Movable graphitization furnace system and power supply device thereof

A technology of graphitization furnace and power supply device, which is applied in the field of power supply device and mobile graphitization furnace system, can solve problems such as hidden dangers, long bus line loss, and indistinguishable operating procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

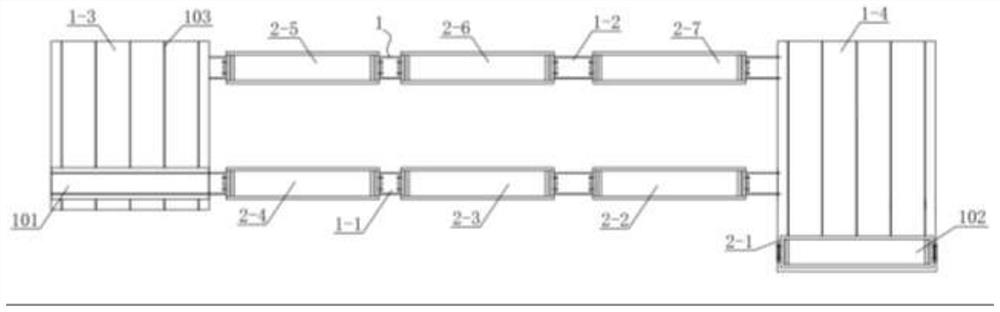

[0034] In order to solve the defects existing in the existing stationary graphitization furnace, the embodiment of the present invention provides a mobile graphitization furnace system, such as figure 1 As shown, it includes the main body of the graphitization furnace, the track 1 and the station.

[0035] In this embodiment, the track 1 is used for the graphitization furnace body to move along it. Specifically, in this embodiment, a kiln car is slidably connected to the track 1, and the graphitization furnace body is fixed on the kiln car. above, to realize the movement of the graphitization furnace body, but the movable structure of the graphitization furnace body is not limited thereto. In other embodiments, the graphitization furnace body can also be directly connected to the rail 1 by sliding fit, that is A slide block or a pulley is arranged at the bottom of the graphitization furnace body, and the slide block or pulley is then slidingly connected with the track 1 .

[...

Embodiment 2

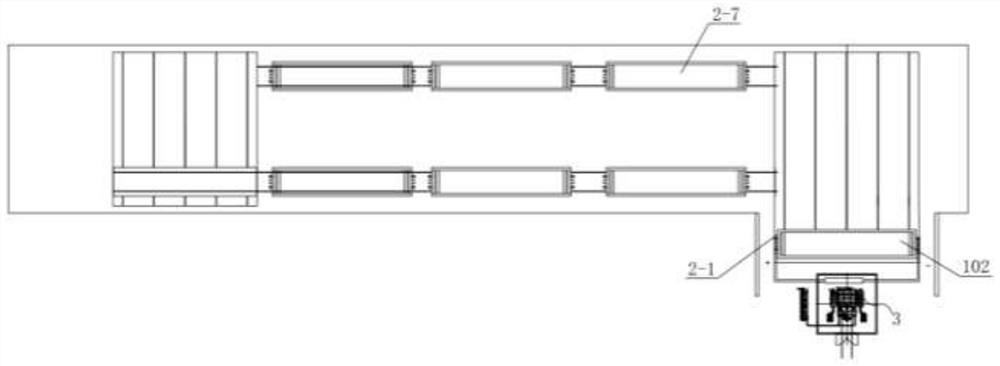

[0046] Power supply for mobile graphitization furnace systems, such as image 3 As shown, including the transformer 3 and the mobile graphitization furnace system in Example 1, the transformer 3 is arranged at the electrification and temperature rise station 2-1 of the mobile graphitization furnace system, and the transformer 3 is a rectifier transformer, and the model is ZHSFPT-25000 / 110, its specific structure is as follows Figure 4 shown.

[0047] The graphitization furnace body is provided with a positive conductive electrode and a negative conductive electrode, the positive conductive electrode of the graphitization furnace body corresponds to the positive electrode of the transformer 3, and the negative conductive electrode of the graphitization furnace body corresponds to the negative electrode of the transformer 3.

[0048] In this embodiment, the positive conductive electrode and the positive pole of the transformer 3 are clamped by the clamping assembly, and the ne...

Embodiment 3

[0054] The power supply device of the mobile graphitization furnace system is different from Embodiment 2 in that in this embodiment, the three positive conductive electrodes are connected through copper plates or copper softly to form a positive connection point, and then the positive connection point is connected to the transformer The positive connection of the three negative conductive electrodes is connected through copper plates or copper softly to form a negative connection point, and then the negative connection point is connected to the negative pole of the transformer, which can reduce the setting of clamping components or pressing mechanisms .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com