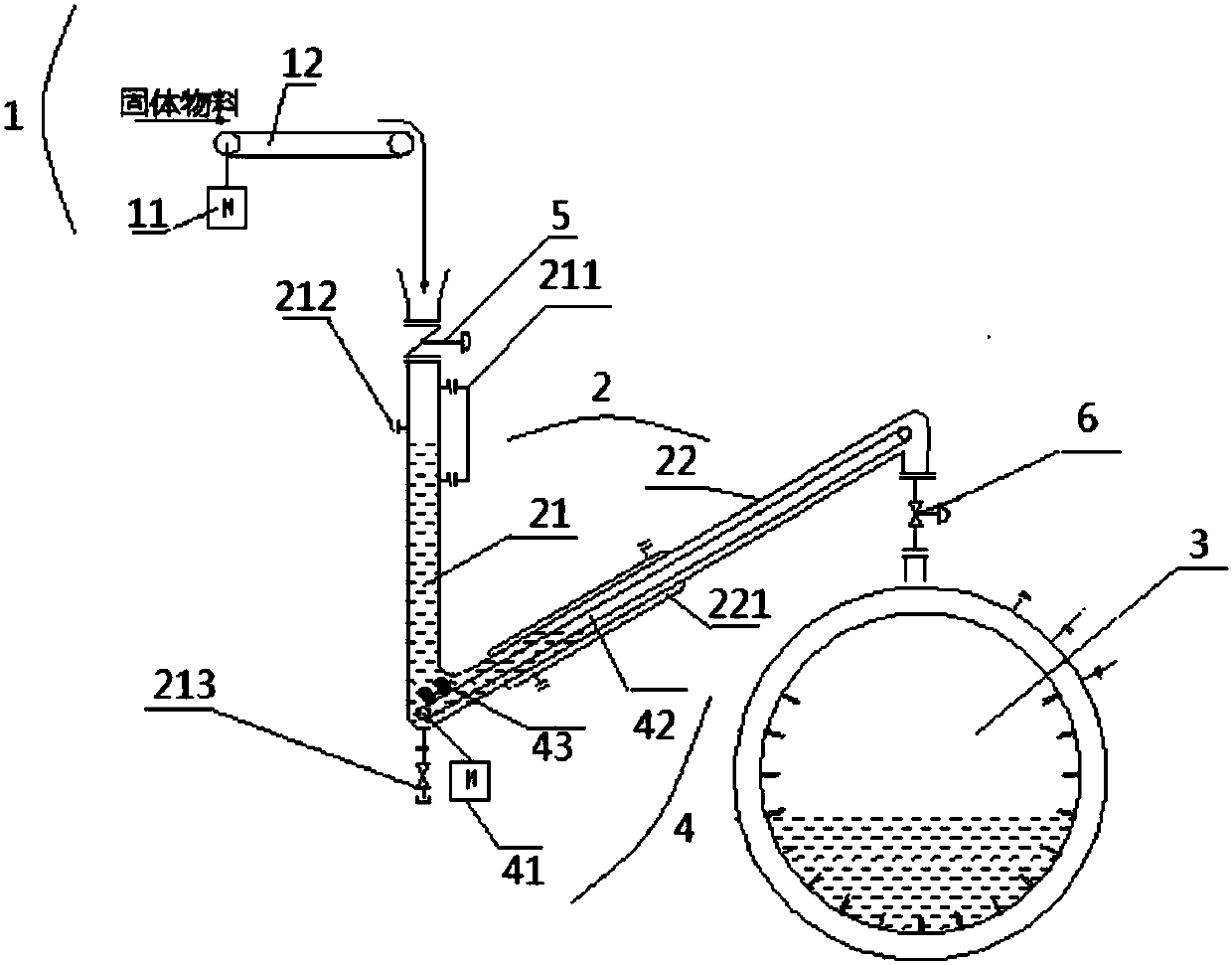

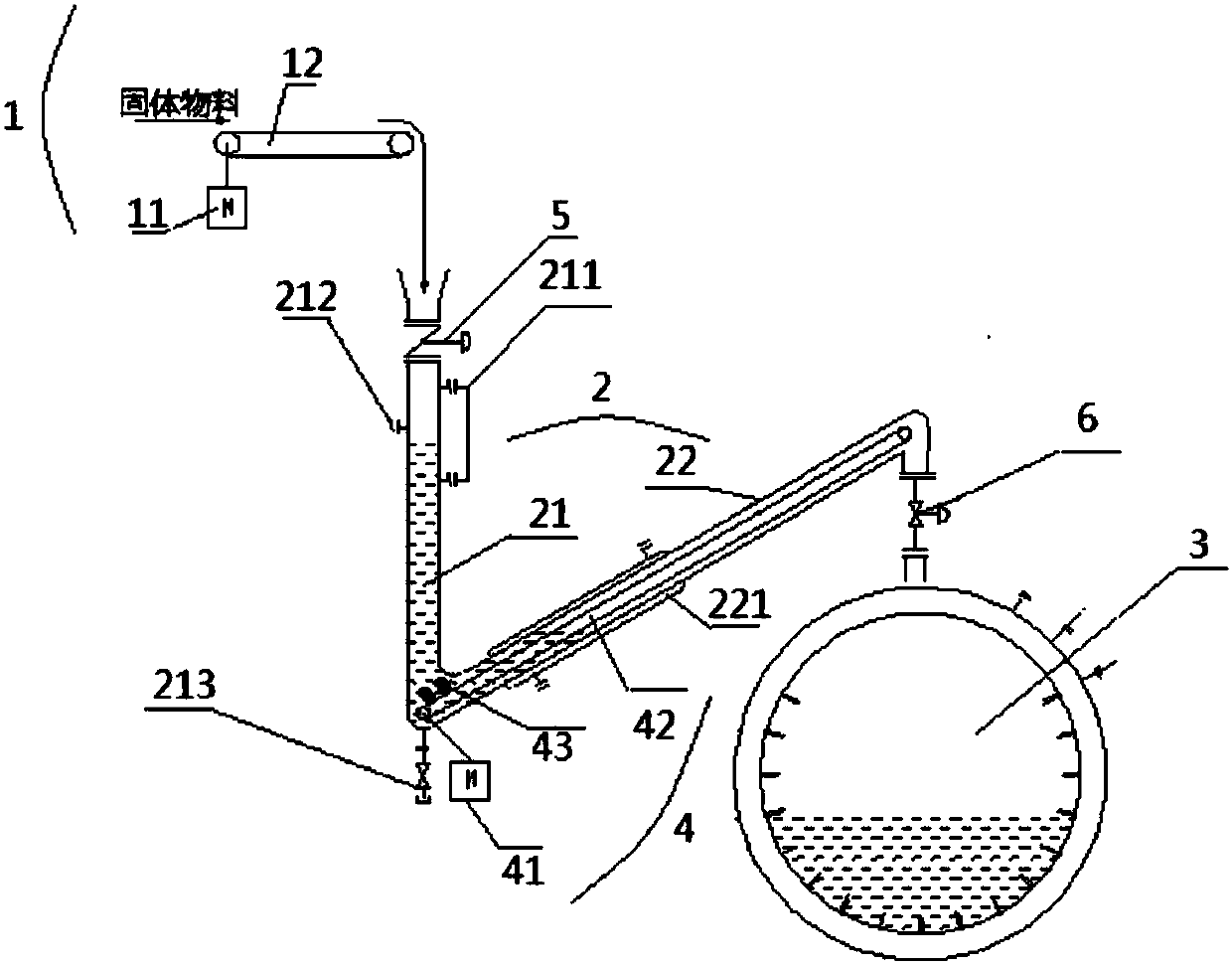

Automatic feeding reaction system and application thereof and feeding method of solid raw material

A reaction system and automatic feeding technology, applied in chemical methods, chemical instruments and methods, and feeding devices for reacting liquids and non-granular solids, can solve problems such as low production efficiency, high labor intensity, and high risk. Achieve the effect of improving production efficiency, reducing labor intensity and reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A liquid seal solvent is injected into the first part 21 of the liquid seal device 2, and the liquid seal solvent is a C4 alcohol used as a reaction solvent for preparing high-purity aluminum hydroxide.

[0053] Open the first pneumatic regulating valve 5 on the upper part of the liquid seal device 2, start the delivery module 12 (belt conveyor), and pass through the weighing module according to the feeding amount and feeding speed of metal aluminum particles or metal aluminum flakes in the following table 1 11 After accurate weighing, add it to the feeding hopper of the conveying module 12 (belt conveyor), and adjust the moving conveying module 12 (belt conveyor) to an appropriate rate, and continuously and stably feed the metal aluminum particles or metal aluminum flakes It is sent to the first part 21 through the first pneumatic regulating valve 5 . In the first part 21 , the metallic aluminum particles or flakes pass through the liquid sealing solvent to isolate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com