Mounting structure of novel fabricated bamboo fiber film-coated wallboard

A technology for installing structures and bamboo fibers, which is applied in covering/lining, building construction, construction, etc., and can solve problems such as fire hazards, complicated installation and construction procedures, and high technical requirements for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

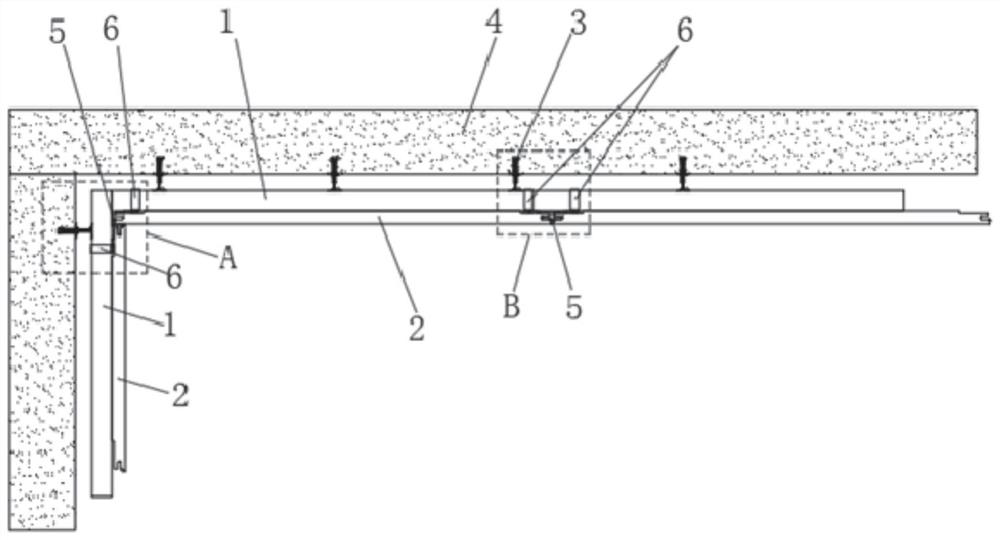

[0041] see figure 1 , the figure shows the installation structure of an assembled new bamboo fiber film-coated wallboard provided by Embodiment 1 of the present invention, mainly including: a keel 1; a film-coated wallboard 2, which is arranged on the bottom of the keel 1 or Outside; Fastener 3, which is fixedly connected to the keel 1 and the original wall 4; Connector 5, which is fixedly connected to two adjacent film-coated wallboards 2; Fixer 6, which is fixedly connected to the keel 1 and The film-coated wallboard 2 ; the fixing part 6 is arranged on both sides of the connecting part 5 , and the bottom of the fixing part 6 is engaged with the connecting part 5 . Wherein, the bottom of the fixing member 6 is provided with a locking groove 61 .

[0042]The installation structure of a new type of assembled bamboo fiber film-coated wallboard provided in this embodiment mainly includes a keel 1, a film-coated wallboard 2, a fastener 3, a connecting piece 5 and a fixing piece ...

Embodiment 2

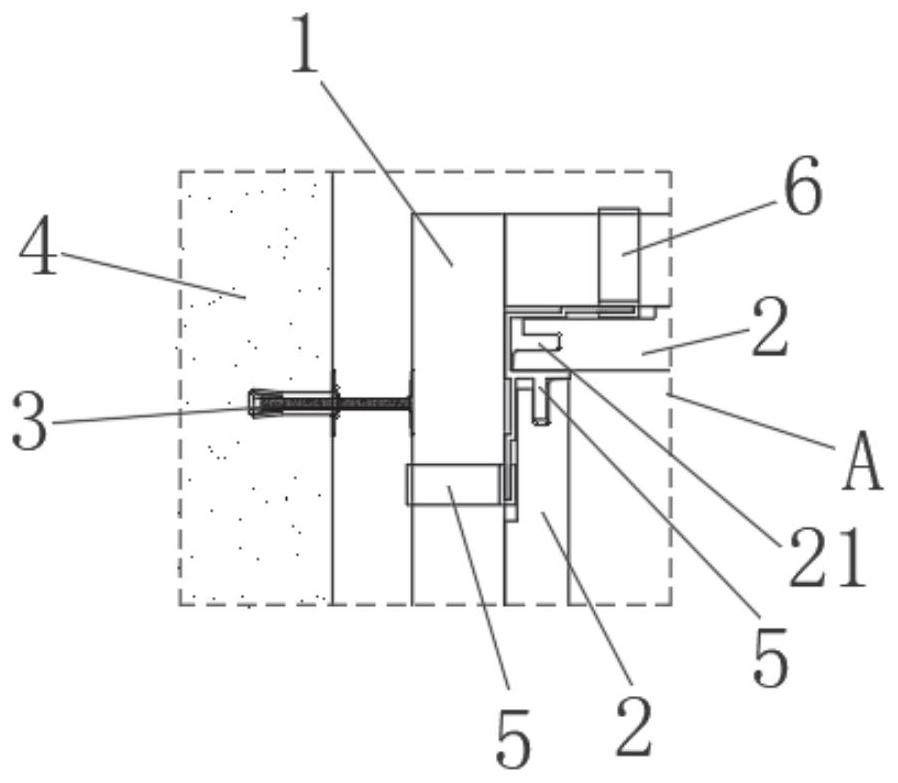

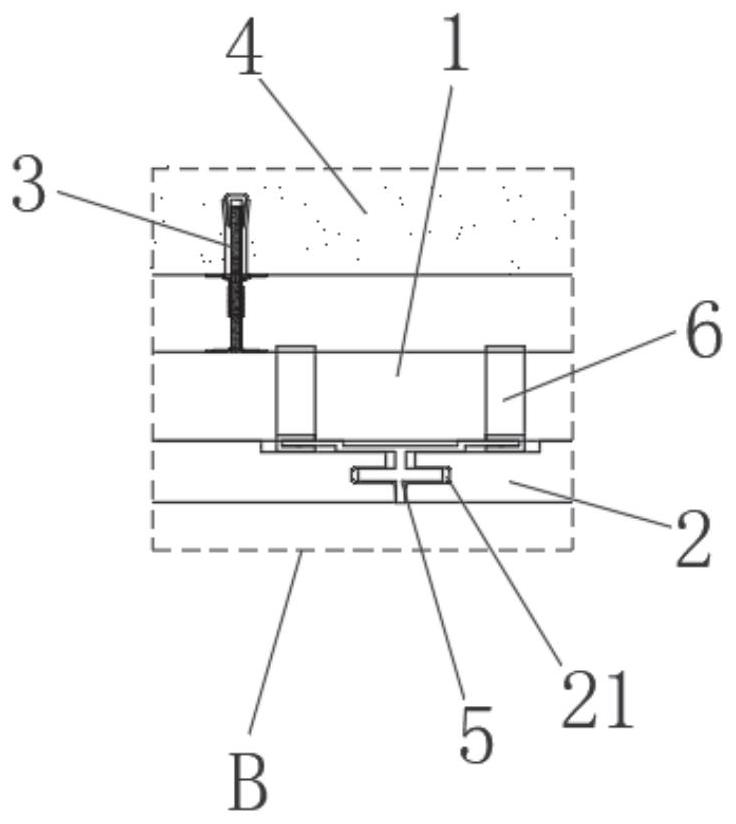

[0050] see Figure 2-4 , the figure shows the installation structure of a new type of assembled bamboo fiber film-coated wallboard provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improvements Solution: the fastener 3 includes a keel fixing cap 31, an expansion screw 32, an expansion tube 33 and a pressure riveting 34, the keel fixing cap 31 is connected to the keel 1, and the expansion tube 33 is sleeved on the expansion screw 32 , the pressure riveting 34 is sleeved on the expansion screw 32 and located at the bottom of the expansion tube 33 . Through the setting of the above structure, the connection strength between the keel 1 and the original wall body 4 can be improved, and the installation effect is better.

Embodiment 3

[0052] see Figure 2 to Figure 3 , Figure 5-6 , the figure shows the installation structure of a new type of assembled bamboo fiber film-coated wallboard provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improvements Solution: the connecting piece 5 is an "F" type connecting piece or a "soil" type connecting piece; " type connector for splicing; when the two film-coated wall panels 2 are spliced at the inner corner, the two film-coated wall panels 2 are spliced using the "F" type connector. Through the setting of the above structure, the two types of connectors can be installed according to the position of the film-covered wall panels 2, solving the installation problem when two adjacent film-covered wall panels 2 are connected in the plane position and the vertical position, and the installation is firm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com