Lobby space large wave aluminum plate modular installation structure

A technology with installation structure and large space, applied in building components, building structures, building insulation materials, etc., can solve the problems of inability to change, consume a lot of manpower and material resources, and cannot be well adjusted for installation, so as to reduce consumables and improve Construction speed and the effect of facilitating standardized operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

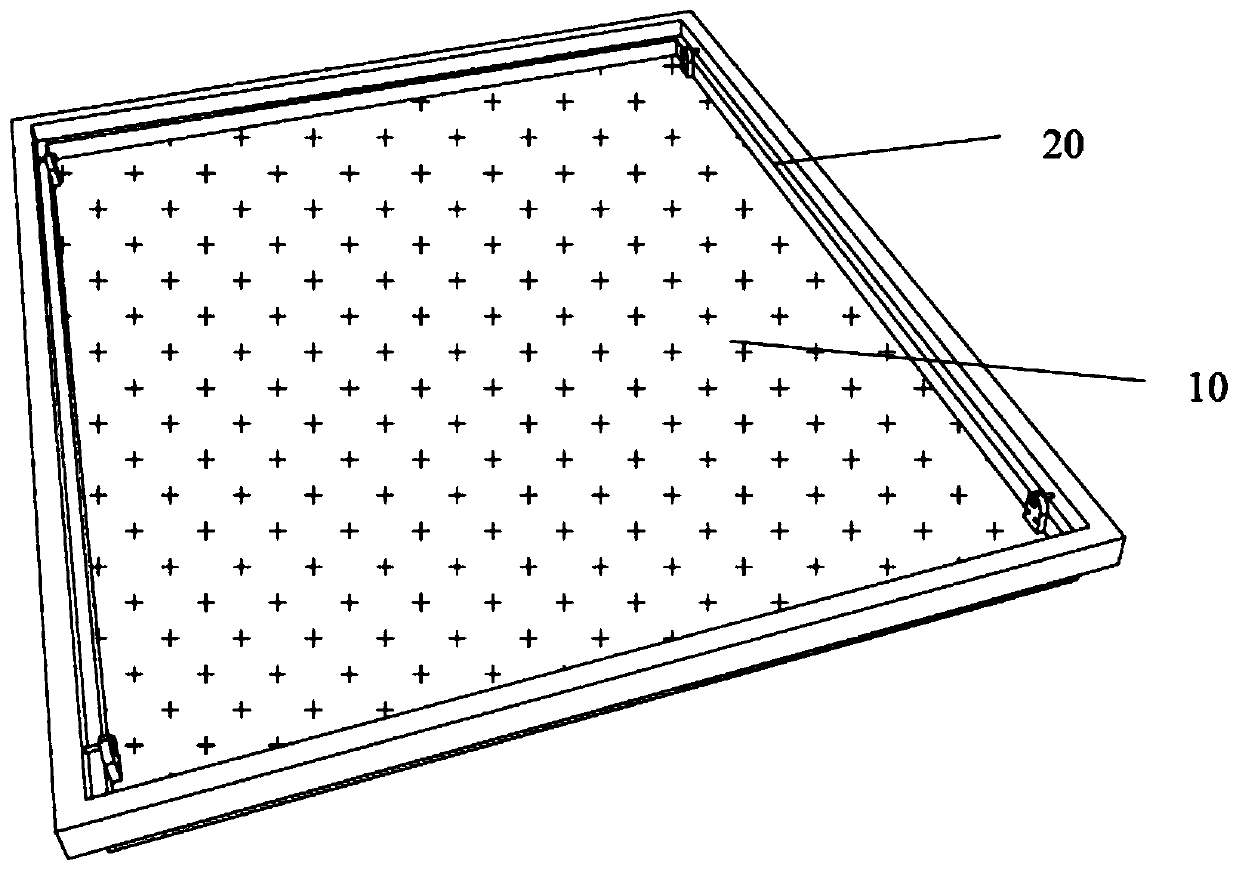

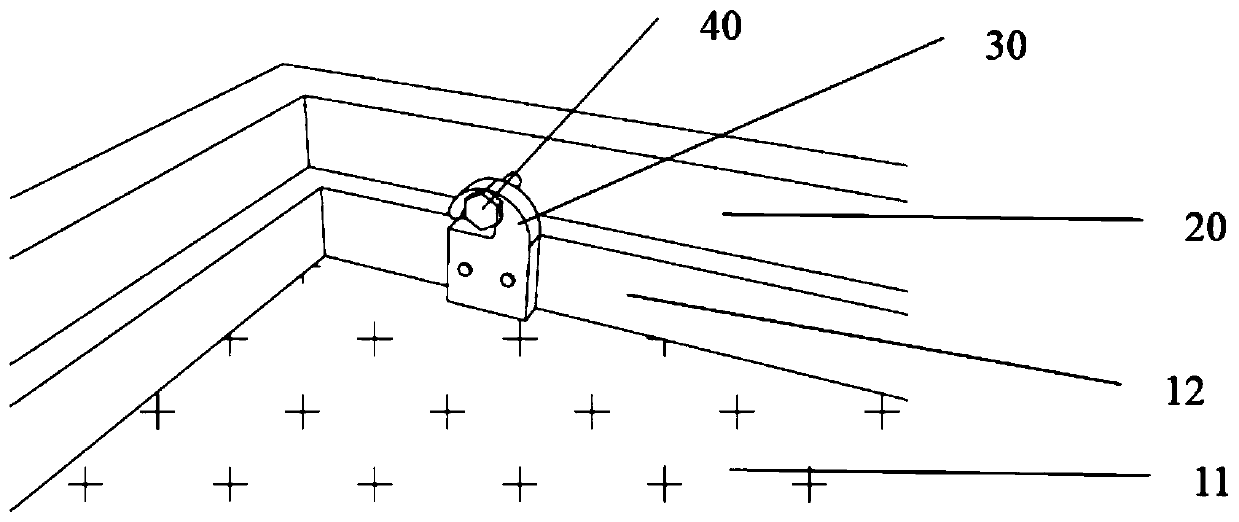

[0025] see figure 1 and figure 2 , as shown in the legend therein, a modular installation structure of a large wave aluminum panel in the lobby space, including an aluminum panel assembly 10 and a ceiling joist 20, the aluminum panel assembly 10 is connected to the lower side of the ceiling joist 20, and the aluminum panel assembly 10 is provided with a first positioning member 30 , the ceiling keel 20 is provided with a second positioning member 40 , and the first positioning member 30 is detachably connected to the second positioning member 40 .

[0026] In a preferred implementation of this embodiment, the first positioning member 30 is suspended from the second positioning member 40 .

[0027] In a preferred implementation of this embodiment, the first positioning member 30 includes a hook-shaped portion, and the hook-shaped portion is hooked on the second positioning member 40 .

[0028] In a preferred implementation of this embodiment, the second positioning member 40...

Embodiment 2

[0035] The rest is the same as the first embodiment, except that the above-mentioned first positioning member includes an annular portion, and the above-mentioned annular portion is hooked on the above-mentioned second positioning member.

Embodiment 3

[0037] The rest is the same as that of Embodiment 1, except that the above-mentioned second positioning member is a lateral L-shaped portion, including a horizontally extending support portion and a vertically extending limiting portion, and one end of the above-mentioned support portion is connected to the above-mentioned ceiling keel , the above-mentioned limiting portion is connected to the other end of the above-mentioned supporting portion, and the above-mentioned first positioning member is hooked on the above-mentioned supporting portion.

[0038] Through the above structure, the modular installation structure of the large wave aluminum plate in the lobby space provided by the present invention mainly has the following advantages compared with the prior art:

[0039] 1) The large wave aluminum plate modular installation structure in the lobby space disclosed by the present invention, the aluminum plate components and the ceiling keel can be adjusted according to requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com