Automatic double-bin feeding device for pasting light bars into LED modulator tubes in flexible automatic production line

An automatic production line, LED lamp technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of large loss, increased production cost, and large production space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

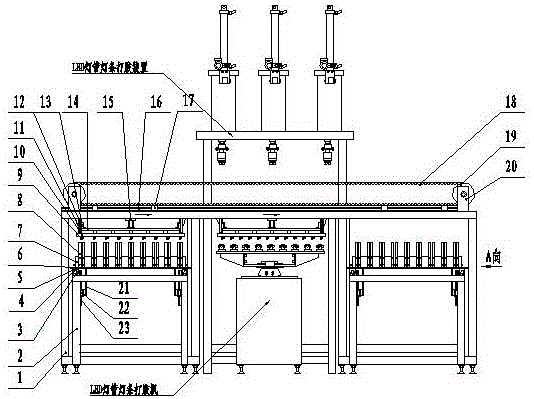

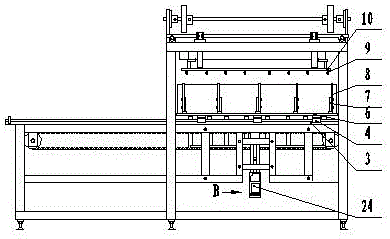

[0025] The LED tube flexible automatic production line sticks the light strip double warehouse automatic feeding device, the automatic feeding device includes the rack, the light strip feeding device, the light strip vacuum feeding device, the light strip vacuum transmission device and the light strip vacuum loading device. into the device.

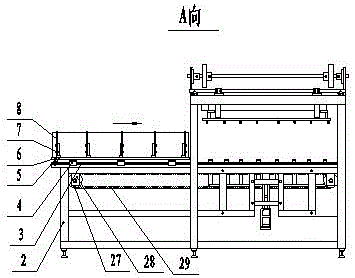

[0026] The light bar feeding device includes left and right light bar feeding bins, a feeding device frame 2, a feeding device track 3, a feeding device open track bearing 4, an open track bearing backing plate 5, and a feeding bin bottom plate 6. Plywood fixing plate 7, splints on both sides of the upper material bin light bar 8, upper material bin transmission mobile synchronous motor 27, synchronous motor fixing frame 28, synchronous belt 29, transmission track 16, open track bearing 17,

[0027] The splints 8 on both sides of the light bar of the upper hopper are fixed on the splint fixing plate 7, and the splint fixing plate 7 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com