Plastic grid ceiling system

A plastic and grid technology, applied in the direction of ceilings, building components, buildings, etc., can solve the problems of high quality requirements for pipeline and roof concrete construction, limit the diversity of aluminum grids, and fail to achieve decorative effects, which is conducive to standardization. Work, reduce open flame work, shorten the effect of changing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

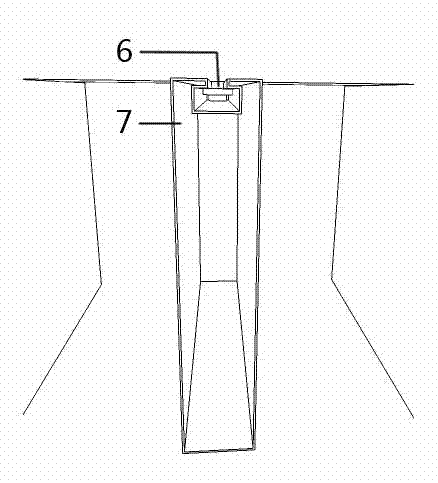

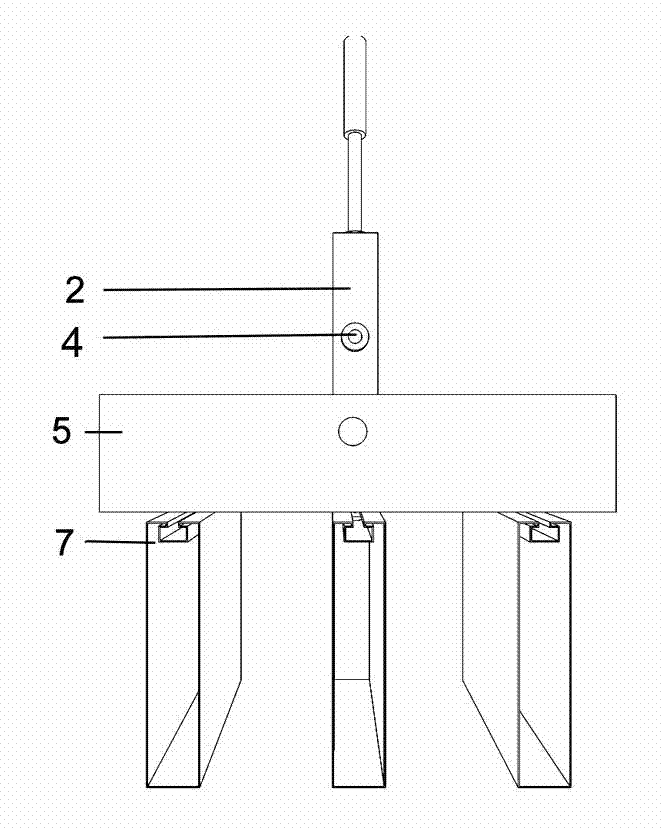

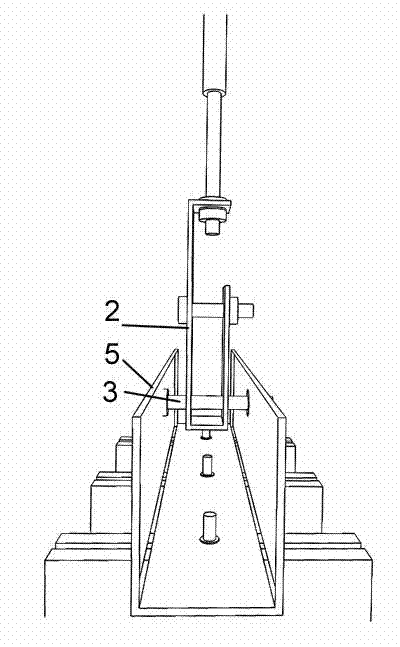

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a plastic grid ceiling system includes a main keel 5, an auxiliary keel 7, a connecting bolt 6, a pull bolt 3, a hanging part 2, a screw rod 1, a screw rod 1 is connected to a hanging part 2, and a hanging part 2 It is connected with the main keel 5 through the pull bolt 3, the auxiliary keel 7 is an aluminum grid, and the auxiliary keel 7 is provided with a connection card slot extending along the length direction of the auxiliary keel 7; the upper end of the connecting bolt 6 is connected to the main keel 5, and connected The lower end of the bolt 6 includes a nut, which snaps into the connection slot, and the connection bolt 6 can move along the connection slot.

[0025] The height of the auxiliary keels 7 is greater than the distance between adjacent auxiliary keels 7 . The traditional aluminum grid ceiling can be observed from all angles, and the interior of the ceiling can be observed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com