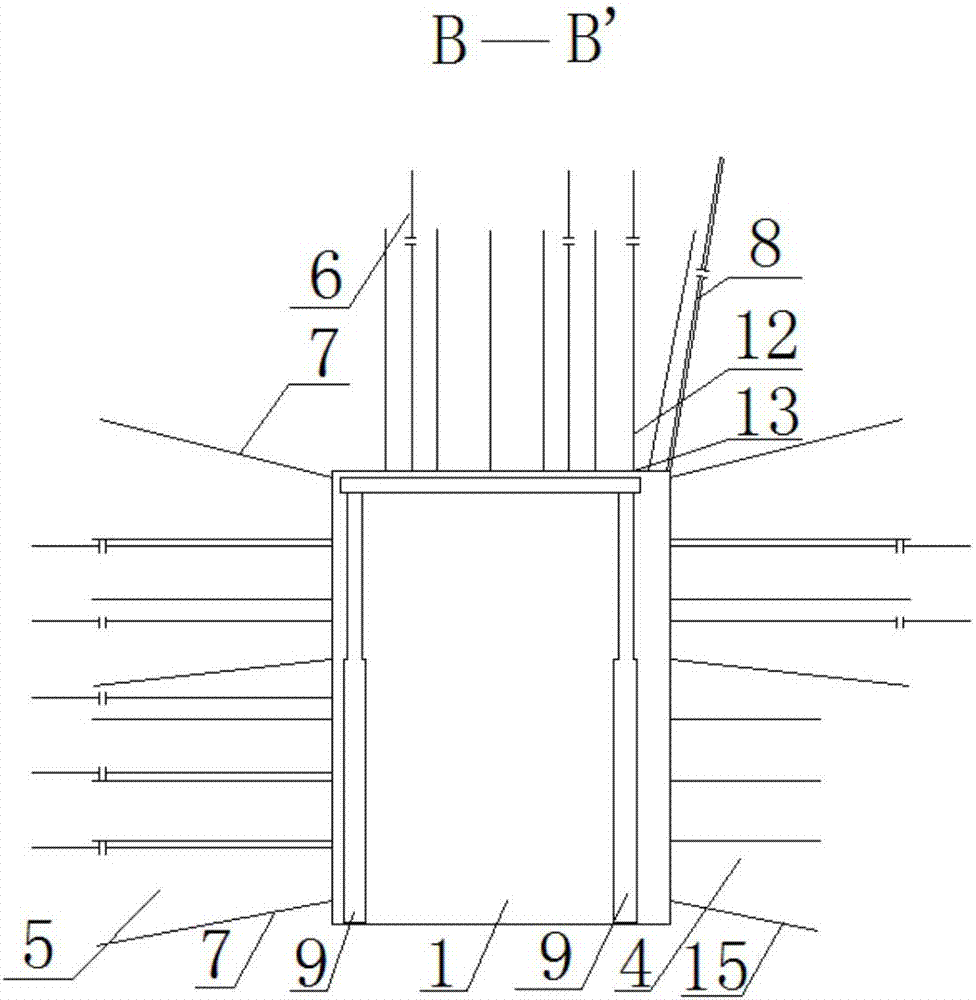

Automobile framework

PendingCN106864598AReduce typesQuick removable installationSuperstructure subunitsPassenger vehicle superstructuresStructural engineeringEngineering

Owner:苏州安耐驰汽车科技有限公司

Crushing and ridging culture method of rice

InactiveCN102246676BHighlight substantiveSignificant progressRice cultivationSoil-working methodsSoil scienceInsect pest

Owner:韦本辉

Machining method of valve seat of relief valve

The invention discloses a machining method of a valve seat of a relief valve. The machining method of the valve seat of the relief valve is characterized by comprising performing turning machining on the valve seat of the relief valve through a numerical control lathe, wherein the turning machining comprises drilling a rough hole in the valve seat of the relief valve through a drilling bit, machining a thread bottom hole at the bottom of the rough hole through a tapping bit and forming an expanded hole in the middle section of the rough hole through boring cutter machining; performing finish machining on the top of the rough hole through a milling cutter to form a tapered hole; performing grinding machining on the expanded hole through internal and external circular grinding machines; machining the top of the tapered hole through a self-made grinding tool and performing grinding and polishing processing in a low rotating speed and rapid feeding mode and a low rotating speed and slow feeding mode to form a small frustum. The machining method of the valve seat of the relief valve has the advantages of being wide in applicable range, high in machining accuracy, low in production cost, high in production efficiency and the like.

Owner:龙工(上海)精工液压有限公司

Lobby space large wave aluminum plate modular installation structure

The invention provides a lobby space large wave aluminum plate modular installation structure. The lobby space large wave aluminum plate modular installation structure comprises an aluminum plate component and ceiling joists; the aluminum plate component is connected to the lower sides of the ceiling joists; the aluminum plate component is provided with a first positioning piece; each ceiling joist is provided with a second positioning piece; and the first positioning piece is detachably connected with the second positioning piece. According to the lobby space large wave aluminum plate modularinstallation structure disclosed by the invention, the aluminum plate component and the ceiling joists can be regulated according to requirements; and the lobby space large wave aluminum plate modular installation structure is simple in structure, is required to be operated by a specialized person, is popular in construction, improves the construction speed, and is beneficial to standardized operation.

Owner:GOLD MANTIS CONSTR DECORATION

Method for construction of vibro-compacted crushed-stone pile in silty soil

InactiveCN108643172ASimple construction processFast progressBulkheads/pilesCrushed stoneUltimate tensile strength

A method for the construction of a vibro-compacted crushed-stone pile in silty soil is characterized by comprising the following steps: first, forming a hole, filling a tubular pile with crushed stone, filling the crushed stone while pulling a tube and carrying out vibration, and sequentially and cyclically carrying out operation in this way. The method has the beneficial effects that the method is simple in construction technology, rapid in progress, low in cost, simple and efficient, and the construction quality is ensured; 2, normalized, programmed and standardized operation is facilitated,and the method is easily grasped by operators and managers; and 3, the strength and the whole stability of a foundation are ensured, and the great effects of rapid construction, energy saving and high efficiency are realized.

Owner:JINAN URBAN CONSTR GRP

Special-shaped cantilever hyperboloid wood veneer installation structure

The invention discloses a special-shaped cantilever hyperboloid wood veneer installation structure comprising a base steel frame, a multilayer board layer (4), a plurality of right-angled trapezoid battens (5), a plurality of wooden mouldings (6) and a U-shaped curved face wood veneer (7). The base steel frame is stably and fixedly connected to a civil wall (1), the surface of the base steel frame is fixed to the multilayer board layer (4), the surface of the multilayer board layer (4) is provided with the right-angled trapezoid battens (5) at intervals, and the bevels of the right-angled trapezoid battens (5) are fitted to the surface of the multilayer board layer (4) tightly; the surface of the multilayer board layer (4) is provided with the wooden mouldings (6) at intervals; the section of the U-shaped curved face wood veneer (7) is in a U shape, and the opening of the U-shaped curved face wood veneer (7) covers the multilayer board layer (4). By the aid of the structure, the installation of the hyperboloid wood veneer with large spanning space can be implemented, the installation quality is guaranteed, and the productized construction of the hyperboloid wood veneer can be implemented.

Owner:GOLD MANTIS CONSTR DECORATION

Mounting structure of novel fabricated bamboo fiber film-coated wallboard

PendingCN112814311AImprove construction efficiencyFast constructionCovering/liningsFire hazardFastener

The invention provides a mounting structure of a novel fabricated bamboo fiber film-coated wallboard. The mounting structure comprises a keel, film-coated wallboards, fasteners, connecting pieces and fixing pieces, wherein the film-coated wallboards are arranged at the bottom or on the outer side of the keel; the fasteners are fixedly connected with the keel and an original wall body; each connecting piece is fixedly connected with two adjacent film-coated wallboards; the fixing pieces are fixedly connected with the keel and the film-coated wallboards; the fixing pieces are arranged on two sides of the connecting pieces; and the bottoms of the fixing pieces are clamped with the connecting pieces. Compared with the prior art, the mounting structure provided by the invention has the advantages of being low in technical requirement, rapid to mount, favorable for standardized operation and high in construction efficiency, and fire hazards are avoided.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Movable graphitization furnace system and power supply device thereof

PendingCN112815722AReduce usageReduce dosageElectric heating for furnacesWaste heat treatmentNonferrous metalProcess engineering

The invention provides a movable graphitization furnace system and a power supply device thereof, and belongs to the field of graphitization furnaces. The movable graphitization furnace system comprises a track of an annular structure; a graphitization furnace body movably arranged along the track; and a plurality of stations distributed along the track, so that the graphitization furnace body sequentially passes through the plurality of stations. The electrifying heating station, the first cooling station, the second cooling station, the discharging station, the renovating station, the charging station and the station to be electrified are sequentially arranged along the track. The graphitization furnace body is movably arranged along the track, and the graphitization furnace body can be moved as required so that the use quantity of buses can be reduced, the use quantity of the buses is only 15% that of existing design, the use quantity of non-ferrous metals is reduced, and meanwhile the line loss is greatly reduced; and the plurality of stations are arranged along the track, thus, fixed operation items can be completed at all the stations at the same time, and standardized operation is facilitated.

Owner:魏开军

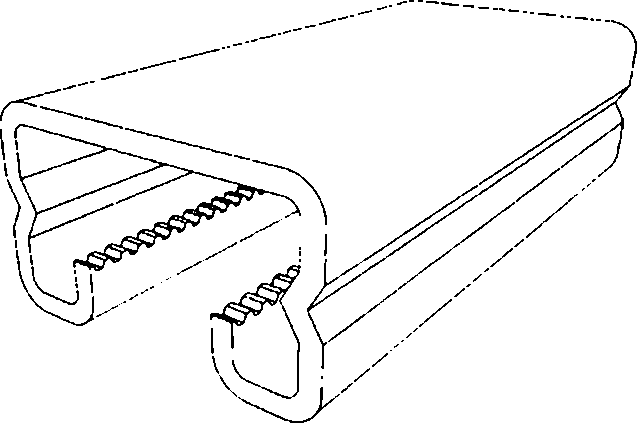

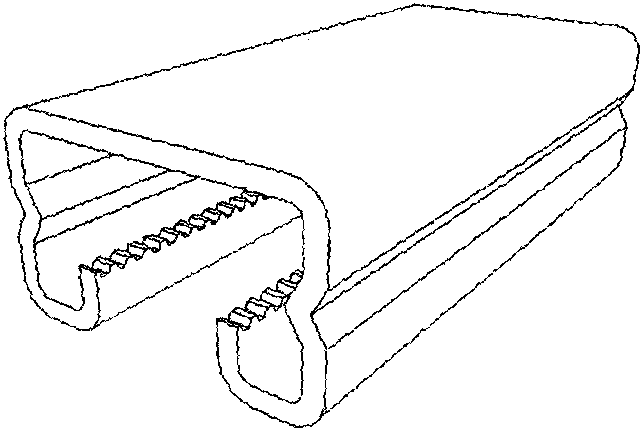

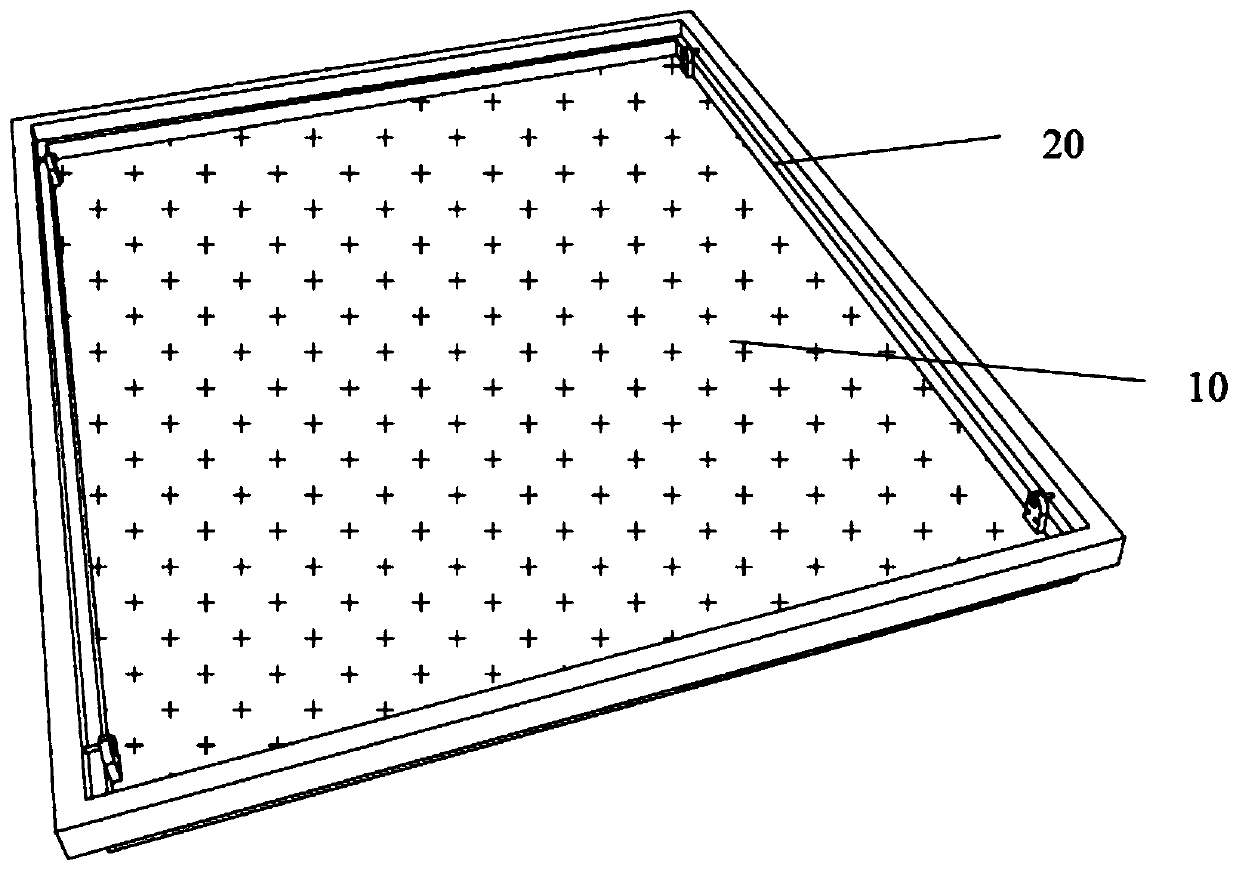

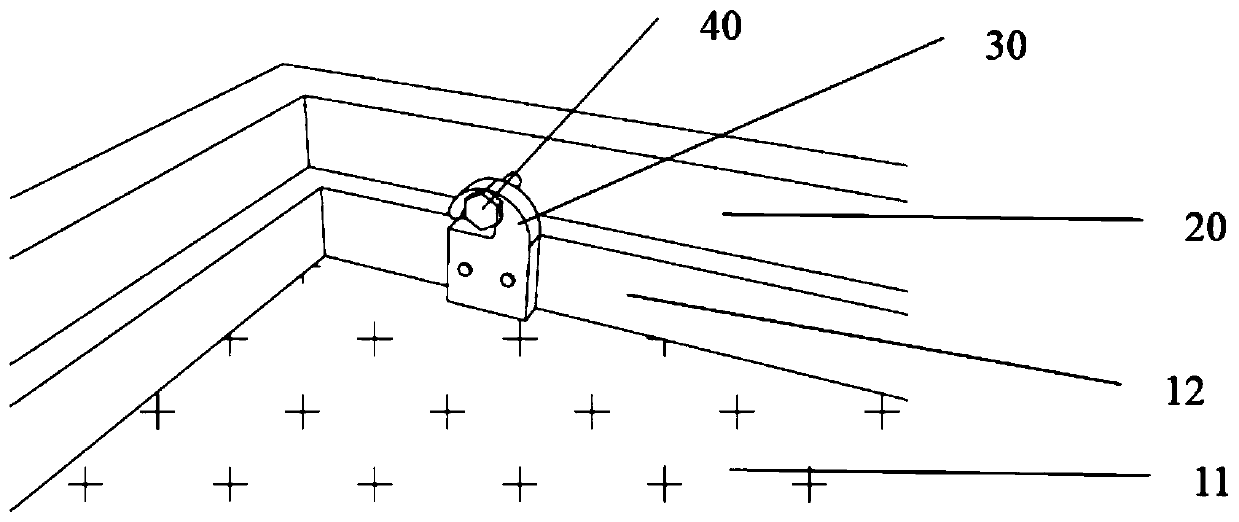

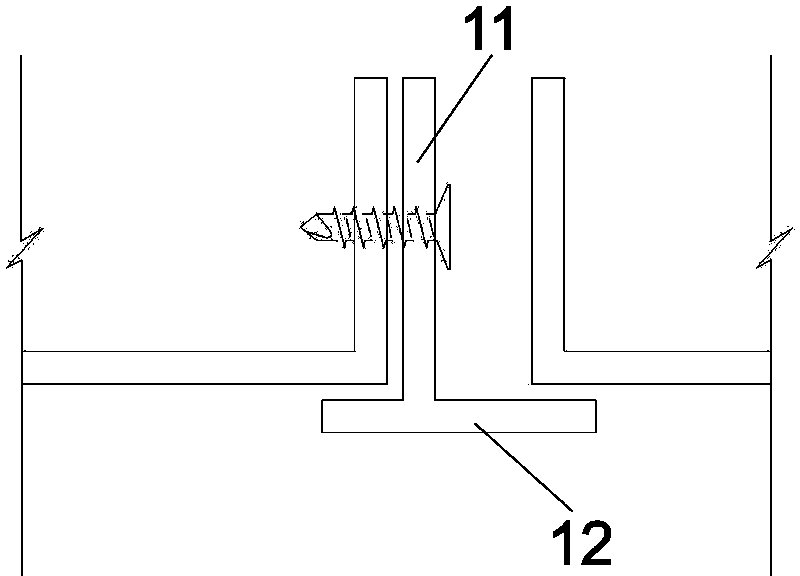

Aluminum profile clamping strip mounting structure

ActiveCN104295044AEasy constructionFacilitate standardized workCovering/liningsEngineeringSingle plate

The invention discloses an aluminum profile clamping strip mounting structure which comprises an aluminum profile clamping strip (1), an inner aluminum single board (2) and an outer aluminum single board (4). The section of the aluminum profile clamping strip (1) is in an inverted T shape. A splicing seam is reversed between the inner aluminum single board (2) and the outer aluminum signal board (4). The ridge of the aluminum profile clamping strip (1) is located in the splicing seam and fixed to the outer side of the inner aluminum single board (2) through a self drilling screw (3). The head of the aluminum clamping strip (1) is located below the splicing seam and covers the splicing seam. The bottom face of the inner aluminum signal board (2) is located above the aluminum profile clamping strip (1), and a seam is reversed between the bottom face of the inner aluminum single board (2) and the aluminum profile clamping strip (1). The outer aluminum single board (4) is suspended above the aluminum profile clamping strip (1) and is kept separated from the aluminum profile clamping strip (1). The aluminum profile clamping strip mounting structure is simple in construction and easy to implement and capable of decorating the splicing seam in the aluminum single board and avoiding cambering and wear, caused by thermal expansion, between the aluminum single boards, no professional staff is needed to conduct operation, and the standardized work is facilitated.

Owner:GOLD MANTIS CONSTR DECORATION

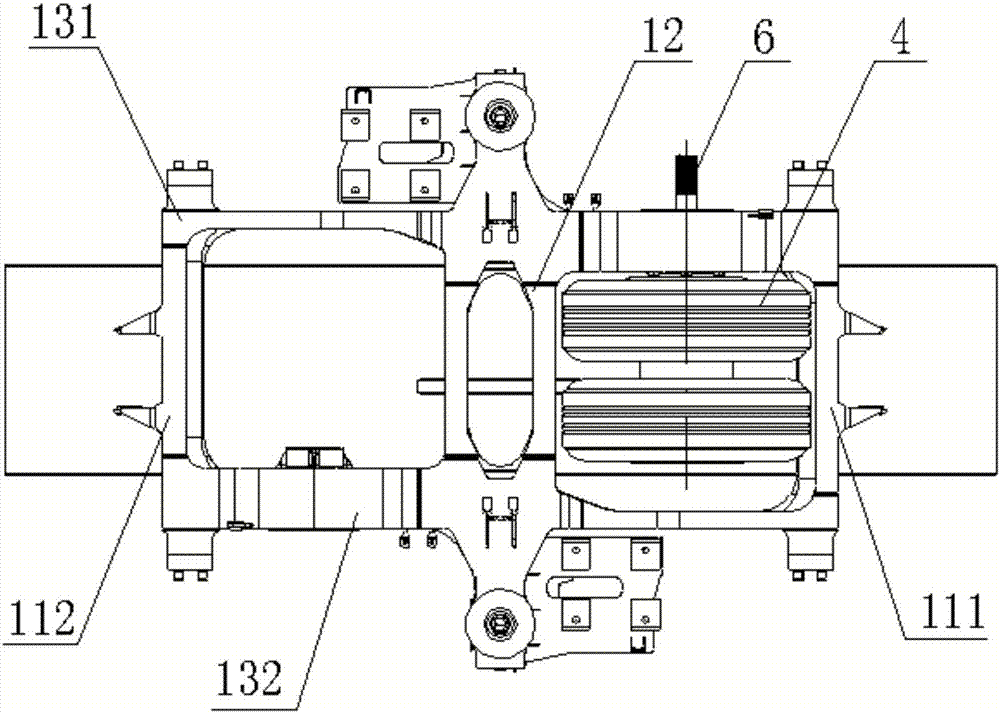

Single-track bogie and track vehicle with single-track bogie

The invention provides a single-track bogie. The single-track bogie comprises a framework, a traction device fixed on the framework, a motor fixed on the framework, a gearbox connected to the motor, a drive shaft of which one end is connected to the gearbox and wheels fitted with the drive shaft, wherein two sets of centrally symmetric transmission systems are disposed on the framework. In this way, the transmission systems are set into a centrally symmetric form, so mass on two sides is more balanced and driving stability of the bogie is enhanced. In addition, a motor output shaft is connected to an input shaft of the gearbox, and transmission of an input shaft of the gearbox and the drive shaft is achieved by a bevel gear. The design has the advantages that transmission efficiency is increased; excessive energy loss in multi-stage transmission is avoided. In addition, because of first-stage transmission of the motor and the gearbox, the structure is more stable and vibration does not take place easily. The invention also provides a track vehicle.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com