Emulsified ammonium nitrate fuel oil explosive double-roller mixing device and design method

A mixing device and technology of ammonium explosives, which are applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of destroying the porous granular structure of ammonium nitrate, easy to produce dead corners when mixing materials, and insufficient mixing uniformity, and achieve mixing. Good uniformity, low manufacturing cost and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

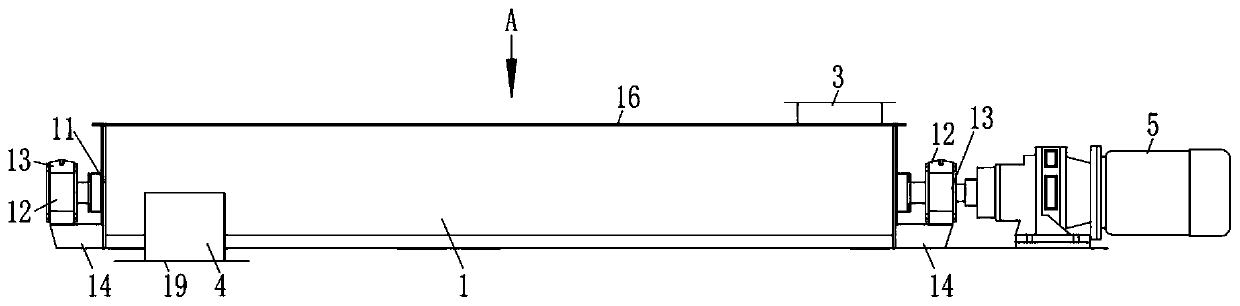

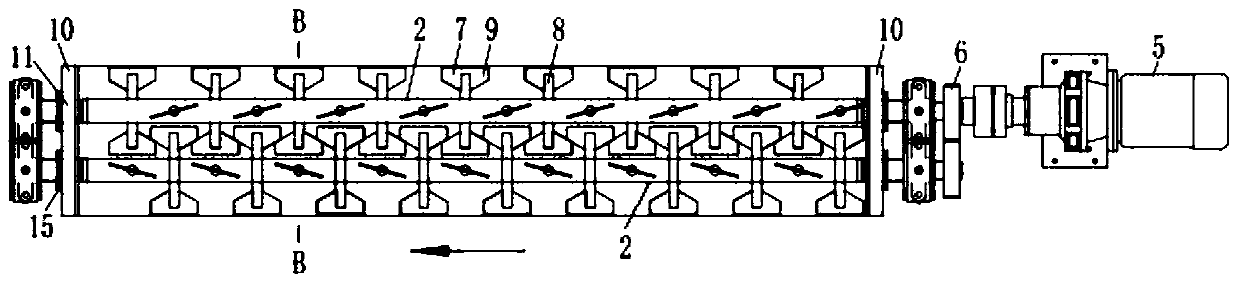

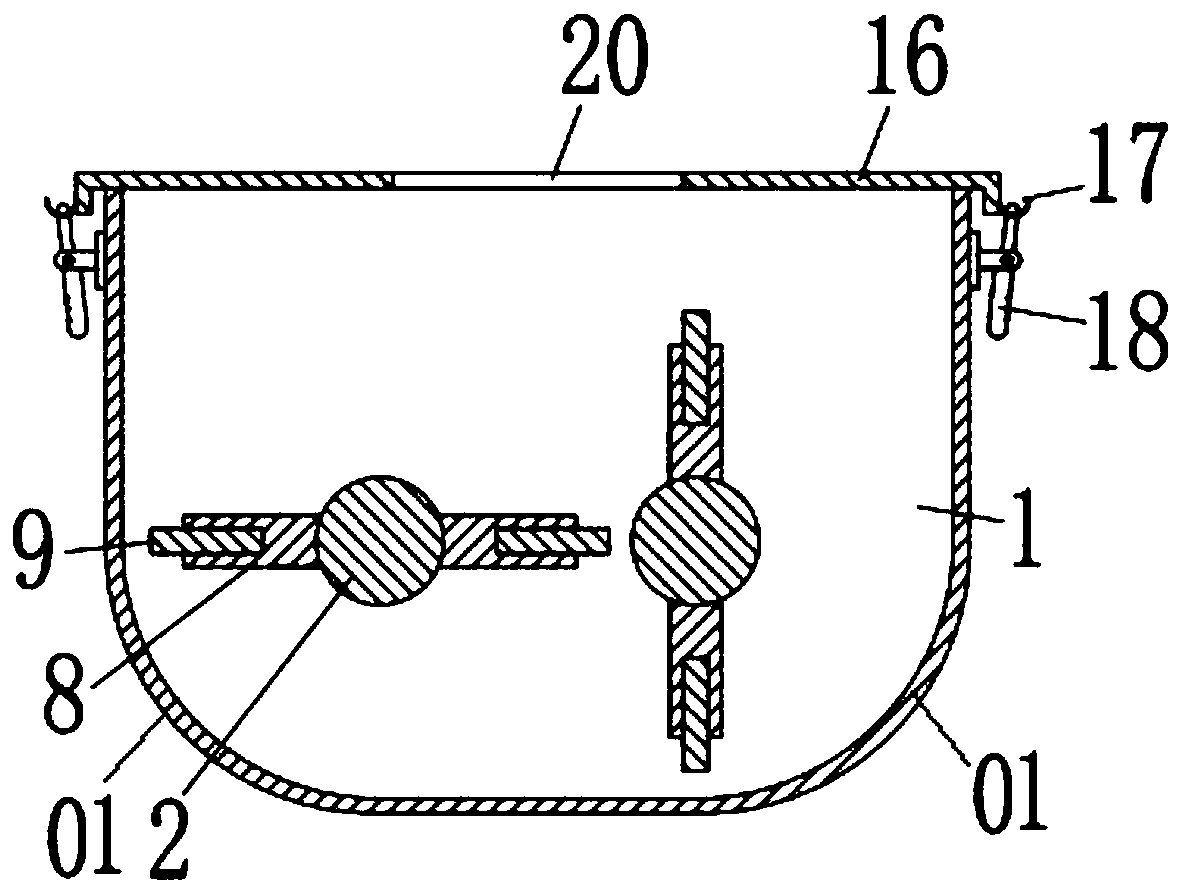

[0066] Such as Figure 1-3 As shown, an emulsified ammonium oil explosive pair-roll mixing device of the present invention includes a mixing tank, two spiral conveying rollers installed in parallel in the length direction of the mixing tank, and the screw conveying roller includes a roller shaft and A bracket vertically fixed on the roller shaft, the mixing tank is provided with an inlet and an outlet, and any one of the two screw conveyor rollers is equipped with a mixing driver and drives the other The transmission part of the roller shaft, the roller shaft is provided with a plurality of brackets, the plurality of brackets on the roller shaft form several sets of brackets, and each bracket of each set of brackets is along the axis of the roller shaft The brackets are arranged in a straight line at intervals, and each set of brackets is arranged in a circular array along the center line of the roller shaft; each bracket of any set of brackets on the same roller shaft and each...

Embodiment 2

[0071] An emulsified ammonium explosive compound double-roller mixing device of the present invention includes a mixing tank and two spiral conveying rollers arranged in the length direction of the mixing tank. The mixing tank is provided with a feed port and a discharge port. A mixing drive and a transmission member for driving other rollers to mix are installed on any one of the plurality of rollers, and a plurality of brackets are provided on the rollers.

[0072] In this embodiment, the mixing drive is connected with a speed governor, which may be a mechanical gearbox mechanically connected with the mixing drive, or a frequency converter electrically connected with the mixing drive. Changing the rotation speed of the roller can change the mixing rate and the conveying and discharging rate.

[0073] The distance between the blade of the transverse screw conveying roller and the inner wall of the mixing tank is 6 mm.

[0074] Such as figure 1 , figure 2 As shown, the extension pa...

Embodiment 3

[0077] The difference between this embodiment and embodiment 2 is:

[0078] The distance between the blades of the transverse spiral conveying roller and the inner wall of the mixing tank is 3.5 mm, and also during the mixing process, the porous granular structure of ammonium nitrate will not be damaged, and the product quality of the emulsified ammonium explosive is guaranteed. image 3 Wherein, the bottom and two side parts of the mixing tank are excessively connected with chamfers (or called mixing tank chamfers), and the size of the mixing tank chamfers ensures that the transverse spiral conveyor roller blades and the inner wall of the mixing tank The distance is 3.5mm.

[0079] An insert plate is provided on one side of the discharge port. The discharge port can be opened or closed by the plug-in board. When the mixing drive is turned on for mixing, the discharge port shall be sealed by the plug-in board, so that the mixing tank that is gradually filled with materials runs for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com