Aluminum profile clamping strip mounting structure

A technology for installing structures and aluminum profiles, applied in building construction, covering/lining, construction, etc., can solve the problems of large thermal expansion and cold contraction, gap expansion, wear and other problems, and achieves simple and easy construction and is conducive to standardized operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

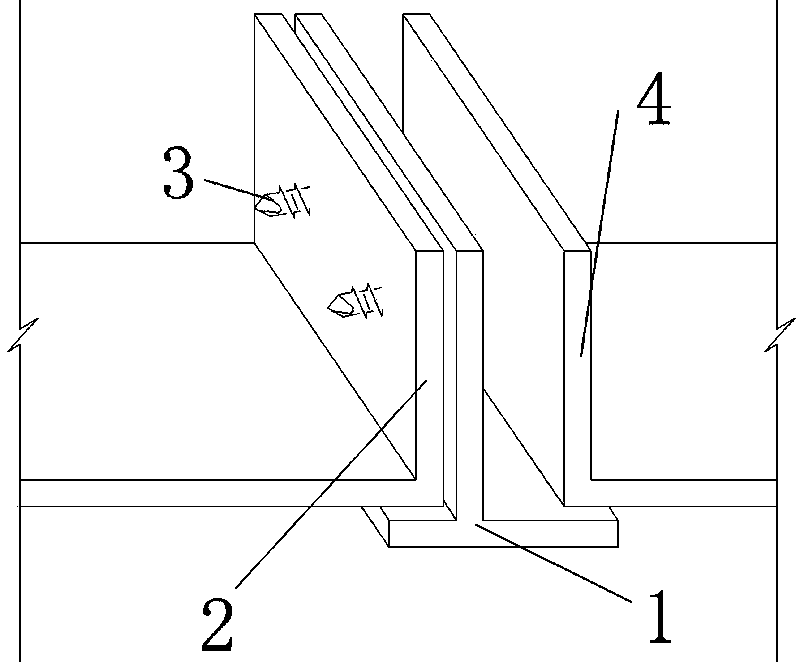

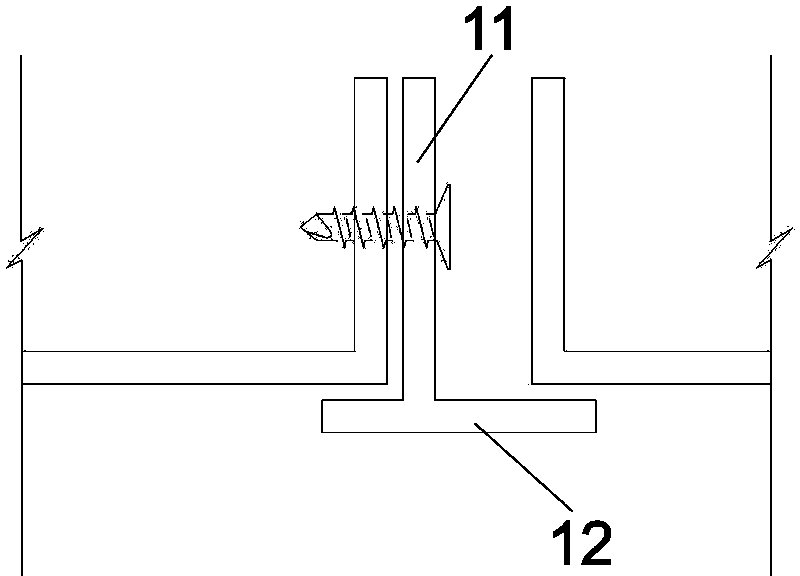

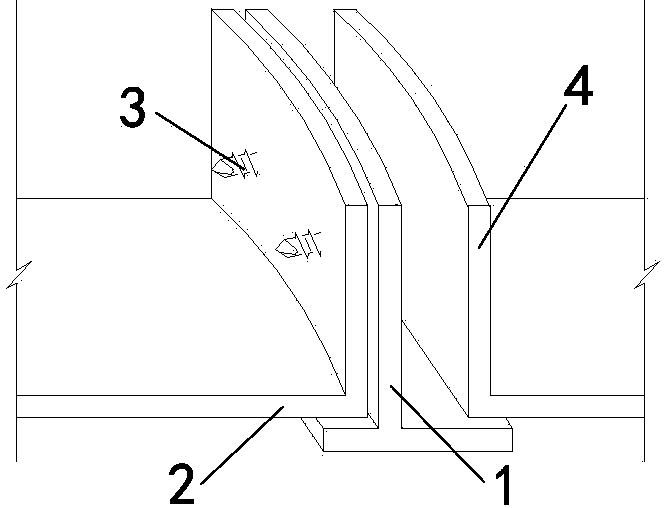

[0014] Example: such as figure 1 , figure 2 As shown, a mounting structure for aluminum profile clips includes an aluminum profile clip 1 , an inner aluminum veneer 2 , and an outer aluminum veneer 4 .

[0015] The cross-section of the aluminum profile clip 1 is in an inverted T shape. There is a splicing seam reserved between the inner aluminum veneer 2 and the outer aluminum veneer 4. The ridge 11 of the aluminum profile clip 1 is located in the splicing seam and passes through the drill tail. The screw 3 is fixed on the outer side of the inner aluminum veneer 2, and the head 12 of the aluminum profile clip 1 is located below the seam and covers the seam. The bottom surface of the inner aluminum veneer 2 is located above the aluminum profile clip 1, leaving a gap with the aluminum profile clip 1, and the gap width is 1 mm. The outer aluminum veneer 4 is suspended above the aluminum profile clip 1 and kept separated from the aluminum profile clip 1 .

[0016] The processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com