Multi-spliced-board and multi-internal-positioning edge milling structure and machining method thereof

A technology of edge milling and splicing, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of milling deviation, short service life of bakelite, easy to produce heavy holes, etc., and achieves broad market prospects. The effect of reducing the processing cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

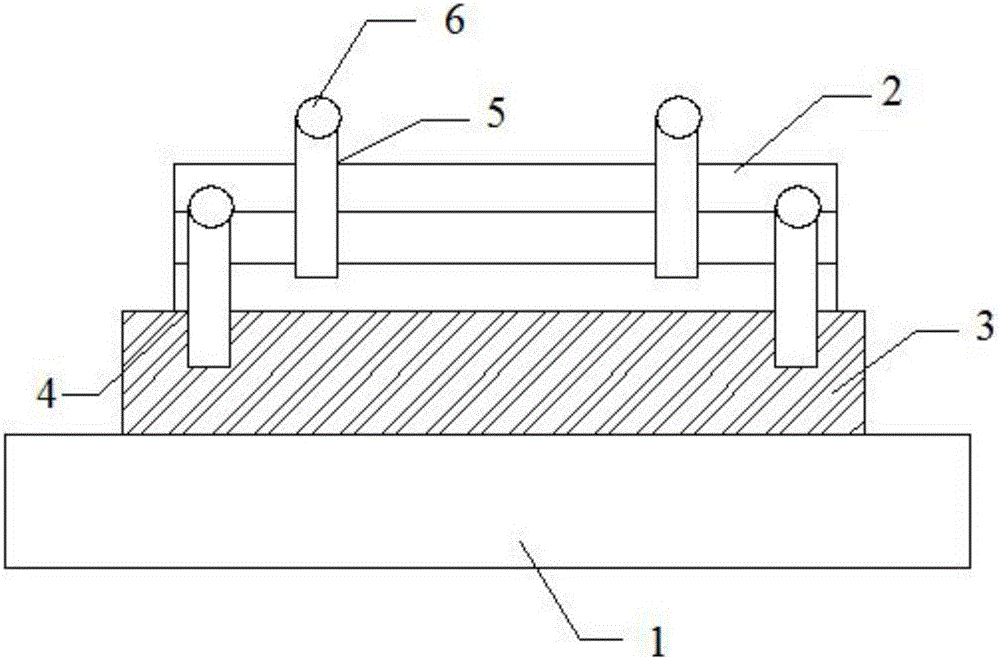

[0019] A multi-joint multi-internal positioning and edge milling structure, the product includes an equipment table 1, a wooden backing board 2 and a bakelite board 3, the bakery board 3 is provided with positioning drilling holes 4, and the wooden backing board 2 is provided with There are positioning holes 5, the bakelite 2 is arranged on the equipment table 1, the wooden backing plate 2 is arranged on the bakelite 3 through pins 6 and the positioning holes 5, and the number of the positioning drill holes 4 is four, The number of the wooden backing boards 2 is three, the size of the wooden backing boards 2 is 2.5mm, the wooden backing boards 2 are connected by pins 6, the size of the bakelite board 3 is 12mm, the 6 types of pins are inserted into the bakelite board 3 and the depth is 6mm.

[0020] The method for processing the multi-joint multi-internal positioning and milling structure includes the following steps:

[0021] (1) First find 4 holes on the bakelite board for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com