Facing integrated board dry hanging installation structure with adjustable and dismountable facade

A technology for installing structures and integrated panels, applied in building construction, covering/lining, construction, etc., can solve the problems of unsmooth installation of surface layers, low construction efficiency, secondary damage to panels, etc., to facilitate standardized operations, reduce The effect of repetitive labor and avoiding the risk of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

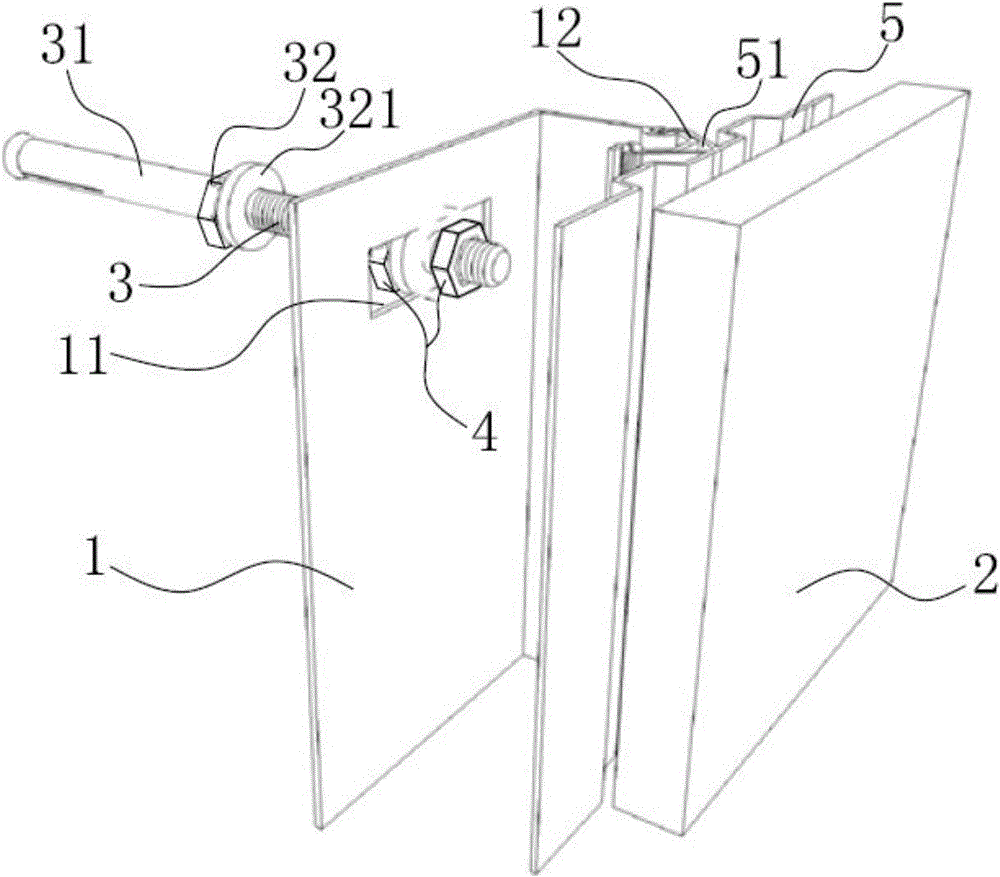

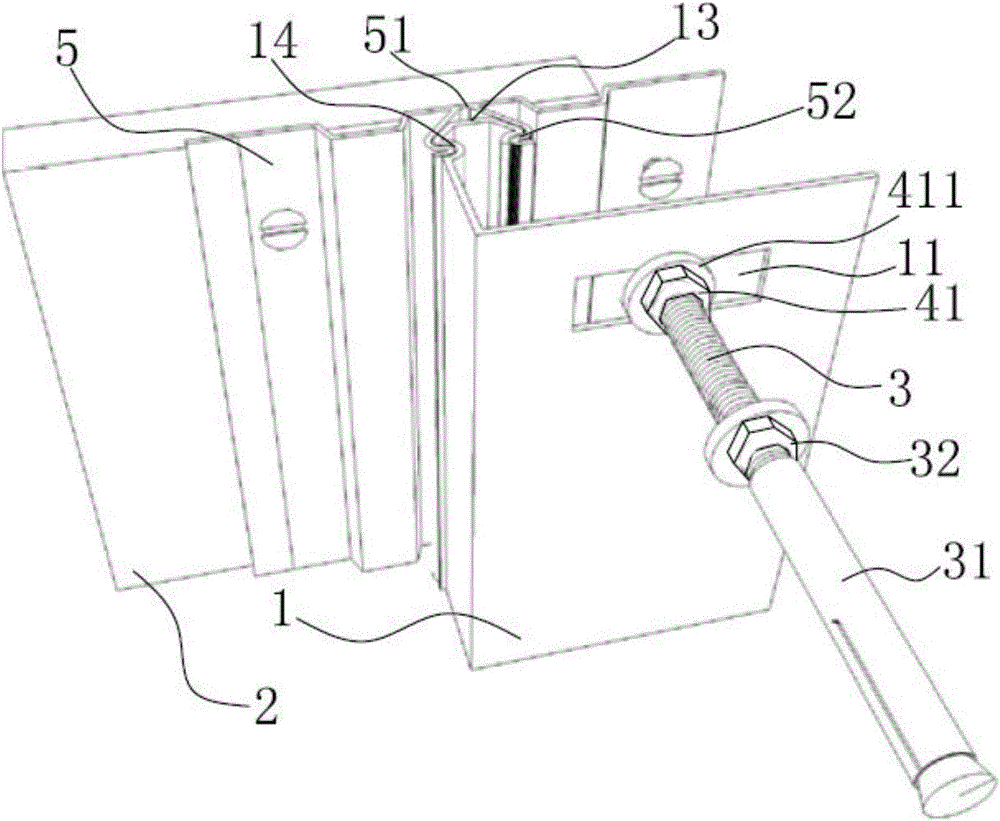

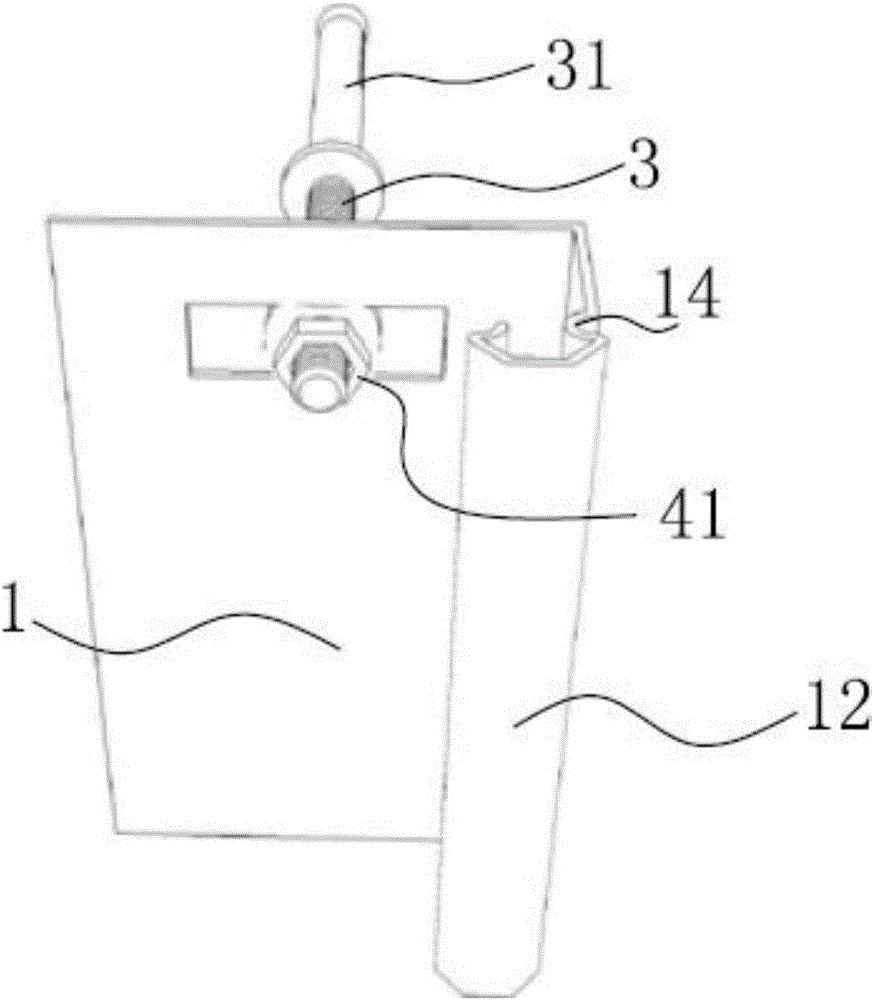

[0038] In order to achieve the purpose of the present invention, as Figure 1-3 As shown, in some embodiments of the adjustable and detachable facade integrated panel dry-hanging installation structure of the present invention, it includes: a connecting piece 1, one side of which is detachably connected with the decorative integrated panel 2, opposite There is a strip hole 11 on the other side of the shaft; one end of the screw rod 3 is passed through the strip hole 11 and its position is fixed by the fastener 4, and the opposite end is fixedly connected to the wall by means of screw connection or the like. (not shown). Wherein, the fastener 4 may preferably include two pieces of first nuts 41 located on the inner and outer sides of the elongated hole 11. Through the two inner and outer first nuts, while ensuring the adjustment of the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com