Patents

Literature

32results about How to "Realize continuous automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

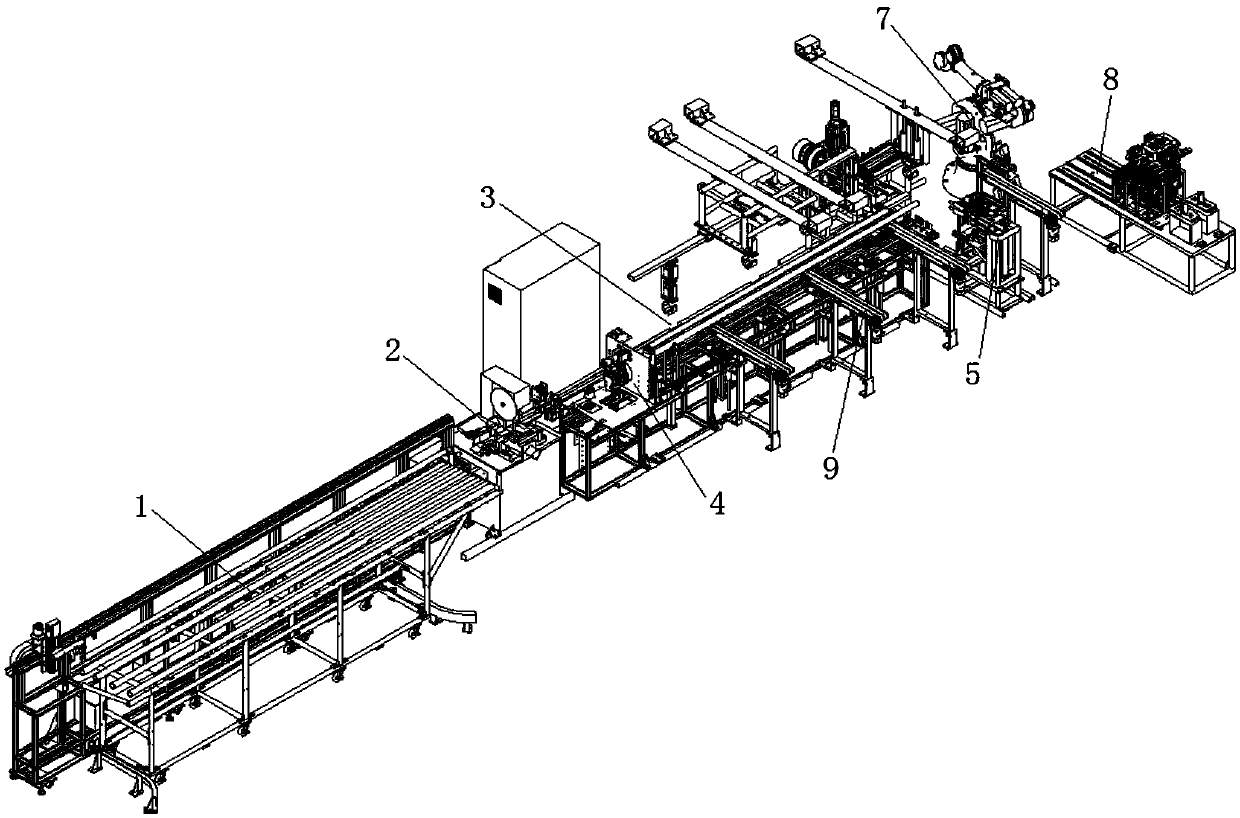

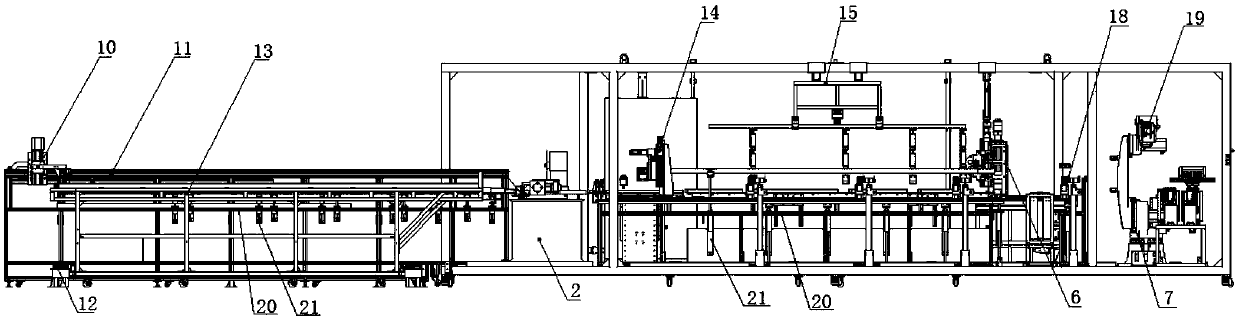

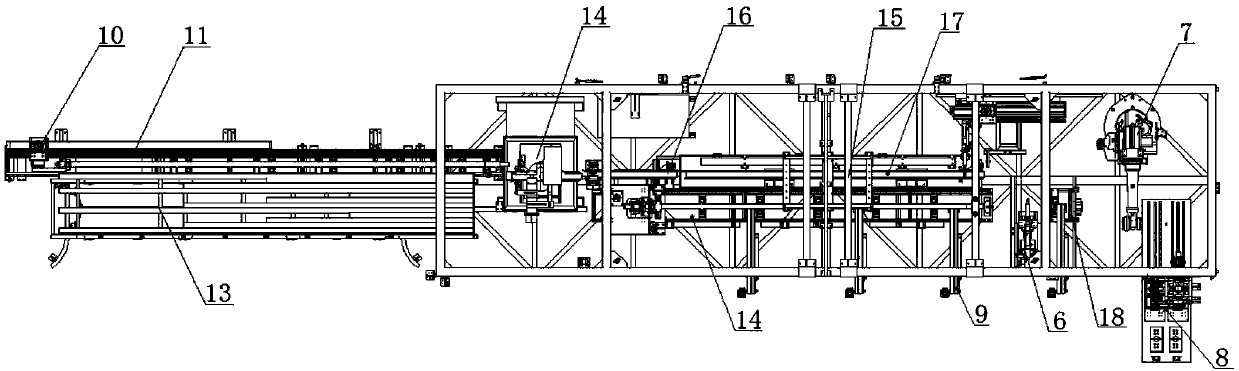

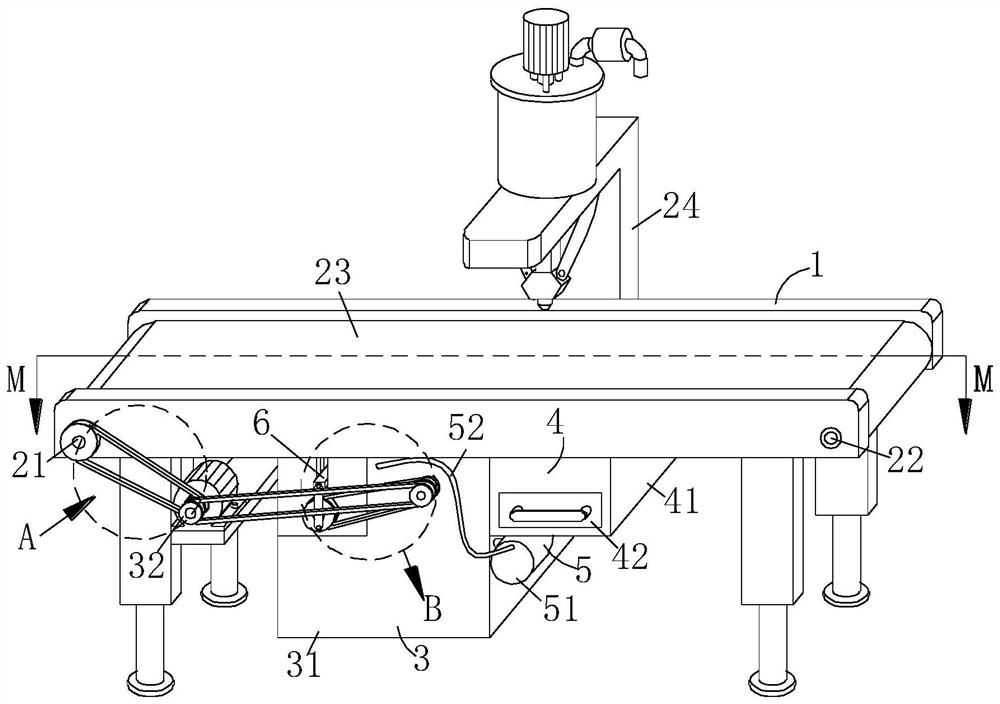

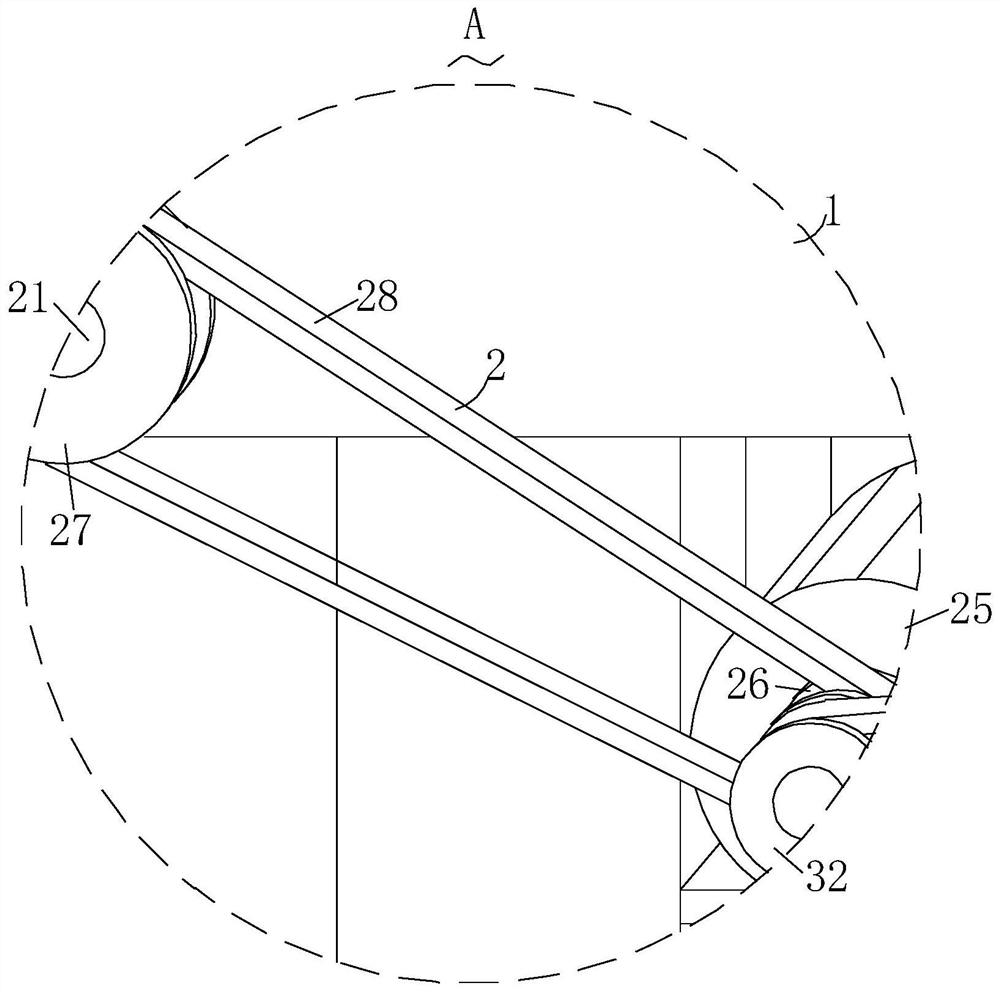

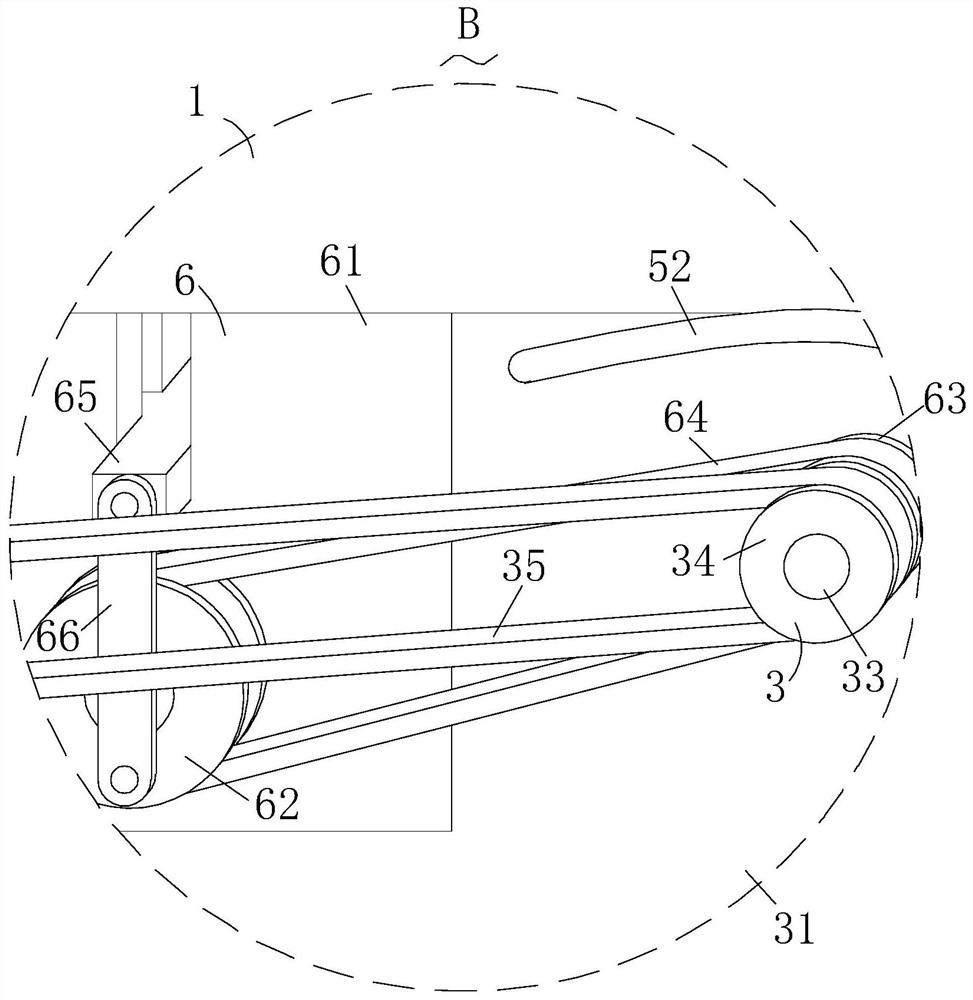

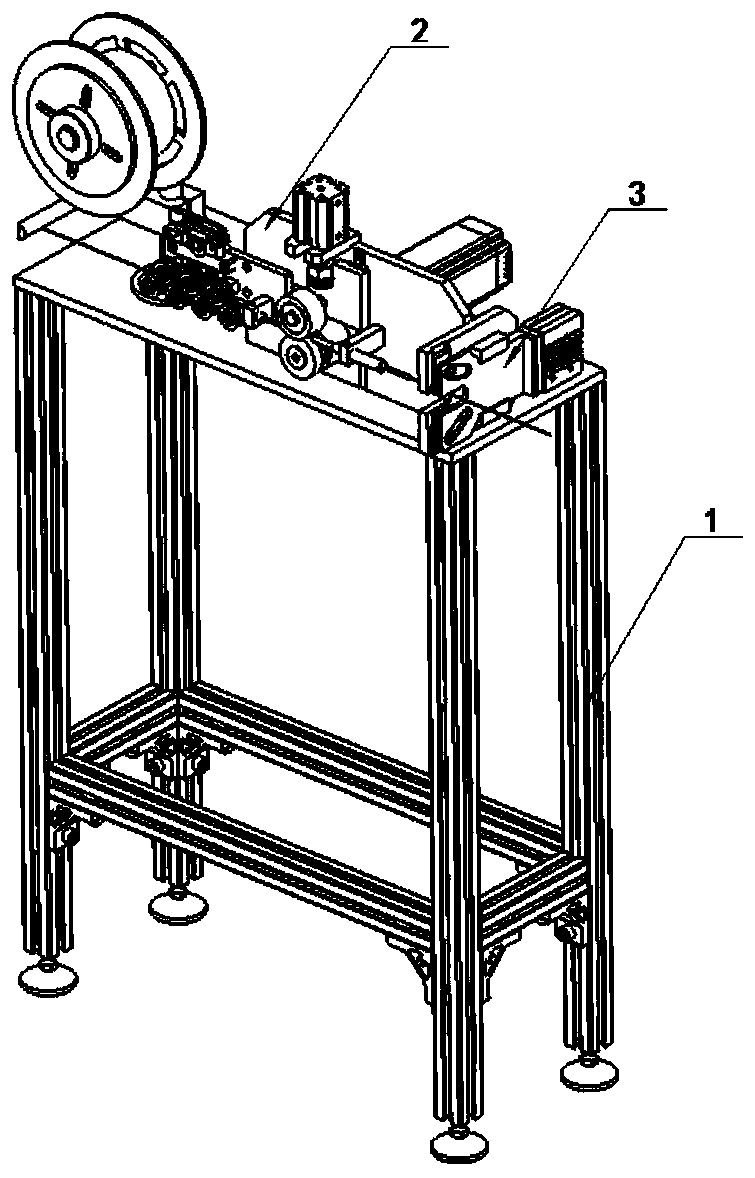

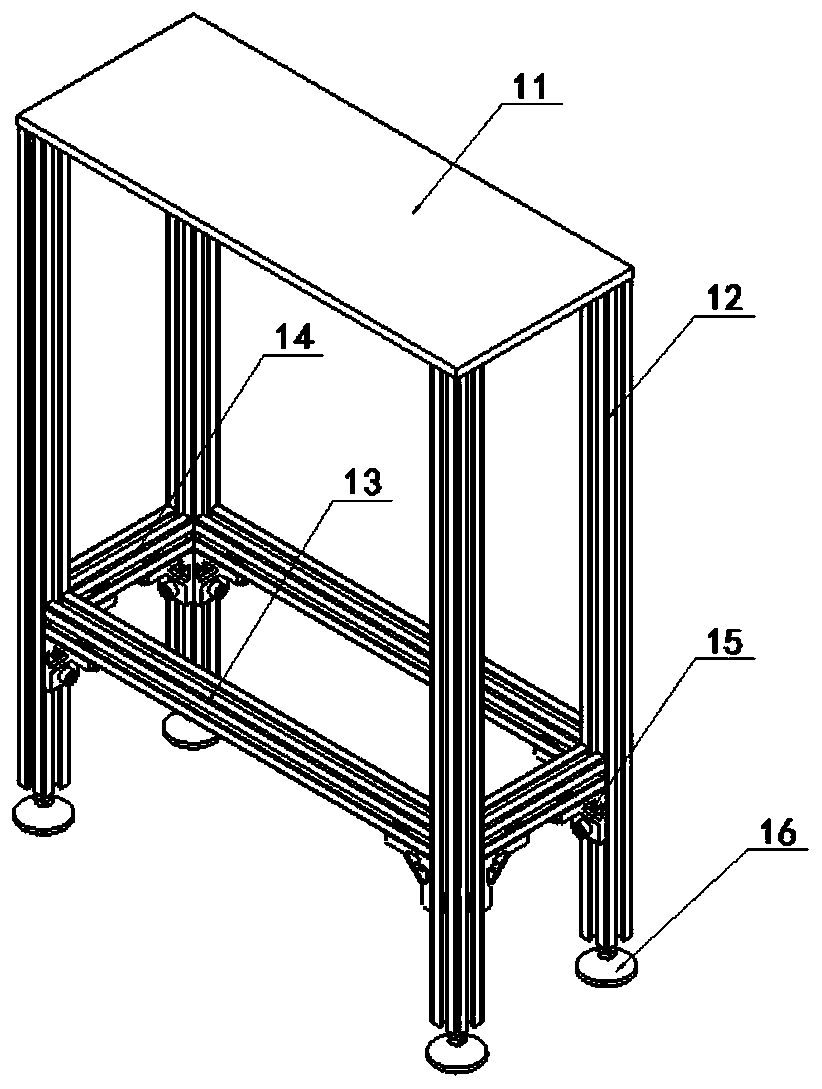

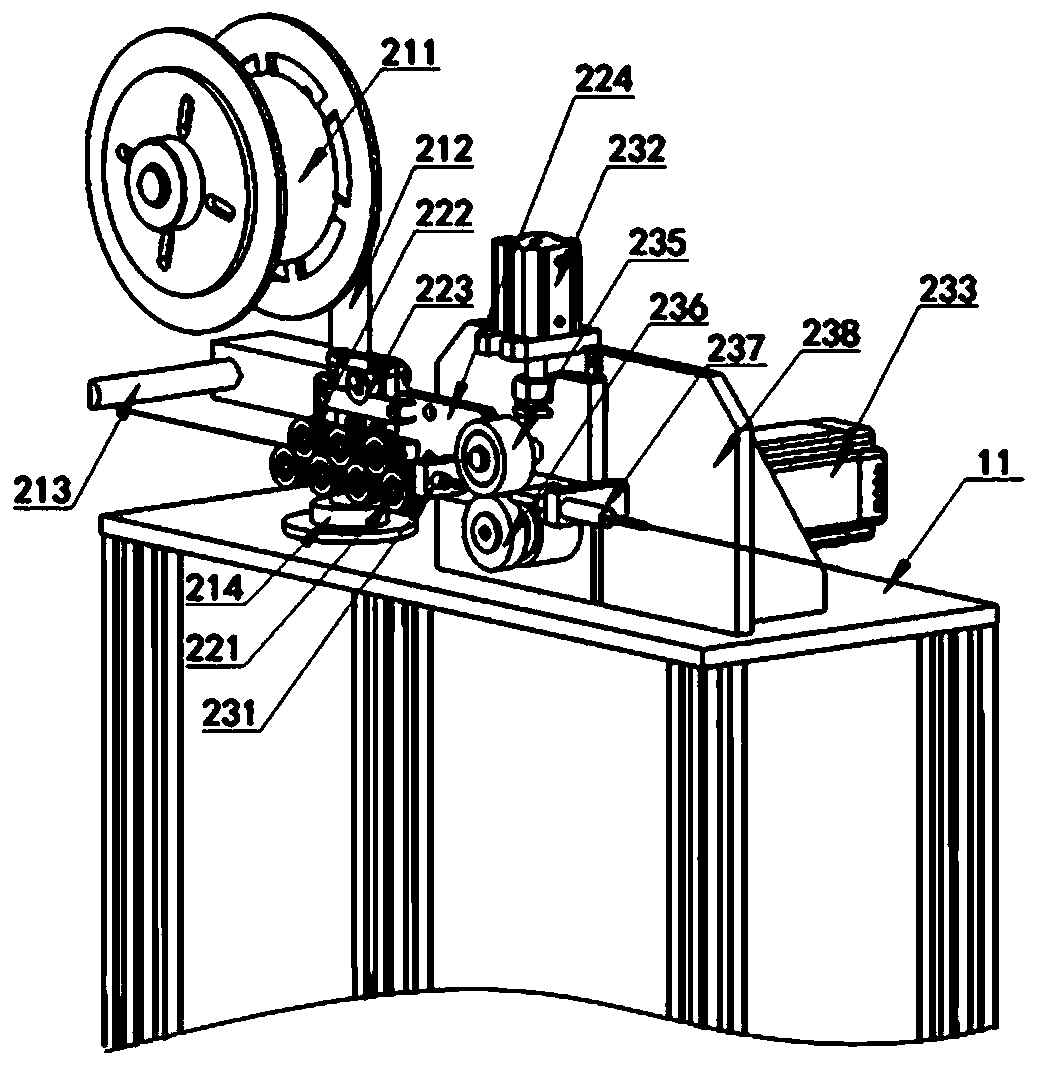

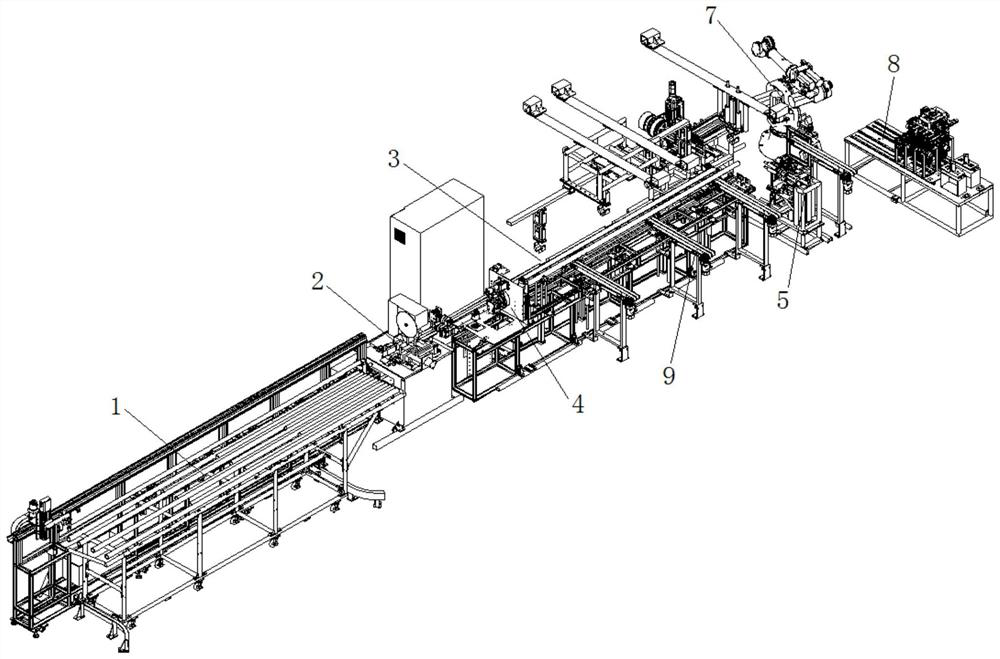

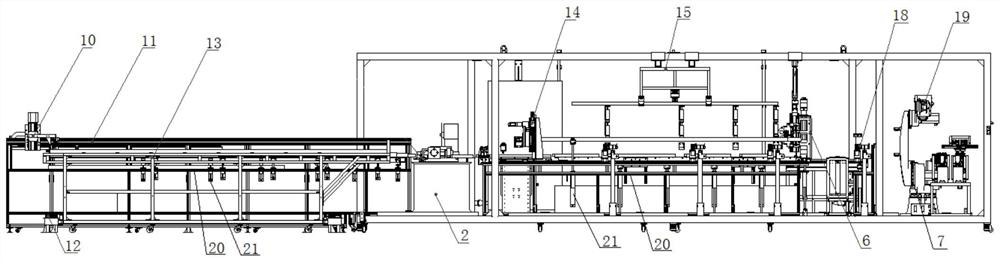

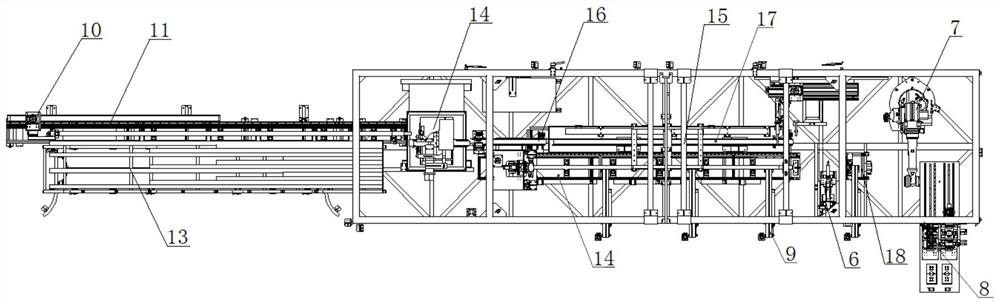

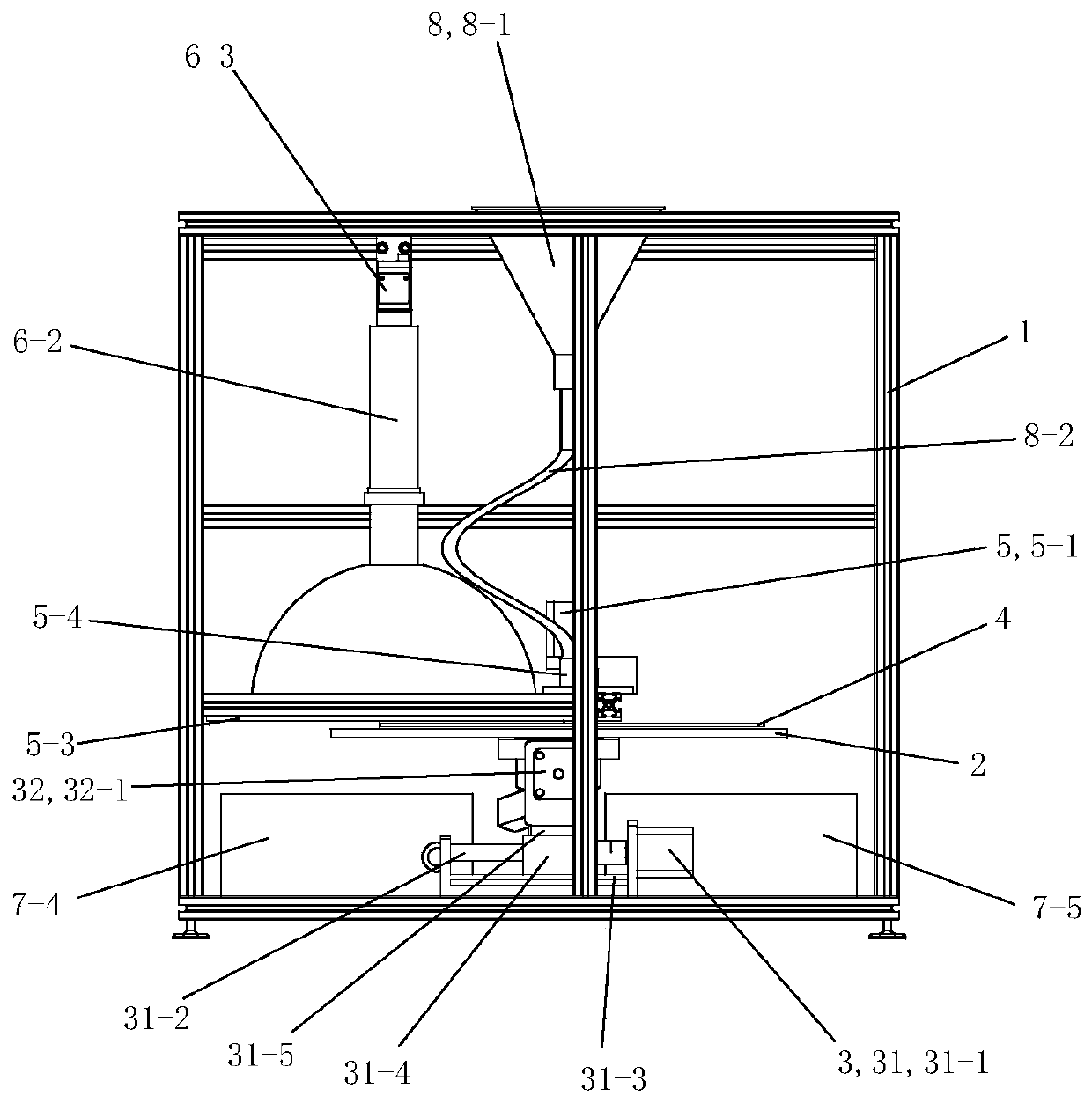

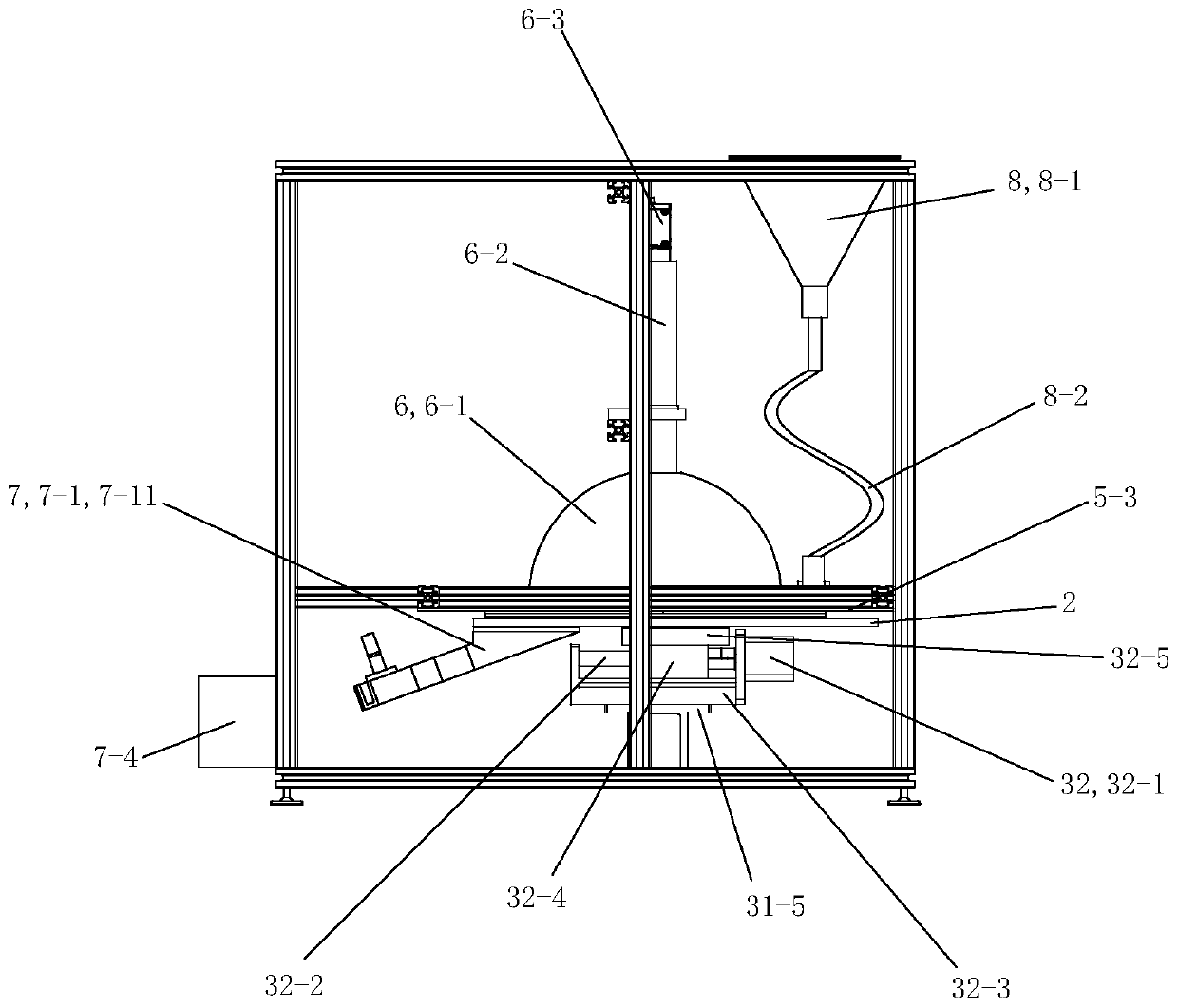

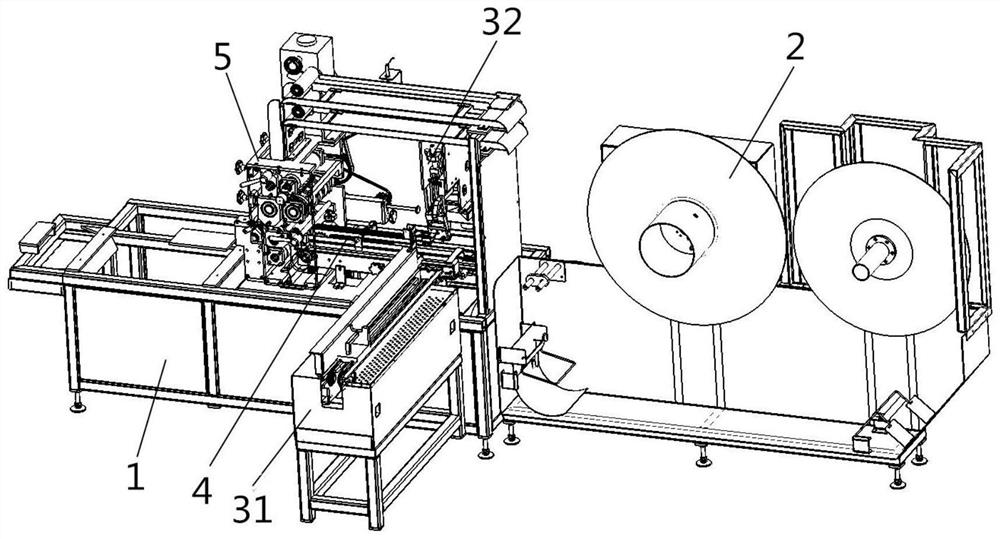

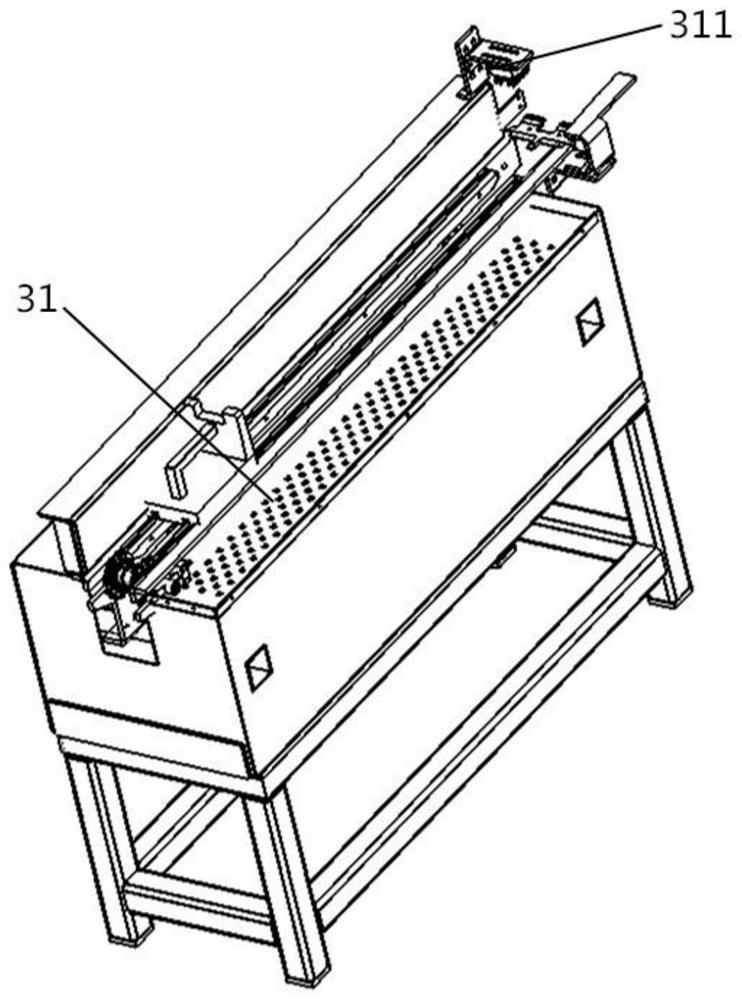

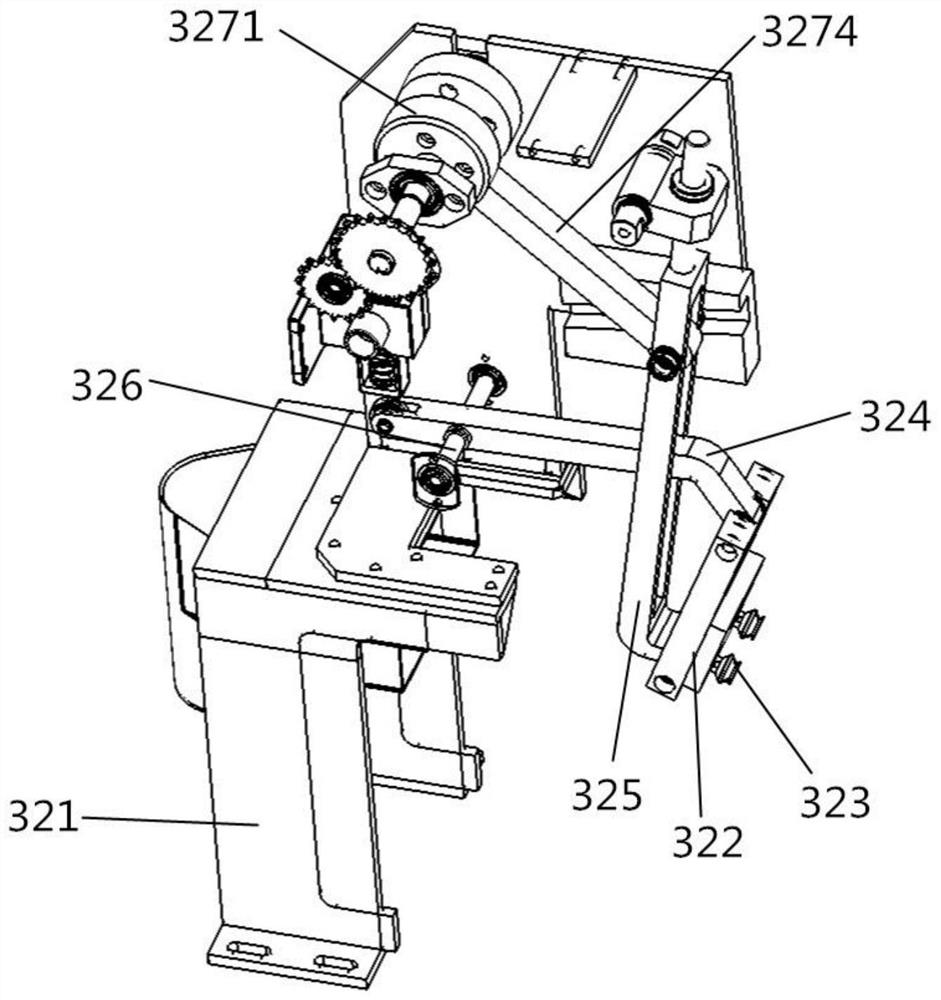

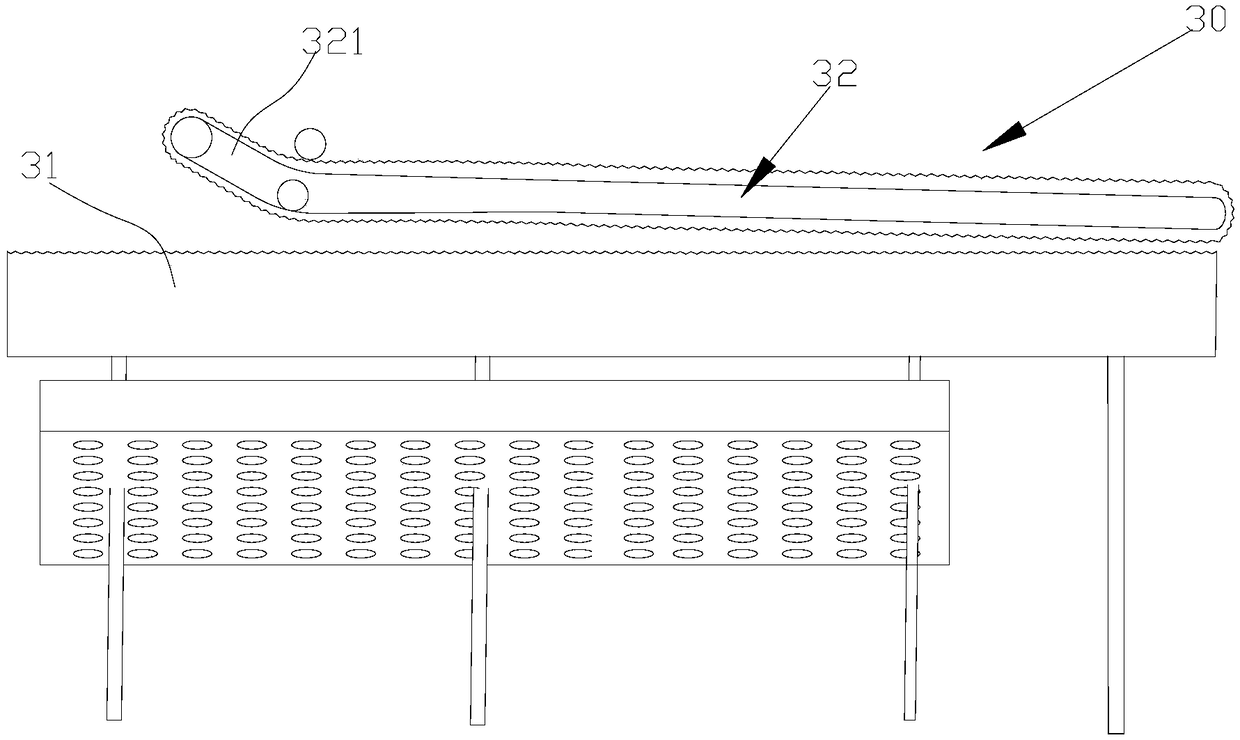

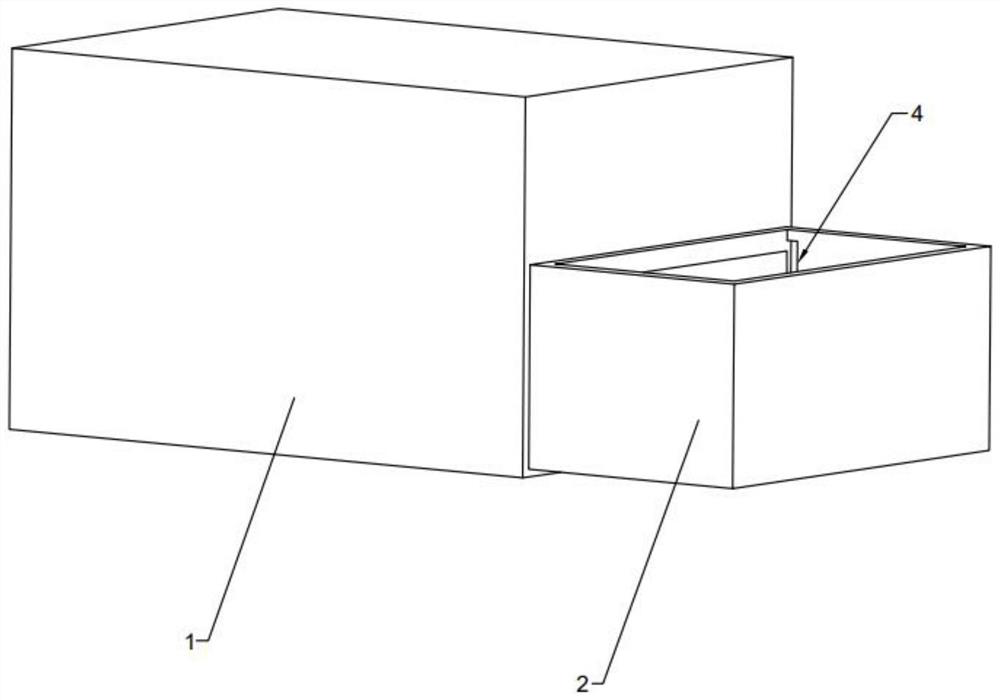

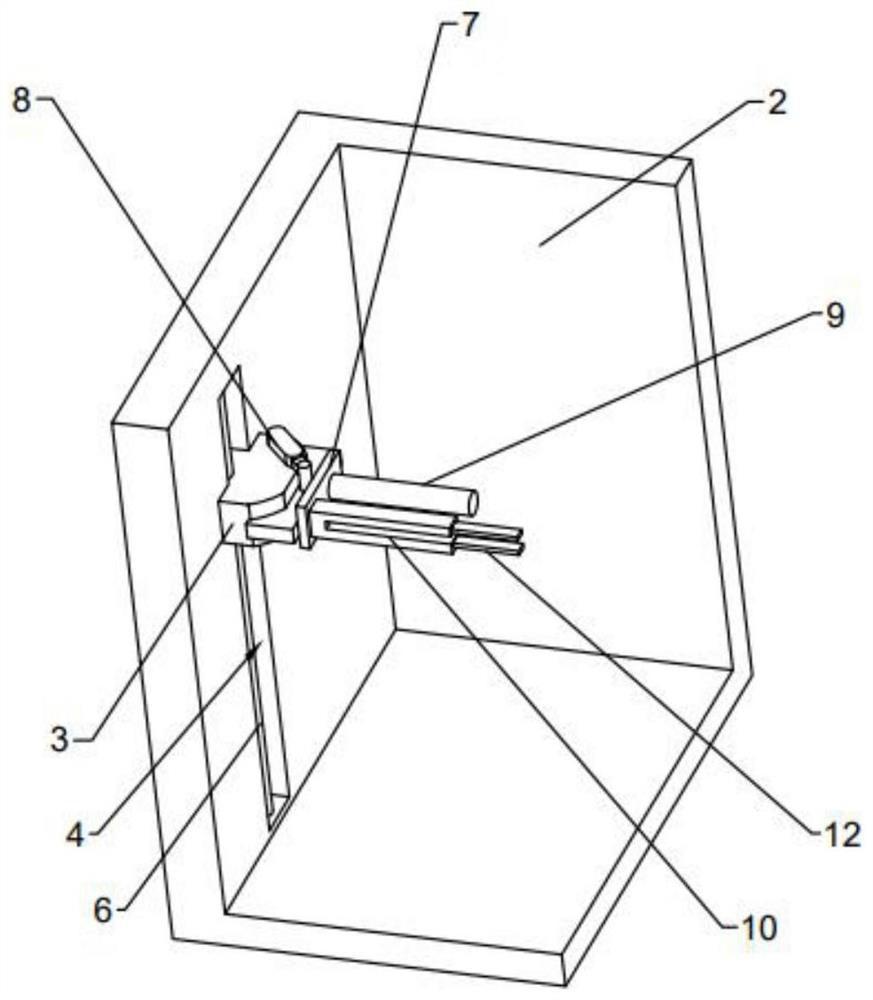

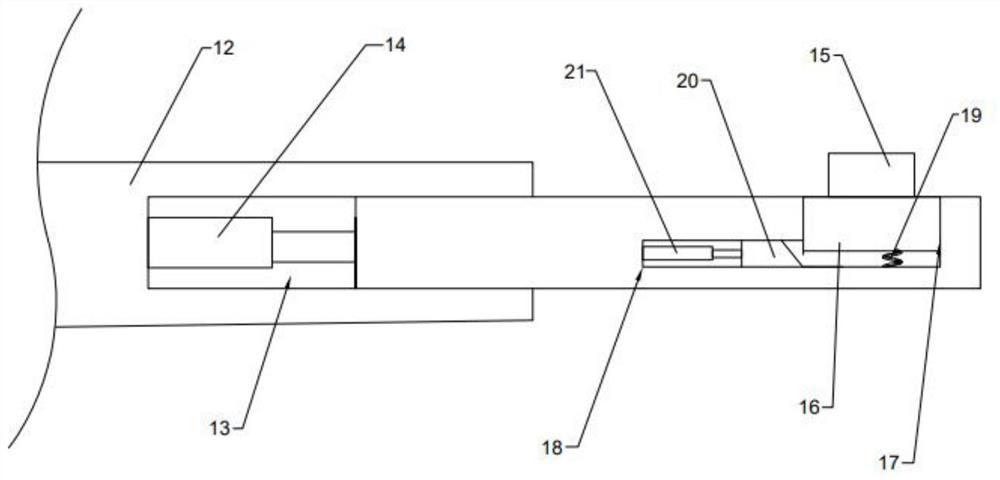

Pipe material assembling platform production line

ActiveCN109648343ARealize continuous automatic feedingImprove continuityOther manufacturing equipments/toolsTube shearing machinesProduction lineContact network

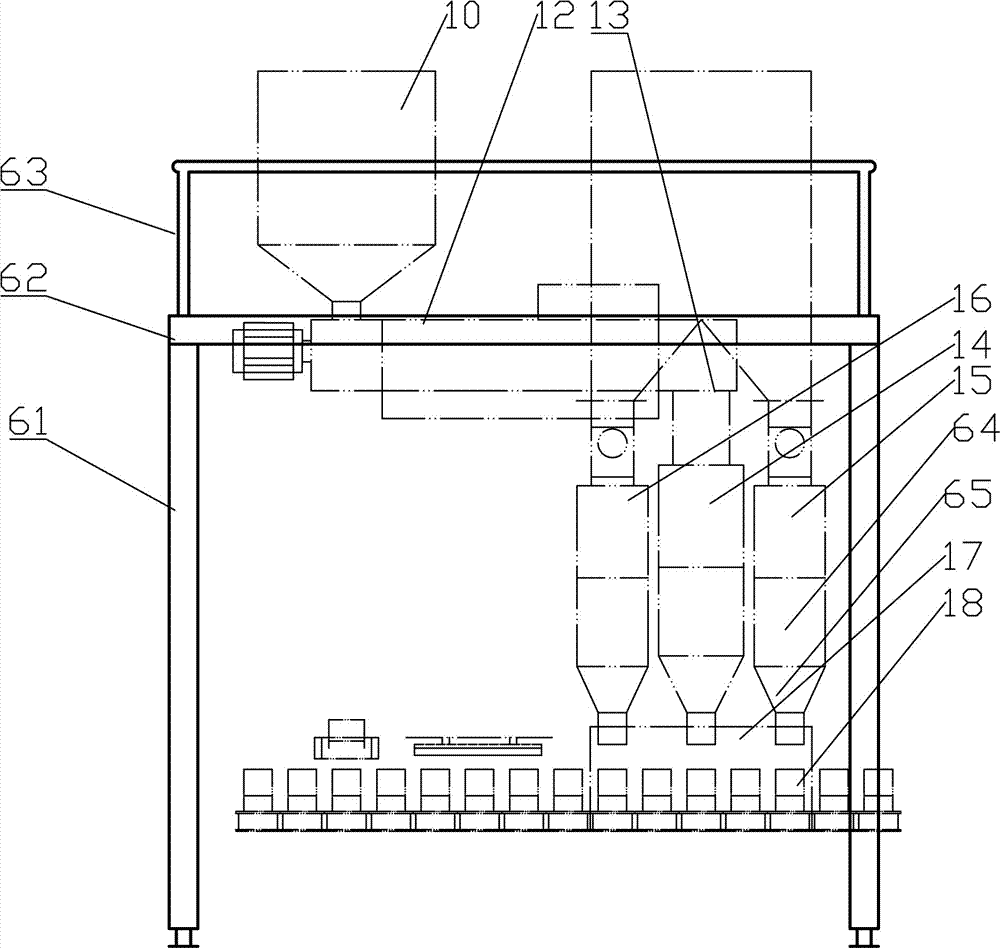

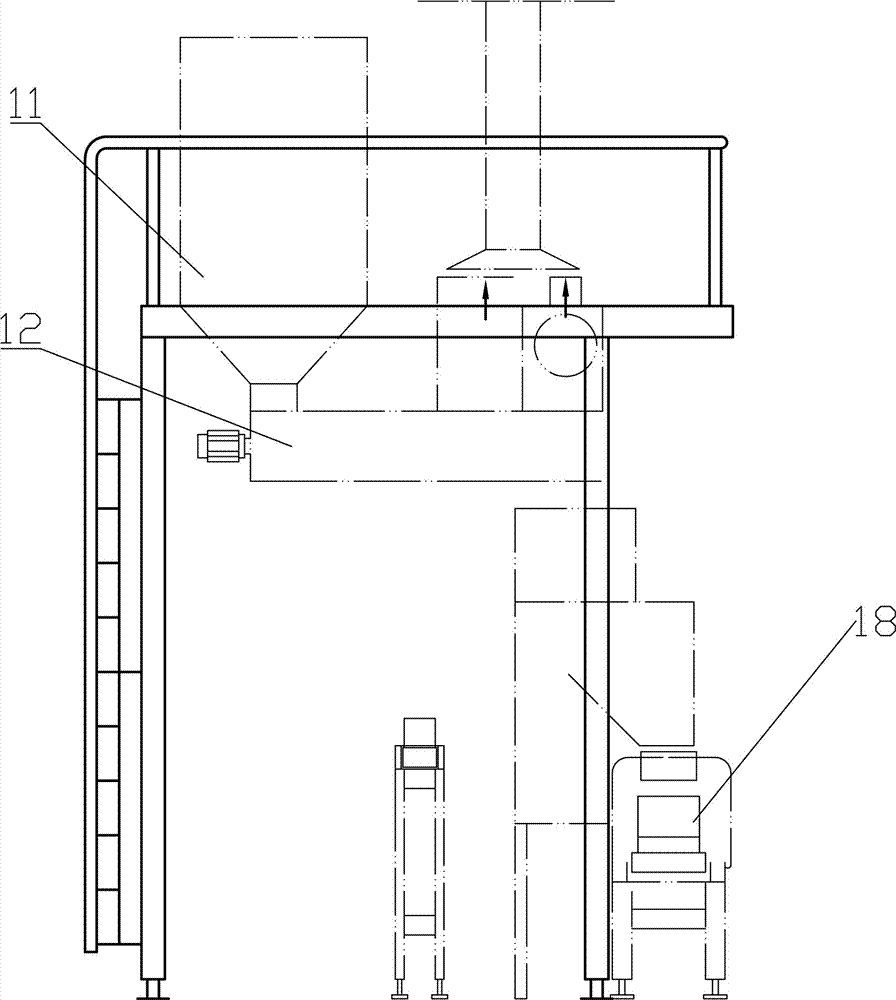

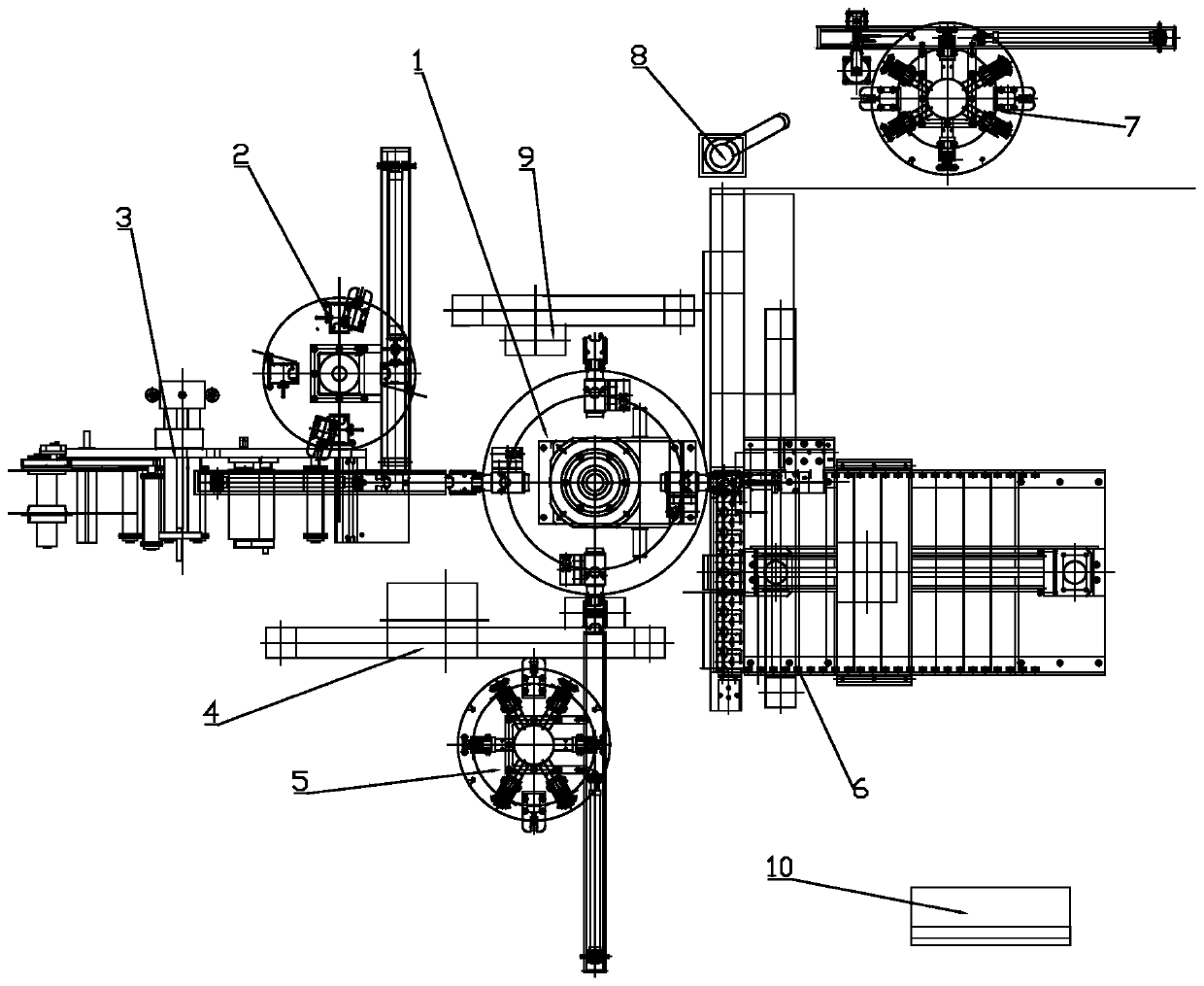

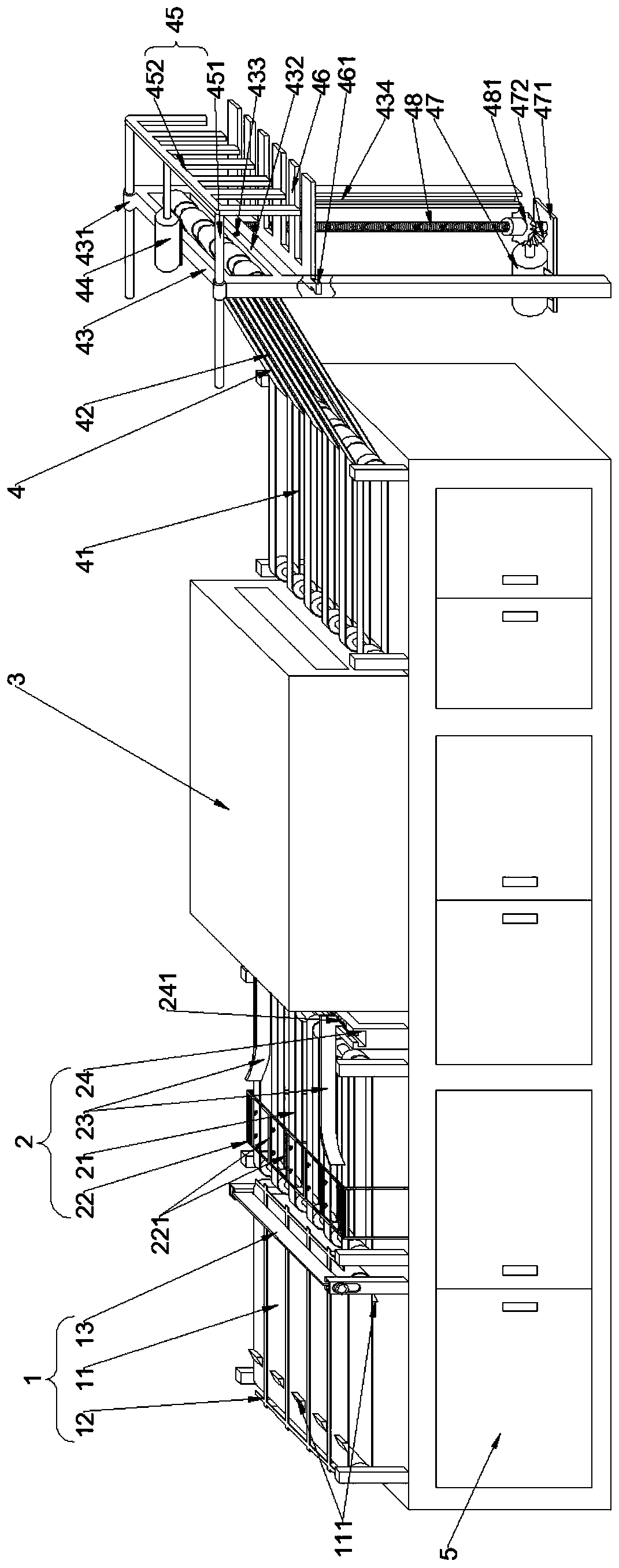

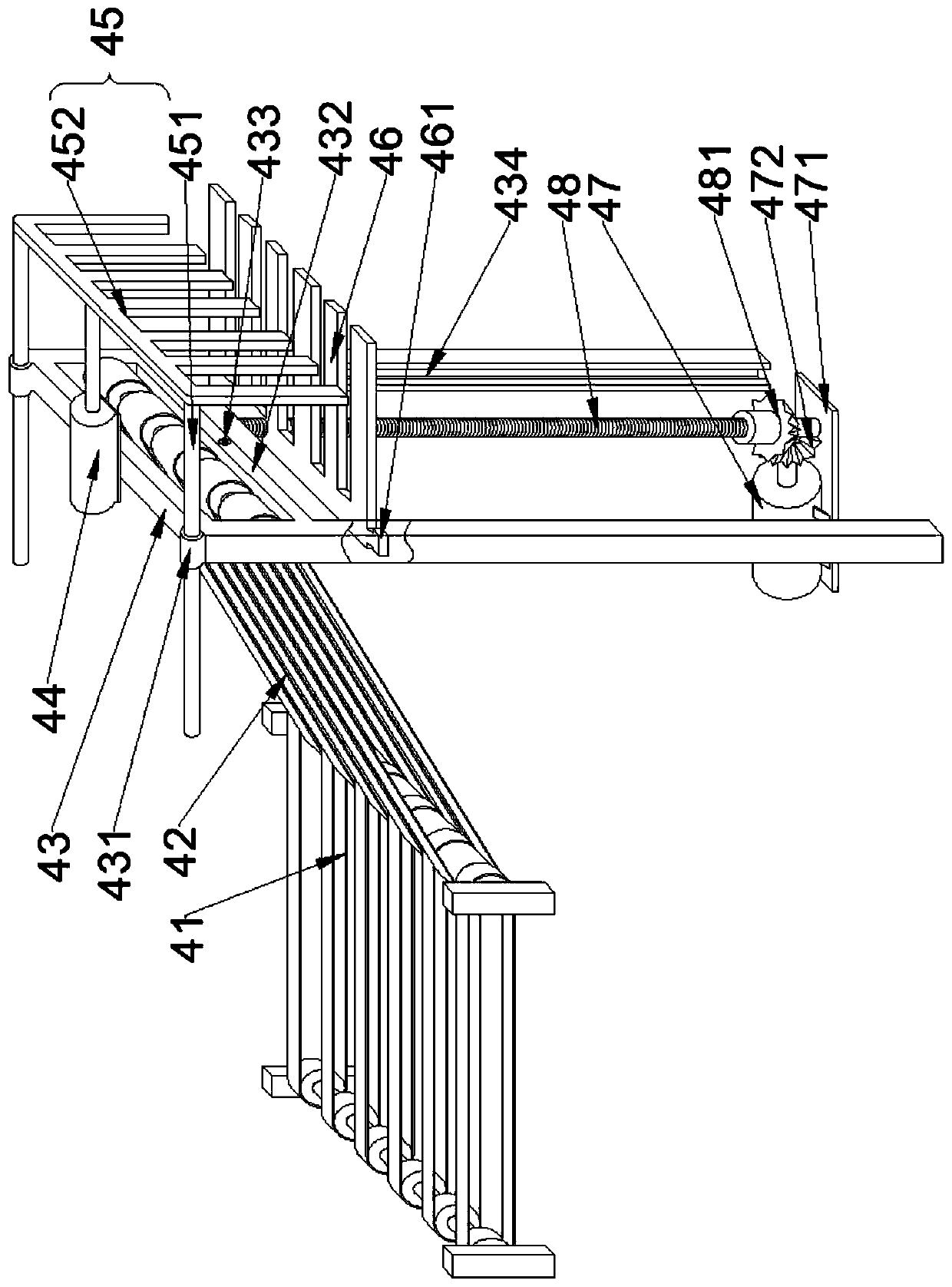

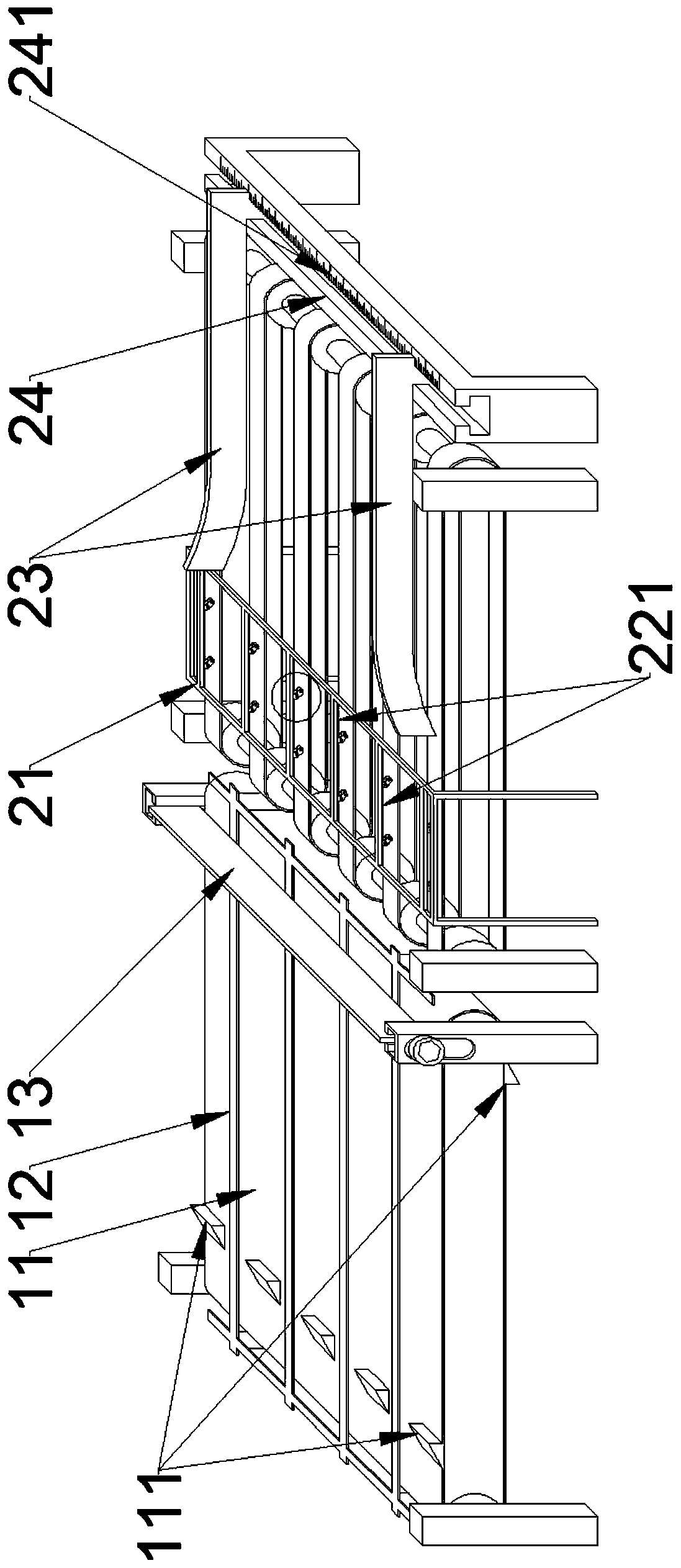

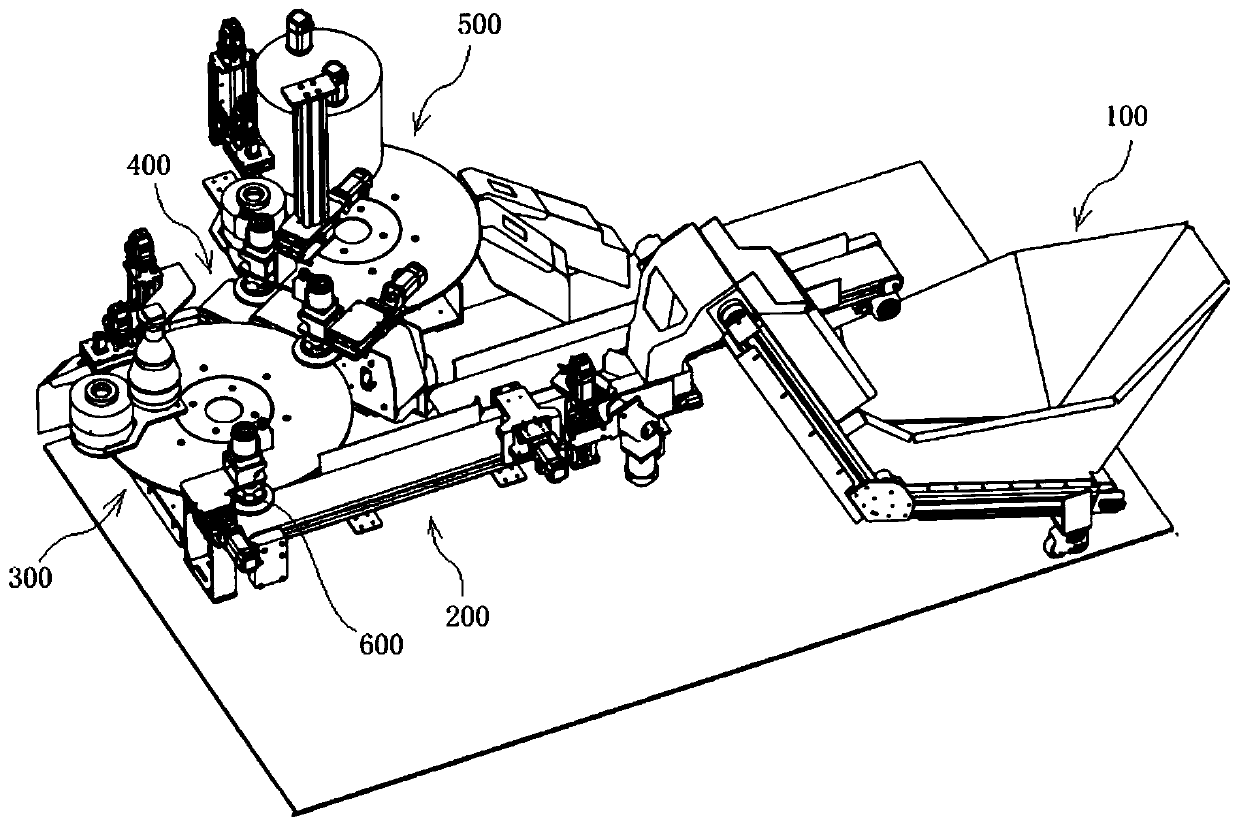

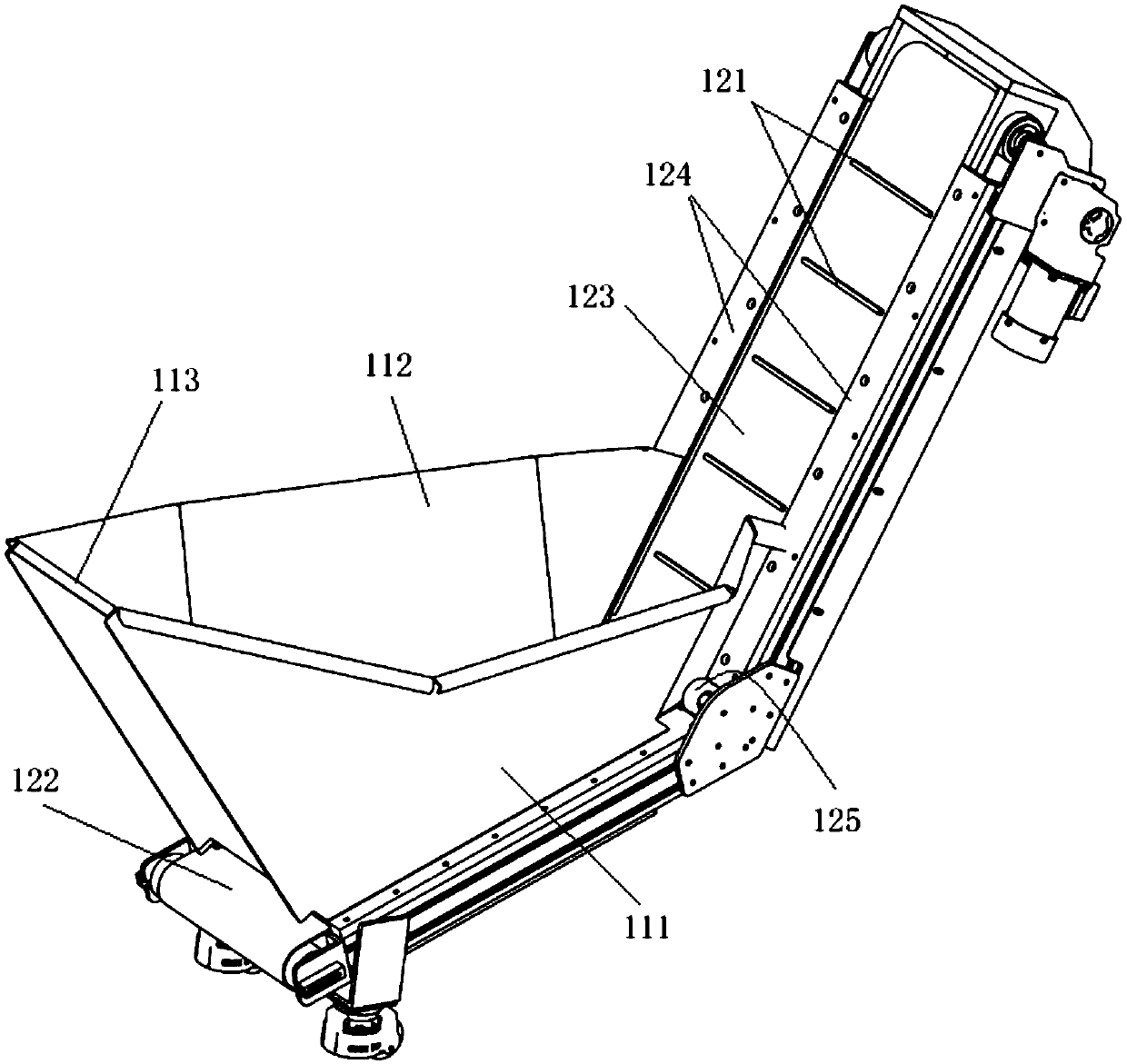

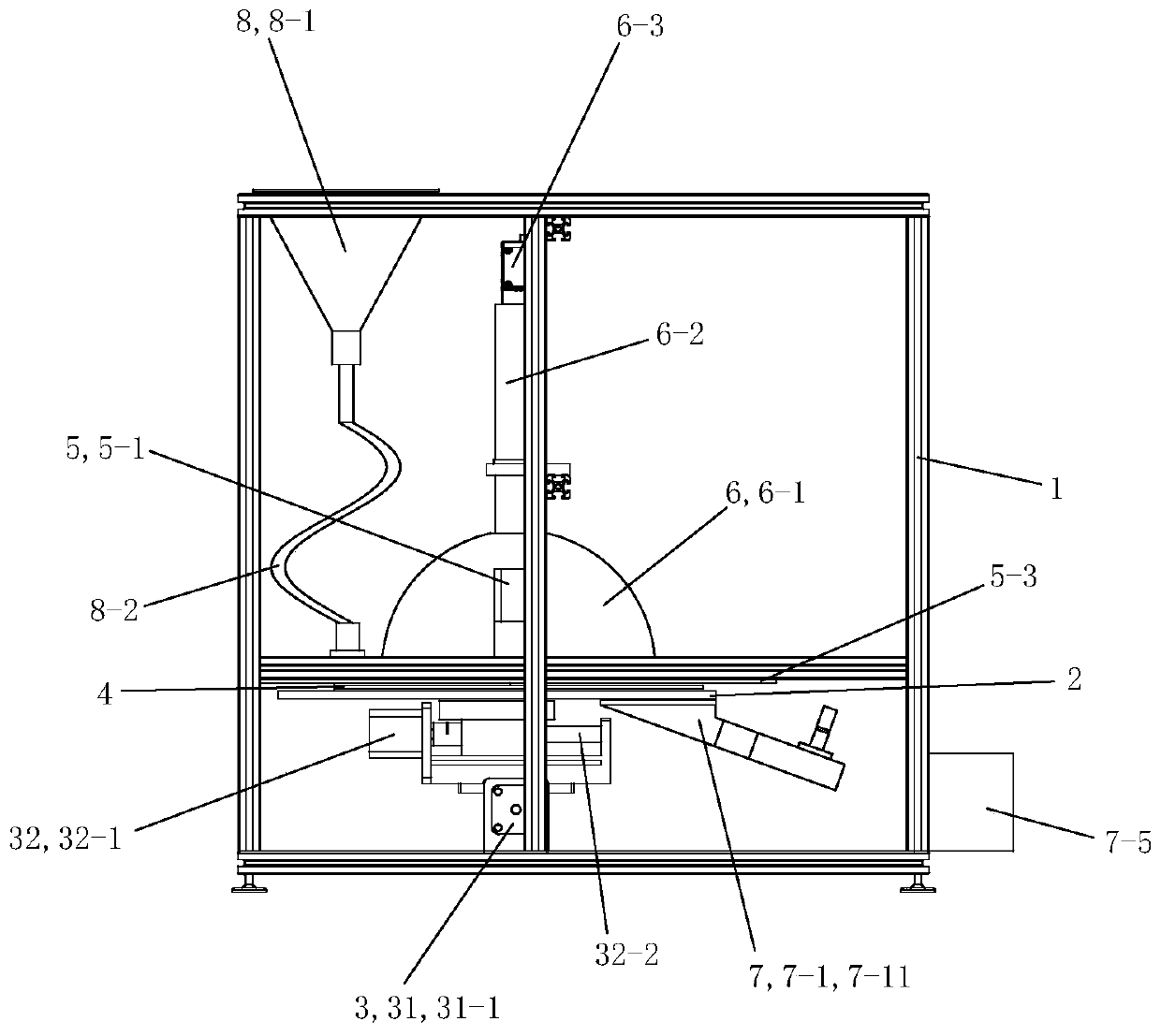

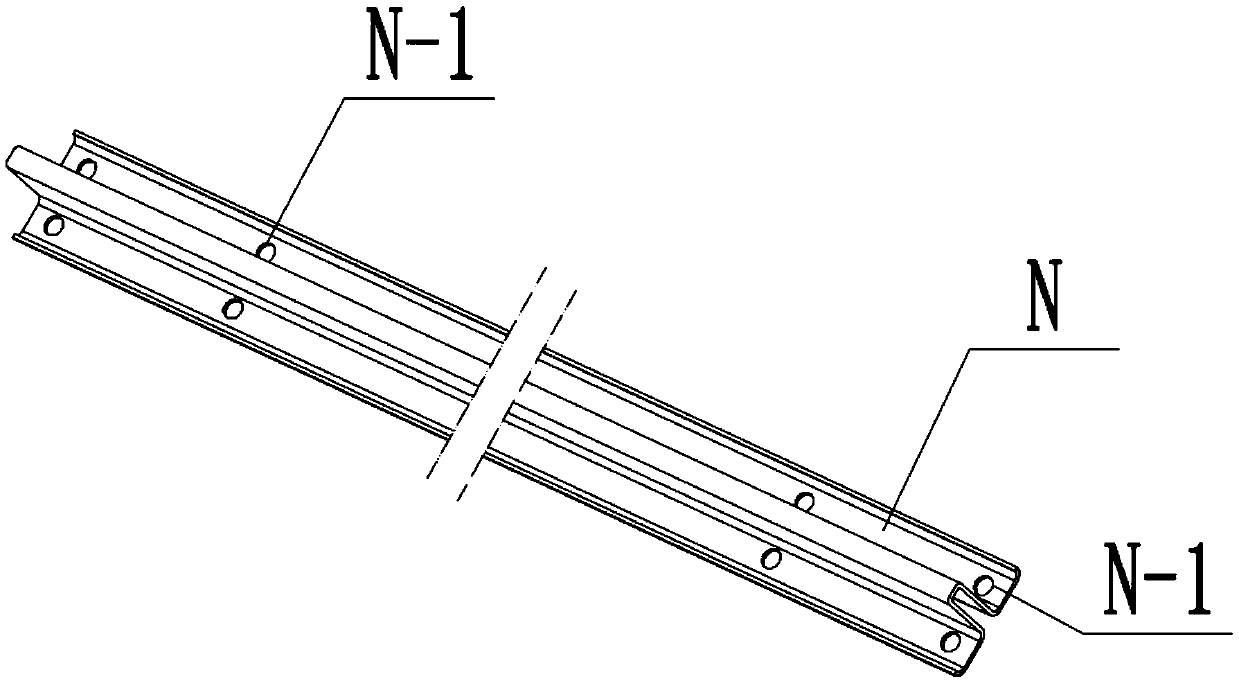

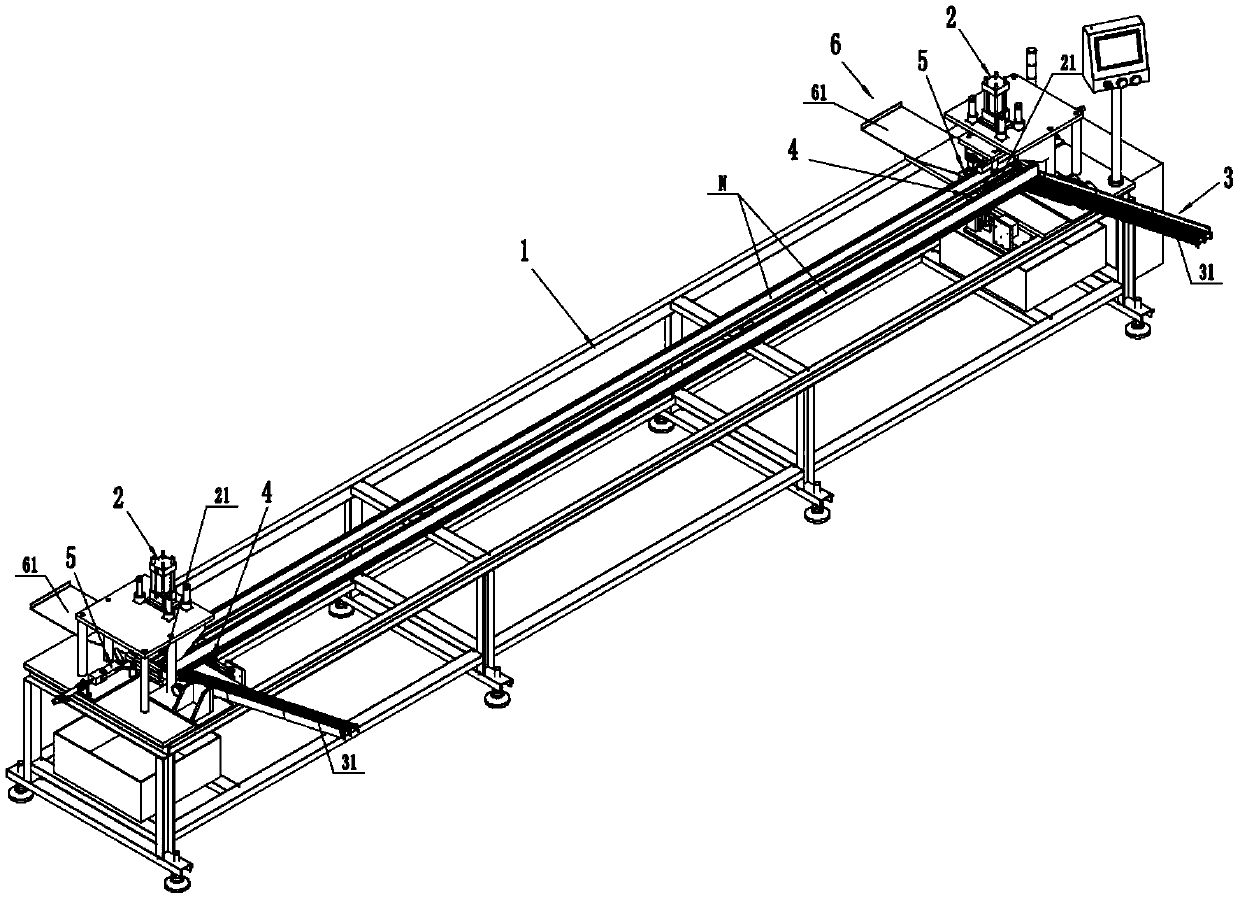

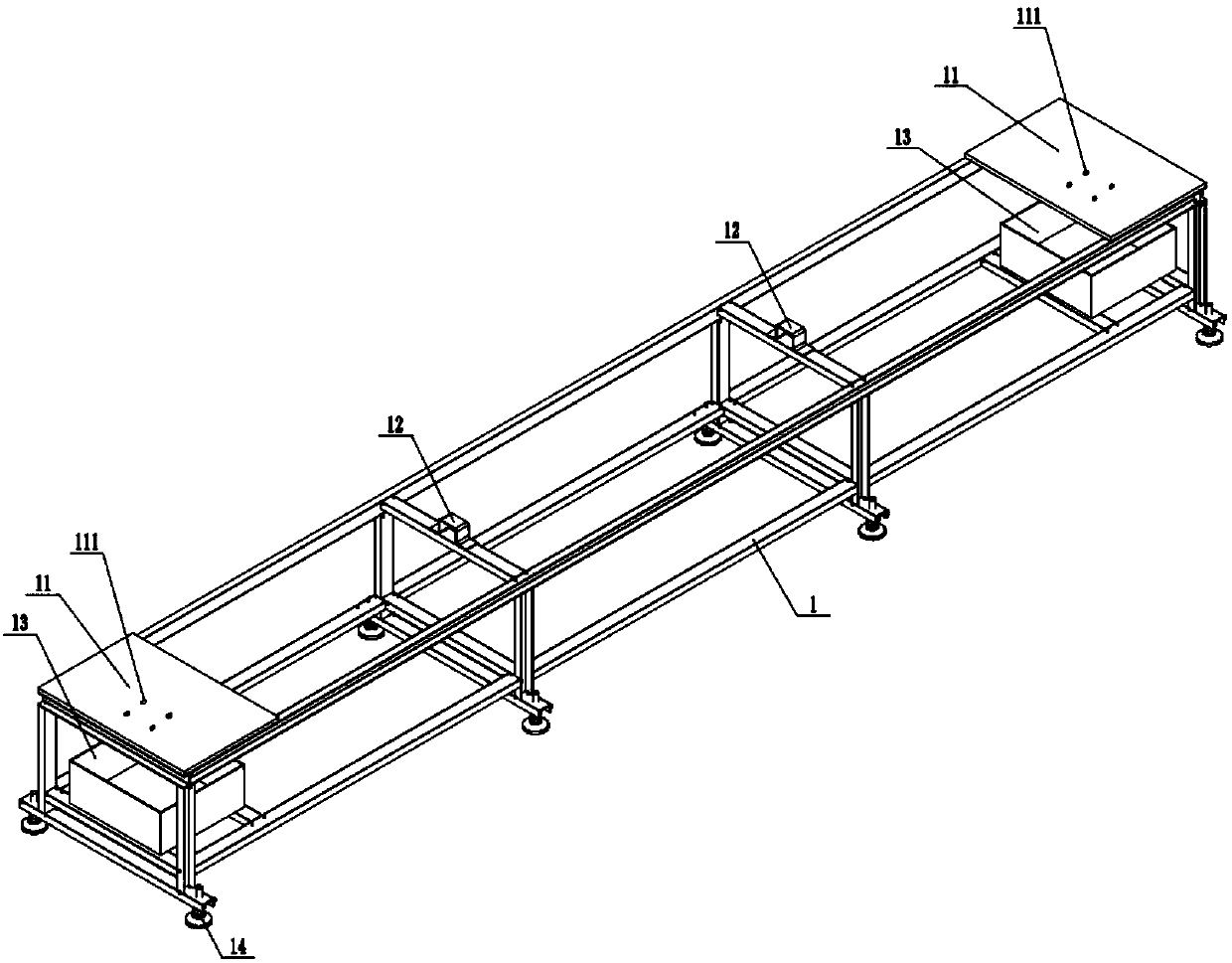

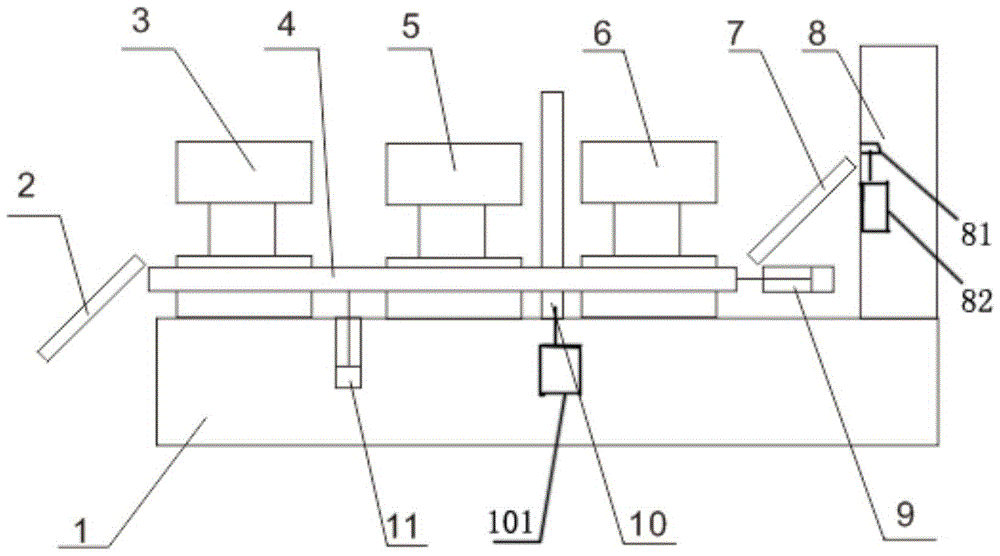

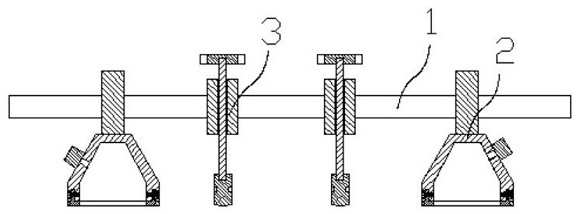

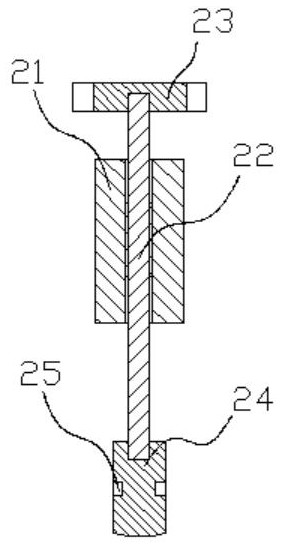

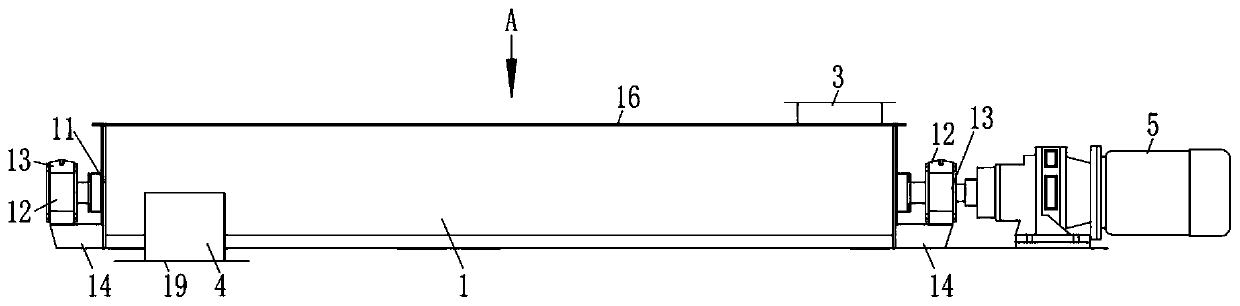

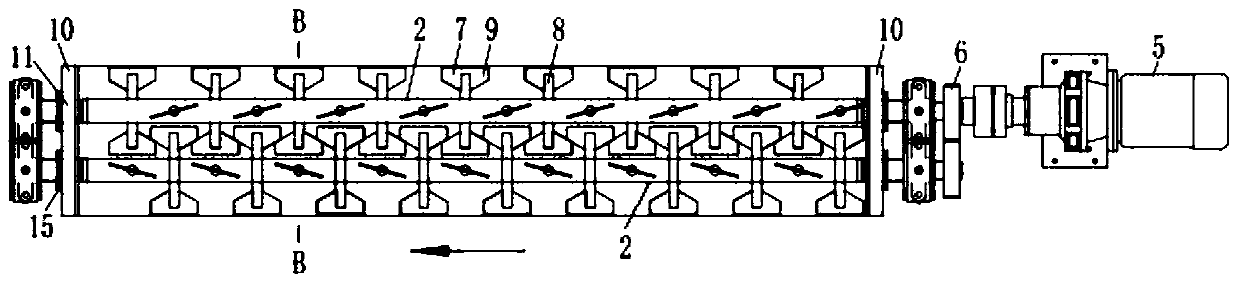

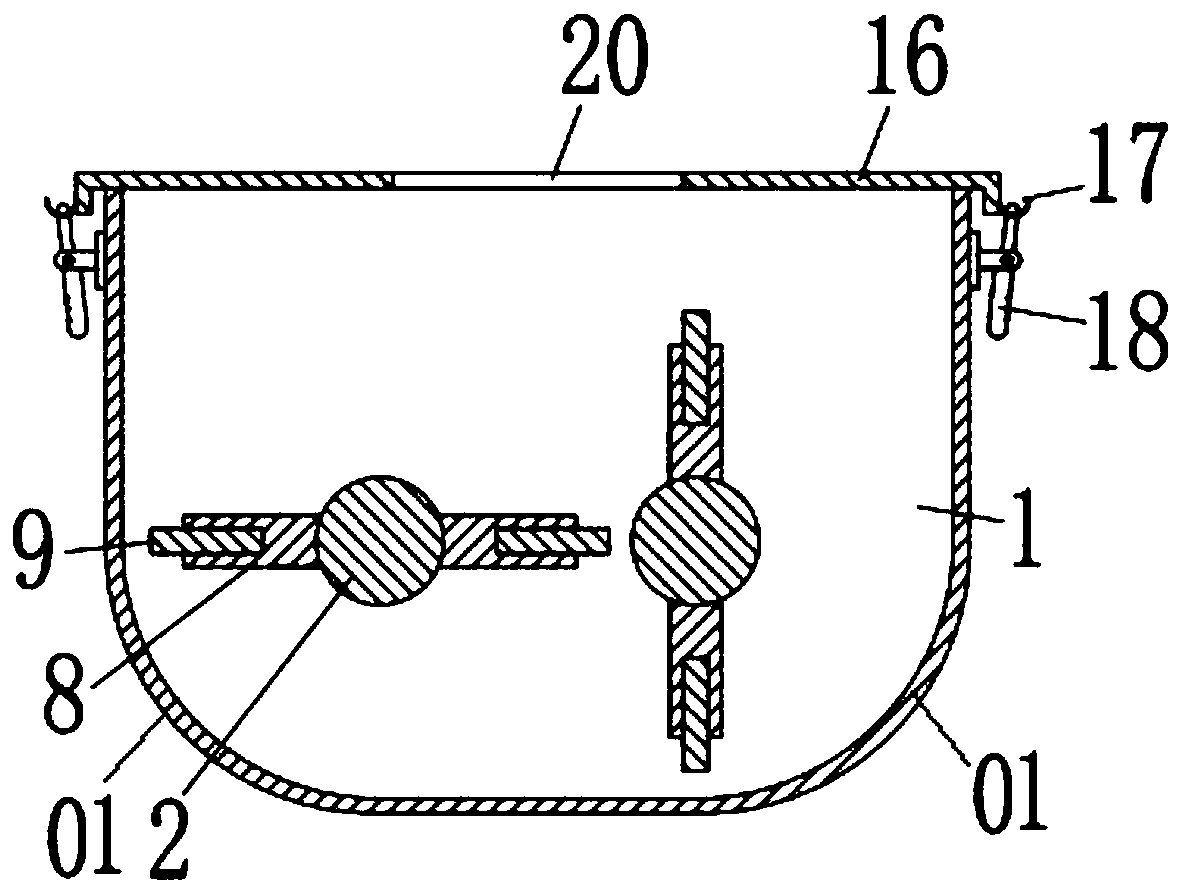

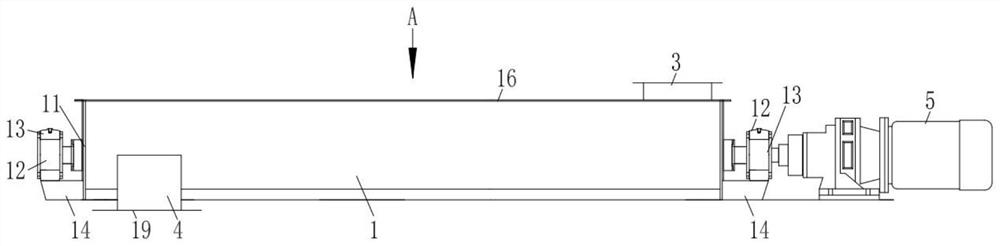

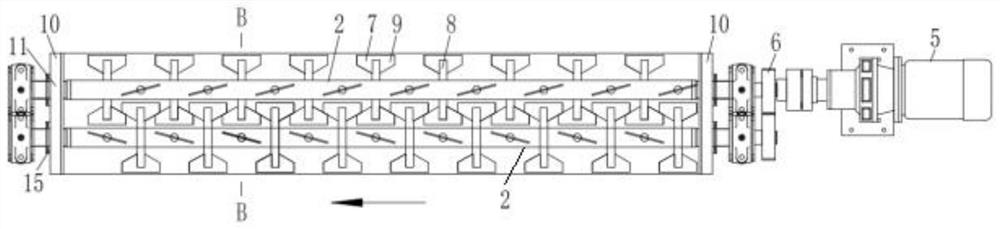

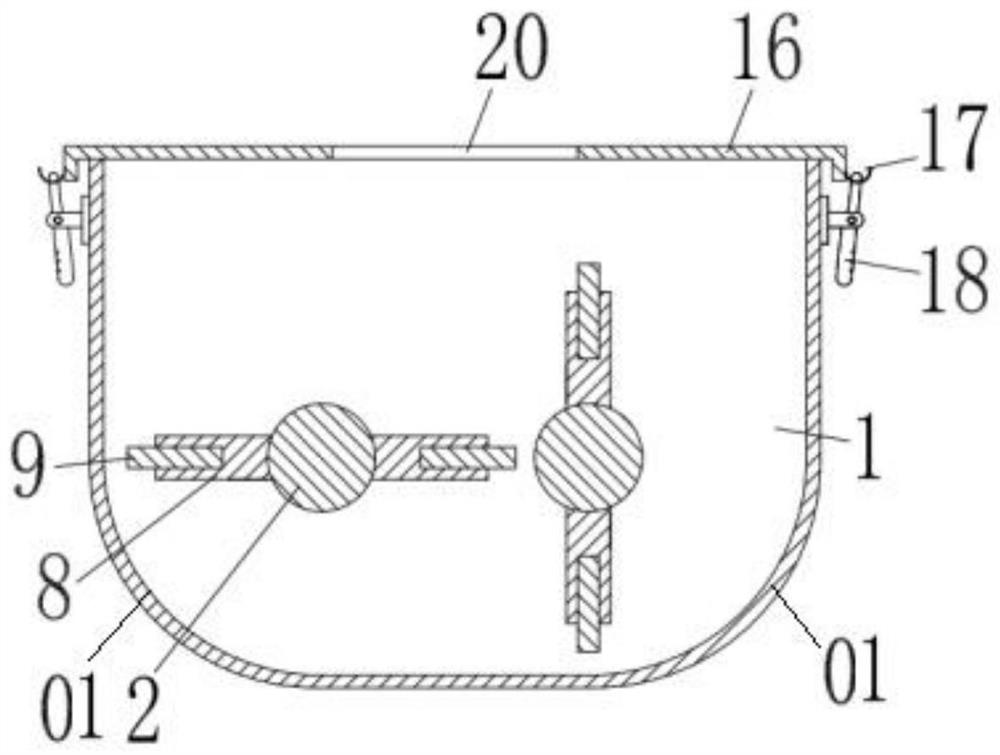

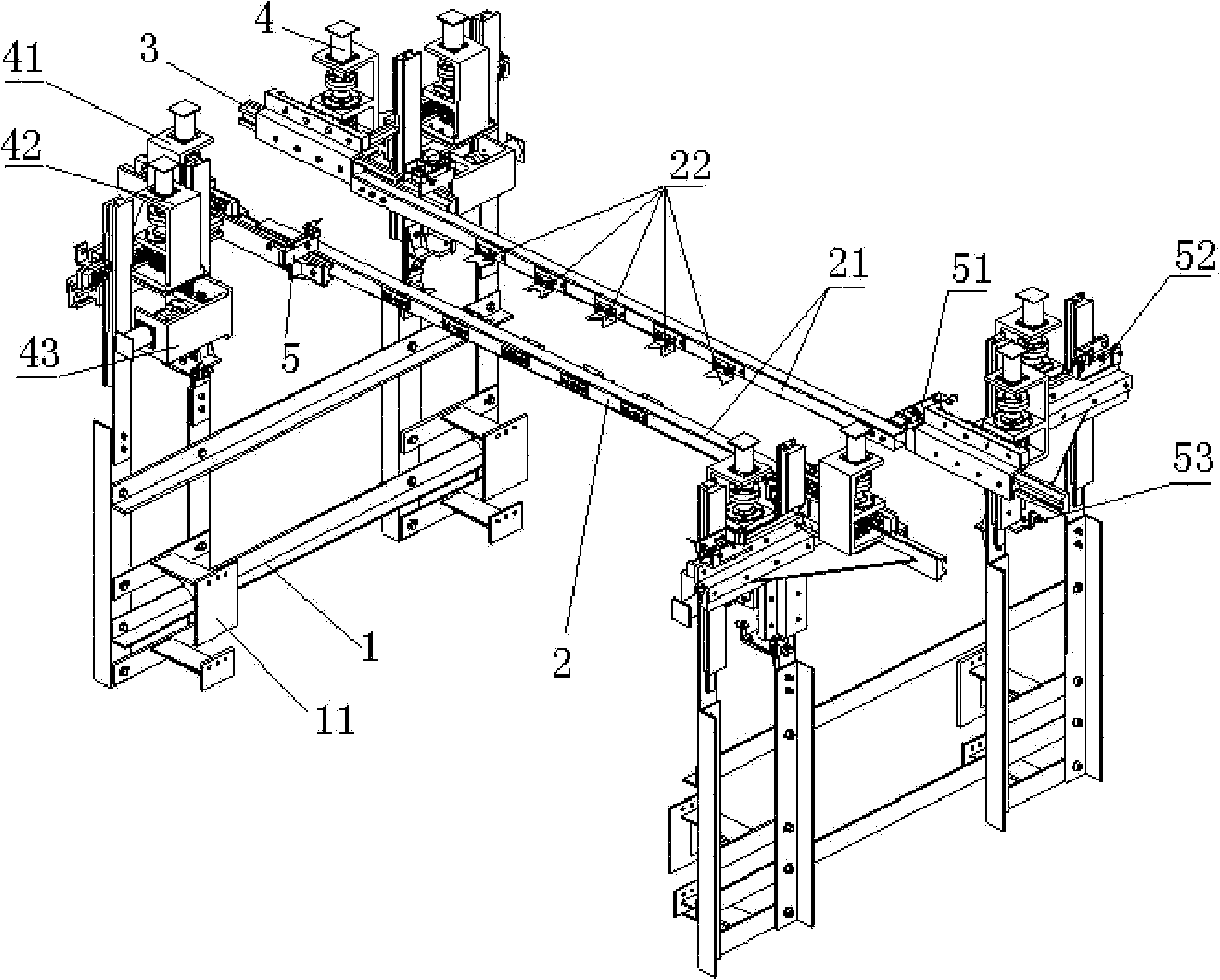

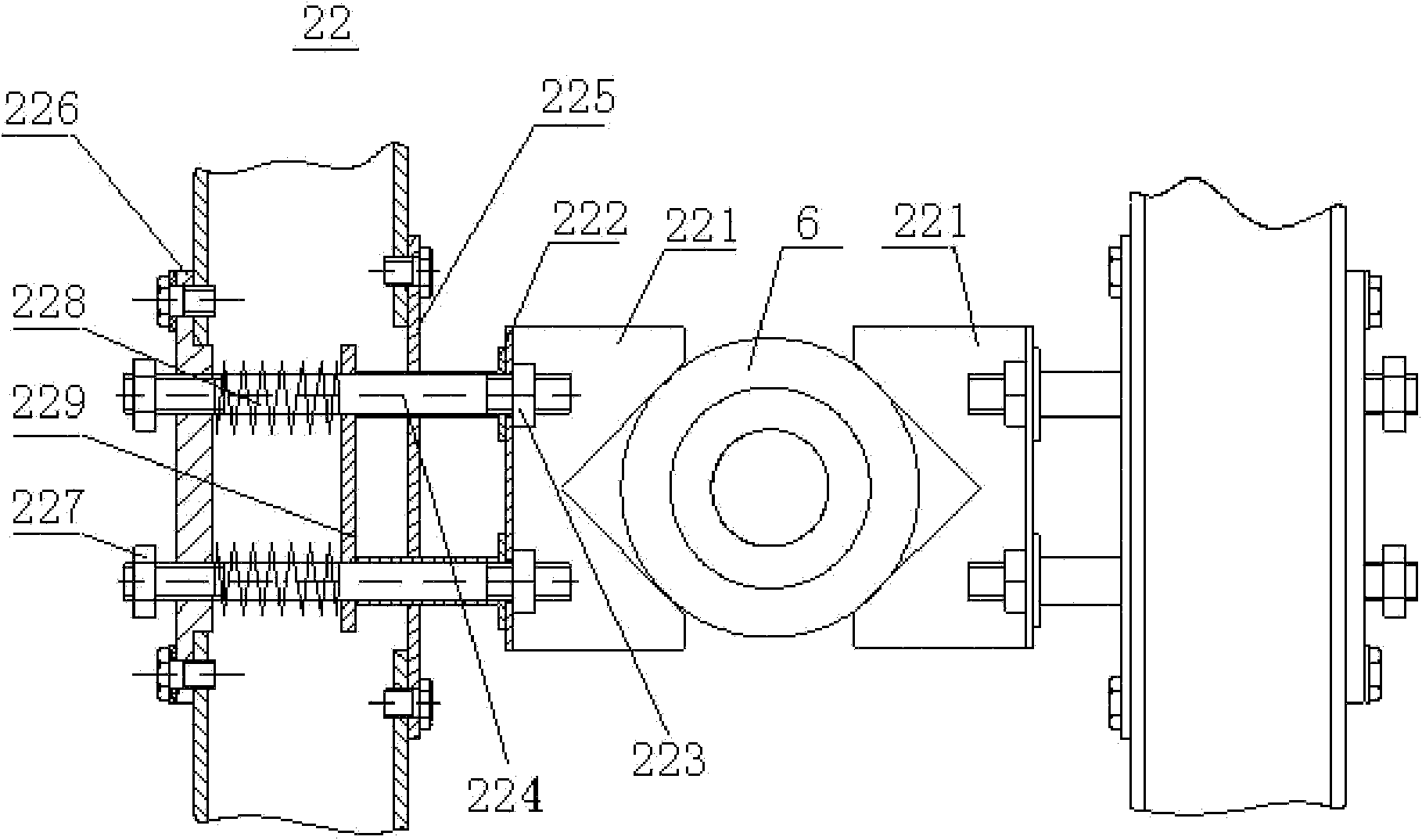

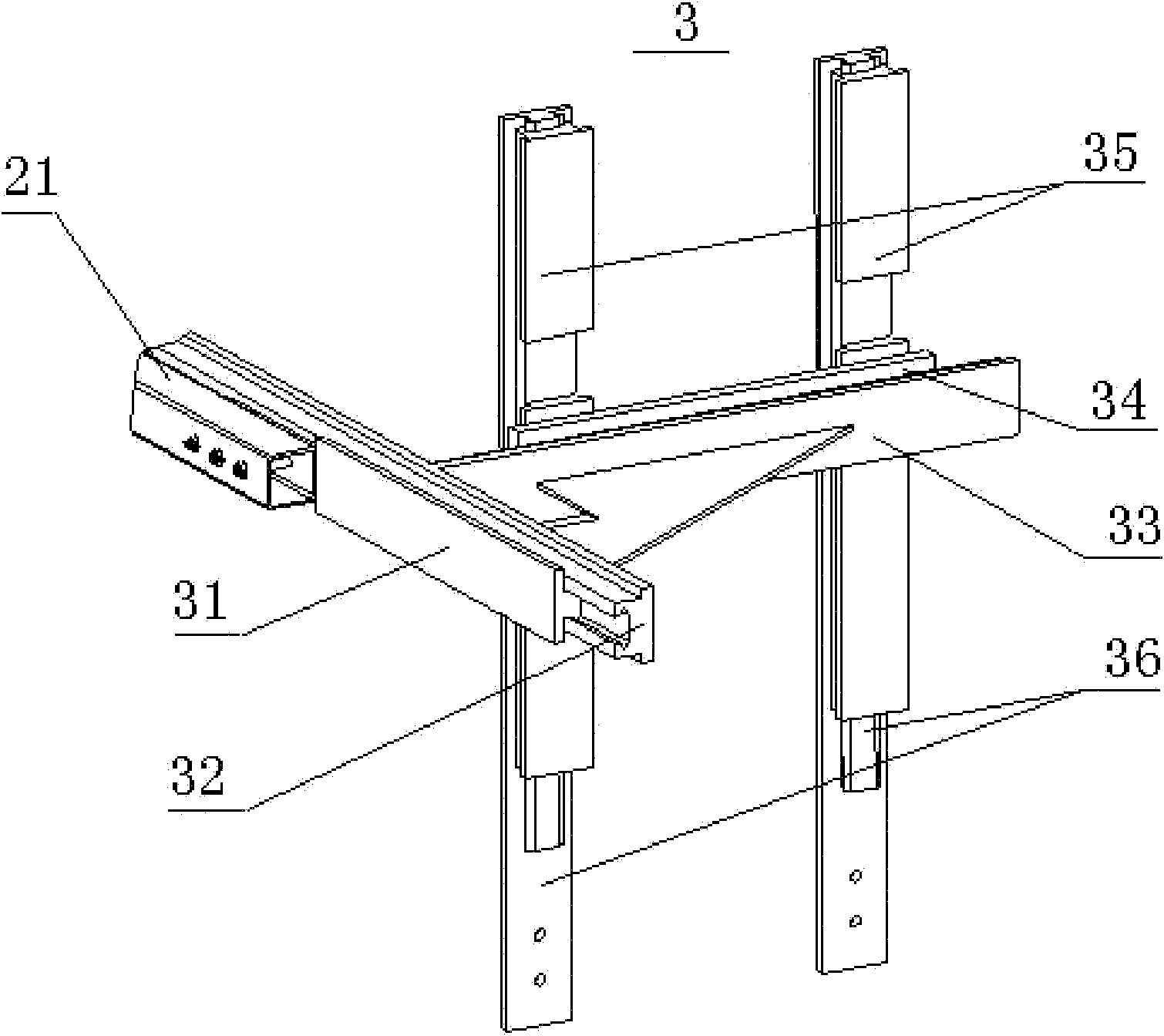

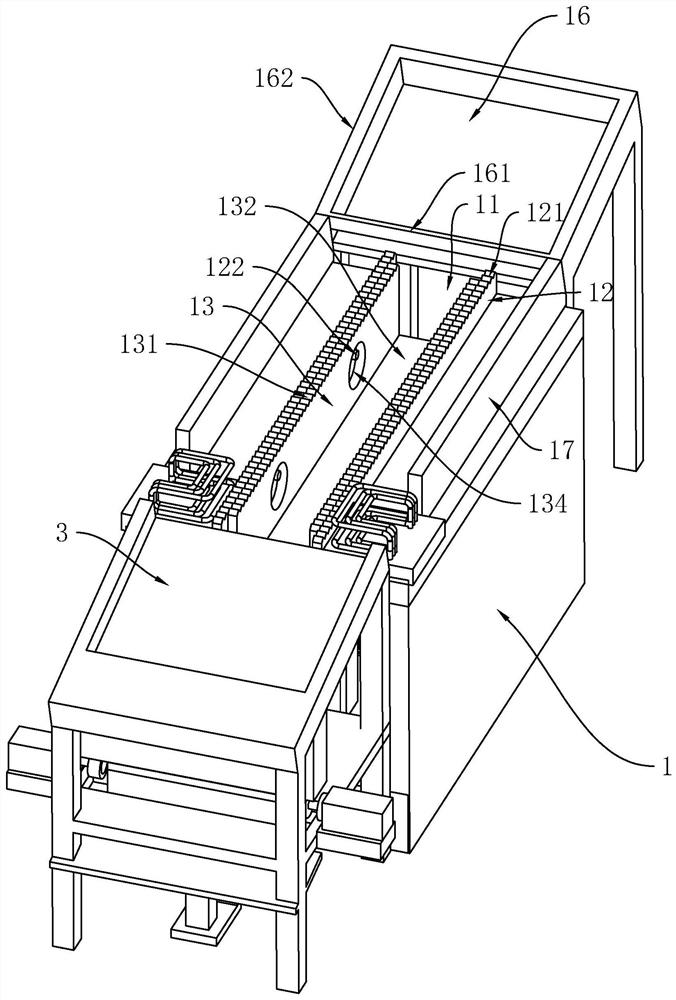

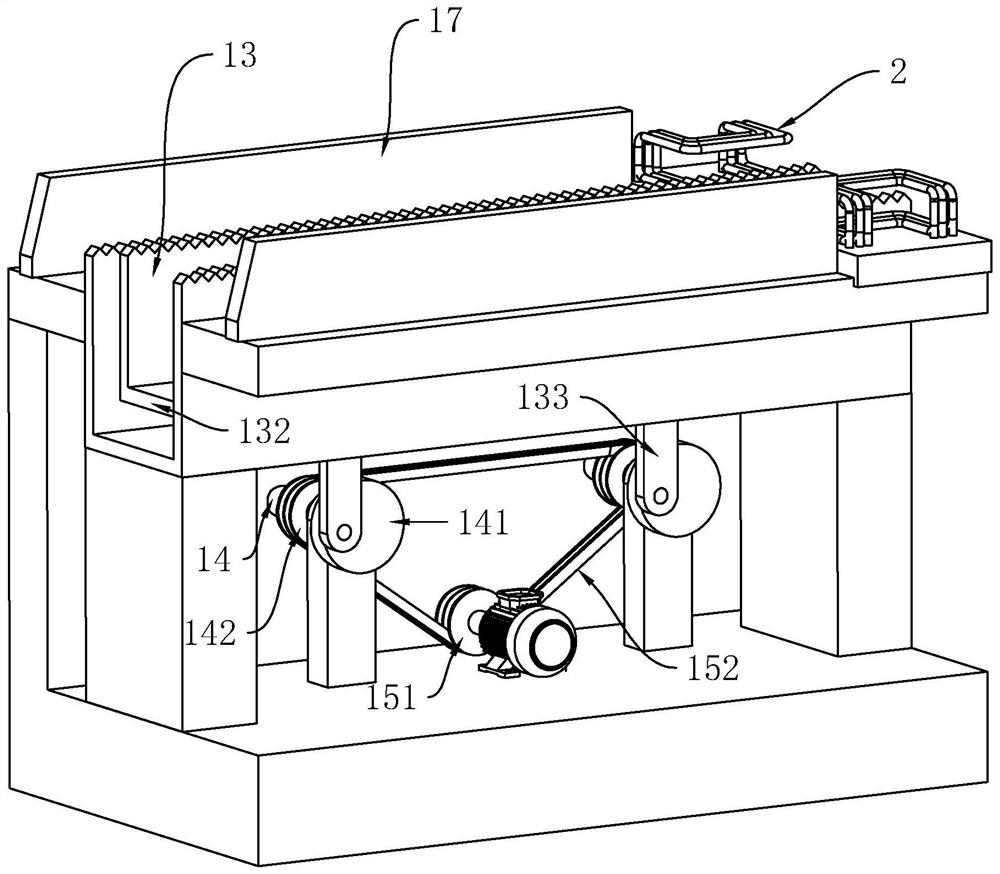

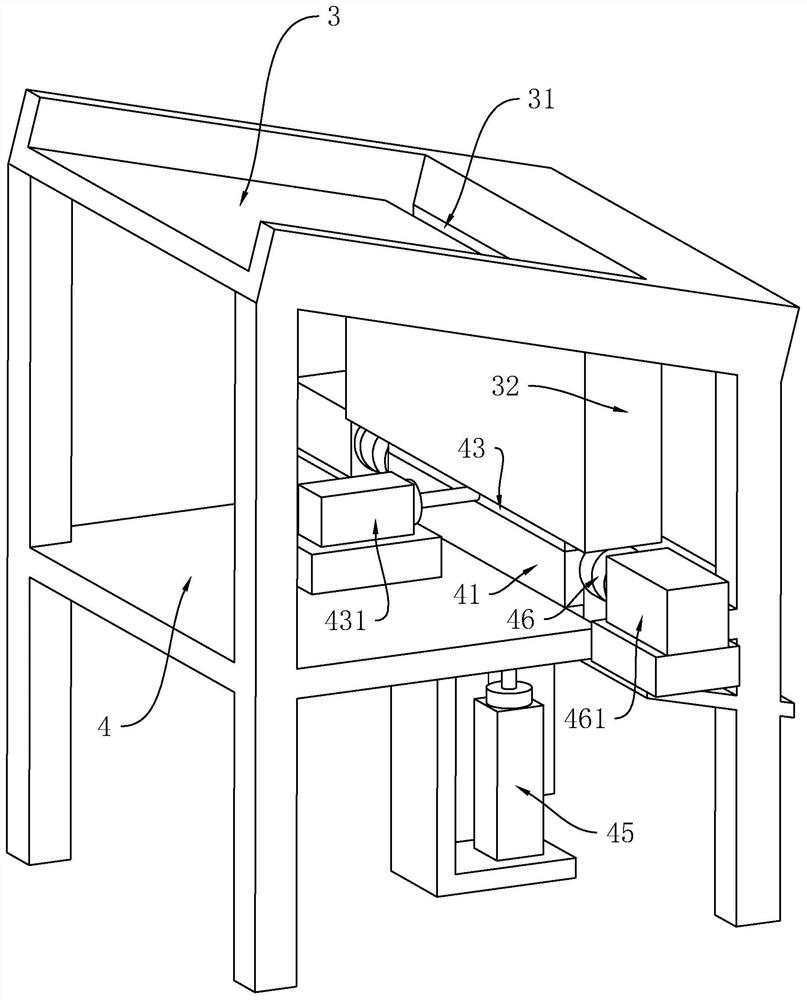

The invention discloses a pipe material assembling platform production line. The pipe material assembling platform production line comprises a feeding conveying part, a cutting machine, a carrying part, a hole finding part and a robot, wherein an output end of the feeding conveying part is in butt joint with an input end of the cutting machine, an output end of the cutting machine is in butt jointwith an input end of the carrying part, the hole finding part is arranged on one side of the carrying part, and the robot is arranged on one side of the hole finding part. continuous automatic feeding, length fixing, cutting and hole finding of a pre-assembled contact network cantilever pipe material and automatic assembling of a workpiece and the pipe material can be realized, field operators can be reduced, the labor intensity can be reduced, and the working efficiency can be improved.

Owner:武汉中安佳通装备技术有限公司

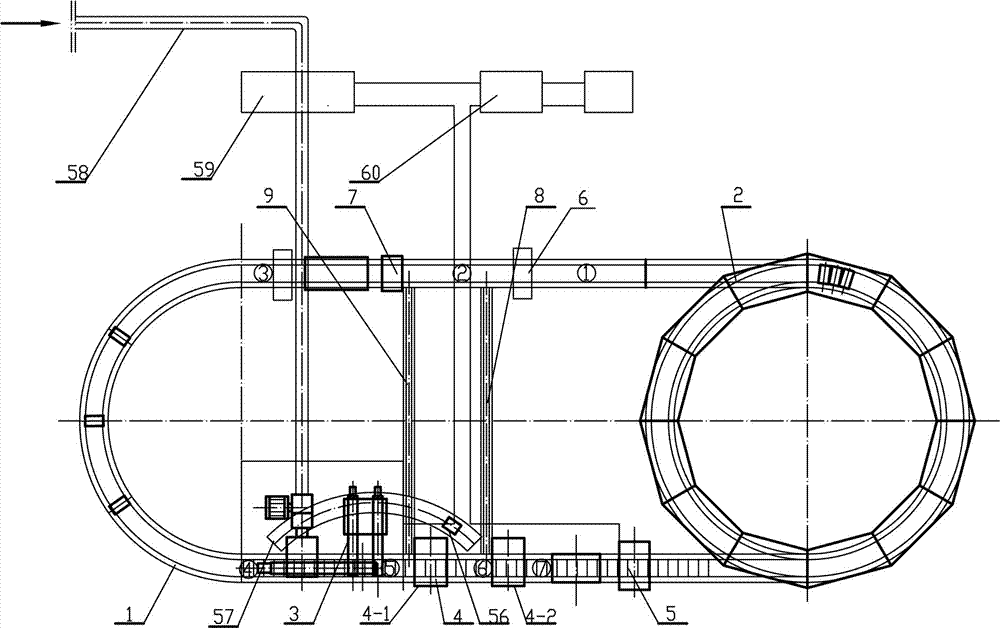

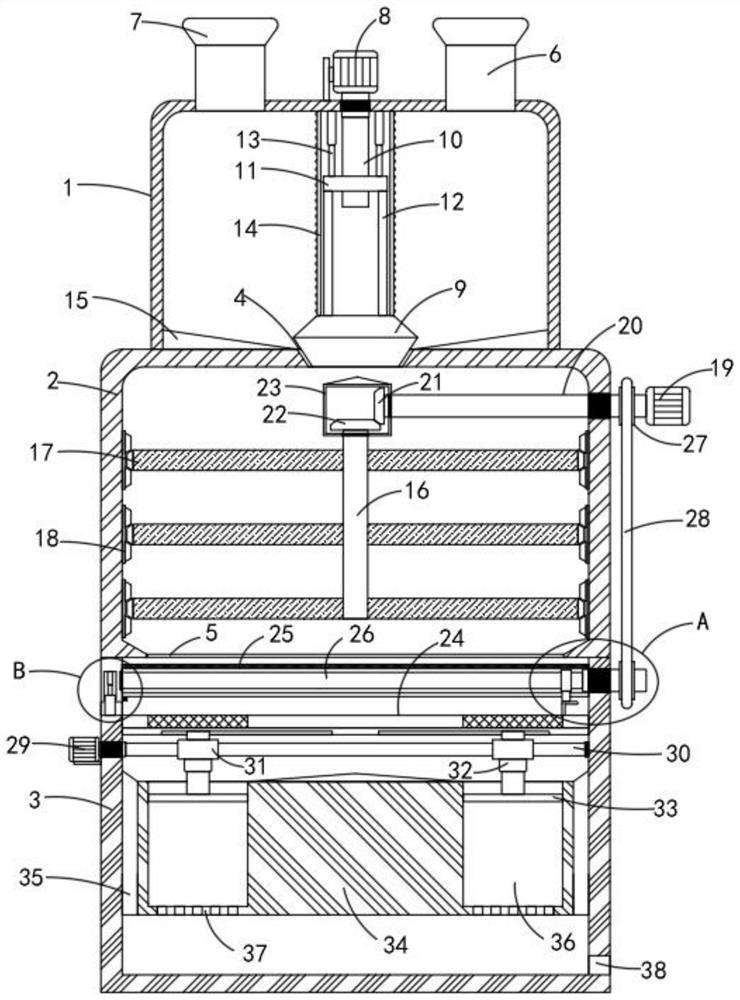

Large production line of green brick tea and production method

ActiveCN107136238AReduce frictionEasy to operatePre-extraction tea treatmentClimate change adaptationProcess engineeringTea leaf

The invention discloses a large production line of green brick tea and a production method, primarily, a production device which comprises an annular conveying track and a spiral conveying track, wherein a tea automobile matching and blanking device, a pressing device and a lifting device are arranged on one side of the annular conveying track; a mould head disassembly device and a green brick tea ejection device are arranged on the other side of the annular conveying track; the mould head disassembly device and the green brick tea ejection device are connected with a mould head conveying belt and a panel cleaning conveying belt respectively; the other ends of the mould head conveying belt and the panel cleaning conveying belt are connected with the annular conveying tracks in front of and at back of the pressing device. According to the large production line of green brick tea and the production method disclosed by the invention, by setting a complete production line, the labor intensity can be greatly reduced, and the production efficiency is improved.

Owner:XINDING BIOLOGICAL SCI & TECH

Automatic feeding device for sheep breeding

PendingCN109924133AImprove feeding efficiencyReduced propulsionAnimal feeding devicesFood processingEngineeringAirbag

Provided is an automatic feeding device for sheep breeding. A feed box is arranged at the top of a shell, a discharging cavity is formed in the bottom of the feed box, a sector rotary shaft capable ofsealing a discharging opening in the bottom of the feed box is arranged in the discharging cavity, and a feeding wheel is arranged in the shell. Four bosses are arranged on the feeding wheel in the circumferential direction at equal intervals, and a feed groove is formed. A feed collecting trolley for bearing feed flowing out of the feed groove is arranged at the bottom of the shell, a sector step is arranged on one side of the bottom of the shell, and therefore the feed collecting trolley can move obliquely downwards after moving to the sector step; an airbag for pushing the feed collectingtrolley to move towards the sector step is arranged at the bottom of the shell, and a gas compressing device for inflating the airbag and a gas collecting chamber for collecting gas exhausted by the airbag are arranged on the shell. A spring is connected between the side wall, towards the airbag, of the feed collecting trolley and the inner wall of the shell, and used for pulling the feed collecting trolley to the original position through the elastic acting force when the feed on the feed collecting trolley moving to the sector step is eaten by sheep to cause weight reduction of the feed collecting trolley.

Owner:HENAN UNIV OF SCI & TECH

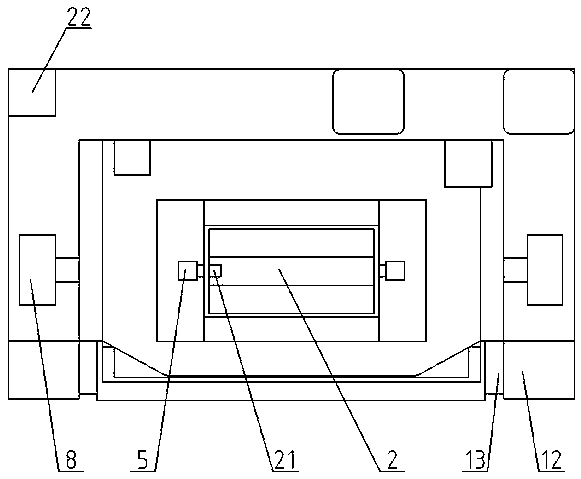

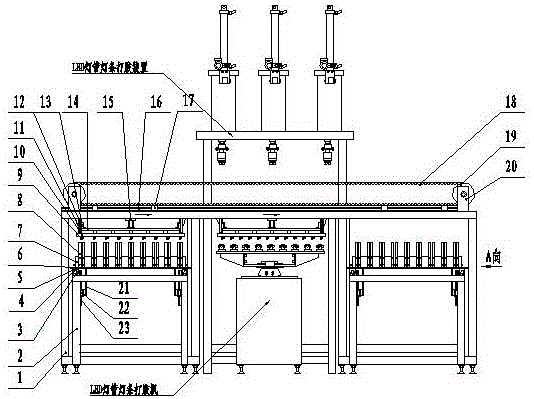

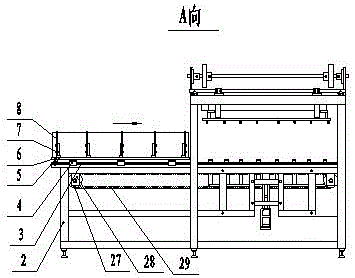

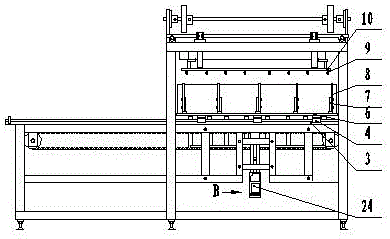

Automatic double-bin feeding device for pasting light bars into LED modulator tubes in flexible automatic production line

PendingCN106629033ARealize continuous automatic feedingRealize flexible automatic productionConveyor partsProduction lineEngineering

The invention relates to an automatic double-bin feeding device for pasting light bars into LED modulator tubes in a flexible automatic production line. The automatic feeding device comprises a rack, a light bar feeding device, a light bar vacuum feeding device, a light bar vacuum conveying device and a light bar vacuum putting device. According to the automatic feeding device, in actual production, feeding can be conducted through a left feeding bin and a right feeding bin, and automatic continuous feeding of the light bars is achieved; and the purpose that one bin is used for the hard light bars, and the other bin is used for the soft light bars can be achieved as well, the light bars of different varieties and specifications can be pasted into the modulator tubes, and flexible automatic production is achieved.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

Polyurethane waterproof coating production and processing equipment

InactiveCN113213407AGuaranteed cleanlinessImprove filling efficiencyConveyorsCleaningChemistryManufacturing engineering

The invention relates to the field of waterproof coating production and processing equipment, in particular to polyurethane waterproof coating production and processing equipment. The equipment comprises a support, a conveying structure, a sweeping structure, a scraping structure, a circulating structure and a dewatering structure. When the conveying structure continuously conveys packaging barrels, the sweeping structure can be synchronously driven to work, through work of the sweeping structure, a coating adhering to a conveying assembly on the conveying structure can be swept, and therefore the cleanliness of the conveying structure is guaranteed; and by installing the scraping structure at the bottom end of the support, the coating adhering to the conveying assembly can be scraped and cleared, the scraped coating can be collected, the cleanliness of the conveying assembly can be guaranteed, the scraped coating can be prevented from polluting the workshop ground, and the sweeping structure can synchronously drive the dewatering structure to work while working, so that the cleaned conveying assembly is wiped and dried, and a wiped assembly can be extruded and dehydrated.

Owner:汤健

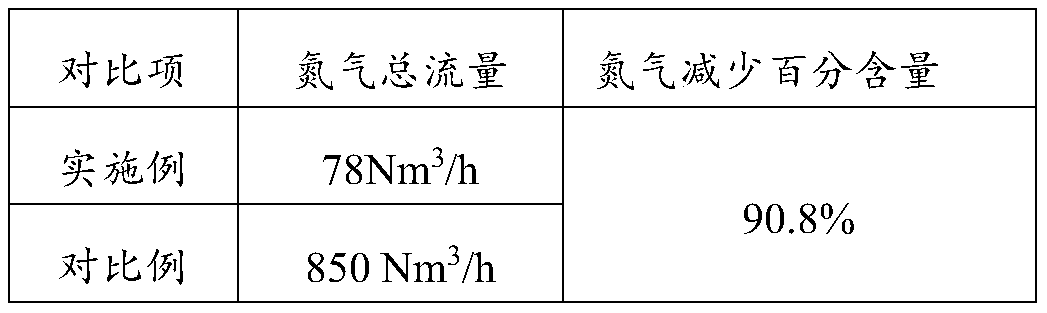

Continuous vertical feeding system and method for fluidized bed reactor

PendingCN111495283AAvoid wear and tearPrevent backflowDispersed particle filtrationChemical/physical processesGas solidFluidized bed

The invention discloses a continuous vertical feeding system and method for a fluidized bed reactor. The feeding system comprises a supply system, a vertical discharging section, a horizontal conveying section, a gas conveying system and a pressure adjusting assembly which are connected in sequence. The other end of the horizontal conveying section is connected with a fluidized bed reactor, and the pressure adjusting assembly is connected with the supply system and the gas conveying system. The self-weight of a solid particle reaction material and the effect of an input gas are used to make particle materials uniformly fluidized and transferred to the vertical discharging section from the supply system, then transferred to the horizontal conveying section and continuously uniformly conveyed into a fluidized bed reactor, so the particle material abrasion caused by mechanical feeding is avoided, the fine powder amount is reduced, the entrainment loss of gas-solid reaction is further reduced, the gas amount introduced by pneumatic feeding is greatly reduced, and great benefits are brought to chlorination production.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Automatic processing and assembling system and method for circuit board product

ActiveCN111246672AReduce site occupancyReduce labor costsPrinted circuit assemblingControl systemControl engineering

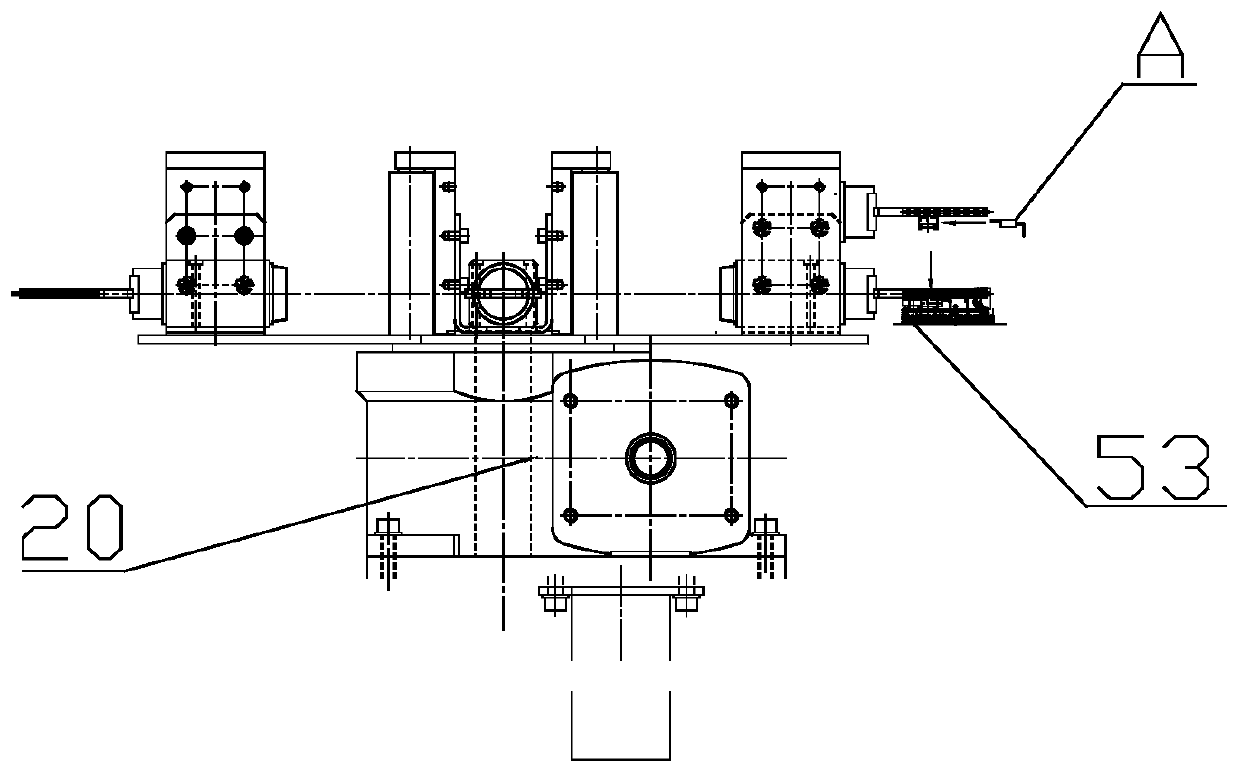

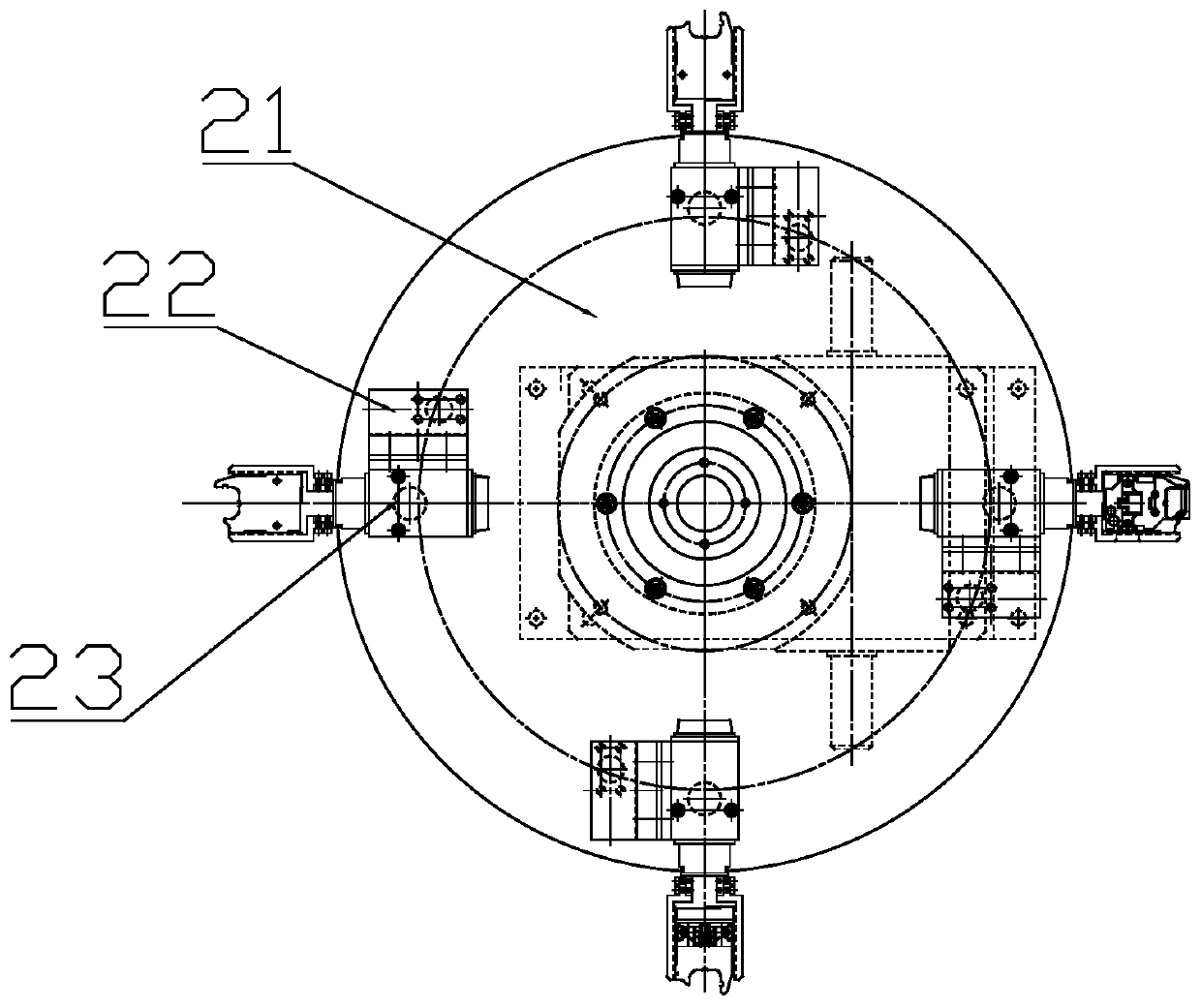

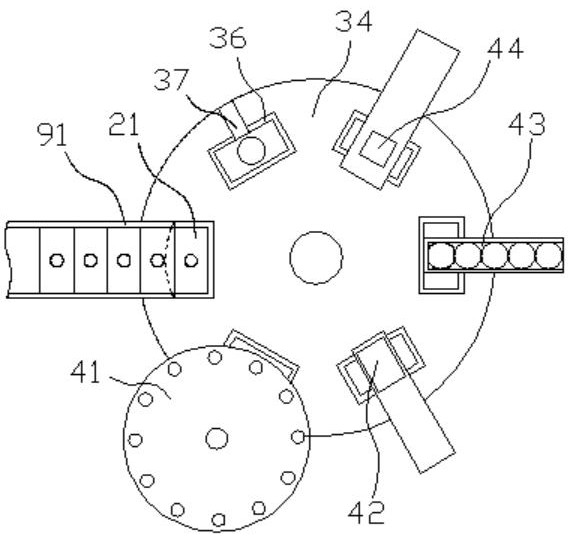

The invention relates to an automatic processing and assembling system and method for a circuit board product. The assembling system comprises a central multi-station rotary table mechanism and a bottom plate multi-material box rotary table feeding device installed around the central multi-station rotary table mechanism. An automatic rubberizing machine, an automatic screw locking machine, a basemulti-magazine turntable feeding device, a circuit board cave magazine rack feeding device, an element multi-magazine turntable feeding device, an assembly robot and an automatic tin soldering machineare arranged on All mechanisms and devices are controlled by a control system. the central multi-station turntable mechanism comprises four stations, and each station is provided with a sliding tablecapable of moving up and down and a rotatable clamping jaw. Transferring and circulating of workpieces at different stations are achieved through the central multi-station rotary disc mechanism, thecomplex machining and assembling process and continuous circulating automatic operation can be achieved in a compact site space, the circuit board assembling quality is ensured, the labor cost is reduced, and automatic and efficient production is achieved.

Owner:SHANGHAI DIANJI UNIV

Automatic feeding and discharging die cutting machine

The invention provides an automatic feeding and discharging die cutting machine which comprises a feeding mechanism, a feeding adjusting mechanism, a die cutting mechanism, a discharging mechanism anda box body. The feeding mechanism, the feeding adjusting mechanism, the die cutting mechanism and the discharging mechanism are sequentially arranged on the box body; the discharging mechanism comprises a first conveyor belt, a second conveyor belt, a supporting frame, an air cylinder, positioning racks, a material table, a servo motor and a screw rod; the first conveyor belt is hinged to the second conveyor belt; one side, far from the hinged side of the first conveyor belt, of the second conveyor belt is arranged on the supporting frame; the air cylinder is arranged at the middle part of the upper part of the supporting frame; the positioning racks are arranged at two ends of the upper part of the supporting frame; one end of the material table is arranged in the supporting frame; the servo motor is arranged below the supporting frame; and the screw rod penetrates through the material table to be arranged below the supporting frame and is in threaded connection with the material table. The automatic feeding and discharging die cutting machine can realize the automatic feeding of printing products, the positions of the printing products are automatically adjusted after feeding, during discharging, the printing products are orderly and stably stacked, and are easily collected, and meanwhile, the damage caused by falling of the printing products is avoided.

Owner:爱邦(南京)包装印刷有限公司

Comprehensive detection device for parts in large amount

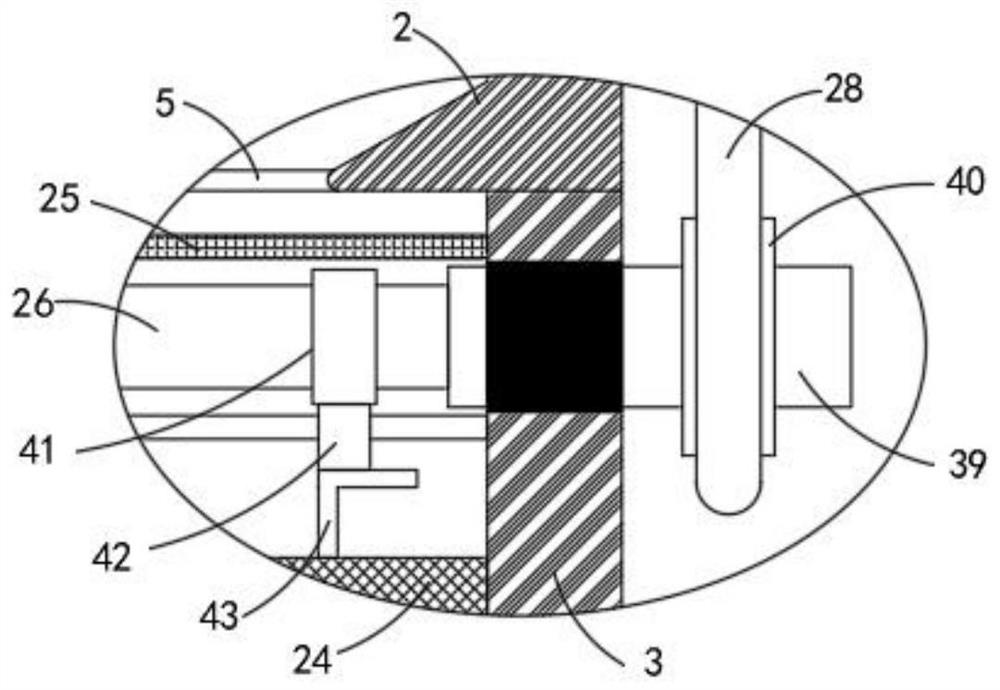

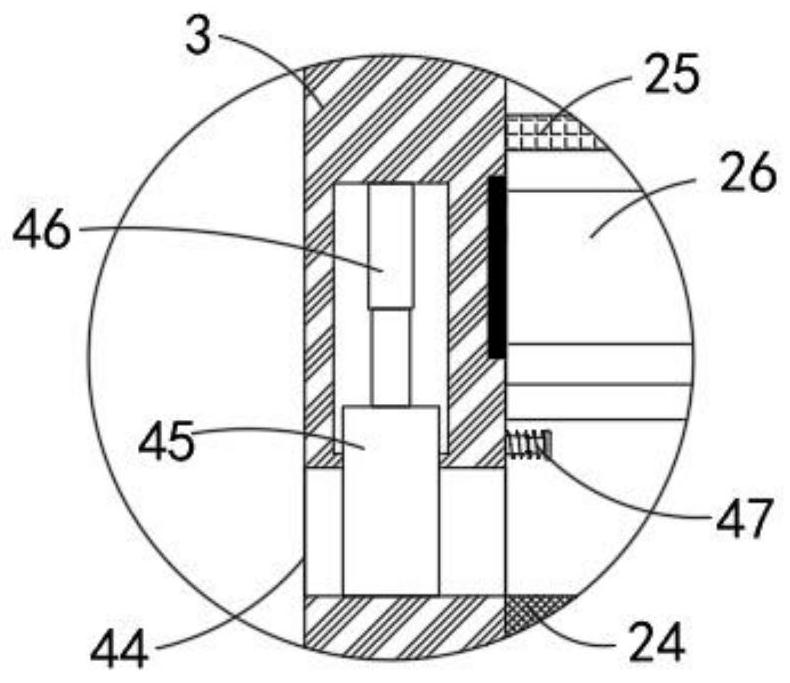

PendingCN108896553ARealize continuous automatic feedingLarge peripheral spaceOptically investigating flaws/contaminationUsing optical meansElevation angleEngineering

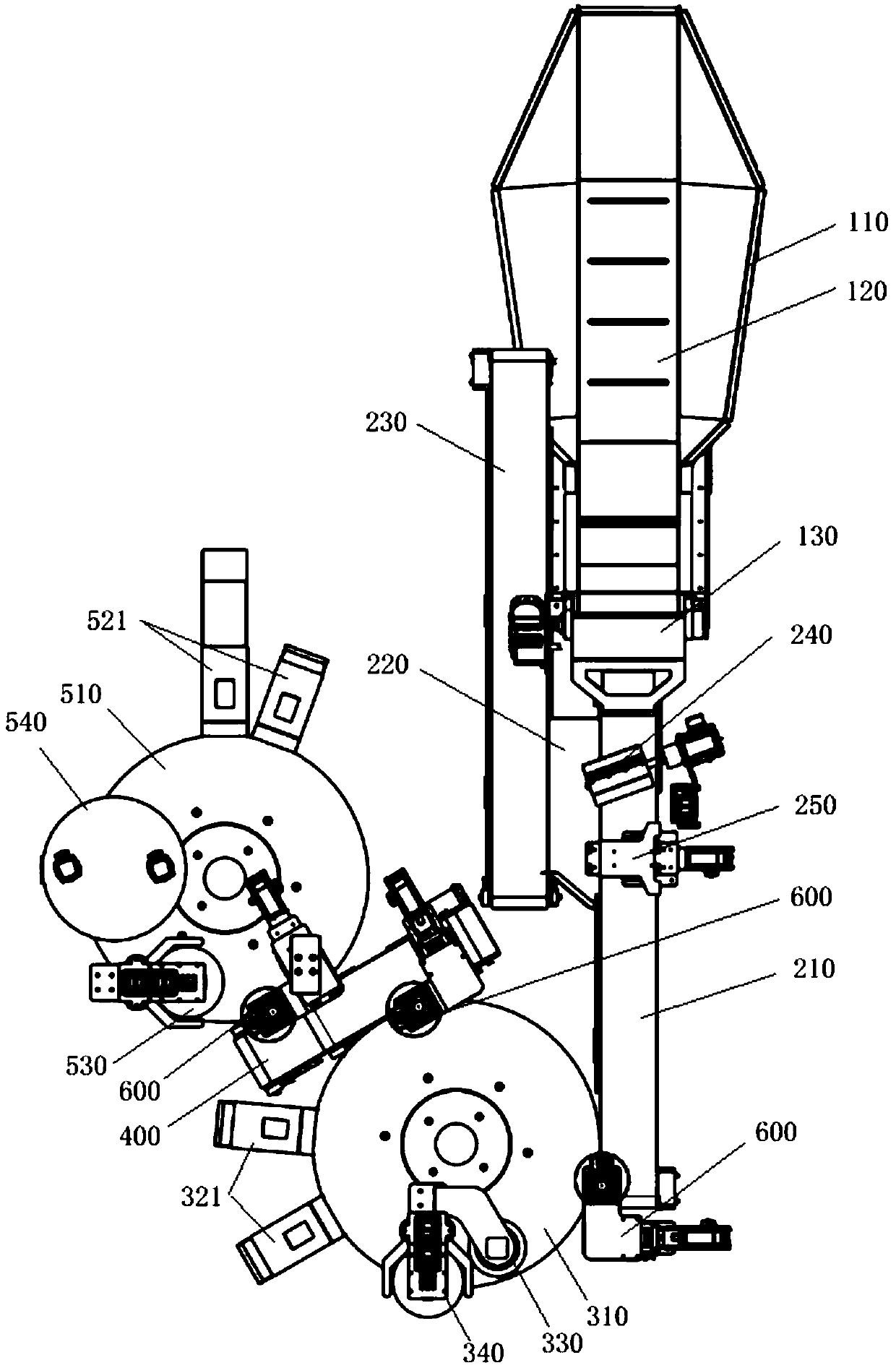

The invention provides a comprehensive detection device for parts in a large amount, comprising a quantitative sampling device, a collating unit, a first-side detecting device, a second-side detectingdevice, an overturn device and a plurality of guide devices, wherein the quantitative sampling device comprises a hopper, a first conveyer belt and a discharge channel, sampling stop dogs are arranged on the first conveyer belt at intervals, the working face of the first conveyer belt comprises a sampling section and a screening section arranged with a large elevation angle, and the sampling section extends at the bottom of the hopper; the overturn device is used for conveying samples on a third conveyer belt to a fourth conveyer belt by clamping; and the plurality of guide devices are used for guiding the samples from the second conveyer belt to a first detection disc, guiding samples from the first detection disc to the third conveyer belt and guiding the samples from the fourth conveyer belt to a second detection disc. The device realizes continuous and automatic feeding of large-scale components, and the peripheral spaces of the first detection disc and the second detection disc are relatively large, so as to be suitable for the flexible arrangement of multiple receiving boxes and meet the requirement of multiple classification of the samples.

Owner:合肥市雅视智能科技有限公司

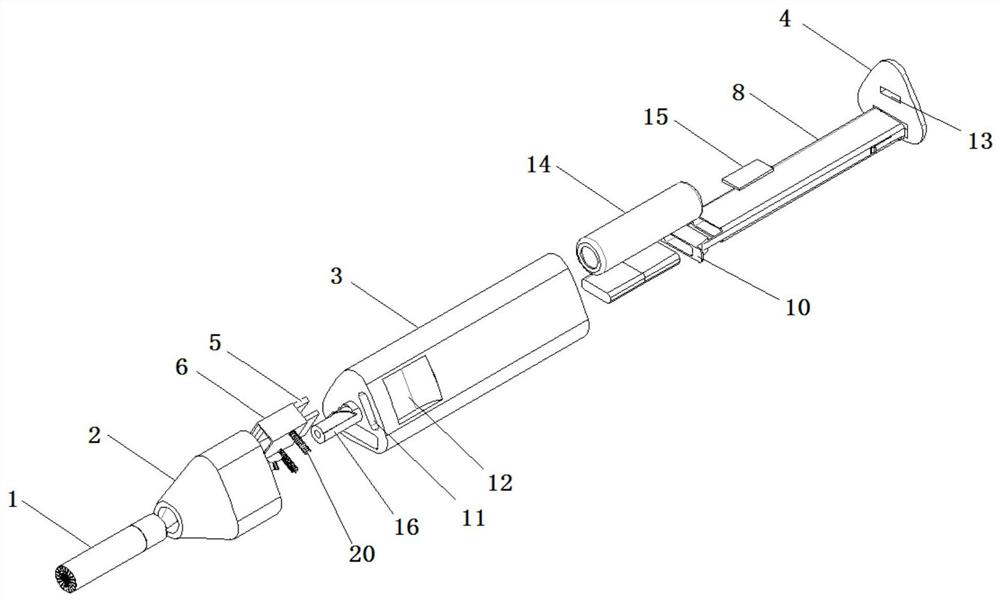

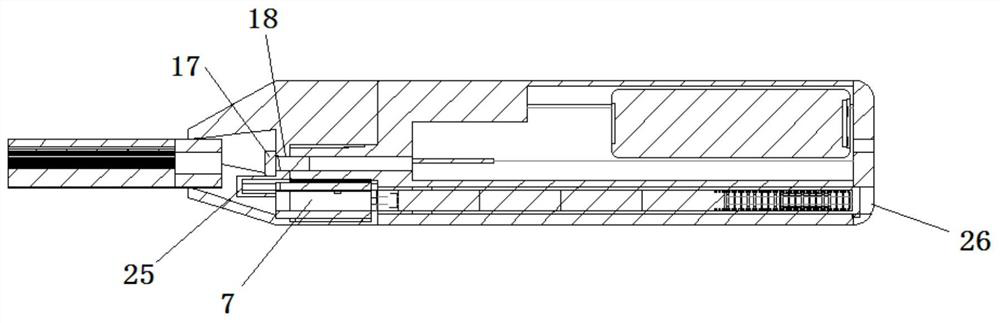

Rotary type automatic cigarette-feeding heat-not-burn smoking set

PendingCN112167722ARealize continuous automatic feedingQuick and automatic ejectionTobaccoEngineeringMechanical engineering

Owner:BEIHANG UNIV YUNNAN INNOVATION INST +5

Battery wrapping machine and battery wrapping assembling machine comprising battery wrapping machine

ActiveCN110676507AIncrease productivityEliminate manual operationAssembling battery machinesFinal product manufactureElectrical batteryElectrical and Electronics engineering

The invention relates to a battery wrapping machine comprising a frame and a paper feeding device, a feeding device, a plate feeding and conveying device, a partition plate paper cutting device and apressing mechanism which are arranged on the frame. The partition plate paper cutting device is internally provided with a paper feeding channel for conveying partition plate paper from top to bottom.The feeding end of the paper feeding channel extends upwardly to the upper end of the partition plate paper cutting device. The discharging end of the paper feeding device is communicated with the feeding end of the partition plate paper cutting device. The partition plate paper is cut into a set length in the paper feeding channel. The partition plate paper cutting device is internally providedwith an electrode plate channel for conveying an electrode plate along the left and right direction. The feed end of the electrode plate channel is communicated with the discharging end of the paper feeding channel. The feeding device conveys the electrode plate to the feeding end of the electrode plate channel through the plate feeding and conveying device. The feeding end of the pressing mechanism is connected and communicated with the discharging end of the electrode plate channel. The invention also provides a battery wrapping assembling machine comprising the battery wrapping machine. Thebattery wrapping and assembling can be automatically completed.

Owner:HUBEI ENG UNIV

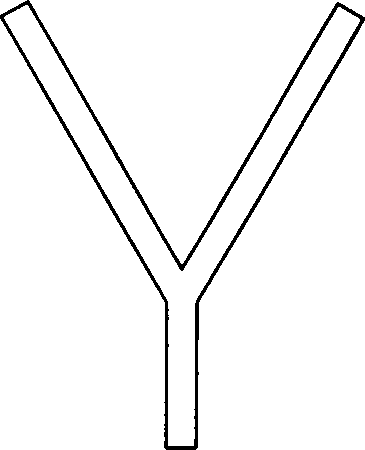

Wire leading-out and shearing device for automatic wine jar tying equipment

PendingCN111301783ARealize continuous automatic feedingHigh degree of automationBottle/container closureFilament handlingControl systemStructural engineering

The invention provides a wire leading-out and shearing device for automatic wine jar tying equipment. The wire leading-out and shearing device comprises a supporting mechanism, and further comprises awire leading-out mechanism and a wire shearing mechanism which are arranged on the supporting mechanism, the wire shearing mechanism is arranged in front of the wire leading-out mechanism in the wireleading-out direction of the wire leading-out mechanism, and the wire leading-out mechanism and the wire shearing mechanism are both connected with a control system; the supporting mechanism comprises a supporting plate, the four corners of the bottom face of the supporting plate are vertically connected with supporting rods correspondingly, and the bottom ends of the supporting rods are connected with foot supports; the wire leading-out mechanism comprises a wire storage unit, a straightening unit and a guiding unit which are arranged in sequence, wherein the wire storage unit is used for storing a standby iron wire, the straightening unit is used for straightening the iron wire, and the guiding unit is used for leading out the iron wire; and the wire shearing mechanism comprises a wireshearing fixing bottom plate, two blades for shearing the iron wire short, a Y-shaped track plate used for enabling the two blades to be closed or separated, and a wire shearing pushing air cylinder used for pushing the Y-shaped track plate. Wine jar tying materials are continuously and automatically fed, the tying materials are shorn, the automation degree is increased, and the working efficiencyis improved.

Owner:ZHEJIANG UNIV OF TECH

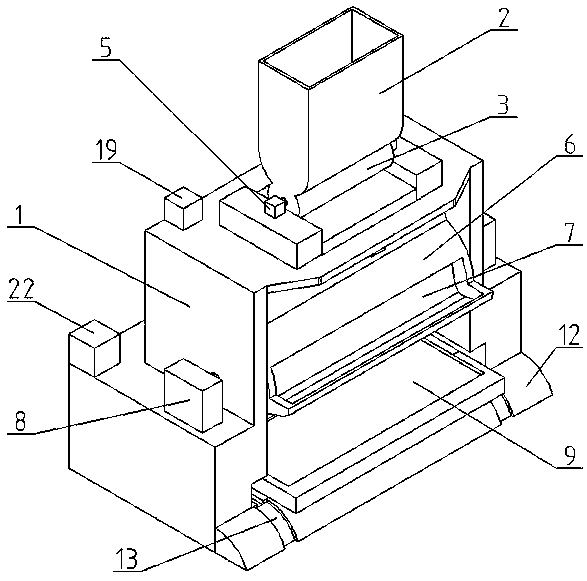

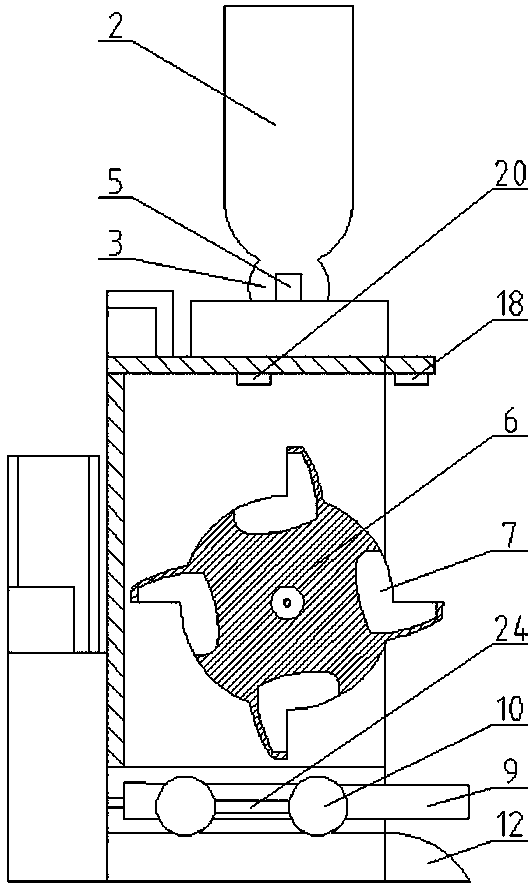

Grinding and squeezing device for peanut oil processing

ActiveCN113021986AIncrease the number ofRealize continuous automatic feedingSievingScreeningThermodynamicsElectric machinery

The invention discloses a grinding and squeezing device for peanut oil processing. The device comprises a grinding box and an oil squeezing box, the grinding box is fixedly arranged on the upper side wall of the oil squeezing box, the grinding box communicates with the oil squeezing box through a falling port, a feeding box is fixedly arranged on the upper side wall of the grinding box, and the feeding box communicates with the grinding box through a discharging port; and a matched material blocking plug is arranged in the discharging port, feeding pipes are symmetrically arranged on the upper side wall of the feeding box, a first motor is fixedly arranged at the center of the upper side wall of the feeding box, an output shaft of the first motor downwards penetrates through the upper side wall of the feeding box to be fixedly connected with a first reciprocating lead screw, and the first reciprocating lead screw is in threaded connection with a lifting nut. The device can achieve continuous and automatic feeding, does not need manual regular feeding, and is better in grinding effect, so that the oil squeezing efficiency is improved, extrusion oil squeezing of raw materials is achieved, feeding, grinding and oil squeezing are integrated, and the structure is simplified.

Owner:陕西商丹粮油工业有限公司

Precise feeding equipment used for livestock cultivation

PendingCN112997904AImplement auto-completionOvercoming the problem of not being able to feed continuouslyTransportation and packagingAnimal feeding devicesWater storageWater storage tank

Owner:HENAN LONGGANG TECH CO LTD

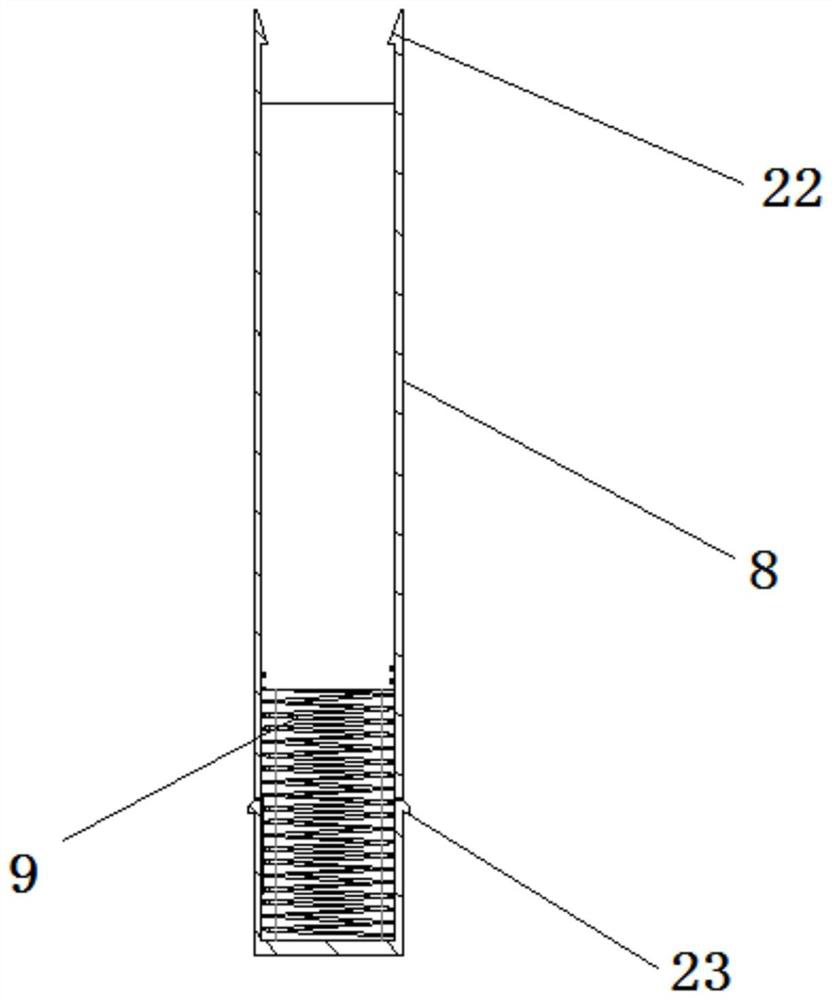

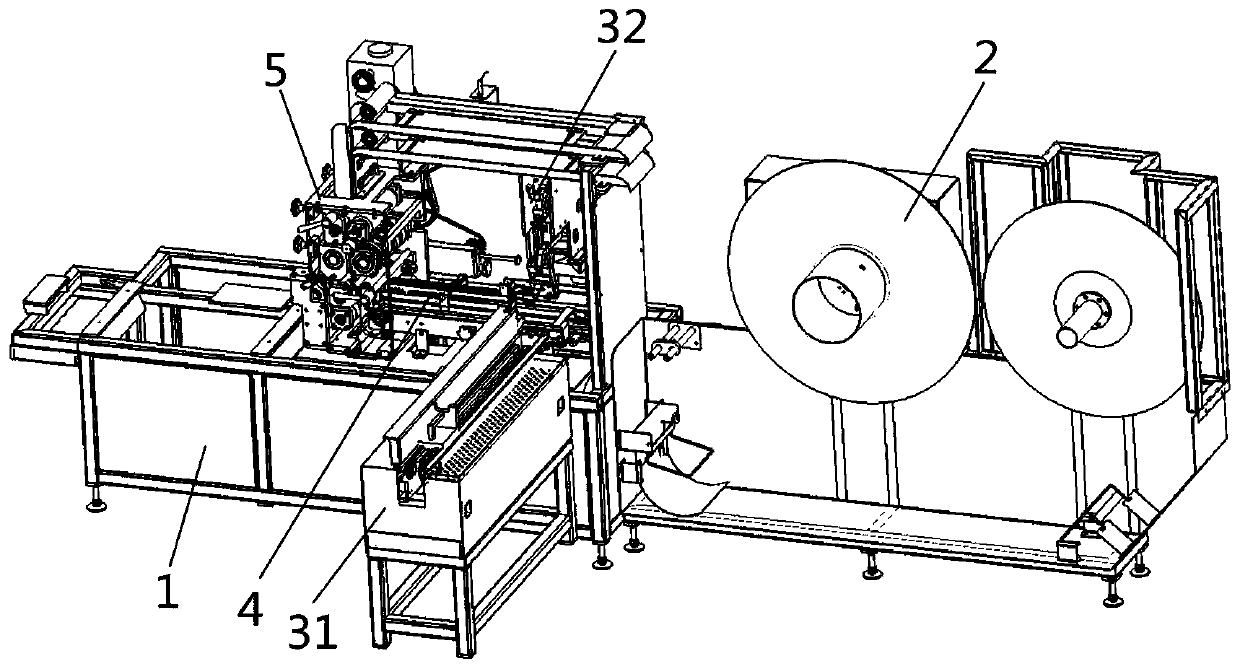

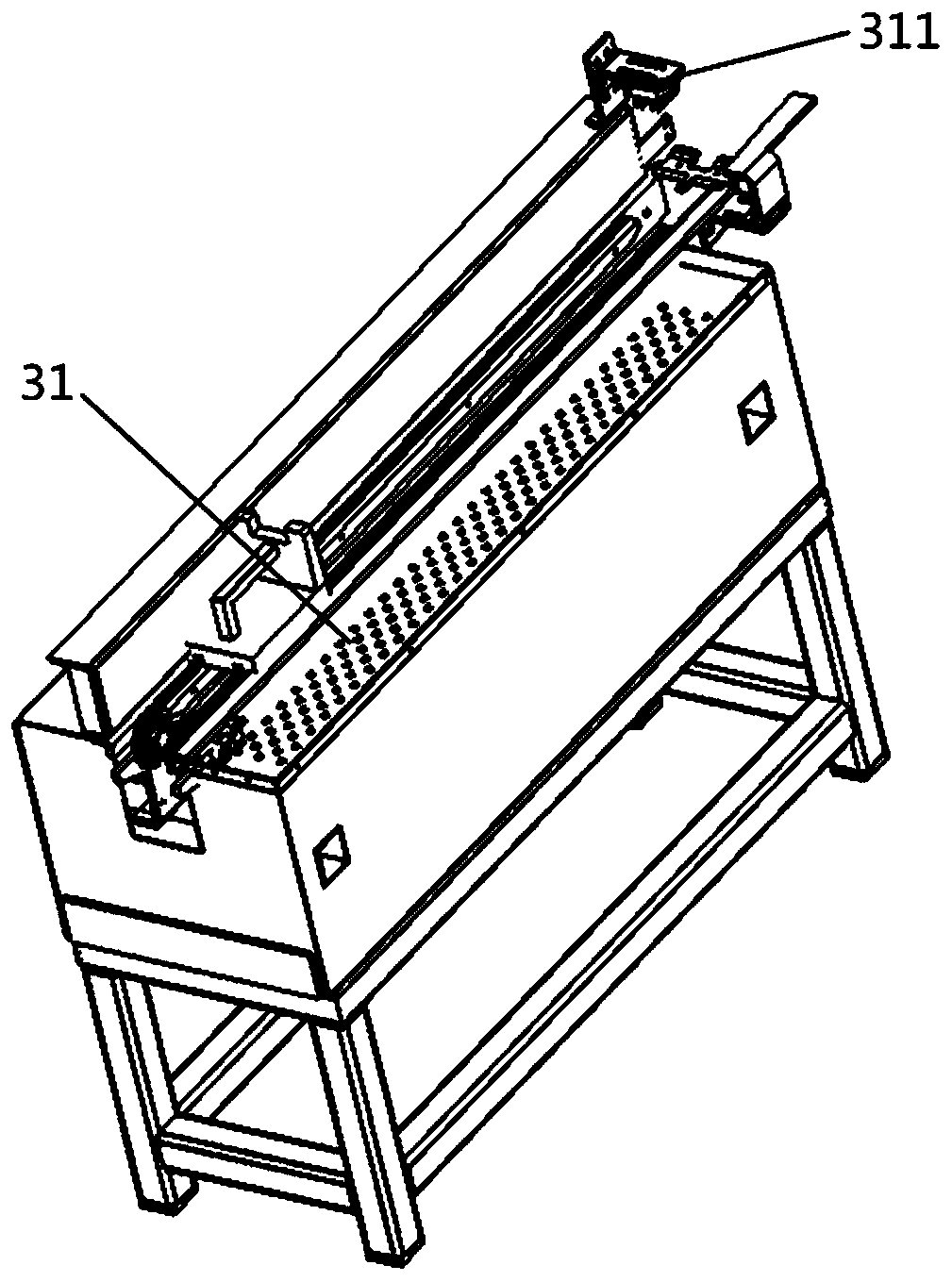

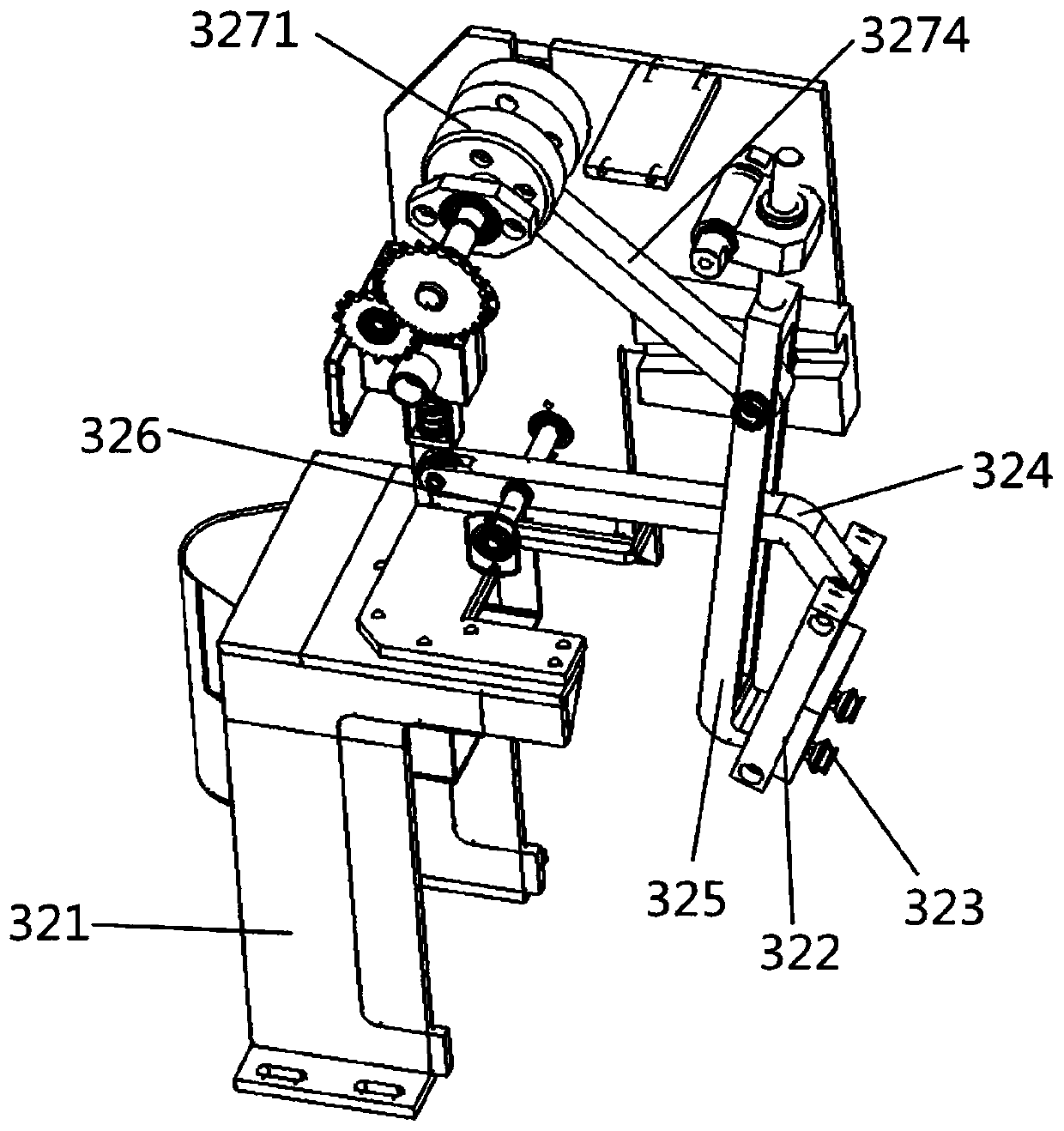

Pipe material assembly platform production line

ActiveCN109648343BRealize continuous automatic feedingRealize automatic assemblyOther manufacturing equipments/toolsTube shearing machinesMachineCantilever

The invention discloses a pipe material assembling platform production line. The pipe material assembling platform production line comprises a feeding conveying part, a cutting machine, a carrying part, a hole finding part and a robot, wherein an output end of the feeding conveying part is in butt joint with an input end of the cutting machine, an output end of the cutting machine is in butt jointwith an input end of the carrying part, the hole finding part is arranged on one side of the carrying part, and the robot is arranged on one side of the hole finding part. continuous automatic feeding, length fixing, cutting and hole finding of a pre-assembled contact network cantilever pipe material and automatic assembling of a workpiece and the pipe material can be realized, field operators can be reduced, the labor intensity can be reduced, and the working efficiency can be improved.

Owner:武汉中安佳通装备技术有限公司

Ceramic ball sphere surface defect detection system

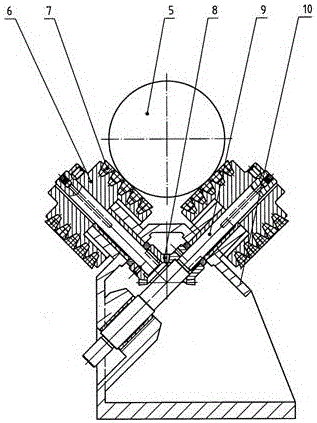

PendingCN110501345ASimple structureRealize continuous detectionOptically investigating flaws/contaminationSortingMachine visionEngineering

The invention discloses a ceramic ball sphere surface defect detection system. The system comprises a frame, a friction disk, a friction disk drive mechanism, a sphere tray, a tray drive mechanism, amachine vision photographing device and a sphere classification mechanism. The tray drive mechanism drives the sphere tray to rotate above the friction disk. The sphere tray is provided with a spherelimiting hole which runs through the sphere tray. The corresponding middle part of a ceramic ball is located in the sphere limiting hole. The corresponding lower part of the ball contacts the frictiondisk. The sphere tray is used to change the position of the ball in a horizontal plane. The ceramic ball can rotate freely in the sphere limiting hole. The friction disk drive device is arranged on the frame. The friction disk drive device drives the friction disk to move in the same horizontal plane. The friction disk enables the ball to freely rotate in place in the sphere limiting hole throughfriction. The machine vision photographing device is used to photograph the surface of the ceramic ball. The sphere classification mechanism is used to separate and collect qualified ceramic balls and unqualified ceramic balls.

Owner:CHANGZHOU INST OF OPTOELECTRONICS TECH

Synchronous punching equipment at both ends of a few-shaped steel beam

ActiveCN107737834BEasy to produceReduce labor intensityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses n-shaped steel beam two-end synchronous punching equipment. The n-shaped steel beam two-end synchronous punching equipment comprises a machine frame, two punching mechanisms, amaterial placing frame, a material passing control mechanism, a material blocking control mechanism and a material receiving frame; the two punching mechanisms are arranged on the two sides of the machine frame in the length direction correspondingly; the material placing frame and the material receiving frame are positioned on the two sides of the machine frame in the width direction correspondingly; the material placing frame is provided with an inclined discharging support; the material passing control mechanism is used for performing blocking and passing control on an n-shaped steel beamat the lowest position of the inclined discharging support; the two ends of the n-shaped steel beam slide on the workbenches of the two punching mechanism correspondingly after the material passing control mechanism allows to pass; the material blocking control mechanism is used for performing positioning blocking during processing of the n-shaped steel beam on the machine frame and performing passing control after processing; and the material receiving frame is provided with a material receiving support. The n-shaped steel beam two-end synchronous punching equipment can perform punching processing on the two ends of the n-shaped steel beam simultaneously, can perform secondary positioning processing without turning 180 degrees and can realize automatic continuous production.

Owner:芜湖恒驰钢构有限公司

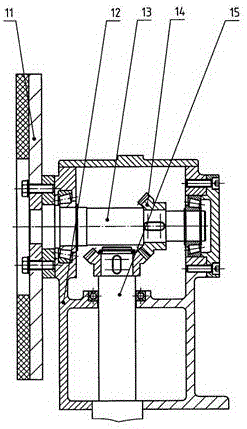

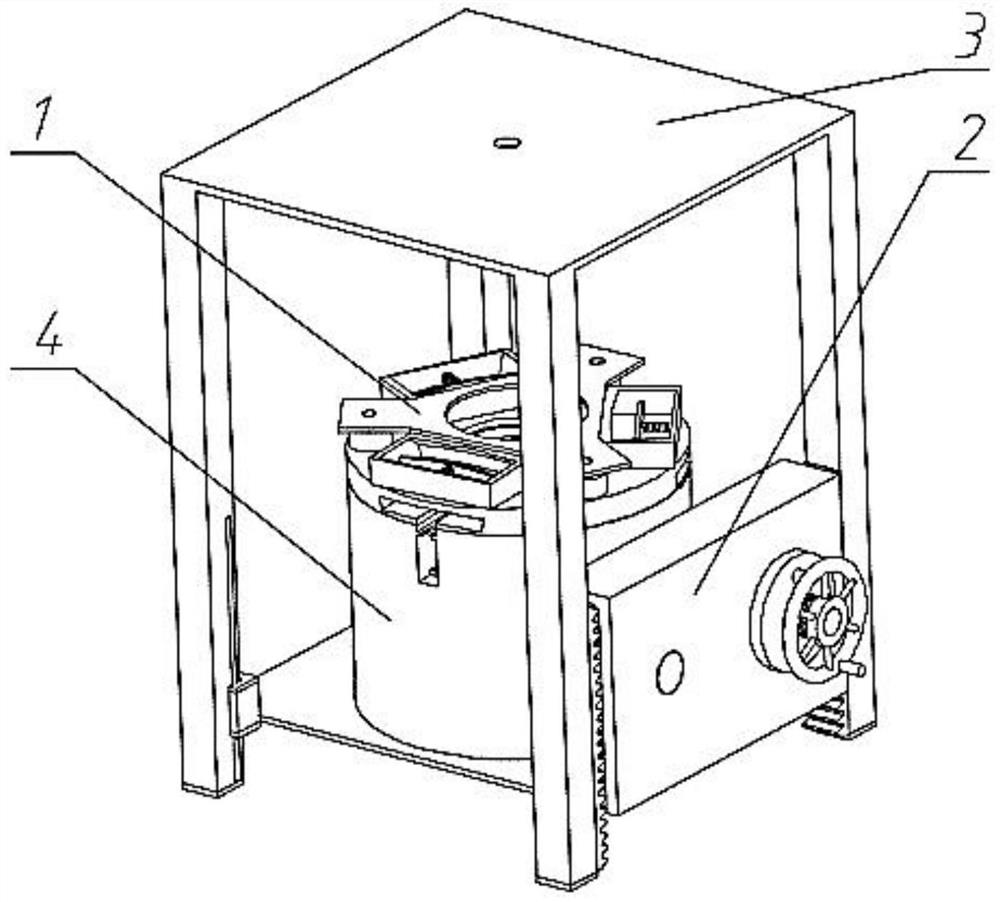

A new type of automatic riveting device for the rear cover of automobile exhaust fan motor

InactiveCN105234300BRealize continuous automatic feedingImprove efficiencyMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a novel automatic riveting device for automobile exhaust fan motor rear covers. The novel automatic riveting device solves the technical problems that the riveting efficiency and the riveting accuracy of the exhaust fan motor rear covers in the prior art are low. The novel automatic riveting device for the automobile exhaust fan motor rear covers comprises a machine body, a chuck storage bin, a gasket storage bin, a locating rotation head capable of rotating, a pre-pressing head with the punching function, a riveting head and a feed device, wherein the chuck storage bin, the gasket storage bin, the locating rotation head, the pre-pressing head, the riveting head and the feed device are arranged on the machine body. The feed device comprises a feed frame, a horizontal air cylinder pushing the feed frame to move horizontally and a vertical air cylinder pushing the feed frame to move vertically. An attracting device attracting gaskets is arranged on the pre-pressing head. A jacking air cylinder jacking the gaskets to the attracting device is arranged below the gasket storage bin. The chuck storage bin is provided with a discharge port, and a thumbing piece thumbing chucks in a reciprocating mode is arranged on the discharge port of the chuck storage bin and thumbs the chucks to the feed frame. The locating rotation head is provided with a locating pin used for locating the chucks. The locating rotation head, the pre-pressing head and the riveting head are provided with position clamping grooves.

Owner:平湖拓伟思自动化设备有限公司

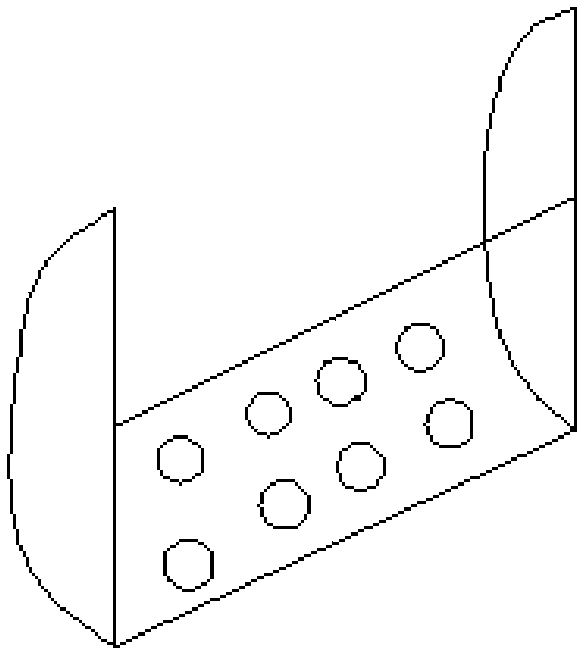

Continuous feeding device

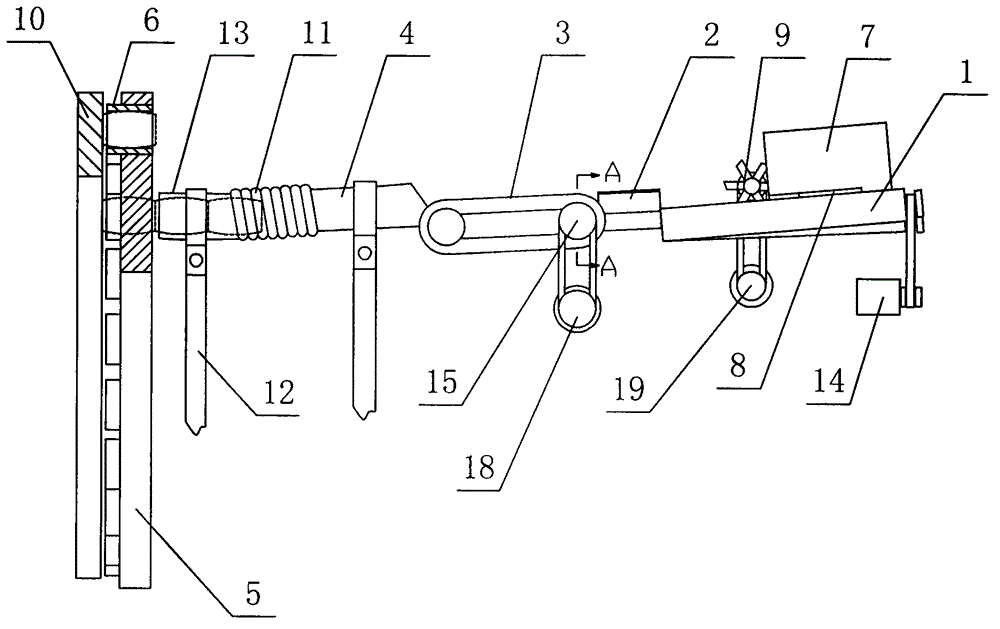

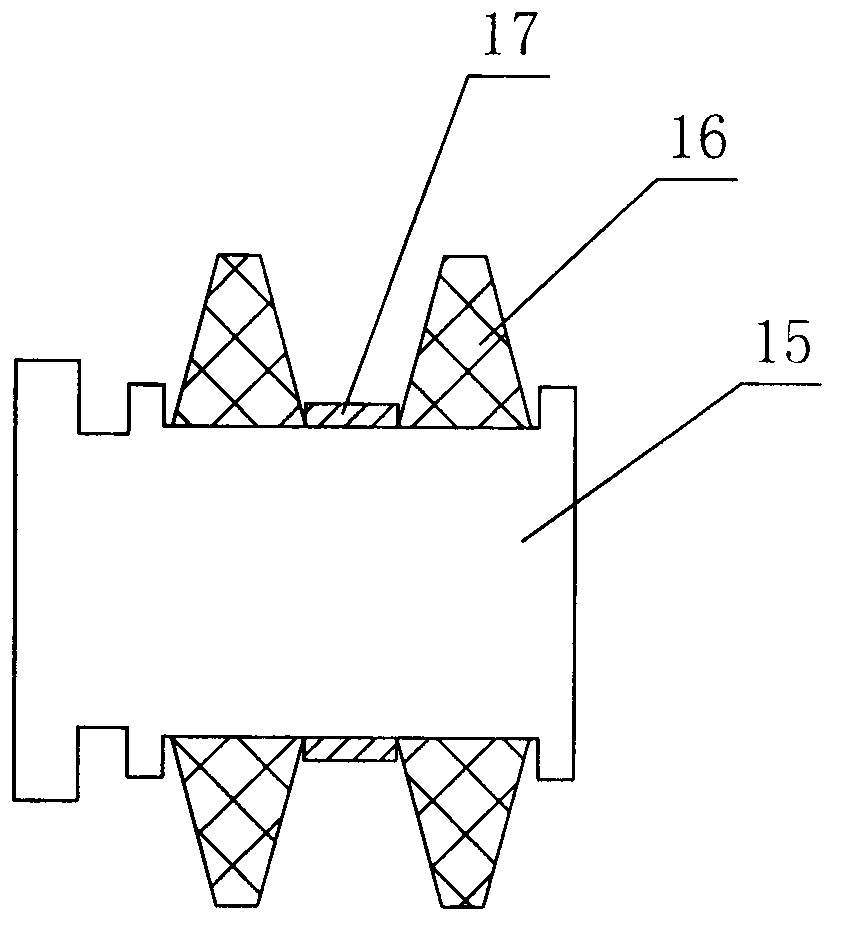

ActiveCN102873603BRealize continuous automatic feedingReasonable structural designPlane surface grinding machinesUltimate tensile strengthConveyor belt

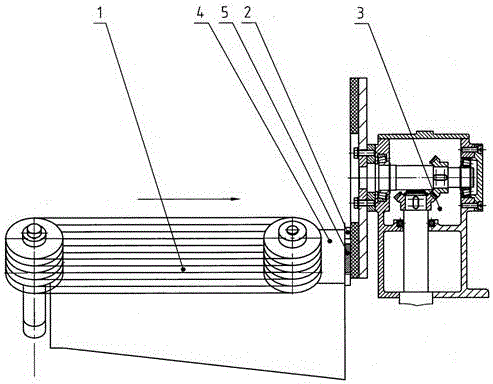

The invention relates to a continuous feeding device. The continuous feeding device comprises a rack, wherein a delivery round roller set, a Y-shaped connection track, a triangular conveyor belt and a conduit are arranged on the rack from back to front in sequence along the moving direction of materials; the conduit is opposite to a sleeve of a round material tray; a material storing trough fixed on the rack is positioned on the delivery round roller set; and the position of a discharging opening of the material storing trough corresponds to the position of the delivery round roller set. The continuous feeding device has a reasonable structure and can be used safely and reliably; and through the delivery round roller set, the Y-shaped connection track, the triangular conveyor belt and the conduit which are arranged on the rack from back to front in sequence along the moving direction of materials, and corresponding power devices, materials can be automatically and continuously fed to the round material tray, so that the manual work is saved, the labor intensity is reduced, the working period is shortened, and the working efficiency is greatly improved.

Owner:SHANDONG YUJIE BEARING MFG CO LTD

An automatic feeding device for thin workpieces for double-end grinding machines

ActiveCN103264328BRealize continuous automatic feedingGuaranteed smoothnessGrinding machine componentsPlane surface grinding machinesSurface grindingMechanical engineering

The invention relates to a special automatic feeding device for thin workpieces of a double-ended grinding machine. The special automatic feeding device comprises a transverse feeder, a rubber disc feeder, a feeding plate, a workpiece and the like, and is characterized in that the feeding plate is arranged on the right side of the transverse feeder; the workpiece is pushed by the transverse feeder to a position on the same plane of the feeding plate; and the workpiece is pushed by the rubber disc feeder to enter the feeding plate so as to finish feeding. The special automatic feeding device has the advantages of reasonable design, time saving, labor saving, improvement on grinding efficiency and the like.

Owner:RUSHAN HONGYUAN MACHINE MFG

A battery pack board machine and a battery pack board assembly machine including the same

ActiveCN110676507BIncrease productivityEliminate manual operationAssembling battery machinesFinal product manufactureProcess engineeringBattery cell

The invention relates to a battery wrapping machine, which includes a frame, a paper feeding device, a feeding device, a plate feeding conveying device, a partition paper cutting device and a pressing mechanism arranged on the frame. The partition paper cutting device has a The paper feed channel that transports the separator paper from top to bottom, the feed end of the paper feed channel extends upwards to the upper end of the separator paper cutting device, the discharge end of the paper feeding device communicates with the feed end of the board paper cutting device, and the separator The paper is cut to the set length in the paper feeding channel, and the separator paper cutting device is equipped with a plate channel for conveying the plate along the left and right directions, and the feeding end of the plate channel is connected with the discharging end of the paper feeding channel. The feeding device transports the polar plate to the feeding end of the polar plate channel through the plate feeding conveying device, and the feeding end of the pressing mechanism is connected and communicated with the discharging end of the polar plate channel. The present invention also provides a battery pack board assembly machine comprising the above battery pack board machine. It can automatically complete the battery pack board and assembly.

Owner:HUBEI ENG UNIV

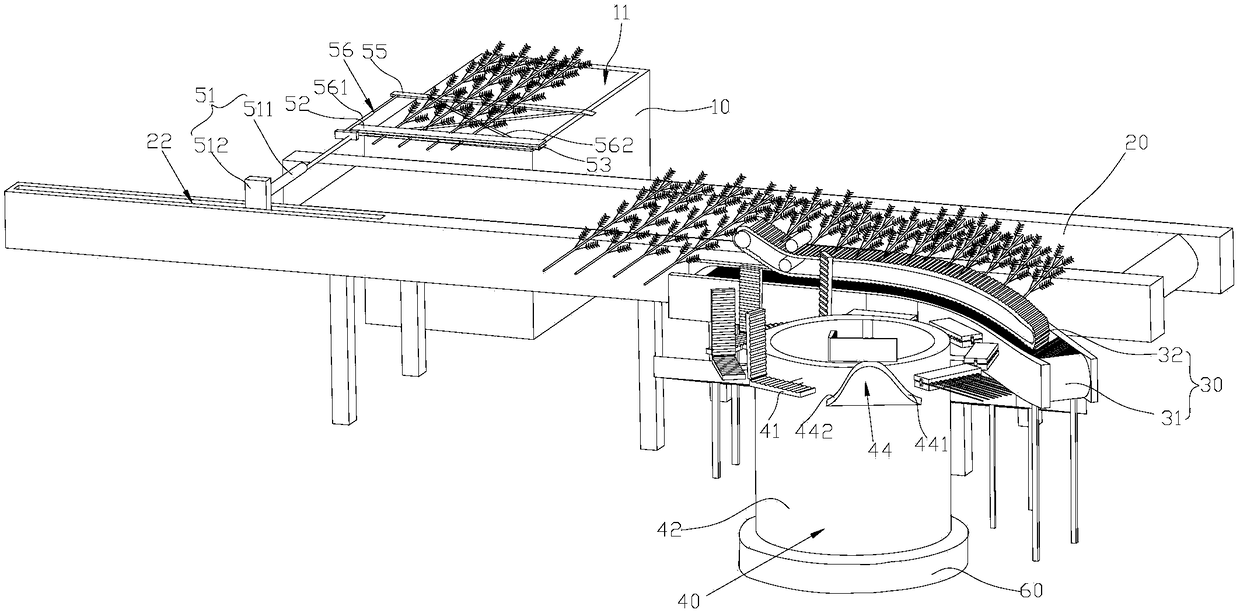

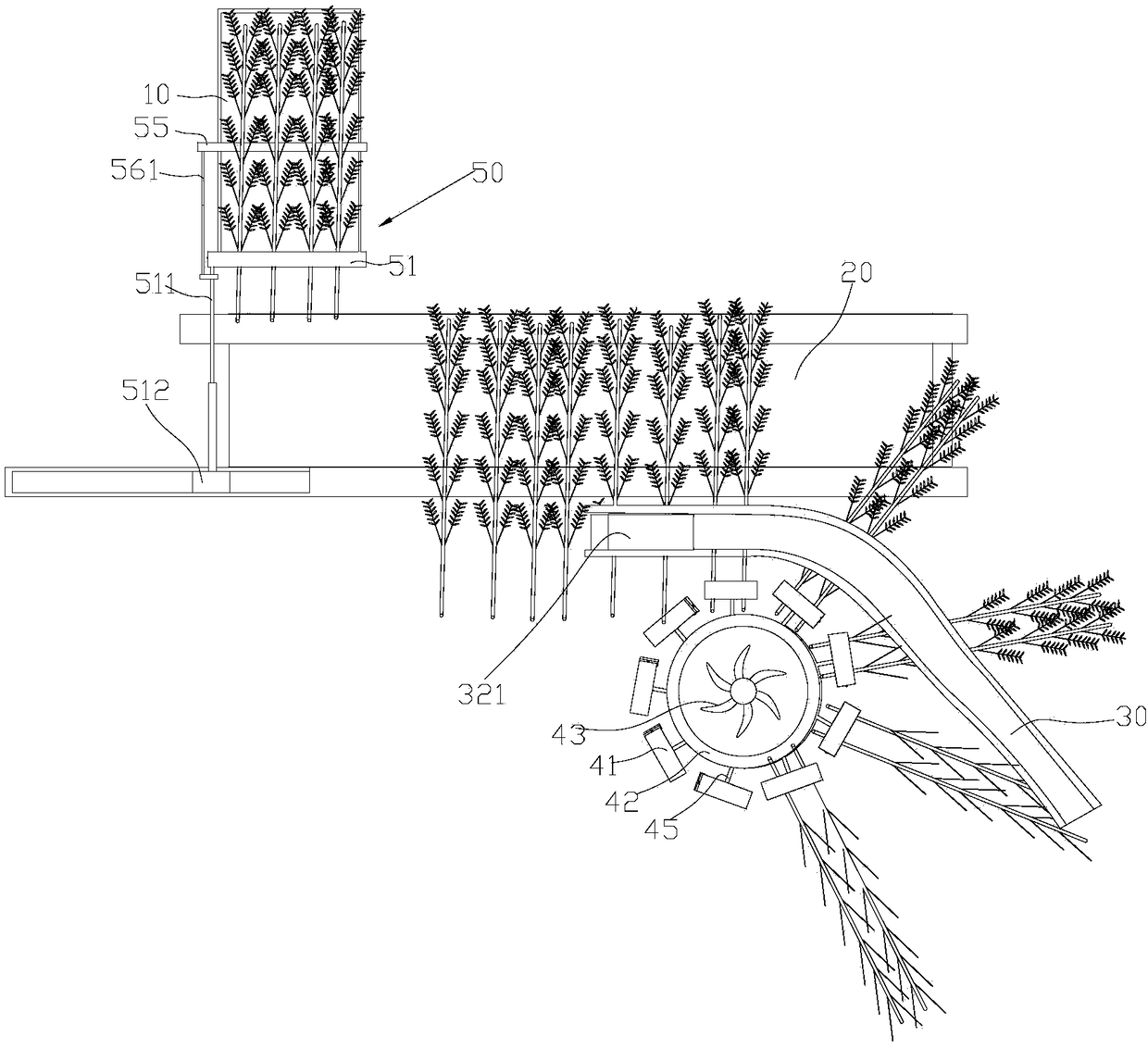

Forage feeding system

InactiveCN109043612ARealize continuous automatic feedingLow costFood treatmentAnimal ForagingMaterial resources

The invention relates to the field of wormwood, in particular to a forage feeding system. The system comprises a horizontal feeding platform and a clamping conveying mechanism which are arranged sideby side, the feeding directions of the clamping conveying mechanism and the horizontal feeding platform are consistent, the wormwood is placed on the horizontal feeding platform, wormwood rhizomes cross the clamping conveying mechanism and then hang and extend to the exterior of the clamping conveying mechanism which is used for clamping stems of the wormwood and follow the horizontal feeding platform to convey the wormwood forwards. After the wormwood is put on the horizontal feeding platform and moved to the clamping conveying mechanism, the clamping conveying mechanism clamps the stems of the wormwood, the clamping conveying mechanism clamps the stems of the wormwood, the wormwood follows the horizontal feeding platform and the clamping conveying mechanism to move forwards, continuous automatic feeding of the wormwood is achieved, and meanwhile preparation is made for leaf picking. The system is low in cost, high in efficiency and capable of saving a lot of manpower and material resources.

Owner:胡转香

Invoice printer

PendingCN113800296AGuaranteed replacementRealize continuous automatic feedingTypewritersOther printing apparatusComputer printingInvoice

The invention discloses an invoice printer, and relates to the technical field of invoice printer equipment. The invoice printer comprises a case, and one side of the case is provided with a feeding box; the feeding box is internally provided with a feeding device for realizing material feeding and installation; and a control device for controlling materials to stably transportate is arranged at the connection position between the case and the feeding box. The invention discloses the invoice printer capable of achieving the effects of continuously and automatically feeding printing paper, ensuring normal operation of equipment, improving the working efficiency of the equipment and ensuring that the printing paper can be replaced on the premise that the equipment does not stop printing.

Owner:黄顺阳

Automatic assembling equipment of pressing structure

InactiveCN113618361ARealize continuous automatic feedingReduce difficultyMetal working apparatusElectric machineryEngineering

The invention relates to automatic assembly equipment of a pressing structure. The automatic assembly equipment of the pressing structure comprises a base, a rotating disc motor is arranged on the base, the rotating disc motor is connected with a rotating disc rotating shaft in a vertical direction, an upper rotating disc and a lower rotating disc sleeve the rotating disc rotating shaft, and a movable seat bearing frame matched with a pressing movable seat is embedded in the upper rotating disc. A handle bearing device matched with a pressing handle is arranged on the lower rotating disc, and a movable seat conveying groove, a screw discharging device, a screw tightening device, a pressing head discharging device and a pressing head locking device which are matched with the movable seat bearing frame are sequentially arranged on the outer side of the upper rotating disc in the rotating direction of the rotating disc. A handle conveying groove matched with the handle bearing device is formed under the movable seat conveying groove, the side face, matched with the movable seat conveying groove, of the movable seat bearing frame exceeds the upper rotating disc, a movable seat conveying arc opening is formed in the tail end of the movable seat conveying groove, and the circle center of the movable seat conveying arc opening is consistent with that of the upper rotating disc. The diameter is consistent with the rotating diameter of the outermost end of the movable seat bearing frame, continuous and automatic discharging of a pressing movable seat can be achieved, and the feeding difficulty is lowered.

Owner:长沙市旭峰设计有限公司

Emulsified ammonium nitrate fuel oil explosive double-roller mixing device and design method

ActiveCN110713426AInnovative designSimple structureExplosive working-up apparatusProcess engineeringThermodynamics

The invention provides an emulsified ammonium nitrate fuel oil mixture double-roller mixing device and a design method, wherein the design method comprises the following steps: S1, carrying out the preliminary model selection and parameter calculation of a spiral conveying roller of the double-roller mixing device; S2, adjusting and optimizing the parameters of a spiral conveying roller of the double-roller mixing device; S3, designing the form of a spiral conveying roller of the double-roller mixing device; and S4, designing the distance between a spiral conveying roller of the double-rollermixing device and the inner wall of the mixing tank. The design method of the double-roller mixing device for the emulsified ammonium nitrate fuel oil explosives has the following advantages: the double-roller mixing device designed according to the scientific and reasonable design method can be used for production lines of different productivities; the device is efficient, simple in structure andgood in mixing and stirring uniformity, emulsified ammonium nitrate fuel oil explosive raw materials are automatically, efficiently and uniformly mixed and stirred, production requirements are met, and high-quality emulsified ammonium nitrate fuel oil explosives are obtained.

Owner:JIANGXI JIAN GUOTAI SPECIAL CHEM

A pair-roll mixing device and design method for emulsified ammonium oil explosives

ActiveCN110713426BInnovative designSimple structureExplosive working-up apparatusProduction lineExplosive Agents

The invention provides an emulsified ammonium oil explosive double-roll mixing device and a design method, comprising the following steps: S1, preliminary type selection and parameter calculation of the spiral conveying roller of the double-roll mixing device; S2, the screw conveyor of the double-roll mixing device Adjustment and optimization of the parameters of the conveying roller; S3, the design of the spiral conveying roller of the double-roller mixing device; S4, the design of the distance between the spiral conveying roller of the double-roller mixing device and the inner wall of the mixing tank. The design method of the double-roller mixing device for emulsified ammonium oil explosives has the following advantages: it is suitable for production lines of various capacities, and the double-roller mixing device designed according to this scientific and reasonable design method is efficient, simple in structure, and uniform in mixing Well, the raw materials of the emulsified ammonium oil explosives are automatically and efficiently mixed evenly to meet the production requirements to obtain high-quality emulsified ammonium oil explosives.

Owner:JIANGXI JIAN GUOTAI SPECIAL CHEM

Multi-station automatic feeding method and device

InactiveCN102173097BRealize continuous automatic feedingAccurate clamping forceMetal-working feeding devicesForging/hammering/pressing machinesControl systemFeed drive

Owner:CHINA AGRI UNIV

A production system and process for lifting anchor rods

ActiveCN111014529BRealize continuous automatic feedingRealize unmanned operationForging/hammering/pressing machinesOther manufacturing equipments/toolsRobot handForging manipulator

The invention relates to a production system and technology for lifting anchor rods, including automatic feeding and heating equipment capable of heating both ends of a steel column and forming equipment. The forming equipment includes a bottom plate and two shaped plates fixed on the upper side of the bottom plate. A sizing groove with the same width as the diameter of the steel column is arranged between the two sizing plates, and the upper side of the sizing groove is provided with a closing plate that can close the upper side of the sizing groove with sliding, and the position of the bottom plate corresponding to the sizing groove is opened There is a through slot, and the lower side of the bottom plate is also provided with an inserting block that can move upwards through the through slot and be inserted into the shaping groove. One side of the upper surface of the inserting block is inclined downward, and the bottom plate corresponds to Both ends of the shaping groove are also provided with top blocks that can move toward each other, and the sides of the top blocks that are close to each other are also provided with circular shaping grooves. The invention can realize simultaneous heating, placement and forging of both ends of the bolt, and realizes unmanned operation under the automatic operation of the manipulator.

Owner:青岛建邦士金属制品有限公司

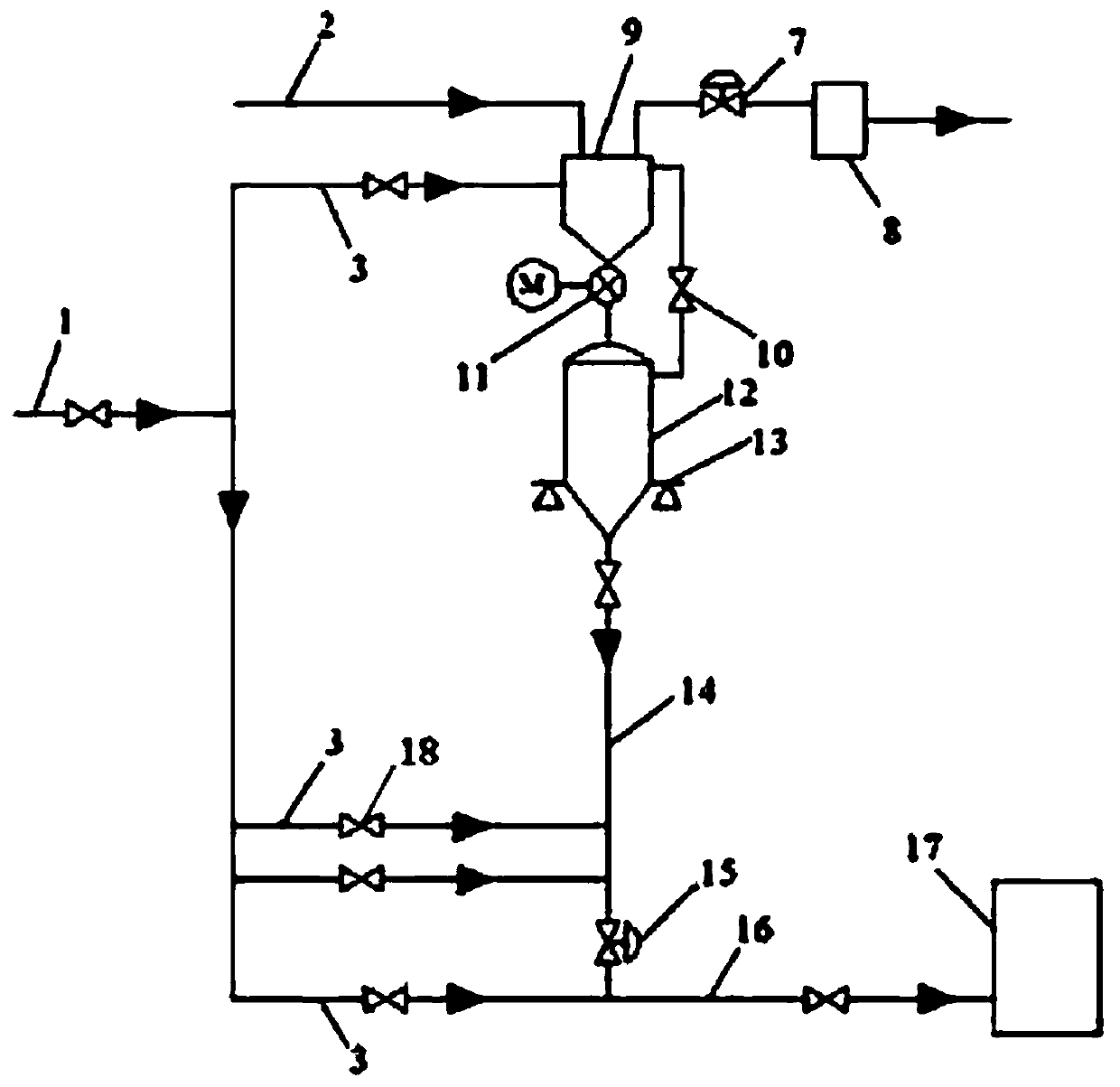

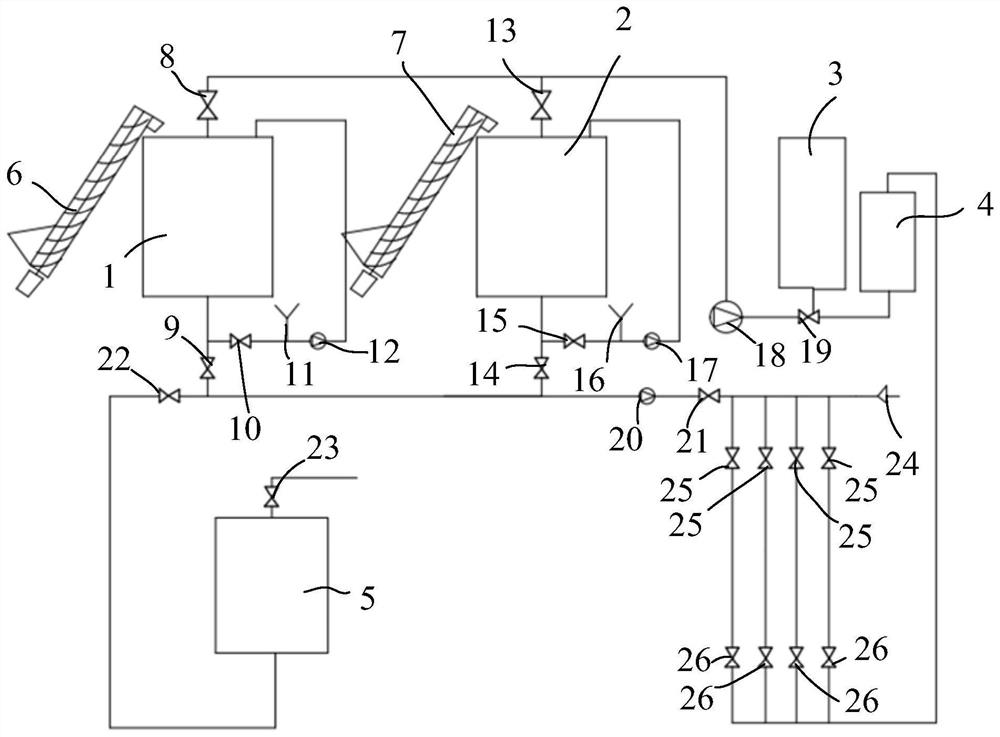

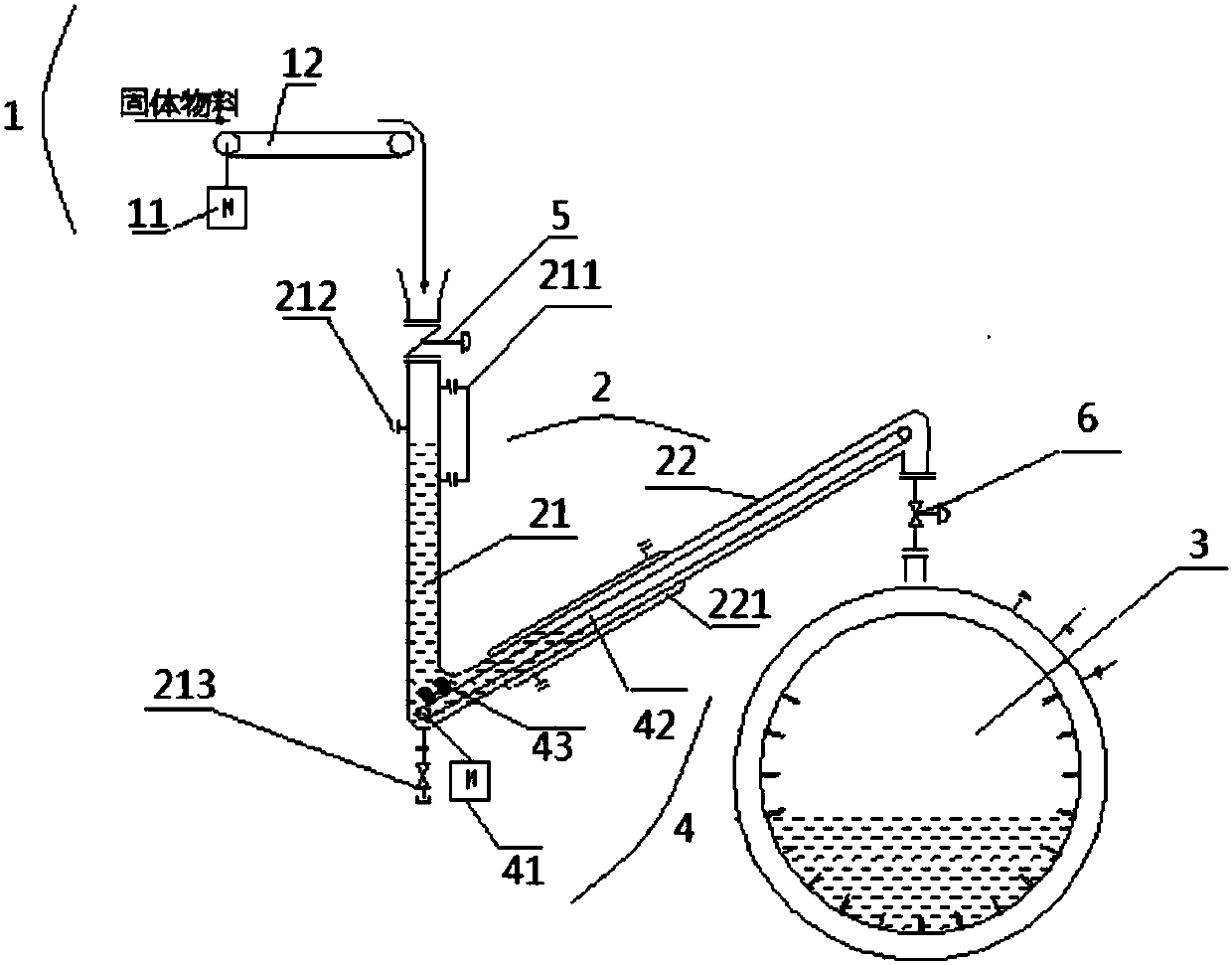

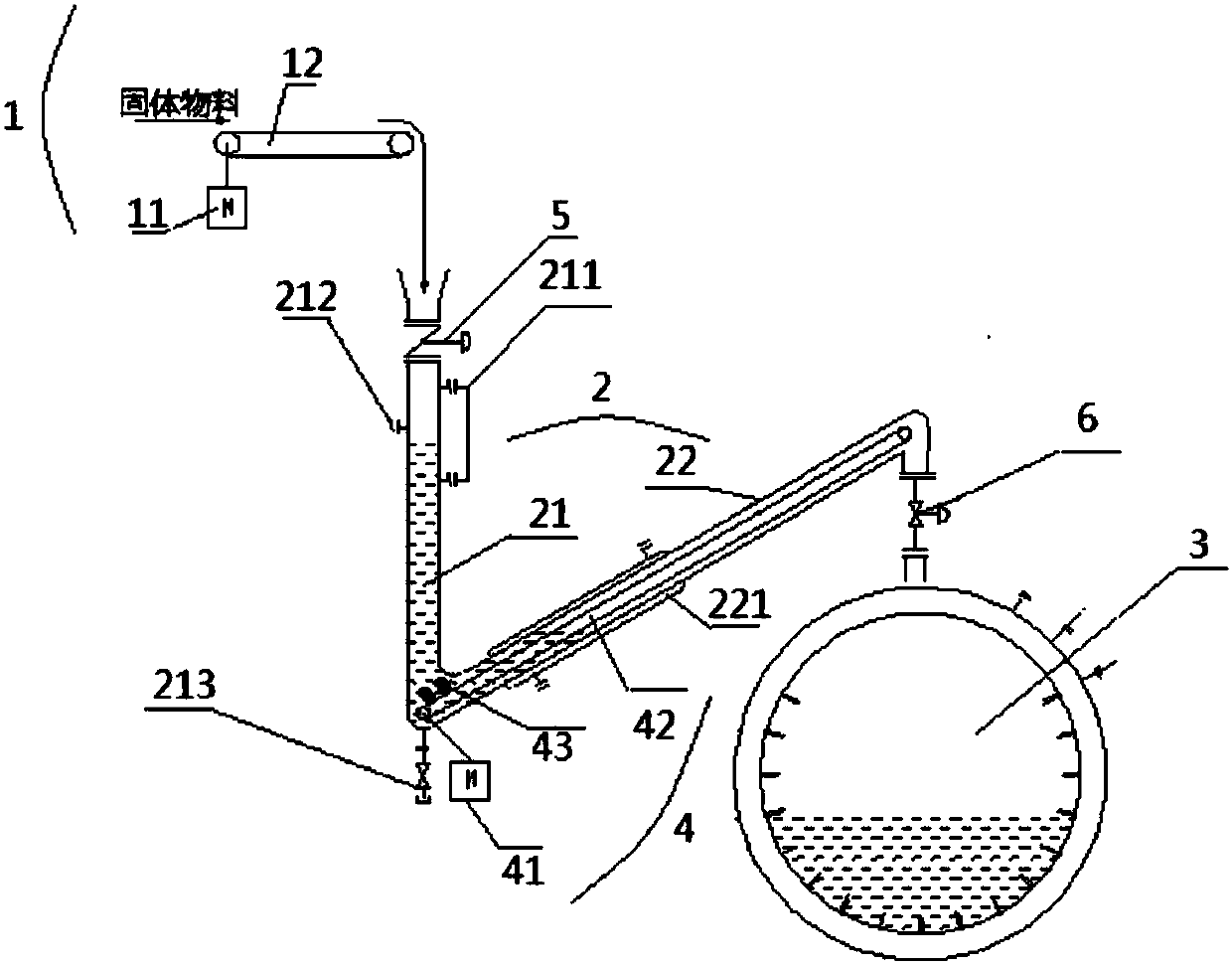

Automatic feeding reaction system and application thereof and feeding method of solid raw material

InactiveCN110013819ARealize continuous automatic feedingReduce labor intensityAluminium oxide/hydroxide preparationChemical/physical/physico-chemical stationary reactorsChemical industryBiochemical engineering

The invention relates to the field of chemical industry, in particular to an automatic feeding reaction system and an application thereof and a feeding method of a solid raw material. The system comprises a feeding apparatus (1), a liquid sealing apparatus (2) and a reaction apparatus (3) which are connected in sequence; wherein a conveying apparatus (4) is arranged inside the liquid sealing apparatus, and a material passing through a liquid sealing solvent in the liquid sealing apparatus is delivered to the reaction apparatus by the conveying apparatus. The application of the automatic feeding reaction system in a closed reaction using a solid raw material as a starting raw material is also provided. The feeding method of the solid raw material in a closed environment is further provided,and the feeding method comprises: continuously adding the solid raw material and making the solid raw material pass through the liquid sealing solvent to remove a gas carried in the solid raw material, and adding the carried-gas removed solid raw material into a closed reactor to carry out a reaction. According to the system and method, the continuous and automatic feeding of the reaction solid raw material is realized, the labor intensity is greatly reduced, the production efficiency is improved, the feeding environment and the reaction environment are isolated, and the reaction can be carried out in a closed environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

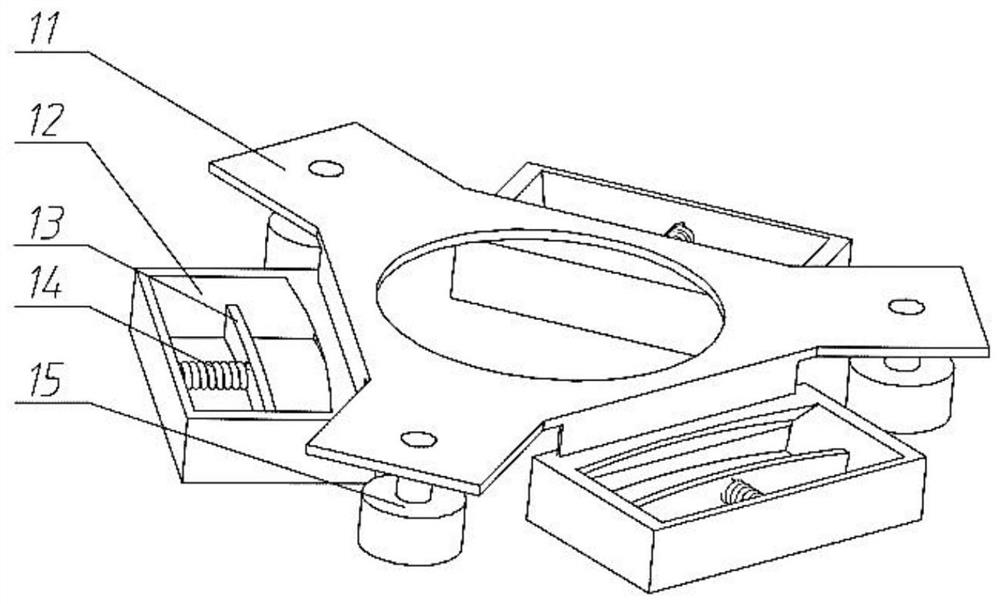

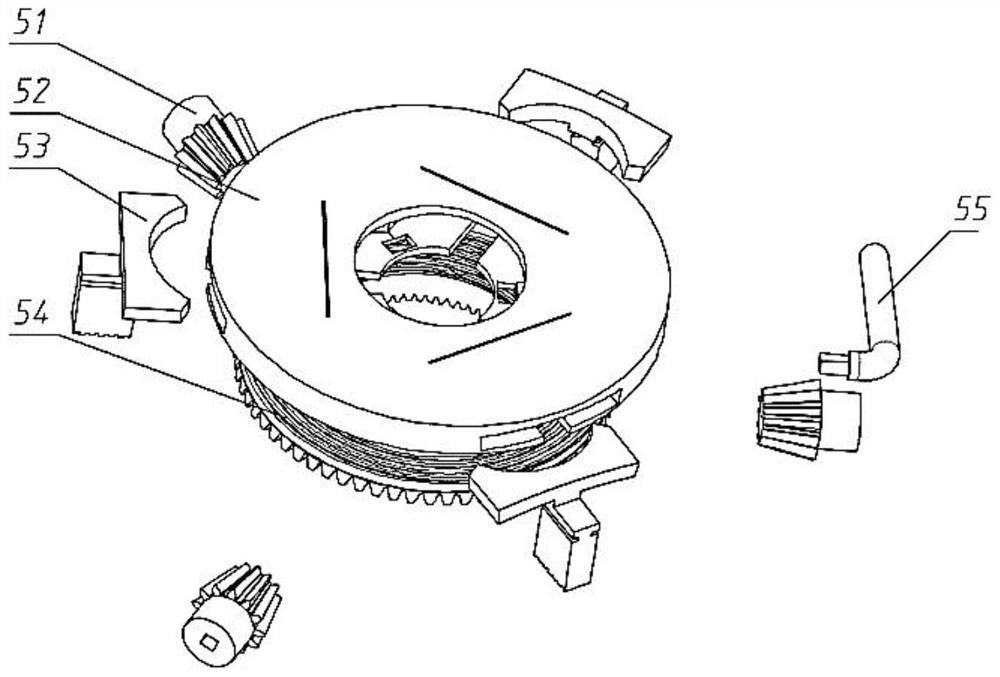

A self-feeding, multi-function, spring-up gear ring friction plate attachment mechanism

ActiveCN111173818BRealize continuous automatic feedingSave labor costsMaterial gluingFriction liningMotor vehicle partGear wheel

The invention discloses a multifunctional gear ring friction plate attaching mechanism capable of realizing automatic feeding and bouncing, and belongs to the field of automobile part manufacturing. The gear ring friction plate attaching mechanism comprises an external material feeding mechanism, an external material attaching mechanism, an internal material attaching mechanism, a positioning andbouncing mechanism, a lifting mechanism and the like; an external material feeding inserting plate of the external material feeding mechanism inserts a friction material into a material bending attaching groove, and a material pushing plate carries out feeding; the external material attaching mechanism is composed of a material bending disc, an external material bending attaching sliding block, abevel gear disc, a small bevel gear and the like, wherein the small bevel gear is rotated to drive the sliding block to move so as to press the material in the material bending attaching groove to a gear ring, so that attachment is achieved; the internal material attaching mechanism is similar to the external material attaching mechanism; the positioning and bouncing mechanism is composed of springs and positioning blocks; and the lifting mechanism adopts gear and rack transmission so as to be matched with the use of an internal material forming mechanism. According to the mechanism, the mechanical structure is used for achieving the attachment of the gear ring paper-based friction material, the defect that the material is prone to be cracked in the manual bending process is overcome, andthe productivity is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com